LMCDYN User Manual Beijing JCZ Technology Co. Ltd 1 LMCDYN User Manual

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

LMCDYN User Manual

Beijing JCZ Technology Co. Ltd 1

LMCDYN User Manual

LMCDYN User Manual

Beijing JCZ Technology Co. Ltd 2

版本记录

版本号 更新日期 更新人 更新说明

V1.0 2008-4

V2.0 2012-2-17 张涛

LMCDYN User Manual

Beijing JCZ Technology Co. Ltd 3

Content

Safety During Installation And Operation............................................................................................ 1

1. Overview..............................................................................................................................................2

2. Pin Definition....................................................................................................................................... 3

CON2:power supply and laser control interface..................................................................4

CON3:IPG laser module control interface............................................................................6

3. Jumpers............................................................................................................................................... 8

inputs with GND as if reference ground...................................................................................9

4. Outputs...............................................................................................................................................11

5. DAC board.........................................................................................................................................12

Pin Definition..............................................................................................................................13

CON1:digital Inputs................................................................................................................13

CON2:power supply...............................................................................................................14

CON3 / CON4 / CON5:scan head control..........................................................................14

DAC dimensions and structures.............................................................................................15

6. software manual............................................................................................................................... 16

Dynamic control board User Manual

1

SafetySafetySafetySafety duringduringduringduring InstallationInstallationInstallationInstallation andandandandOperationOperationOperationOperationPlease read these operating instructions completely before you proceed with installing andoperating this product. If there are any questions regarding the contents of this manual, pleasecontact BJJCZ.1. Steps For Safe Operation

� Please observe all the safety instructions regarding a laser system(include butnot limited to the laser source, scan head and every specifics described in thisdocument)

���� AlwaysAlwaysAlwaysAlways turnturnturnturn onononon thethethethe powerpowerpowerpower ofofofof thisthisthisthis productproductproductproduct andandandand thethethethe powerpowerpowerpower supplysupplysupplysupply forforforfor thethethethe scanscanscanscanheadheadheadhead firstfirstfirstfirst beforebeforebeforebefore turningturningturningturning onononon thethethethe laser.laser.laser.laser. OtherwiseOtherwiseOtherwiseOtherwise theretheretherethere isisisis thethethethe dangerdangerdangerdanger ofofofofuncontrolleduncontrolleduncontrolleduncontrolled deflectiondeflectiondeflectiondeflection ofofofof thethethethe laserlaserlaserlaser beam.beam.beam.beam.

� This product is intended for controlling a laser scan system. Therefore all relevantlaser safety directives must be known and applied before installation and operation.The customer is solely responsible for ensuring the laser safety of the entire system.

� Please observe all laser safety instructions as described in you scan head or scanmodule manual, and this manual.

� Carefully check your application program before running it. Program errors cancause a system breakdown. In this case neither the laser nor the scan head can becontrolled.

� Protect the board from humidity, dust, corrosive vapors and mechanical stress.

� For storage and operation, avoid electromagnetic fields and static electricity. Thesecan damage the electronics on the product. For storage, always use the antistaticbag.

� The allowed operating temperature range is 25℃ ± 10℃.� The storage temperature should be between –20℃ and +60℃.

Dynamic control board User Manual

2

I.I.I.I. OverviewOverviewOverviewOverview

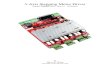

Dynamic focus control board( LMCDYN) is developed for 3-dimensions dynamic focusfunction, shown in figure 1.

Figure 1 LMCDYN board

CON1:SCAN HEAD interface, DB15.CON2:Power supply, extensional axis and laser control interface. DB25CON3:IPG YLP laser module control interface.

Dynamic control board User Manual

3

PinPinPinPin definitiondefinitiondefinitiondefinition

There are 3 groups interface on LMCDYN board. CON1 is digital galvanometer interface,CON2 is power and laser control interface, CON3 is IPG laser interface.

