Off The Road Tyres Detailed Project Report

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Off The Road TyresDetailed Project Report

Group Members• Prashant Deshinge (05)• Vijoyendra Goswami (09)• Piyush Jhaveri (12)• Yatish Patali (27)• Deepak Salian (35)• Rohit Salunke (36)• Varad Shetty (41)• Chetan Mav (54)• Nawalkumar Agarval (55)• Nipun Mehra (58)

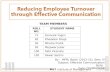

Agenda• Introduction• Indian tyre industry statistics• Radialisation and Tyre Retreading• Off the Road Tyres• Marketing • Porter’s Five Forces Model• SWOT Analysis• Peculiar Features of the Tyre Industry• Commercialisation of the Project • Financial Projections

Introduction• The Indian Tyre Industry produced 13.5 lakhs tonnes

of tyres garnering Rs. 25,000 crores in FY10.• The Indian tyre industry is characterized by its:– Raw material intensity(70% of operating income)– Capital intensity– Cyclicality– Fierce competition among the top players– Low bargaining power and resulting low margins

• Demand derived from the automobile Industry both OEM and replacement

• The main category of tyres produced in the country is that of Truck & Bus tyres (57% of the total tyre tonnage production in FY10 )

Indian tyre industry statisticsOverview of Financial Year 2009-2010 (Est.)

Turnover of Indian Tyre Industry Rs. 25,000 Crores

Tyre Production (Tonnage) 13.50 lakh M.T.

Tyre Production – All Categories (Nos.) 971 Lakh

Tyre Export from India (Value) : Rs. 3625 crores

Number of tyre companies: 36

Industry Concentration 10 Large tyre companies account for over 95% of total tyre production.

Radialisation Level - Current (as a % of total tyre production)

Passenger Car tyres: 98% Light Commercial Vehicles: 18%Heavy Vehicles ( Truck & Bus ): 12%

Indian tyre industry statisticsProduction 2003 - 04 2004 - 05 2005 - 06 2006 - 07 2007 - 08 2008 - 09 2009 - 10

Truck & Bus 10821 11092 11941 12367 13137 12839 14811

Passenger Car 9959 11862 13605 14264 16437 16571 20047

Jeep 1440 1462 1272 1368 1467 1469 1402

Light Comml. Veh. (L.C.V.)

3271 3945 4529 4820 5320 5298 5739

Tractor Front 1148 1311 1383 1754 1814 1842 2386

Tractor Rear 842 1096 1134 1296 1234 1315 1634

Tractor Trailer 415 408 596 823 886 758 903

A.D.V. 295 197 325 381 409 281 294

Scooter 9274 9992 9519 9643 11604 10882 13558

Motor Cycle 16688 18127 21053 26079 27921 30148 35664

Moped 168 124 55 0* 0* 0 0

Industrial 295 377 514 635 733 568 538

O.T.R. 74 89 106 115 141 136 161

Aero 0 0 0 0 0 0 0

TOTAL 54690 60082 66032 73545 81103 82107 97137

Radialisation and Tyre Retreading

• Radialisation:– Radialisation can be aptly classified as the most

important innovation in tyre technology with several advantages like additional mileage, fuel saving and improved driving

– It however did was not initially accepted, but has picked momentum in recent years

– The future of radialisation will be governed by the following factors: • Cost - Benefit Ratio • Road Development • Overload Control • User Education • Retreading Infrastructure

Radialisation and Tyre Retreading

• Tyre Retreading:– Tread is the portion of the tyre which meets

the road surface – In the manufacture of a new tyre,

approximately 20%-25% of the cost is incurred in mfg of the Tread and the rest in body

– Thus retreading can save a lot of costs for the user instead of changing the whole tyre

– Retreading is primarly done in the Truck and Bus trye segment. On an average a Truck/Bus trye is retreaded 1.5 times.

