-

8/11/2019 VSL HK Catalogue

1/44

-

8/11/2019 VSL HK Catalogue

2/44

VSL Post-Tensioning Systems

have been used commonly

throughout the world since 1956.

They are technically mature and

have earned a reputation for

quality and reliability. Today,

VSL is a recognized leader in

post-tensioning and related

engineering.

VSL Post-Tensioning is used in

virtually every area of concrete

construction. While used

primarily in bridges and

buildings, the system is also

employed for the construction of

concrete containment structures,anchoring in rock and soil,

structural strengthening and

repair, lifting and sliding of heavy

loads, and many other

applications.

Harbour Front, Hong Kong

Tsing Ma and Kap Shui Mun Bridges, Hong Kong

Bank of China, Hong Kong

The VSL technology is based

on the principle of post -

tensioning. The prestress is

permanently introduced into

the structure after the

concrete has hardened. This

is achieved by the stressing

of suitably arranged, high-

strength prestressing

tendons. VSL Post-

Tensioning generates

favorable stress conditions in

the structure, enabling

efficient use of building

materials while controlling

deformations under service

conditions.

This publication comprises a

summary of the VSL Post-

Tensioning Systems and contains

important information of design

and construction. The dimensions

Gateway I, Hong Kong

-

8/11/2019 VSL HK Catalogue

3/44

Rambler Channel Bridge, Hong Kong

Bee-Do Bridge, South Korea

Koshiki Daimyojin Bridge, Japan

strengths may all be accommodated.

Your local VSL Representative will

furnish additional details regarding

specific applications.

As a subsidiary of VSL

International of Switzerland and a

member of BOUYGUES S.A. of

France, VSL is part of a major

international construction group

with a combined workforce of over

80,000. VSL International Ltd.

further divides its subsidiaries and

licensees into five Operating Units

(OU's). Operating Unit 1 covers

South East Asia with the regional

office in Australia. Operating Unit 2

covers North East Asia with the

regional office in Hong Kong.

Operating Unit 3 covers the United

States with the regional office

With offices throughout the world,

VSL offers a comprehensive

range of professional services for

any post-tensioning project.

These locally based services

include feasibility studies,

structural design assistance,

contractor consulting and field

installation, all aimed at finding

the best solution and insuring the

best value for money.

The scope of VSL's value-added

services is tailored to suit client

needs.

As a technical leader in the post-

tensioning industry, VSL works

continuously, through its quality

assurance program, to refine,

improve, and expand the scope of

its systems and services.

Subscribing to the philosophy that

what is good today may alwaysbe made better for tomorrow, VSL

has always attracted the most

talented and motivated people, all

with one goal: to be your most

valued construct ion partner.

in Raleigh. Operating Unit 4.5

covers Europe, Middle East, Africa

and South America, with the

regional office in France. This

arrangement gives VSL continuous

access to the latest construction

technologies

employed throughout

the world. Our local

based offices allow

VSL to be close to

our clients and offer

our construction

solutions effectively.

and strengths indicated are

subject to change as VSL

continuously improves its systems.

Additional tendon sizes are available

upon request. Alternate dimensions,

special conditions and various

-

8/11/2019 VSL HK Catalogue

4/44

VSL Multistrand System Components

Grout tube

Stressing anchorage

Grout tube Grout tube Grout tube Grout tube

Dead end anchorage

The VSL multistrand system is characterized by the

following features:

• standardized tendon units with up to 55 strands of

13mm (0.5") or 15 mm (0.6") diameter;

• wide selection of anchorage types;

• ducts of steel or plastic PT-PLUS™;

• grouting with cement mortar or other materials;

• economical tendon manufacture on-site or in the

factory;

• no need to determine tendon length in advance;

• simultaneous stressing of all strands in a tendon

but individual locking of each strand at the

anchorage;

• stressing in any number of steps;

• simple and reliable equipment for installation,

stressing and grouting.

-

8/11/2019 VSL HK Catalogue

5/44

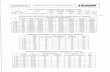

ASTM A416

Grade 270

15.2

1401.1

1670

1860

260.7

ASTM A416

Grade 270

12.7

98.70.775

1670

1860

183.7

EN138 or

BS 5896 Super

12.9

1000.785

1580

1860

186

cicra 195

max 2.5

mm

mmkg/m

MPa

MPa

kN

GPa

%

Strand type

Nominal diameter

Nominal areaNominal mass

Yield strength

Tensile strength

Min. breaking load

Young's modulus

Relaxation

Tendon

unit

5-4

5-7

5-12

5-19

5-22

5-27

5-31

5-37

5-42

5-48

5-55

No. of

strands

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1617

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

5152

53

54

55

Min.

(mm)

36/39

51/54

60/67

75/82

80/87

95/102

95/102

110/117

120/127

130/137

130/137

Duct ID/OD

12.7

367

551

735

919

1102

1286

1470

1653

1837

2021

2204

2388

2572

2756

29393123

3307

3490

3674

3858

4041

4225

4409

4593

4776

4960

5144

5327

5511

5695

5878

6062

6246

6430

6613

6797

6981

7164

7348

7532

7715

7899

8083

8267

8450

8634

8818

9001

9185

93699552

9736

9920

10104

Min. Breaking load

(kN)

STRAND TYPE 13 mm (0.5")

Nominal

(mm)

36/39

51/54

65/72

80/87

95/102

100/107

100/107

110/117

120/127

130/137

135/142

Tendon

unit

6-3

6-7

6-12

6-19

6-22

6-27

6-31

6-37

6-42

6-48

6-55

No. of

strands

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1617

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

5152

53

54

55

Min.

(mm)

36/39

55/62

75/82

90/97

100/107

110/117

120/127

130/137

135/142

150/160

160/170

Duct ID/OD

15.7

530

795

1060

1325

1590

1855

2120

2385

2650

2915

3180

3445

3710

3975

42404505

4770

5035

5300

5565

5830

6095

6360

6625

6890

7155

7420

7685

7950

8215

8480

8745

9010

9275

9540

9805

10070

10335

10600

10865

11130

11395

11660

11925

12190

12455

12720

12985

13250

1351513780

14045

14310

14575

15.2

521

782

1043

1304

1564

1825

2086

2346

2607

2868

3128

3389

3650

3911

41714432

4693

4953

5214

5475

5735

5996

6257

6518

6778

7039

7300

7560

7821

8082

8342

8603

8864

9125

9385

9646

9907

10167

10428

10689

10949

11210

11471

11732

11992

12253

12514

12774

13035

1329613556

13817

14078

14339

Min. Breaking load

(kN)

STRAND TYPE 15 mm (0.6")

Nominal

(mm)

36/39

65/72

80/87

100/107

100/107

110/117

120/127

130/137

135/142

160/170

170/180

Strand Properties

1) 2) 1) 2)

3)

4) 4)

EN138 or

BS 5896 Super

15.7

1501.18

1500

1770

265

13 mm (0.5") 15 mm (0.6")

2

Tendon Properties

12.9

372

558

744

930

1116

1302

1488

1674

1860

2046

2232

2418

2604

2790

29763162

3348

3534

3720

3906

4092

4278

4464

4650

4836

5022

5208

5394

5580

5766

5952

6138

6324

6510

6696

6882

7068

7254

7440

7626

7812

7998

8184

8370

8556

8742

8928

9114

9300

94869672

9858

10044

10230

1) Measured at 0.1% residual strain (0.1% offset method)2) Measured at 1% extension (1% extension under load method)3) After 1000 hrs at 20º C (EN & BS, low relaxation to ASTM)

4) Corrugated plastic PT-Plus™ ducts are also available, refer to page 11

-

8/11/2019 VSL HK Catalogue

6/44

Dimensions

Subject to modification

G

95

125

150

200

230

250

250

305325

365

400

95

125

150

200

250

250

305

325

365

400

F

Ext. Dia.

