Report

Dec 23, 2015

go or no-go guage by Bhupesh

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Introduction to Visual Basic

Starting visual basic: - The first thing we need to do is open a visual basic program.

From the windows start menu, choose programs, Microsoft visual basic 6.0, and

then Microsoft visual Basic 6.0.

When we start VB, we are taken to the visual basic Integrated Development

Environment (IDE) .This is our programming workbench, the place where we

create our program. The IDE presents what looks like an empty window containing

some dots and a little bar with the wordform 1. This window is a form, the primary

building block of a visual basic application. An application can have many form or

forms.

Over view of Visual Basic 6.0:- Visual Basic 6.0 has some interesting new features

is nothing short of an understatement. Visual Basic 6.0 has so many amazing new

features that overstatement is next to impossible because so much is new in so

many areas. New controls allow our applications to incorporate the look, feel, and

functions of Office 97 applications and internet explorer. No more do we have to

have at least one instance of a control on your form to create controls on-the-fly.

With Visual Basic (VB6) , we can add controls to our project dynamically with

only code , and we can make custom ActiveX controls leaner and meaner than

ever. We can even write server – side applications that use Dynamic HTML

embedded with internet information server DLLs.

The parts of the Integrated Development Environment (IDE):- The Visual Basic

IDE is a collection of menus, toolbars, and windows that make up our

programming workbench. Each part of the IDE has features that effect different

aspects of our programming activity. The menu bar lets us direct the overall

activity and management of our programming. The tool bar enables us to access

much of the menu bar’s functionality through various toolbars buttons. Forms- the

basic building blocks of the VB program- are presented in a form window. We use

the toolbox to add the controls to our project. The project explorer displays the

projects on which are working, as well as different parts of each of those projects.

We browse and set a control, form, and module’s properties within the properties

window. Finally position and view a form or forms onscreen within the form

layout window.

Viewing the IDE: - We can view the Visual Basic IDE in two ways : with the

Multiple Document Interference (MDI) or Single Document Interference (SDI).

MDI view shows all the distinct windows of the Visual Basic IDE as member

windows within one large IDE window.

In the SDI view distinct windows of the Visual Basic IDE exist independently of

each other. There is no master window to contain and provide a unified feel to the

IDE.

Forms and Controls: - In Visual Basic, the forms are the foundations we generally

use to build programs. A form is where we put all things that people interact with

as they use our program. Those things we put on the form are controls, which

enables the people who use our program to do things, such as enter text and click

buttons.

Intrinsic controls: - For the most part, we will a relatively small set of controls

when we program in Visual Basic. However, these controls are very powerful.

With them we can add buttons, check boxes, files and text boxes to our programs.

We can use them to see and read a database. These basic controls are intrinsic

controls, and they are available in every edition of Visual Basic 6.

Visual Basic Project: - In Visual Basic, a project is the group of all the files that

make up our program. These might includes forms, modules (blocks of code not

attached to a form), graphics, and ActiveX controls.

The first thing to keep in mind about a project is that as we create our program,

each form, module, graphic, and ActiveX control are saved as an individual file.

Common file types in a Visual Basic Project:

File type Description

FRM Form

BAS Module

FRX Automatically generated file for every graphic in our

project

OCX Active control

CLS Class module

VBP Visual Basic Project

Properties, Methods, and Events: - Put simply, properties describe objectives.

Methods cause an object to do something. Events are what happen when an object

does something. Every object, such as a form or control, has a set of properties that

describe it. We can see every property for a given control by looking at the

properties window in the IDE.

Common properties of visual basic controls: -

Property DescriptionLeft The position of the left side of a control with respect to its

container.Top The position of the top of a control with respect to its

container.Height A control’s height.Width A control’s width.Name The string value used to refer to a control.Enabled The Boolean (true/false) value that determines whether users

can manipulate the control.Visible The Boolean (true/false) value that determines whether users

can see the control.

Storing information in variables: - While the data is being processed in our

program, it’s stored in temporarily variables. For example if we think of a variable

as cup that can hold various amount of jelly beans; we never know how many jelly

beans are in the cup at any given time unless we look in the cup. The same is true

for a variable. A variable can store values many times.

We create a variable by using the following form:

Dim varname As Datatype

In the above written syntax

Dim is the keyword that tells visual basic that we want to declare a variable.

Varname is the name of the variable.

As is the keyword that tells the VB that we are defining the data type for

variable.

Datatype is the data type of the variable viz. Numeric, String, Boolean, Date,

Object, and Variant.

Math operators: - math operators are used to determine customer bills, interest due

on savings or credit card balances and many other tasks. VB supports a number of

different math operations that can be used in program statements.