CON1:CON1:CON1:CON1: DigitalDigitalDigitalDigital GalvoGalvoGalvoGalvo interfaceinterfaceinterfaceinterface

CON1 can be connected to digital galvo directly with DBDBDBDB11115555 connector.... Also we provide atransfer board, which can be used to transfer the digital signal to analog signal that can beconnected to the analog galvo.

Note:Note:Note:Note: totototo useuseuseuse digitaldigitaldigitaldigital galvo,galvo,galvo,galvo, wewewewe needneedneedneed totototo connectconnectconnectconnect thethethethe inputinputinputinput signalsignalsignalsignal NO.NO.NO.NO. 3333 (Pin17(Pin17(Pin17(Pin17 ofofofof CON2)CON2)CON2)CON2)totototo GND,GND,GND,GND, otherwiseotherwiseotherwiseotherwise thethethethe signalsignalsignalsignal cannotcannotcannotcannot bebebebe identifiedidentifiedidentifiedidentified correctlycorrectlycorrectlycorrectly bybybyby digitaldigitaldigitaldigital galvo.galvo.galvo.galvo.

The pin definition of CON1 is shown in figure 2.

Figure 2 Pin definition of CON1

NO. Signal name Comment1,9 CLK-/CLK+ Clock signal; differential output.2,10 SYNC-/ SYNC+ Synchronize signal; differential output3,11 XChannel-/ XChannel+ Data signal of channel X; differential output4,12 YChannel-/ YChannel+ Data signal of channel Y; differential output5,13 ZChannel-/ ZChannel+ Data signal of channel Z; differential output6,14 Status-/ Status+ Status signal of galvo; differential input

Dynamic control board User Manual

4

8,15 GND Ground

5 groups signal ( 10 signals) should be connected: CLK,SYNC,XChannel,YChannel andZChannel. Status signal is reserved.

CON2CON2CON2CON2:PowerPowerPowerPower andandandand LaserLaserLaserLaser controlcontrolcontrolcontrol interfaceinterfaceinterfaceinterface

Figure 3 Pin definition of CON2

Pin no. Name Illustration

1,14 PWM-/PWM+

Differential output. For CO2 laser, this signal is used to set laser

power and also as output of Tickle signal; for Yag laser, this

signal is used for Q-driver as repeat frequency signal. In addition,

PWM+/PWM+/PWM+/PWM+/ GroundGroundGroundGround(pin25) can form a high level active output;

Dynamic control board User Manual

5

PWM-/GroundPWM-/GroundPWM-/GroundPWM-/Ground ((((pin25)))) can form a lower level active output.

2 LaserO- Laser on/off signal, TTL, low level effective.

15 LaserO+ Laser on/off signal, TTL, high level effective.

3 QKILLFirst Pulse Killer signal. TTL output. Reference Ground signal is

GND.

16 PWMTTLPWM, TTL. For a CO2 laser module, this signal controls the power

and also be used as tickle signal. For YAG laser module thisis used as a frequency control for the Q switch.

4 COMWhen out4 – out 6 are set to be oc outputs, connect this pin theexternal power supply which provides voltage and current for theseOC outputs.

17,18,

6,21,9,GND

Reference ground of the board, also the cathode of the 5V powersupply. Any pin without specific declaration sees this signal asreference ground.

5 START Mark the content in RAM on the board. TTL.

19,7 XPUL+/XDIR- Pulse/Direction signal for extensional axis X. it can be eitherdifferential pair or common anode.

8,20 VIN 5V

22,10 OUT0,OUT1 General output OUT0,1. TTL

23,11,24 OUT4--6Out 4-Out 6 can be configured to perform as an OC output by

jumper JP8-10.

12,25 IN4,IN5 General Inputs in4,5. Using INGND as a return path. Built in 1kresistor.

13 INGND return path for IN4,5

Note:CON2 is female socket

Dynamic control board User Manual

6

CON3CON3CON3CON3::::IPGIPGIPGIPG LaserLaserLaserLaser interfaceinterfaceinterfaceinterface

Fig.4 CON3

CON3 can be used to connect to the IPG YLP serial laser. CON3 is DB25 socket, whichcan be connected directly to the laser module. The pins definition is shown in figure 4.