39

54

72

87

102

107

107

117127

137

142

39

54

72

87

107

107

117

127

137

142

E

58

85

120

145

150

175

175

200217

235

250

58

85

120

145

175

175

200

217

235

250

D

100

100

160

210

215

300

300

320340

340

340

100

100

160

210

300

300

320

340

340

340

C

85

110

150

180

200

220

230

250290

290

320

90

110

150

180

220

230

250

270

300

320

B

60

60

60

70

77

92

100

107112

122

150

60

60

60

75

92

100

112

122

142

145

A

135

165

215

265

290

315

315

370390

430

465

135

165

215

265

315

315

370

390

430

465

5-4

5-7

5-12

5-19

5-22

5-27

5-31

5-375-42

5-48

5-55

6-3

6-4

6-7

6-12

6-19

6-22

6-27

6-31

6-37

6-42

Tendon unit

Dimensions in mmDimensions are valid for:Nominal concrete strength at 28 days: 35 MPa (cube), 28 MPa (cylinder).Maximum prestressing force may be applied when concrete reaches 25 MPa (cube) or 20 MPa (cylinder).Max prestressing force is 75% of min. tendon breaking load (temporary overstressing to 80%).

Grout connection

Anchor block

Wedges

Strands

Casting

Duct

B D

M U L T I S T R A N D P O S T - T E N S I O N I N G

Stressing Anchorage VSL Type EC

A C F E

G

A

A

-

8/11/2019 VSL HK Catalogue

7/44

D

4585

85

110

150

180

200

220

230

250

290

290

320

5590

90

120

135

180

220

230

250

270

300

320

340

360

5-1

5-3

5-4

5-7

5-12

5-19

5-22

5-27

5-31

5-37

5-42

5-48

5-55

6-16-2

6-3

6-4

6-7

6-12

6-19

6-22

6-27

6-31

6-37

6-42

6-48

6-55

A

70

115

130

175

230

290

315

370

370

405

500

500

500

75110

135

160

205

270

340

370

435

435

480

580

580

580

B

15

20

20

25

35

40

45

55

55

60

70

70

70

1515

20

25

35

40

50

55

65

65

70

90

90

90

C

45

60

60

60

60

75

82

97

105

112

117

127

155

6060

60

60

70

78

97

107

117

127

147

147

147

187

E

70

190

190

190

370

470

480

550

550

570

680

680

680

70190

190

190

290

460

590

690

690

690

830

950

950

950

F

Ext. Dia.

3636

39

54

72

87

102

107

107

117

127

137

142

3636

39

54

72

87

107

107

117

127

137

160

160

170

Tendon unit

Dimensions

Subject to modificationDimensions in mmDimensions are valid for:Nominal concrete strength at 28 days: 35 MPa (cube), 28 MPa (cylinder).Maximum prestressing force may be applied when concrete reaches 25 MPa (cube) or 20 MPa (cylinder).Max prestressing force is 75% of min. tendon breaking load (temporary overstressing to 80%).

Bearing plate (steel)

M U L T I S T R A N D P O S T - T E N S I O N I N G

Stressing Anchorage VSL Type E

Sleeve

Duct

Grout tube

Anchor block

Strands

Wedges

A D

C B E

F

A

A

-

8/11/2019 VSL HK Catalogue

8/44

Couplers VSL Type K and V

Duct

Casting type EC or

Bearing plate type E

Grout tube

Omega ring

Compression

fittings

Wedges

Tension ring

Sleeve

Couplingblock K

Compression fittings with

retainer plates

Coupling block V

Coupler type K

5-3

5-7

5-12

5-19

5-22

5-31

6-2

6-3

6-4

6-7

6-12

6-19

D

290

410

510

600

690

1000

230

330

360

470

570

700

E

175

175

175

175

175

175

200

205

205

205

205

205

F

230

330

420

490

570

870

185

250

280

370

460

570

øG

130

170

200

240

260

350

130

150

160

190

240

280

Tendon

unit

Coupler type V

Subject to modification

øC

130

150

170

200

240

260

310

350

390395

420

490

150

150

160

200

240

280

310

330

350

440

B

110

110

110

110

110

110

110

110

150150

150

170

128

128

128

128

128

128

128

138

150

170

A

430

440

440

510

590

660

860

1010

10801080

1370

1370

380

490

520

630

730

860

930

1090

1090

1390

Tendon unit

5-3

5-4

5-7

5-12

5-19

5-22

5-27

5-31

5-375-42

5-48

5-55

6-2

6-3

6-4

6-7

6-12

6-19

6-22

6-27

6-31

6-37

Dimensions in mmDimensions are valid for:Nominal concrete strength at 28 days: 35 MPa (cube), 28 MPa (cylinder).Maximum prestressing force may be applied when concrete reaches 25 MPa (cube) or 20 MPa (cylinder).Max prestressing force is 75% of min. tendon breaking load (temporary overstressing to 80%).

Couplers Type K

Fixed coupler.

For coupling to a tendon which has been placed and stressed.

Couplers Type V

Movable coupler.

For coupling to a tendon which has already been placed,

but not stressed.

Cast-in casting

type EC

∆L=Elongation of tendon 1

A

B

E+1.5D∆L

F

-

8/11/2019 VSL HK Catalogue

9/44

Dead End Anchorage VSL Type H

B

70

70

170

70

190

190

270

190

390

190

390

310

430

310

550

350

550

350

430

670

Type

I

I

I

II

II

II

I

II

II

II

II

II

II

II

II

II

II

II

II

II

Alter-

native

1

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

3

Tendon

unit

5-3

5-4

5-7

5-12

5-19

5-22

5-31

5-37

5-42

5-55

A

230

310

150

370

170

350

310

470

310

570

390

670

470

770

470

870

570

1170

870

570

C

930

930

930

1130

1130

1130

1130

1130

1130

1130

1130

1330

1330

1530

1530

1530

1530

1830

1830

1830

D

-

-

-

1280

1280

1280

-

1280

1280

1280

1280

1480

1480

1680

1680

1680

1680

1980

1980

1980

B

90

90

210

90

230

230

330

230470

230

490

260

510

370

510

370

510

650

370

510

790

Type

I

I

I

II

II

II

I

IIII

II

II

II

II

II

II

II

II

II

II

II

II

Alter-

native

1

1

2

1

2

1

2

12

1

2

1

2

1

2

1

2

3

1

2

3

Tendon

unit

6-3

6-4

6-7

6-12

6-19

6-22

6-31

6-37

6-42

6-55

A

290

390

190

450

210

430

390

570390

690

470

810

570

1050

690

1050

810

690

1410

1050

690

C

950

950

950

1150

1150

1150

1150

11501150

1150

1150

1550

1550

1850

1850

1850

1850

1850

2150

2150

2150

D

-

-

-

1330

1330

1330

-

13301330

1330

1330

1700

1700

2000

2000

20000

2000

2000

2300

2300

2300

Strand type 15 mm (0.6")

Dimensions in mmDimensions are valid for:Nominal concrete strength at 28 days: 35 MPa (cube), 28 MPa (cylinder).Maximum prestressing force may be applied when concrete reaches 25 MPa (cube) or 20 MPa (cylinder).Max prestressing force is 75% of min. tendon breaking load (temporary overstressing to 80%).