Off the Road Tyres• The OTR tire classification includes tires for

construction vehicles such as wheel loaders, backhoes, graders, trenchers, and the like; as well as large mining trucks

• Manufacturersof tyres:– The major players consist of MRF, Apollo Tyres, Ceat

and JK Industries, which account for 63 per cent of the organised tyre market

– The other key players include Modi Rubber, Kesoram Industries and Goodyear India, with 11 per cent, 7 per cent and 6 percent share respectively

– Dunlop, Falcon, Tyre Corporation of India Limited (TCIL), TVS-Srichakra, Metro Tyres and Balkrishna Tyres are some of the other players

Marketing • Segmentwise Tyre Supplies:

– Tyre supplies are broadly to the following segments:• Replacement Market (aftermarket)• Original Equipment Manufacturers (OEMs), i.e.

vehicle manufacturers• Export• State Transport Undertakings (STUs) (primarily for

Bus tyres)• Government Purchases

• Dealers (Single and Multi Brand)– Dealers are an important link between the tyre

companies and the end consumers– Dealers of commercial vehicle tyres also financing

purchase of tyres for commercial vehicles and agricultural tyres

Marketing

• Distribution– The distribution system consists of

distributors, followed by large dealers and also small/sub dealers

• Other channels are:– Replacement Market– OEM– Govt– Export– Import

Porter’s Five Forces Model

Bargaining power of supplier Bargaining power of

buyers

Threat of new entrants

Threat of substitute

Competitive Rivalry

Strengths•Brand

name•Distributio

n•R & D

Weakness•Cost•Price•Capital

involved

Opportunity•Growing

Economy•Infrastuctu

re•Global

Sources•Increase in

Radial Tyres

Threats•Increase

in Rubber prices

•Cheaper Imports

•Ban on Overloading

SWOT Analysis

Peculiar Features of the Tyre Industry

Features

CyclicalRetreading

Distribution NetworkHigh

Capital Cost

Technology Incentive

Commercialisation of the Project

• Brilliant future for the tyre manufacturing sector:– Higher rate of consolidation of the Indian

automobile industry– Growing rate of infrastructure development– Increased consumption levels

• As the Indian tyre manufacturers are less differentiated, for a startup company is better to focus on a particular aspect - The ‘Off Road Tyres’

• The current demand from Indian market is 64,400 MT of the OTR tyres

Commercialisation of the Project • The location chosen – State Industries Promotion

Corporation of Tamil Nadu (SIPCOT)– natural resource availability– skilled man power availability– complementary SME availability – proximity of the biggest automobile OEM hub of India

• The approximate investments required for starting and ramping up the production facilities at the selected location are:

Year Year1 Year 2 Year 3 Year 4 Year 5

Capacity (MT) 10,000 11,900 14,161 16,850 20,050Plant Investment (Cr) 88.2 18.2 22.2 27.51 34.6

Financial Projections

• Project & Component CostParticulars Unit Cost/MT TotalCapacity MT 10000LAND & BUILDING Cr 52.45Land Cr 43200 43.2Building Cr 9254 9.25PLANT & MACHINERY Cr 23761 23.76

MISCELLANEOUS FIXED ASSETS Cr 0.48Furniture and Fixture Cr 142 0.14Vehicles-Delivery LCV Cr 230 0.23Others Cr 111 0.11Contingencies 15% 11.50TOTAL Cr 88.20

Financial Projections• Expense Sheet

• Projected Profit & Loss Statement

Expense Sheet Cost Rs/MT Total Rs Cr.Material 170424 170.42Cost of Traded Goods Sold 16313 16.31Personnel Cost 19268 19.26Other Expense 46540 46.54Total Expense 252.54

PARTICULARS RS Cr.Net Revenue Realisation 332Total Expenses 252.54Gross Profit 79.45Depreciation 20.67Interest 13.32Preliminary Expense W/O 1.02Profit Before Tax 44.44Tax 13.35Profit After Tax 31.09

Projected Balance Sheet (in Rs Cr.)SOURCES OF FUNDSEQUITY CAPITAL 32.00TERM LOAN 76.70

Secured Loans 51.20Unsecured Loans 25.50

108.70APPLICATION OF FUNDS FIXED ASSETS

Gross Block 88.20Less: Depreciation (20.67)

Net Block 67.53

CURRENT ASSETS, LOANS AND ADVANCEMENTS 70.38Inventories 39.84

Sundry Debtors 7.30Cash & Bank Balances 23.24

Less :CURRENT LIABILITIES & PROVISIONS 29.22NET CURRENT ASSETS 41.17

108.70

Thank you!

Related Documents

![ppt [final]](https://static.cupdf.com/doc/110x72/557211a2497959fc0b8f45c0/ppt-final-55c1eb754e129.jpg)