PinsPinsPinsPins SignalSignalSignalSignal namenamenamename IIIIllustrationsllustrationsllustrationsllustrations1——8 P0——P7 Laser power. TTL output.9 PLATCH Power latch signal. TTL output.10,11,12,13,14,15,24 Gnd Control card’s Ground

16,21 SGIN0,SGIN1 Laser status input.17 Vcc 5V power output of control card.18 MO Master Oscillator switch. TTL output19 AP Power amplifier. TTL output.

Dynamic control board User Manual

7

20 PRR Repeat pulse power signal. TTL output.22 Out2 Laser’s red light indication signal. TTL output.23 EMSTOP Emergency stop signal. TTL output.25 NC

3.Jumpers3.Jumpers3.Jumpers3.Jumpers

Fig5 illustration for jumper

No. Pins Illustration

JP12

Determines the working mode of this controller, when shorted it

works in YAG mode.

Dynamic control board User Manual

8

JP5,JP6,

JP72

Controller index. When there are multiple controllers connected to

one computer, these pins are used as ID. JP7-JP6-JP5

represents 3 binary bits. When shorted this bit is 0,

otherwise it 1.

JP8,JP9,

JP10 2

Use these jumpers to configure out4-6. When pin 1 and 2 is shorted

the respective output is TTL, when pin 2 and 3 is shorted it becomes

an OC output.

Default settings:

JP1:Shorted.

JP5——JP7:Not shorted.

JP8——JP10:Pin2 and 3 is shorted. The output type is OC.

WiringWiringWiringWiring forforforfor digitaldigitaldigitaldigital I/OI/OI/OI/O

I/OI/OI/OI/O thatthatthatthat cancancancan bebebebe connectconnectconnectconnect totototo GNDGNDGNDGND

As name suggested these kind of I/O can be connected to switch and then to the ground.SGIN0,SGIN1,SGIN2,SGIN3 are of these kind.The following schematics are typical wiring for these kind of signal.

Pic 2-7 wiring for general input pins

Dynamic control board User Manual

9

Pic 2-8 recommended wiring for general input pins

For these pins the resistor of the switch should be below 100ohm.

General input SGIN4,SGIN5

The typical and recommend wiring of general input signals SGIN4;SGIN5 are shown in fig

8.

Fig 8 IN4,IN5

Whether to introduce R1 depends on the voltage. The goal here is to ensure that the inputcurrent is between 10mA and 15mA. If the voltage is over 12V, we recommend acurrent-limiting resistor. Assume the current you choose is 12mA, and then the resistor iscalculated as follow:

1000112

1 ×⎟⎠⎞

⎜⎝⎛ −=VinR Ω

Dynamic control board User Manual

10

4.Out04.Out04.Out04.Out0——Out6Out6Out6Out6Out0/1/2 are TTL signals. Out4/5/6/ can be configured as OC outputs or TTL outputs

through jumper.If an output is in TTL mode, The output must not be short circuited or wire to GND directly.

Otherwise the board can be damaged.If a output is in OC mode, the typical wiring diagram is shown below, if you want to drive a

inductive instrument, the COM signal(PIN3) must be wired to the anode of the power supply.The maximum driving current and voltage are 250mA and 40V respectively.

FigFigFigFig 9999 illustrationillustrationillustrationillustration forforforfor OC(Out4/5/6),OC(Out4/5/6),OC(Out4/5/6),OC(Out4/5/6), R1R1R1R1 isisisis inductiveinductiveinductiveinductive loadloadloadload

Dynamic control board User Manual

11

II.II.II.II. DADADADA transfertransfertransfertransfer boardboardboardboard

The DA transfer board can transfer the custom digital signals to analog signals. It hasfollowing features:

External power supply ±(12~15)V / 500 mA.Receives 3 routes digital signals, and outputs 3 routes analog signals (±5V).Outline dimensions: 74X67X34mm

The outline is shown in figure 9.