Subject to modification

A x B

Bulbs

Grout tube

Duct

Tension ring

Seal

Spacer

Strand type 13 mm (0.5")

Type IType II

DC

-

8/11/2019 VSL HK Catalogue

10/44

Tendon 2

Intermediate Anchorage VSL Type Z and ZU

Intermediate Anchorage Type Z Intermediate Anchorage Type ZU

Centre-stressing anchorages are used for ring tendons in circular structures, or for those tendons where the ends cannot be fitted

with normal stressing anchorages.

F

400

500

700

1000

1300

1450

450

900

1000

1350

1450

1500

C

80

90

130

140

180

200

90

100

140

160

200

250

5-2

5-4

5-6

5-12

5-18

5-22

6-2

6-4

6-6

6-12

6-18

6-22

Intermediate anchorage type Z

Tendon

unit B

60

70

90

140

160

160

70

80

100

160

180

180

D

60

65

85

90

110

120

65

70

90

100

120

145

G

560

720

990

1490

1910

2110

620

1180

1400

1960

2280

2380

H

170

200

240

320

360

390

180

210

250

340

420

440

A

130

160

200

280

320

350

140

170

210

300

380

400

Dimensions in mm

1) Tension ring only on side 22) Dependent upon the shape of the concrete surface.

The values stated apply for surfaces which are not curved.

F

450

560

650

450

560

650

C

80

88

95

90

92

100

5-2

5-4

5-6

6-2

6-4

6-6

Intermediate anchorage type Z

Tendon

unit B

103

103

113

105

105

120

D

60

65

70

65

65

75

G

655

815

925

655

815

925

H

200

200

220

210

210

240

A

165

165

185

170

170

200

Subject to modification

1)

1)

1)

1)

2) 2) 2) 2)

1)

1)

1)

1)

Tendon 1

-

8/11/2019 VSL HK Catalogue

11/44

Minimum Radii of Tendon Curvatures and Minimum Tangent Length

Minimum breaking load of tendon (MN)

Minimum radius of

tendon curvature

Minimum tangent length

Selected Design Considerations

Spacing and Cover of Ducts

In determining minimum spacing and concrete cover

requirements, reference should be made toapplicable standards and recommendations.

-(µα+kx)= Po e , where= Distance from stressing end (in meters)

= Prestressing force at x

= Prestressing force at stressing end

= Coefficient of friction

= sum of all angular deviations (in radians)

over the distance x

= Wobble friction coefficient due to minor

unavoidable tendon curvatures

(placing tolerances)

k= 0.001 (range 0.0008~0.0012)

k= 0.001 (range 0.0008~0.0012)

Tendon Supports

Recommended spacing:

Standard steel ducts 0.8 to 1.2m

Plastic ducts PT-PLUS™: 0.8 to 1.0m

Tendon Force Losses

The effective prestressing force at a specific place

and time differs from the initial prestressing forcefor various reasons.

Significant factors include:

• friction losses due to curvature of the tendon;

• shrinkage and creep of the concrete;

• relaxation of the prestressing steel;

• draw-in of the wedges during lock-off.

The friction losses along the tendon can be

determined with the following formula:

Px

x

Px

Po

µ

α

k

The friction coefficients µ and k can vary fairly widely

and depend upon various factors, including: the

nature and surface condition of the prestressing

steel; the type, diameter and surface condition of the

duct; and the installation method.

The following values may be assumed for design:

Tendon in standard steel ducts:

µ= 0.2 (range 0.16~0.22)

Tendon in plastic ducts PT-PLUS™:

µ = 0.14 (range 0.12~0.15)

For calculating the losses due to shrinkage and

creep of the concrete, reference should be made to

the technical literature and to the standards

applicable to each project.

The relaxation of the prestressing steel depends

primarily upon the types of steel (relaxation class),the magnitude of the prestress and the temperature.

For low relaxation strands commonly used today, the

maximum loss is 2.5% after 1000 hours at 20˚ C and

an initial stress of 70% of the nominal tensile

strength. Further information can be found in the

relevant prestressing steel standards and

manufacturer's literature.

Independent of the type of jack or tendon, a loss due

to wedge draw-in of approximately 6mm occurs at

lock-off. If necessary, this can be compensated for

by suitable procedures.

-

8/11/2019 VSL HK Catalogue

12/44

Sheathing and Corrosion Protection

For conventional applications, corrugated galvanised

steel ducts are used.

For applications requiring enhanced corrosion

protection and improved fatigue resistance of the

tendons, use of the VSL PT-PLUS™ System with

corrugated plastic duct is recommended. This fully

encapsulated and watertight system offers superb

corrosion protection, and the plastic duct eliminates

fretting fatigue between the strand and duct. It also

Strand Position at High Point of Tendon

Strand bundle

Steel

duct

e (mm)

5

6

6

10

14

17

14

13

22

25

Plastic

duct

e (mm)

-

-

-

9

12

18

15

32

28

22

Strand Type 13 mm (0.5") Strand Type 15 mm (0.6")

5-1

5-3

5-7

5-12

5-19

5-22

5-27

5-31

5-37

5-42

5-48

5-55

Tendon

unit

Steel

duct

e (mm)

4

7

8

11

13

12

13

14

23

26

17

23

Plastic

duct

e (mm)

-

-

-

7

9

22

17

14

32

28

24

14

6-1

6-3

6-4

6-7

6-12

6-19

6-22

6-27

6-316-37

Tendon

unit

Strand Type15 mm (0.6")

Tendon unit

6-7

6-12

6-19 / 6-22

6-31

6-37

Strand Type13 mm (0.5")

Tendon unit

5-12

5-19

5-31

5-43

5-55

59

76

100

130

130

73

91

116

146

146

2

2.5

3

3

3

Steel Duct

DuctDimensions (mm)

d D s

Other units on request

provides reduced duct friction. The PT-PLUS™

System may, in conjunction with VSL CS

Anchorages, be configured with special details and

installation techniques to provide Electrically Isolated

Tendons. These tendons may be electrically

monitored at any time throughout the life of the

structure.

All ducts are manufactured in a variety of standard

lengths and are coupled on site.

Strand Position at Low Point of Tendon

Centre line of duct

Centre of gravity of strandse

e

Dimensions of Plastic Ducts PT-PLUS™

Plastic Duct PT-PLUS™

-

8/11/2019 VSL HK Catalogue

13/44

-

8/11/2019 VSL HK Catalogue

14/44

StressingThe unique feature of the VSL Post-Tensioning

system lies in its special procedure for locking the

wedges. The wedges always remain in contact with

the strands during the stressing operation. As the

pressure in the jack is released, the wedges

automatically lock in the conical holes of the anchor

head.

Grouting equipment

Placing of anchor block

Positioning of jack

Stressing, measuring, seating of wedges

GroutingVSL grouting equipment includes mixer and pump inone unit. Grouting is usually carried out as soon aspossible after stressing.