Math operations and the corresponding Visual Basic operator symbol:

Operation Operator symbolAddition +Subtraction _Multiplication *Division /Integer division \Modulus modExponentiation ^

Making decisions in program

Most statements in our programs will be assignment statements, but other

statements are important for handling more complex task. These statements are

known collectively as control statements.

One type of control statement is the decision statement. These statements are used

to control the execution of parts in our program, based on conditions that exist at

the time statement encountered. Two main type of statements are:

If……then and select case.

LIMITS:-

Every manufacturing process is a combination of three elements man, material and

machine. A change in any one of them or all of them will results change in

manufactured parts. It is, therefore, obvious that some permissible variation in

dimension has to be allowed to account for variability.

Two extreme permissible sizes of a part between which the actual size is

contained are called limit.

FITS

When two parts are to be assembled the relation resulting from the difference

between their sizes before assembly is called a fit. The fit signifies the range of

tightness or looseness which may result from the application of a specific

combination of allowances and tolerances in the design of mating parts.

Types of Fits

There are three general types of fit between the mating parts

1. Clearance fit— A clearance fit is one having limits of size so prescribed that a

clearance always results when mating parts are assembled.

2. Interference fit — An interference fit is one having limits of size so prescribed

that an interference always results when mating parts are assembled.

3. Transition fit— A transition fit is one having limits of size so prescribed that

either a clearance or an interference may always result when mating parts are

assembled.

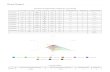

The three types of fits are shown in Fig. The disposition of tolerance zones for the

three classes of fit are shown in Fig. 4.2.

Tolerance is defined as the total permissible variation of a size. It is the difference

between maximum limit and minimum limit of size.

TERMINOLOGY

The terminology used in fits and tolerances is shown in Fig. 4.3 The importantterms are

Basic size — It is the exact theoretical size arrived at by design. It is also called

nominal size.

Actual size— The size of a part as may be found by measurement.

Maximum limit of size— The greater of the two limits of size.

Minimum limit of size— The smaller of the two limits of size.

Allowance—It is an intentional difference between maximum material limits of

mating parts. It is a minimum clearance or maximum interference between mating

parts.

Deviation—The algebraic difference between a size (actual, maximum, etc.) and

the corresponding basic size.

Actual deviation—The algebraic difference between the actual size and the

corresponding basic size.

Upper deviation—The algebraic difference between the maximum limit of size

and the corresponding basic size.

Upper deviation of hole = ES (&art Superior)

Upper deviation of shaft es

Lower deviation—The algebraic difference between the minimum limit of size

and the corresponding basic size.

Lower deviation of hole = El (Ecart Inferior)

Lower deviation of shaft = ei

Upper deviation Lower deviation + Tolerance

Zero line—It is the line of zero deviation and represents the basic size.

Tolerance zone—It is the zone bounded by the two limits of size of the parts and

defined by its magnitude, i.e. tolerance and by its position in relation to the zero

line.

Fundamental deviation—That one of the two deviations which is conveniently

chosen to define the position of the tolerance zone in relation to zero line.

Basic shaft— A shaft whose upper deviation is zero.

Basic hole — A hole whose, lower deviation of zero.

Clearance — It is the positive difference between the hole size and the shaft size.

Maximum clearance—The positive difference between the maximum size of a

hole and the minimum size of a shaft.

Minimum clearance—The positive difference between the minimum size of a

hole and the maximum size of a shaft.

DESIGNATION OF HOLES, SHAFTS AND FITS

A hole or shaft is completely described if the basic size, followed by the

appropriate letter( italic or roman- usually italic preferred) and by the number of

tolerance grade , is given. For example- a 25mm H-hole with the tolerance grade

IT8 is given as

25mmH8 or 25H8

Similarly a 25 mm f shaft with the tolerance grade IT7 is given as

25mm f 7 or 25f 7

A fit is indicated by combining the designations for both the hole and shaft with

the hole designation written first, regardless of the system (i.e. hole based or shaft

based). For example

25H8-f 7 or 25H8/f 7 or 25 H8 f 7

FUNDAMENTAL DEVIATION:-

As stated that setting of tolerance values is not a of itself sufficient to define

particular limit, the position of the tolerance zone relative to the basic size of the

feature must also be specified. This is done by establishing fundamental deviations

which are difference between the basic size and the nearest limit of tolerance.

Fundamental Deviations Letter F or Hole and Shaft Basis.

The Value for the Hole from "A" to "H" are positive (+), for the Shaft from "a" to "h" negative (-). The Value of the Hole from "J" to "K" either positive (+) or negative (-), for Shaft form "j" to "k" either positive (+) or negative (-).