Dynamic control board User Manual

12

Figure 9 DA transfer board

InterfaceInterfaceInterfaceInterface commentcommentcommentcomment

CON1CON1CON1CON1:DigitalDigitalDigitalDigital signalssignalssignalssignals inputinputinputinput socketsocketsocketsocket

This socket is used to receive the digital signal of galvo. BTW, user must set the digital

Dynamic control board User Manual

13

protocol to custom (setup the jumper), please refer to the boards’ manual. For LMCDYN, leavethe Pin17 of CON2 open.

Figure 10 Pin definition of CON1

Pin NO. Name Illustrator1,9 CLK-/CLK+ Clock signal; differential input.2,10 SYNC-/ SYNC+ Synchronize signal; differential input3,11 XChannel-/ XChannel+ Data signal of channel X; differential input4,12 YChannel-/ YChannel+ Data signal of channel Y; differential input5,13 ZChannel-/ ZChannel+ Data signal of channel Z; differential input6,14 Status-/ Status+ Reserved8,15 Gnd Ground of board

Twisted-pairTwisted-pairTwisted-pairTwisted-pair isisisis stronglystronglystronglystrongly recommendrecommendrecommendrecommendedededed totototo connectconnectconnectconnect thethethethedigitaldigitaldigitaldigital signal.signal.signal.signal.

CON2CON2CON2CON2:PowerPowerPowerPower socketsocketsocketsocket

It should be connected to an external power supply. The voltage range of the power is [±12V~±15V]. As shown in figure 11.

Dynamic control board User Manual

14

Figure 11 Power supply socket

CON3CON3CON3CON3 //// CON4CON4CON4CON4 //// CON5CON5CON5CON5: galvogalvogalvogalvo outputoutputoutputoutput signalssignalssignalssignals

Analog voltage output. The default voltage range is ±5V (XVOL+ / Gnd)。

Figure 12 galvo output socket

III.III.III.III. OutlineOutlineOutlineOutline dimensionsdimensionsdimensionsdimensions

Dynamic control board User Manual

15

Figure 13 LMCDYN dimension

Figure 14 DA transfer board dimension

Dynamic control board User Manual

16

IV.IV.IV.IV. SoftwareSoftwareSoftwareSoftware manualmanualmanualmanual

Note:Note:Note:Note: ToToToTo useuseuseuse dynamicdynamicdynamicdynamic focusfocusfocusfocus function,function,function,function, useruseruseruser mustmustmustmust useuseuseuse EEEEzCad2.0.13zCad2.0.13zCad2.0.13zCad2.0.13 UNICODEUNICODEUNICODEUNICODE versionversionversionversion(20080222)(20080222)(20080222)(20080222) orororor later,later,later,later, andandandand thethethethe dongledongledongledongle mustmustmustmust enableenableenableenable thethethethe function.function.function.function.

1.1.1.1. PleasePleasePleasePlease referreferreferrefer totototo thethethethe followingfollowingfollowingfollowing stepsstepsstepssteps totototo setupsetupsetupsetup thethethethe parameters:parameters:parameters:parameters: thethethethe field;field;field;field; distortiondistortiondistortiondistortionadjust;adjust;adjust;adjust; scalescalescalescale adjust;adjust;adjust;adjust; thethethethe dynamicdynamicdynamicdynamic focusfocusfocusfocus parameters.parameters.parameters.parameters.

2.2.2.2. IfIfIfIf thethethethe fieldfieldfieldfield parametersparametersparametersparameters areareareare changed,changed,changed,changed, pleasepleasepleaseplease adjustadjustadjustadjust thethethethe dynamicdynamicdynamicdynamic focusfocusfocusfocus parametersparametersparametersparametersagain.again.again.again.���� ParametersParametersParametersParameters setupsetupsetupsetup inininin EzCadEzCadEzCadEzCad

EzCad divides the mark field into 10 concentric circles; the round center is the center ofthe mark field. Each field corresponds a different Z offset value. When marking throughdifferent fields, the software output the corresponding Z position automatically.

Run EzCad2.EXE,click “Param(F3)” ――”Dynamic Focus”。The setup dialog is shown asfigure 15. User can setup all Z offset values of the 10 fields, or adjust the Z offset value of onefield.