Placing of anchor block and wedges

Positioning of the jack

Stressing

Seating of wedges

Grouting of tendon

-

8/11/2019 VSL HK Catalogue

15/44

Push Through Machine Hydraulic Pump

ZPE-60

III

615

180

250

126.4

632

500

745-2

to 5-4

6-2

6-3

ZPE-12/St2

II

550

310

100

309.4

1850

598

1515-12

6-6

6-7

ZPE-200

III

960

315

300

325.7

2000

614

3055-12

6-6

6-7

ZPE-460/31

II

580

485

100

804.0

4660

580

4355-22

5-31

6-18

6-19

ZPE-1250

II

1290

620

150

2168.0

12500

577

17305-37

to 5-55

6-31

to 6-55

ZPE-1000

III

1200

790

200

1809.5

10000

553

22905-37

to 5-55

6-31

to 6-43

ZPE-750

II

1185

520

150

1247.0

7500

601

11005-31

5-37

6-31

ZPE-500

III

1000

550

200

894.6

5000

559

10645-22

5-31

6-18

to 6-22

ZPE-19

II

750

390

100

500.3

2900

580

2945-18

5-19

6-12

ZPE-7/A

III

690

280

160

203.6

1064

523

1155-6

5-7

6-4

ZPE-3

III

475

200

160

103.6

500

483

475-2

5-3

6-2

ZPE-30

III

720

140

250

58.32

320

549

285-1

6-1

ZPE-23FJ

I

790

116

200

47.10

230

488

235-1

6-1

(mm)

(mm)

(mm)

(cm )

(kN)

(bar)

(kg)

Designation

Type

Length

Diameter

Stroke

Piston area

Capacity

WeightUsed for 13 mm

(0.5") tendon types

Used for 15 mm

(0.6") tendon types

Subject to modification

Type I (ZPE-23 FJ)

Stressing Jack Data

E

E

90

100

150

140

200

200

210250

300

330

365

450

375

D

116

140

200

180

300

310

330390

485

585

570

790

660

C

1200

1100

1000

1100

1200

1300

21001500

1500

2000

2300

2200

2250

B

300

600

550

650

800

700

1100850

700

1150

1350

1300

1350

A min.

-

30

30

30

30

50

5050

60

80

80

80

90

Jack type

ZPE-23FJ

ZPE-30

ZPE-3

ZPE-60

ZPE-7/A

ZPE-12/St2

ZPE-200ZPE-19

ZPE-460/31

ZPE-500

ZPE-750

ZPE-1000

ZPE-1250

Dimensions in mm

2

60˚

B

C

D

E

Type III (ZPE-500)Type II (ZPE-19)

Concrete cover according

to applicable standard

-

8/11/2019 VSL HK Catalogue

16/44

ConcretingGrouting

Harbour Front (Hunghom Marine Redevelopment), Hunghom, Hong Kong

Placing tendons Stressing

Owners and designers of the

buildings of today and tomorrowneed to incorporate sufficient

flexibility into their structures to

accommodate the changing

needs of the users of the

building.

Post-tensioning offers larger

spans with reduced structural

depth, resulting in larger

column-free areas. Internal

tenancy layouts are thus not

restricted by tight column grids.Positive deflection and crack

control and, if necessary, crack-

free water-tight slabs offer the

designer the opportunity to

break free of the limitations of

the passive methods ofreinforced concrete or structural

steel.

VSL Post-Tensioning is more

economical than other systems,

especially when faster

construction cycles are

considered. There is less

material handling on site and

also a reduced site labour force

which minimises congestion on

site. Most importantly, there isthe quality and service of VSL

specialized high-performance

teams and optimum back-up on

site.

The VSL Post-Tensioning slab

system has been used in manyprestigious buildings and

structures throughout the Far

East. The system uses up to

five strands in flat-shaped

ducting and anchorages. The

strands are individually stressed

and are gripped by wedge

action. After stressing, the duct

is subsequently filled with a

cementitious grout, which is

injected under pressure, so that

the strands are fully bonded tothe surrounding concrete.

Construction Sequence

-

8/11/2019 VSL HK Catalogue

17/44

-

8/11/2019 VSL HK Catalogue

18/44

Stressing Anchorage VSL Type S

Subject to modification

Subject to modification

Type

S 5-4

S 5-5

S 6-4

S 6-5

A

265

265

315

315

B

100

100

105

105

C

240

240

254

266

D

73

73

82

82

E

90

90

100

100

F

305

305

338

338

X

350

350

400

400

D

215

215

215

215

C

95

95

95

95

B

110

110

110

110

A

265

265

265

265

Type

S 5-4

S 5-5

S 6-4

S 6-5

Dimensions in mm.

Dimensions are valid for a concrete transfer strength of 25 MPa (Cube), 20 MPa (Cylinder).

Couplers VSL Type SK

Recessformer

Strands

Compressionfittings

Coupling block

Wedges

Casting

Flat duct

B O N D E D S L A B P O S T - T E N S I O N I N G

Grout tube

Wedges

Strands

Anchor block

Casting

Duct

Grout tube

D

C

600

B

F

E

-

8/11/2019 VSL HK Catalogue

19/44

Dead End Anchorage VSL Type H and Type P

Type P

Type H

Dimensions in mm.

Dimensions are valid for a concrete transfer strength of 25 MPa (Cube), 20 MPa (Cylinder).

Grout tube

Seal

P-plate

Compressionfittings

C

370

370

435

435

B

75

75

80

80

A

250

300

260

410

Type

P 5-4

P 5-5

P 6-4

P 6-5

C

750

750

950

950

B

70

70

90

90

A

310

390

390

490

Type

H 5-4

H 5-5

H 6-4

H 6-5

Seal

Grout tube

Flat duct

Bulb

A x B

C

A x B

C

-

8/11/2019 VSL HK Catalogue

20/44

Anchorage Reinforcement

Anchorage at Slab Edge

Anchorage at Edge Beam

The above sketches show the preferred arrangement for the local confinement reinforcement at the anchorages. Please consult your local VSL

representatives for more details.

Details at Slab Edge

VSLAB ™ Encapsulated Two Strand System

End anchor head

Bearing plate

Half shell

Duct

Clip

Grout vent

Wedge

Gasket

High performance grout

Encapsulated strandG

40

70

F

130

130

E

105

105

D

90

90

C

150

150

B

163

163

A

163

163

Type

SA5-2

k5-2

Grout cap

E F

G

A C

G

B D

Extra links whereshown for S6-5 only Grout vent

Grout vent

Details at Edge Beam Plan

Place innermost linkshard against castingas shown

Extra links whereshown for S6-5 only

-

8/11/2019 VSL HK Catalogue

21/44

50

Plan

Section A Section B

Internal Stressing Pocket

13 mm and 15 mm strand

Details shown are typical and may vary for particular applications

Stressing Jack Clearance Requirements

C

(mm)

280

400280

400

250

320

300

400

B

(mm)

260

260260

260

260

260

400

400

A

(mm)

1100

11001100

1100

800

800

850

850

Tendon

unit

5-4

5-56-4

6-5

5-4

5-5

6-4

6-5

Jack type

ZPE-23FJ

DKP-5

DKP-6

Jack type

A

B

C

D

Stroke

Piston area

Capacity

Weight

(mm)

(mm)

(mm)

(mm)

(mm)

(cm )

(kN)

(bar)

(kg)

ZPE-23FJ

790

116

-

195

200

47.10

230

488

23

DKP-6

615

240

84

165

200

49.26

230

467

30

DKP-5

560

162

105

150

200

31.03

147

473

19

2

Stressing Jack Data

B O N D E D S L A B P O S T - T E N S I O N I N G S Y S T E M S

B=Strand projection C

A

DKP-5/DKP-6

A

ZPE-23FJ

A B

B

A

B

450

42030

-

8/11/2019 VSL HK Catalogue

22/44

External post-tensioning is well suited to bridges due to the resulting economies in construction costs and the high

degree of corrosion resistance provided by the system. External tendons are easy to inspect and can be replaced if

necessary. They are ideal for strengthening existing structures and have a multitude of applications in addition to

bridges.