Table : Formulae for fundamental deviation for shafts for sizes : up to 500mm

For js : the two deviations are equal to ± IT / 2

Upper Deviation (es) Lower Deviation (ei)

Shaft Designation In Microns (for D in mm) Shaft DesignationIn Microns (for D in

mm)

a

= - (265 + 1.3 D) for D ≤ 120

j5 to j8 No formula

k4 to k7 = +0.6 (D)1/3

= - 3.5 D for D> 120 k for grades ≤ 3 and ≥ 8 = 0

= - (140 + 0.85 D) for D≤ 160

m = + (IT 7 – IT 6 )

= - 1.8 D for D > 160 n = + 5 D0.34

bp = +IT 7 + 0 to 5

c

= 52 D0.2 for D≤ 40 r= geometric mean of values ei for p and s

= - ( 95 + 0.8 D ) for D>40

= +IT 8 + 1 to 4 for D D≤50

d = - 16 D0.44 s= +IT 7 + 0.4 D for

D>50

e = - 11 D0.41 t = +IT 7 + 0.63 D

F = - 5.5 D0.41 u = +IT 7 + D

g = - 2.5 D0.34 v = +IT 7 + 1.25D

h= 0

x = +IT 7 + 1.6 D

y = +IT 7 + 2 D

z = +IT 7 + 2.5 D

za = +IT 8 + 3.15 D

zb = +IT 9 + 4 D

zc = +IT 10 + 5 D

CALCULATION OF TOLERANCE GRADE:-

For all sizes the values of the tolerance grades IT6 to IT16 inclusive are multiples

of tolerance unit i calculated using the R5 series of preferred numbers. The value

of the tolerance unit is obtained from the following formula for sizes up to

including 500mm.

i= 0.45 3√ D +0.001D

i is given of 0.001mm.

THE R5 SERIES

This is collection of five geometric progressions proposed by col. Charles Reynard

in1877. In geometric progression successive terms are obtained by continued

multiplication using a multiplier of a fixed value. The fixed multiplier, or common

ratio, is denoted by r. the formulae for common ratio in geometric progression is

r= (n-a) √ (b/a)

Where a is the first term in the progression

b is the final term in the progression

n is the number of terms in the progression

In case of first term a=1 and the final term is b= 10, r is i.5849.

This gives constant increase in 60% between successive tolerance values when

used to calculate the tolerance grades IT6 to IT16. The value of IT6 is 10i.

Table: Value of Tolerances Grades

Tolerance Grade Calculations Value

IT 6 = 10 i × 1.60 10 iIT 7 = 10 i × 1.61 16 iIT 8 = 10 i × 1.62 25 iIT 9 = 10 i × 1.63 40 iIT 10 = 10 i × 1.64 64 iIT 11 = 10 i × 1.65 100 iIT 12 = 10 i × 1.66 160 iIT 13 = 10 i × 1.67 250 iIT 14 = 10 i × 1.68 400 iIT 15 = 10 i × 1.69 640 iIT 16 = 10 i × 1.610 1000 i

Diameter Steps for sizes up to 500mm

General Cases Special Subdivisions

MillimetersAbove up to

MillimetersAbove up to

- 33 6 - -6 10

10 1810 1414 18

18 3018 2424 30

30 5030 4040 50

50 8050 6565 80

80 12080 100100 120

120 80120 140140 160160 180

180 250180 200200 225225 250

250 315250 280280 315

315 400 315 355

355 400

400 500400 450450 500

These are used in certain cases for the deviations a to c and r to zc or A to C and R to ZC.

CALCULATIONS OF TOLERANCES AND LIMITS OF SIZE:-

For example the calculations for 60H8/f 7 can be preceded in the following

manner:-

Because 60 mm dia. comes in the dia. step between 50-80mm hence

D=√(d¿1+d 2)¿

D=√(30¿+50)¿ = 63.25mm

Fundamental deviation for shaft = -5.5D0.41

= -5.5(63.25)0.41

=-30.113 microns = -0.030 mm

The tolerance unit i is:-

i=0.45 3√D+0.001D

i=0.453√ (63.25 )+0.001(63.25)

=1.856 microns

Tolerance Grade IT8:-

IT8 =25 i

=25(1.856)/1000

=0.046 mm

Tolerance Grade IT7:-

IT8 = 16 i

=16(1.856)/1000

=0.030 mm

Calculation for Limit:-

A. Hole

Low Limit = Basic size + fundamental deviation hole

= 60.00+0.00

= 60.00 mm

High Limit = Low Limit + Tolerance

= 60.00+0.046

= 60.046 mm

B. Shaft

High Limit = Basic size - fundamental deviation

= 60.00 – 0.030

= 59.970 mm

Related Documents

![For The Region: Report, Report, Report [Eng]](https://static.cupdf.com/doc/110x72/579079761a28ab6874c751c6/for-the-region-report-report-report-eng.jpg)