Center

Figure 15 Dynamic Focus Parameters

EnableEnableEnableEnable DynamicDynamicDynamicDynamic Focus:Focus:Focus:Focus: Check it to enable the function.Dist.Dist.Dist.Dist. ToToToTo centercentercentercenter (%):(%):(%):(%): The distance to the center. Shown in percent value of the maximum

marking field. Assume that the marking field is 500mm × 500mm, then the maximum radiusis 250mm.

Dynamic control board User Manual

17

The 1st zone (10%): means the circle region with central point of the mark field as thecenter of circle, and 25mm radius

The 2nd zone (20%): means the ring region, with central point of the mark field as thecenter, and the radius 25mm – 50mm.

Other zones is analogous。The 10th field (100%): means the region with central point of the mark field as the center

and the radius greater than 225mm.OffsetOffsetOffsetOffset Z:Z:Z:Z: Offset Z value corresponding to each zone.SwitchSwitchSwitchSwitch Automatically:Automatically:Automatically:Automatically: If user checks this option, the software would mark the test graph

one by one in the 10 zones when the “Start Test” button is press down. If un-check the option,graph would be marked only in the specified zone.

MicroMicroMicroMicro adjustadjustadjustadjust Z:Z:Z:Z: Slightly adjust the Z offset value while clicking button “Add Z” and “Sub Z”,or checking “Auto Add/Dec Z”. Add or decrease value is determined by the “Micro increment” inthe “Advanced” dialog box. If this option is not checked, the value is determined by “IncrementZ”.

AutoAutoAutoAuto Add/DecAdd/DecAdd/DecAdd/Dec Z:Z:Z:Z: Automatically add or decrease Z value, then mark the test graph inspecified zone. Note that if we check the “Switch automatically” option, this option would beignored. In test procedure, if “Add Z” button is pressed, the software would increase the Z valueautomatically and continue working; if “Dec Z” button is pressed, the software would decreasethe Z value automatically and continue working. Once the most suited Z Value is found, youcan press “Stop Test” button to stop the test.

AddAddAddAdd Z:Z:Z:Z: Increase the Z value, and corresponding output voltage is increased.DecDecDecDec Z:Z:Z:Z: Decrease the Z value, and corresponding output voltage is decreased.StartStartStartStart Test:Test:Test:Test: Start the test procedure. Move the Z axis to appointed position and mark a

rectangle there. The rectangle’s size can be set in the “Advanced” dialog box.StopStopStopStop Test:Test:Test:Test: Stop the test procedure.Save:Save:Save:Save: Save the Z values to a file.Load:Load:Load:Load: Load the Z values from saved fileUpdateUpdateUpdateUpdate All:All:All:All: Update all of the Z values. The hardware output is not updated when we

modify the Z-value manually. In this case we must click this button to refresh the data.ZZZZ ReverseReverseReverseReverse:Reverse the movement direction of Z axis.Advanced:Advanced:Advanced:Advanced: Click this button, the “Advanced” dialog box is shown, see figure 16.

Dynamic control board User Manual

18

Figure 16 Advanced parameter

LengthLengthLengthLength ofofofof TestTestTestTest Rect:Rect:Rect:Rect: The size of the test rectangle that is marked in the appointed zone.Please note that the size should be adapted with the mark field size. Assume that the markfield is 500mm × 500mm. Then the maximum circle radius is 250mm and the gap distance ofeach ring zone is 25mm. So if we set the length is 30mm or greater, the rectangle would acrosstwo or more zones. For mark field greater than 200mm × 200mm, please use the defaultvalue 10mm.

MarkMarkMarkMark Speed,Speed,Speed,Speed, JumpJumpJumpJump Speed:Speed:Speed:Speed: Set the speed that the software using in marking.IncrementIncrementIncrementIncrement Z,Z,Z,Z, MicroMicroMicroMicro IncrementIncrementIncrementIncrement Z:Z:Z:Z: Set the movement value of Z axis in test procedure.LinearLinearLinearLinear Mode:Mode:Mode:Mode:Whether using the linear interpolation arithmetic to calculate the Z values.

Related Documents