VSL ext ernal tendons consist of :• strand bundle;

• polyethylene duct;

• end and intermediate anchorages as well as tendon couplers;

• grouting compound.

External tendons, usually guided over deviation saddles, have many similarities to stay cables and permanent soil

and rock anchors.

Detailed information about design and construction is given in the VSL publication "External Post-Tensioning".

Stressing anchorage Dead end anchorage

VSL External Post-tensioning System Components

Tendon deviation saddle

Strand bundle and sheathing

Bois de Rosset Viaduct, Switzerland

-

8/11/2019 VSL HK Catalogue

23/44

A wide selection of VSL anchorage types is available to meet the full range of practical requirements. In addition

to the anchorages illustrated here, intermediate anchorages and couplers are also available . The strand bundle

can be assembled from uncoated or individually greased and sheathed strands. The anchorages for these two

types of tendon differ only in detail, the principle remains the same.

Tendon

unit

5-12

5-19

5-31

5-43

5-55

6-7

6-12

6-19

6-31

6-37

A

270

310

370

430

520

250

310

390

430

520

B

125

150

165

200

220

125

150

165

200

220

øC

222

258

320

390

420

222

258

300

390

420

D

110

125

150

180

200

110

125

150

180

200

øE

65 / 3.6

90 / 5.1

110 / 6.3

125 / 7.1

140 / 8.0

63 / 3.6

90 / 5.1

110 / 6.3

140 / 8.0

160 / 9.1

Dimensions (mm)

Notes : 1. Nominal external duct diameter / wall thickness

2. Other sizes are available upon request

1)

Ext ernal prestressing components,

Anchorage Type ECR Ext ernal tendons at deviation saddle

B

A øE

Anchorage Type EC R

øEøC

D

Anchorage Type CS

-

8/11/2019 VSL HK Catalogue

24/44

Dead end anchoragewith split bearing plate

PE sheath Strand

Guide tube/ Extension tube

Bundle ofmonostrands

HDPE stay pipe

Guide tube/ Extension tube

Bundle ofmonostrands

VSL Staycable System 200

VSL Staycable System 200 SSI

VSL Stay Cable SystemVSL Stay Cable System has been developed to fulfil the stringent requirements for the design,

construction and maintenance of cable stayed bridges.

VSL Stay Cable System consists of:• a tendon made of multiple parallel 15mm high tensile steel strands;

• each strand having an extruded coating of grease and polyethylene;

• each strand having an individual polyethylene guide tube continuous from anchorage to anchorage (option for

system 200 SSI only);

• an outer sheath of thick walled polyethylene pipe;• anchorages that are prefabricated in the factory.

The feat ures of t he system are:• high fatigue resistance of 200 MPa at 45% of tendon capacity through 2,000,000 load cycles;

• high degree of corrosion resistance with multi-layers of corrosion protection;

• excellent corrosion protection of strands during construction provided by extruded coating;

• simple erection of stay cable assembly without the weight of the tendon strands;

• simple Single Strand Installation of the tendon into the erected stay assembly;

• all strands are parallel within guide tubes with no risk of intertwining;

• no requirement for on-site grouting of cable;

• easy to adjust or monitor the tendon force at any stage of the cable life;

• able to remove and replace individual strands or entire cable for inspection or repair at any time withoutdismantling the installed anchorages;

• Single strand stressing.

Guide pipe

Adjustable stressinganchorage with threadedanchorage head and ring nut

Damper andneoprene boot

Parallel monostrandtendon, guide tubes andstay pipe

PE sheath Strand

Grease

Transition pipeHDPE stay pipe Grease

-

8/11/2019 VSL HK Catalogue

25/44

øG

(mm)

219/6.3

267/6.3

273/6.3

324/7.1

355.6/8

406/8.8

419/10

419/10

508/11

508/11

559/12.5

O

(mm)

1100

1350

1500

1650

1850

2100

2200

2400

2600

2700

2900

P min

(mm)

90

105

115

135

150

155

175

190

190

220

230

VSL Stay Cable System 200

1) Tendon units 6-4 and 6-7: dimensions on request.

2) Strand in accordance with Euronorm 138-79 super; other types of strandwith 15 mm (0.6) diameter see VSL's .

3) Valid for nominal concrete strength at 28 days: 45 MPa (cube), 36MPa (cylinder). Local zone reinforcement not shown.

4) External diameter / wall thickness.

5) Min. height of anchor head allow an adjustability of ± 20 mm.

6) Dimensions valid only for load monitoring/adjustment. Min. requiredlength for removal of cable to be determined acc. to project.

7) Threaded holes in bearing plate.

Dimensions in mm

Transition

pipe

Bearing

plate

Pregrouted

section

M min

L min

S min Pmin

Protection cap

O 50

Connectionsleeve

Boot

T

L min

M min

Pregrouted

sectionDamper

O

Split shim

R

ii i

i

l

i

I i i

min. 220 M

K min

H

.

-

8/11/2019 VSL HK Catalogue

26/44

The VSL anchors are of similar construction, whether

intended for installation in rock or in soil, and consist

basically of the following three parts:

• bond length;

• free length;

• anchor head for attaching to the component to beanchored.

Depending upon the intended application and

service life of the anchor, the type of rock or soil and

the magnitude of force to be transmitted, each of

these parts must be capable of satisfying the most

varied requirements. These factors therefore

influence the individual components of which the

anchor will be constructed and the dimensions of the

anchoring length and of the borehole.

The anchor head is the main characterisic feature ofthe VSL anchor. It always consists of a stressing

anchorage selected from the VSL prestressing

systems. The other parts of the anchor may,

however, be adapted to the particular requirements

in regard to their length, load-carrying capacity, form

and individual components. Depending upon its

construction, the VSL anchor may then be used as a

temporary or permanent anchor, as a test anchor or

surveillance anchor, in certain circumstances it may

comprise special protective measures against

corrosion and mechanical damage. Further

information about the soil and rock anchors will be

found in the following VSL publications, which are

obtainable on request:

• VSL Measuring Technique;

• VSL Soil and Rock Anchors - Examples from

Practice.

Strengthening of a gravity dam

Tie-down for a tall building

Securing a slope

-

8/11/2019 VSL HK Catalogue

27/44

Section B.B

Permanent VSL Strand Anchor Fully Encapsulated

Section A.A

Bore hole

Bore hole

Spacer

Bare clean strand

Bearing plate

Anchor block

Section A.AGrout tube

Corrugated sheath

Internal spacer

External spacerBore hole

Section B.B

Bore holeExternal spacer

Smooth sheath

Grout tubes

Greased and plasticcoated strand

Anchor block

Smooth sheath (Polyethylene) orcorrugated sheath

Temporary VSL Strand Anchor

G R O U N D A N C H O R S

Bare clean strand

Grout tubes

Grout

External spacer

Bare clean strand

Be

-

8/11/2019 VSL HK Catalogue

28/44

Fig. a: VSL anchorage Type ER

A B C

Diagrammatic

Presentation

Anchor block for surveillance anchors:

Alternative

Type E with threadStressing jackwith coupling

None

Type E normalStressing jack

Required

VSL anchor headForce measure-ment with

Protection of strand

Type E normalLoad cell, installedpermanent or onlywhen measuring

None

Fig. b: VSL anchorage Type EA

Stressing Anchorage

VSL Anchorage Type E

The VSL stressing anchorage Type E, is composed

basically of an anchor block, wedges and bearing

plate. A protective cap may also be fitted over the

anchorage, if the latter must be accessible for

surveillance purposes.

