INTRODUCTION TO BIO- MEMS/NEMS 丁卫平 副教授、博士生导师 电子科学与技术系 电子邮件:[email protected] 电话:18056099696 实验室:科技楼东楼 403/409/416

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

INTRODUCTION TO BIO-

MEMS/NEMS

丁卫平 副教授、博士生导师 电子科学与技术系

电子邮件:[email protected]

电话:18056099696

实验室:科技楼东楼 403/409/416

Dr. Ding’s Course

When: 1st to 9th week, Tuesday (6,7)

Where:

Lectures: 3A110;

Experiments: East Tech. Lab Bldg. (Dr. Ding’s Lab Rm 403/409/416)

Assignments and Grading:

Total points: 50+5

Class participation (30%): 8+2

Presentation (10%): 1

Final report (10%): 1

Experiments (+5%): 1

Presentation:

PPT (review articles)

Textbook:

《Introduction to BioMEMS》Albert; Folch CRC Press 2012-07-08

Reference books:

1.《BioMEMS (microsystems)》Gerald

Urban Springer,2006

2.《微纳加工科学原理》唐天同、王兆宏 编

著,电子工业出版社,2010

3.《图解微流控芯片实验室》林炳承、秦建华

编著,科学出版社,2008

Great Expectations Student Learning Goals Know the state of the art of BioMEMS (lectures)

Learn to design/operate from scratch a microfluidic device (labs)

Be able to comprehend a text from the BioMEMS literature (assignments)

Experiment Goals

Photomask design (computer)

Photolithography

Soft lithography

Microfluidic gradient

Quantitative analysis (microscopy, image processing)

Outlines 0: It’s a small world

1: How do we make small things?

2: Micropatterning of substrates and cells

3: Microfluidics

4: Molecular biology on a chip

5: Cell-based chips for biotechnology

6: BioMEMS for cell biology

7: Tissue microengineering

8: Microfabricated implants and sensors

9: The frontiers of BioMEMS

0. It’s a small world

Dimensions and scaling in biology

• Size: from our bodies to our molecules

• Time: from life’s origin to enzymatic reactions

• Energy: from body heat to chemical bonds

• Electric currents: from electronics to ion channels

• Complexity

Why BioMEMS?

“A technology that allows us to make small “things” that are useful for biomedicine”

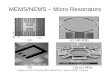

1. How do we make small things? Microfabrication techniques

Micropatterning

Photolithography

Scanning Lithographies

Soft Lithography

Microstamping (“Microcontact Printing”)

Microfluidic Patterning

Stencil Patterning (模板构图)

Dynamic Substrates

Micromachining

Micromolding: PDMS, plastics

Subtraction: dry/wet etching

Addition: deposition/growth

1.1. Benefits of microfabrication

1.2. Photolithography

1. Photoresist

(photosensitive

organic polymer)

2. Selective illumination

through mask

• Positive / Negative

photoresist

• Contact / Projection

3. Dissolution of

photoresist

Section 2: How do we make small things?

Discussion on use of photoresist

for patterning biological material

Clean room requirements: biological solutions?

Substrate requirements: plastic? glass?

Compatible with proteins?

Compatible with cells?

1.3. 3-D photoresist structures

Section 2: How do we make small things?

Depth = 53 µm

• photosensitized

epoxy

• negative photoresist

• 750 rpm ~ 50 µm

• 30 s exp. @ 365 nm

• 20 min. dev.

• aspect ratios > 5:1

• vertical sidewalls

Photoplastic “SU-8”

1.4. The SU-8 era

1.5. Tilted exposure

1.6. Biocompatible photoresists

1.7. Maskless Photolithography

Laser Writer

• Raster Scanning of SU8

1.8. Maskless Photolithography Digital Micromirror Device

• Texas Instruments

1.9. Micromachining

1. Photoresist

micropattern

2. Chemical etching through

photoresist “mask”

• dry etching (ion

plasma)

• wet etch (acids,

bases, etc.)