All the strands of an anchor are stressed

simultaneously, but they are locked off individually by

wedges in the conical bores in the anchor block. The

range of VSL anchorages Type E enables tendons of

1 to 55 strands to be stressed, the principle of

anchoring being the same from the smallest to the

largest unit.

The VSL stressing anchorages Type E are designed

in principle to meet all the special requirements

which may be demanded of an anchor. These

requirements must certainly be known in advance to

enable the anchor to be designed in detail

accordingly. This is particularly necessary when the

anchor is:

• a surveillance anchor;

• required to be restressed later;

• required to be detensioned and again restressed;

• required to be removed after use.

Surveillance AnchorsA surveillance anchor is an anchor at which

observations are carried out periodically and enables

the stressing force to be read at any time. The table

shows diagrammatically various forms of

construction of the anchorage. The choice of a

suitable type will depend upon the access available

to the anchor, its required service life and

economical considerations. For alternatives B and C,

an anchor head of Type E is used, with a thread on

it's external cylindrical surface.

Restressing of AnchorsWhere force losses are to be expected as a

consequence of soil movements or structural

deformations, the anchor should be so constructed

that it can be restressed.

Alternatives A and B in the table are also suitable for

restressing. To restress, the anchor block is lifted off

from the bearing plate and shims are inserted between

them. A third solution is to use VSL anchorage Type

ER, which has a ring nut enabling the prestressing

force to be adjusted (Fig. a).

Detensioning and Restressing of Anchors

Where an anchor is to be detensioned later, anarrangement is required consisting of a different type

of wedge and an accessory device incorporated in

between the jack and the anchor head. With this

arrangement the wedges can be released and again

locked at any time thus enabling the anchor to be

completely detensioned in one or more stages.

Where strands must be cut off and not project beyond

the anchor block, a VSL anchorage Type EA can be

used (Fig. b). This works on the principle of an

adjusting ring nut and a coupler being used for

destressing.

Removable Anchors

For temporary rock or soil anchors which are required

to be removed after use, the VSL Removable Anchor

System can fulfill such a special requirement.

After destressing of the anchor, the entire strand

tendon can be removed. All that is left behind in the

ground is a small piece of steel component and the

grout column with plastic sheathing which would not

affect neighbouring foundation activities in the future.

For details of the VSL Rock and Soil Anchor Systems

please contact your local VSL branch office.

-

8/11/2019 VSL HK Catalogue

29/44

VSL Permanent Ground Anchors (Strand Type)

Jack

type

required

ZPE-7/A

ZPE-12/St2

ZPE-19

ZPE-460/31

ZPE-750

ZPE-750

ZPE-1000

ZPE-1000

ZPE-1250

Drill

hole

dia. (mm)

130

150

175

200

215

275

310

325

350

Ultimate

capacity

(kN)

1060

1855

3180

5035

7155

8215

9805

11395

14575

Number

of

15mm strands

4

7

12

19

27

31

37

43

55

70

84

102

130

130

160

160

210

260

75

90

110

140

140

170

170

220

270

85

100

125

165

165

195

195

256

270

65

80

100

125

125

150

150

200

250

Note: Where block outs, voids or drill hole casing are required,

drill hole diameters and bearing plate dimensions should be confirmed with the local VSL office.

VSL Permanent Ground Anchors (Stressbar Type)

Drill hole sizes are based on 10mm external cover *VSL Deformed Tie Bar

**VSL Threadlok Bar

50

50

5050

65

65

65

80

80

80

80

80

100

65

65

6565

85

85

85

100

100

100

100

100

125

Jack

type

required

ZPE-3

ZPE-3

ZPE-3ZPE-3

ZPE-3

ZPE-3

ZPE-60

ZPE-7/A

ZPE-7/A

ZPE-7/A

ZPE-200

ZPE-200

ZPE-19

Drill hole

dia. mm

50

50

5050

75

75

75

87

100

100

100

100

125

Drill hole

dia. mm

75

75

7575

87

87

87

100

100

112

112

112

165

Bar

dia.

mm

15

*15

**2020

23

**25

26

29

32

36

38

40

56

Ultimate

capacity

(kN)

190

191

188325

450

295

575

715

870

1050

1225

1295

2460

Drill hole

dia. mm

100

100

100100

125

125

125

150

150

150

150

150

175

Corrugated

sheath mm

ID OD

Smooth

ID OD

Corrugated

ID OD

Sheath Diameter (mm)

Permanent Encapsulated Epoxy Coated Temporary

Minimum

drill hole

dia. mm

100125

150

175

Ultimate

capacity

kN

13622232

3534

5022

No. of

13 mm

strands

712

19

27

VSL Temporary Ground Anchors

13mm Strand

Jack

type

required

ZPE-7 / AZPE-12 / St2

ZPE-19

ZPE-460 / 31

Minimum

drill hole

dia. mm

100125

150

175

Ultimate

capacity

kN

18553180

5035

7155

No. of

15 mm

strands

712

19

27

VSL Temporary Ground Anchors

15mm Strand

Jack

type

required

ZPE-12/St2ZPE-19

ZPE-460/31

ZPE-500

-

8/11/2019 VSL HK Catalogue

30/44

Tsing Ma Bridge, Hong Kong

Lifti ng of portal beams, formwork and steel t russes

(weight 270 ~ 420 to nnes)

Loire River Bridge, France

Lift ing of 162 m long steel portal (2,400 tonnes) for the main span

Today's civil engineering structures and industrial plants are often assembled from large, heavy prefabricated

components. This may be done for economic or technical reasons, or to save construction time. For projects in

which cranes or other conventional handling equipment cannot be used because of excessive weight,

dimensions or space limitations, VSL Heavy Lifting will often provide the most effective solution.

VSL Heavy Lifting provides builders, engineers and owners with a broad range of advantages, including:• custom-designed solutions for each project;

• the highest level of safety, based upon sound engineering practices and over two decades of experience;

• economy and efficiency through the use of advanced an reliable hydraulic equipment.

Unique SolutionsVSL will plan lifting, lowering or sliding operations and

design the necessary temporary structures to suit your

requirements. Sound engineering, clear thinking, the ability

to innovate, and years of successful experience give you a

guarantee of reliable and cost-effective solutions.

New Airport Passenger Terminal Building Roof sliding, Hong Kong

-

8/11/2019 VSL HK Catalogue

31/44

Pump

Flat Jack

SafetySafety is VSL's first priority. Our specialised

hydraulic lifting equipment is designed for the highest

level of reliability, and all equipment is rigorously

tested and serviced through VSL's quality control

and maintenance programme. VSL field services are

also based upon a total commitment to safety, the

extensive experience of our personnel and VSL's

exceptional record provide further assurance of

reliable performance.

FlexibilityVSL's heavy lifting equipment includes a large

selection of hydraulic jacks, pumps, control units,

monitoring devices and jacking frames. This range of

equipment gives us the capability to perform virtuallyany project requiring lifting, lowering or sliding.

Type

120c

150c

220c

250c

270c

300c

350c

420c

480c

600c

750c870c

920c

*1150c

Outside

diameter D

mm

120

150

220

250

270

300

350

420

480

600

750870

920

1150

Maximum force

at 13.5MPa

kN

85

155

390

525

605

780

1080

1605

2170

3470

54007385

8975

13635

Effective area at

zero extension

10 mm

6.4

11.5

29

39

45

58

80

119

161

257

400547

665

1010

T

Thickness **

mm

25

25

25

25

25

25

25

25

25

25

2525

25

25

E

Maximum travel

mm

25

25

25

25

25

25

25

25

25

25

2525

25

25

Installation

gap

mm

38

38

38

38

38

38

38

38

38

38

4545

45

50

* 1150c Flat Jacks are specially produced to order and require longer lead times

** Flat Jack thickness may vary ±3mm

3 2

Segment Erect ion, Normandy Bridge, France

Flat Jacks

Flat jacks are widely used for a multitude of civil engineering and construction applications such as:

• under pinning;

• prestressing of columns;

• counteracting sinking foundations;• prestressing of road works or airport runways;

• prestressing concrete in confined spaces;

• lifting and lowering of bridge superstructures for bridge bearing adjustments;

• counteracting loads applied during backfilling;

• lifting heavy weights;

• pile testing.

The VSL flat jack is constructed of two moulded steel sections welded together to form a containment vessel.

Hydraulic fluid or grout is injected at pressures of up to 13.5MPa into the peripheral ring, moving the lifting plates

aparts, so that a force is applied with a maximum lifting stroke of 25mm per jack. Other shapes of flat jacks are

available upon request.

Plan

Closed

Fully Inflated

-

8/11/2019 VSL HK Catalogue

32/44

-

8/11/2019 VSL HK Catalogue

33/44

Application

VSL bar systems are ideal for the economic application of post-tensioning forces on relatively short tendons.

Through the use of threaded connections and anchorages they are simple to use and lend themselves to many

applications.

Typical Applications are:

Buildings

• Prestressed Beams and Columns

• Precast Connections

Bridges

• Stay Cable Hangers

• Prestressed Segments

• Strengthening (Timber & Steel Bridges)

• Tension Piles and Caissons

Wharves & Jett ies• Stressed Deck Planks

• Tie Backs

Characterist ic Propert ies

VSL Bar Properties are nominally as listed in the Tables.

Corrosion Protect ion

All bars and fittings must receive protection when installed under permanent conditions. In normal concreteconstruction the use of galvanised duct, injected with grout, provides good protection. Anchorage recesses must

also be filled with cement mortar to protect these ends.

Bars

When bars are used in an exposed environment then one of the following coating systems may be used:

• single coat of inorganic zinc;

• three coat epoxy paint system;

• molybond coated bar ends only;

• greased and sheathed in poly tube;

• galvanising - (Threadlok Bar only).

A combination of the above systems may also be specified. Consideration must also be given to the threaded

ends to ensure correct installation of fittings after coating.

Fittings

Fittings may be treated as above but with preference given to galvanising.

Temporary Bar Anchors

Anchors used in a temporary environment may be used without protection apart from grout cover.

Permanent Bar Anchors

These anchors require installation into corrugated polyethylene sheathing to provide multiple levels of protection.

This is accomplished by the internal grout and sheathing barrier. Additional protection may also be used by

incorporating the above bar coatings.

Anchors

• Permanent and Temporary Ground Anchors

• Uplift Anchors (Dam & Foundation)

• Roof Bolting

• Slope Stabilisation

• Crane Bases

• Light Towers

Specialist Engineering

• Heavy Lifting

• Formwork Ties or Hangers• Frame Ties

• Pile Testing

• Architectural Ties

-

8/11/2019 VSL HK Catalogue

34/44

VSL CT StressbarCharacteristic Properties

Nominal

area

sq. mm177

314

415

531

661

804

1018

1134

1257

2463

4185

Nominal

mass

kg/m1.52

2.39

3.46

4.40

5.44

6.59

7.86

9.23

9.72

20.74

34.68

Nominal tensile

strength

MPa1080

1030

1080

1080

1080

1080

1030

1080

1030

1000

1000

Nominal 0.1%

proof stress

MPa930

835

930

930

930

930

835

930

835

810

810

Nominal

Dia.

mm15

20

23

26

29

32

36

38

40

56

73

Minimum

elongation

%6

6

6

6

6

6

6

6

6

6

6

Appr. Modulus

of elasticity

kN/sq.mm170

170

170

170

170

170

170

170

170

205

205

Major Dia.

of thread

mm17.2

21.2

25.2

28.2

31.2

34.4

37.4

40.4

41.4

58.5

76.5

Thread

pitch

mm6

6

6

6

6

6

6

6

6

6

6

0.1% Proof165

260

385

495

615

750

850

1055

1050

1995

3390

Max. force190

325

450

575

715

870

1050

1225

1295

2460

4190

Note: 1. Relaxation properties, as per AS1313, are 4% maximum at 1000 hrs when loaded to 70% of minimum breaking load.

2. Fatique results exceed two million cycles when loaded over a stress range of 80 N/sq.mm. (For unbonded tendon only).3. Minimum bending diameter = 200 x Bar Dia.

Recommended MinimumBar

Dia.

15, 20

23, 26

29, 32, 3638, 40

56

73

B

125

150

150175

220

320

A

125

150

150175

220

320

C

75

80

100112

250

250

A

100

130

130150

200

300

B

100

130

130150

200

300

C

70

75

90100

200

200

Normal bar

Dia.

15, 20

23, 26, 29

32, 36, 3846

56

73

E

180

270

612

410

Weight

kg

13.5

56

249

295

Capacity

kN

295

996

1980

4570

Jack

model

RH303

ZLP-100/80

ZLP-200

ZPE-460/31

D

121

280

200

485

Stroke

76

80

300

100

Jack Dimension (mm)

Hydraulic Stressing Jack and Accessories

Recess Details (mm) Jack Details

F

390

5601120

750

G

75

150110

250

H

125

150200

300

Jack

model

RH303

ZLP-100/80ZLP-200

ZPE-460 / 31

Jack Clearance Details (mm)

DEL

F

Stroke

Characteristic StrengthkN

S T R E S S B A R

C

200

-

8/11/2019 VSL HK Catalogue

35/44

Permanent VSL Stressbar Anchor Fully Encapsulated

A

Temporary VSL Stressbar Anchor

Spherical nut

Hot-Dip galvanizedprotective cap

Spherical washer

Hot-Dip galvanizedbearing plate withtrumpet

Protective grease

CT Stressbar

Grout

Grout tube outer

Grout tube inner

Protective grease

Nitroseal PX220

Internal spacersat 1500 max. centres

O-ring

External spacersat 1500 max. centres

Corrugated sheathing(Polyethylene)

Grout tube outerGrout tube inner

Bore hole

Corrugated sheathing(Polyethylene)

CT Stressbar

Internal spacers

Section A-A

Grout tube

Grout

CT Stressbar epoxycoated if required

Greased bar over free length

Bearing plate

Spherical washer

Spherical nut

Section B-B

Bore hole

Spacers

Heat shrink

CT Stressbar

A

A

H.D.P.E. smooth or corrugated boresheathing over free length

B

B

Heat shrink& sleeve

H.D.P.E. smooth sheathingover free length

Spacers at 1500 max. centres

Steel nose cone

Grout tube

-

8/11/2019 VSL HK Catalogue

36/44

VSL RETAINED EARTH is a composite soil reinforcing system which employs welded wire mesh to improve the

shear and compressive strength of an earth backfill.