• selectivity is an issue

3. Photoresist

“stripping”

Section 2: How do we make small things?

1. Photoresist micropattern

2.a. “Blanket” deposition of material

• Metal evaporation

• Metal sputtering

3. Photoresist “lift-off”

2.b. Selective growth

• Electrochemical growth

• Self-assembly

1.10. Metal deposition and lift-off

Section 2: How do we make small things?

• Deposition of Si3N4

• Etch of Si3N4 with reactive plasma

• Etch of Si with HNO3/HF

• Three masks

Si3N4

Si

1.11. Micromachining of a

cantilevered tip

Section 2: How do we make small things?

1.12. Flexible substrates

1.13. Laser-cut laminated devices

1.14. Laser deposition in-situ

1.15. Laser direct writing

Micromolding

• Duroplastic

(“thermoset”)

polymers

• Thermoplastic

polymers

• Elastomeric

polymers

• Injection molding • Hot embossing • Soft Lithography

1.16. Photolithography vs.

Soft Lithography

Soft lithography

Section 2: How do we make small things?

First paper on microcontact printing

First paper on microfluidic patterning

Kim, E., Xia, Y., and Whitesides, G.M. Nature 376, 581-584 (1995)

Section 2: How do we make small things?

1. Photolithography 2. Pour polymer precursor(s)

and cure

3. Peel off and cut 4. Apply

1.17. PDMS micromolding

Section 2: How do we make small things?

Photoresist (SU8) master

30 µm

PDMS replica

PDMS

• Multiple replicas

• Inexpensive

1.17. PDMS micromolding

Section 2: How do we make small things?

Inexpensive

Very elastic and soft

Transparent down to 300 nm

Surface is hydrophobic

Self-seals by conformal contact

Inert, but can be oxidized, etched, and derivatized

Biocompatible

Swells when exposed to solvents

High permeability to gases and fluids

Expands a lot with temperature

Si

O OO

Si

CH3

CH3

CH3

CH3

1.17. The magic of PDMS

1.18. Structural integrity of PDMS walls

Section 2: How do we make small things?

Soft lithography: Microcontact printing

1. Ink

2. Transfer

Poly-dimethylsiloxane (PDMS) (transparent rubber)

Material is added where stamp contacts surface

Section 2: How do we make small things?

Microcontact printing

1.20. Selective inking of a flat stamp

Section 2: How do we make small things?

Soft Lithography: Microfluidic Patterning

1. Fill

2. Remove microchannels

microchannels

Material is added where stamp does not contact the surface

• Inlet fabrication?

• Seal?

• Filling method?

• Uniformity of filling?

• Types of solutions?

• Immobilization of material?

• Procedure for removal of microchannels?

1.21. Micromolding in capillaries (MIMIC)

1.22. Microfluidically-patterned

polyurethane 3D structures

Section 2: How do we make small things?

Microfluidic patterning for BioMEMS

Science 276, 779 (1997)

microchannels filled by capillarity

1.23. Stopped-flow lithography

1.24. Railed microfluidic fabrication

1.25. Lock-release microfluidic lithography

1.26. Lock-release microfluidic lithography

1.27. Fabrication of PDMS stencils

1.28. Fabrication of PDMS stencils by

exclusion molding

1.29. Tunable micromolding

1.30. Molding of PDMS from liquid patterns

Section 2: How do we make small things?

Traditional photolithography is limited to 2-D

1. Homogeneous photoresist

thickness

2. Mask only has 2 levels of

opacity

3. Developing is homogeneous

1.31. Microfluidic photomasks for

grayscale photolithography

1.32. Agarose stamps(琼脂糖模板)

1.33. Depositing and etching of posts

and wells using agarose stamps

1.34. Nanoscale lithography

Also: scanning beam deposition:

Energetic particles (electrons, ions,

photons) break bonds in gas or liquid,

resulting in solid remains

1.35. Mesoscale self-assembly

Related Documents