A RETAINED EARTH structure is a stable, unified gravity mass which may be designed for use in a broad variety

of civil engineering applications. In projects ranging from commercial retaining walls to highway bridge

abutments, VSL RETAINED EARTH has found widespread use and acceptance as a major construction system.

The effective principle of RETAINED EARTH involves the transfer of stresses from the soils to the reinforcingmesh through bearing. Bearing pressure is developed on the projected areas of the mesh crossbars, and the

pressure is in turn transferred to the longitudinal bars. The longitudinal bars are thus placed in tension, which

enables the soil mass to withstand loads in the direction of the reinforcement.

In addition to the significant performance

advantages, the VSL RETAINED EARTH

system is also extremely economical to

design and construct. The system consists

of only three components, reinforcing

mesh, precast facing panels and backfill

material. This simplicity allow construction

to proceed easily and rapidly.Cost savings of up to 50% are regularly

realised when compared with traditional

stabilisation systems.

Fast , Easy and EconomicalThe construction of a RETAINED EARTH

structure is extremely straightforward. A

five-man crew using standard construction

equipment will average 75 square metres of

wall per shift, and can place up to 140

square metres per shift.

Perspective View

VSL RETAINED EARTH

Retaining Wall

F5 Freeway, Heathcot e NSW

-

8/11/2019 VSL HK Catalogue

37/44

Complete Capabilities

VSL provides the client with a complete range of design and engineering

services for a RETAINED EARTH structure. VSL employs the most

advanced Computer Aided Design (CAD) systems available.

Services provided include analysis of external stability, internal stability,

bridge load, overturning and base sliding. In addition, VSL furnishes all

preliminary drawings, shop drawings and complete erection sequencing

documents as required.

Complete Flexibilit y

The VSL RETAINED EARTH concrete facing panels are available in a broad

range of textures and colours. Because local materials are used in the

production of these precast panels, the exposed surface can easily be

coloured to complement the natural surroundings. Standard RETAINED

EARTH panel treatments include raised relief, sandblast finish, exposed

aggregate, and conventional smooth face concrete. These are only a very

few of the possibilities however. Non-concrete faces, such as welded mesh

or steel faced are also available and can be used to make temporary

structures.

Temporary wall with welded mesh face

Fractured fi n finish Ashlar f inish

Raised relief finishSteel face finish

-

8/11/2019 VSL HK Catalogue

38/44

VSL Cli mbform an d Table Formwork Systems

THE VSL Climbform System is a self climbing heavy duty construction platform used primarily to lift static panelvertical wall formwork. The system provides the wall designer with complete flexibility in both the structural design

and selection of finishes.

Standard feat ures include:

• custom designed formwork panels which may be ganged in any shape or size to lift as one unit;

• form heights ranging from 2.5 to 4.0 metres;

• unobstructed access to the forms for:

- cleaning and oiling

- fixing of door frames and blockouts

- reinforcement and reinforcing fabric fixing, including prefabricated reinforcement;

• truss members of fixed height assembled in "Meccano like fashion" to form a platform of any plan shape

or size;

• easy levelling and plumbing of the external platform,

which is typically supported on four, six or eight

seatings;

• variation of wall thickness by moving the internal or

external forms;

• parking the internal platforms at mid-lift to facilitate

blockout and reinforcement fixing;

• cycle times as low as three days;

• access to external walls for curing;

• hanging access stairway.

Central Plaza Buil ding, Hong Kong

-

8/11/2019 VSL HK Catalogue

39/44

VSL Formtravellers have been developed in

conjunction with the in-house design of balanced or

free cantilevering bridge structures. The formtraveller

of either overhead truss or underslung type, is ahydraulically driven falsework system with built in

working platforms and formwork panels. VSL services

include design, supply, 1st assembly and

commissioning, or a total turnkey package

incorporating the operation of the system with the

post-tensioning application.

VSL System Formwork services include the design of

the formwork systems, hire of the Climbform and

Slipform Systems, prefabrication of forms and

platforms, supervision and 1st assembly of the

formwork and running of the systems.

Tsing Ma Bridge, Hong Kong

Climbformed piers and Slipformed pylons

Alsons Cement Plant, Philippines

Optional feat ures include:

• support of concrete placing booms on the platform;

• access hatches and/or temporary platforms to

install precast stairs;

• external trailing platforms for:

- patching of the tie-bolt holes

- concrete finishing and curing

- welding of beam stubs/brackets to support

steel floor beams;

• provision to allow manhoists to service the top

working platform;

• provision to locate tower cranes within internal

and corridor platforms;

• collapsible door formers.

The VSL Climform System is recognised as the most

powerful commercial formwork system available in

the world today and has been specified on the

largest and tallest vertical structures in Asia and

Australia.

The VSL Slipform System has been used in the

construction of silos, storage tanks, containment

structures, chimneys, cooling stacks and bridge piers

and pylons for over 20 years. Slipforming is

advantageous when rapid construction between 2

and 6 m per 24 hours is required which results from

continuous working and forms a monolithic structure

free from construction joints. The system is raised by

hydraulic jacks with upper working platforms for

reinforcement fixing and concrete placement and a

suspended scaffolding for finishing works.

Phu Luong Bridge, Vietnam

-

8/11/2019 VSL HK Catalogue

40/44

As a specialist involved in the design and construction of bridges, VSL has considerable experience and expertise

in:

• conceptual, preliminary and final detailed design of bridge structure;

• developing construction methods with full engineering;

• full design and detailing for formwork and erection systems;• on-site construction of selected elements of the structure, from post-tensioning through to entire bridge

superstructures.

The application of this knowledge by VSL assists owners, developers, main contractors and consultants with initial

design concepts, alternative designs and construction methods. The result for the project is that:

• the cost is minimised;

• the methods are simplified;

• the time is reduced;

Some of the very different projects successfully carried by VSL are:

Phu Luong Bridge,

VIETNAM

Balanced Cantilever Construction

VSL Scope of Work:

Design of the four lane main superstructure

consisting of a main span of 102 m and side spans

of 65m.

Design, supply and commissioning of the travelling

formwork system and supply of the post-tensioning,

bearings and movement joints.

Tsing Ma Bridge,

HONG KONGPylons and Approach Pier Construction

VSL Scope of Work:

Construction of two number 206m high concrete

pylons by slipforming including all concreting and

reinforcement fixing. Heavy lifting of steel trusses for

portal beams up to 420 tons. Design, supply and

operation of the 4 VSL Climbforms Systems for the

60m high approach piers.

• the quality is enhanced;

• the safety is improved;

• the value of the structure is increased;

-

8/11/2019 VSL HK Catalogue

41/44

-

8/11/2019 VSL HK Catalogue

42/44

Structural Bearings

Positioned between two structures to accommodate

load transfer and relative movements which may

cause damage. Bearings can be divided into two

types, namely elastomeric and mechanical (disc orpot bearings). VSL services include design, testing,

supply and installation.

Slip Joints