-

Note 1 RAMPS KIT WIRES

End Stop Holder

Electronics Board Connector

Switch

Use these connections

The RAMPS Kit Provided Contains 2 pin, 3 Pin and 4 Pin wires. These should be used as follows to ensure that they will plug into the

board:

2 PIN WIRES: Should only be used with Thermistor circuits (Heat Sensing) plugged into T0 and T1 on the RAMPS board.

3 PIN WIRES: Should be used for end stops, although only two wires will be utilized. The remaining wire can be cut away and used elsewhere

4 PIN WIRES: Should be used for extending the stepper motors.

2 PIN WIRES 3 PIN WIRES 4 PIN WIRES

Wire colors and plug design may be different from that illustrated above

TEFLON/HEAT RESISTANT WIRE: Provided in hot end bag and heat bed bag should be used in proximity of heated beds and extruder nozzle.

RED/BLACK ZIP CORD: Should be used to extend heated bed circuits and hot end heater (away from heat source).

All wires in RAMPS kit can be used to extend stepper motors, thermistor circuits ,Fans and end stops (not heated bed or nozzle heater).

-

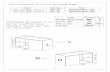

Note 2 Extending Stepper Motor Wires

Electronics Board Connector

Switch

Use these connections

The color of the stepper motor wires can be different depending on the motor provided. However the sequence in which the wires enter the plug is important. This is because they operate in pairs controlling 2 field coils in the motor. That is Red & Green might control one field coil and yellow and blue might control the other. So if the plug order is red/green/yellow/blue then the software will control both field coils correctly. If you switch the polarity of one set, e.g. red/green/blue/yellow the field coils will work against each other causing the motor to malfunction. However if the wires are maintained in the correct sequence and the plug is reversed in the board the only thing that will change is the direction of rotation. This can be adjusted at calibration time in the software or by simply removing the plug from the board, rotating it 180 degrees and plugging it back in.

Method 1 is confusing to some because of the difference in wire colors between the motor provided and the extender wires. If you struggle with this concept, perhaps the easiest way to get it right is to use method 2. That is , take the wires currently on the motor and cut all four midway between the plug and the motor. Then all you need to do is take a piece of the extender wire (or any wire) and attach it to the red lead on the motor. Then take the other end of the extender wire and attach it to the red lead on the plug that you just cut off. The color of the extender wire does not matter as long as red on the motor is connected to red on the old plug. Repeat the same for the other three wires, i.e. green to green, yellow to yellow, blue to blue etc.

Method 1 Cut motor plug and attach extender directly (Easiest method but prone to error!)

Plug Wire sequence = RED,GREEN,YELLOW,BLUE

Plug

Extender Wire from RAMPS kit

Original wire sequence of RED,GREEN,YELLOW,BLUE is maintained and only one set of joins is required.

Method 2 Just extend the individual wires

Plug Wire sequence = RED,GREEN,YELLOW,BLUE

Plug Original wire sequence of RED,GREEN,YELLOW,BLUE is maintained but two sets of joins are required.

Extender Wire from RAMPS kit (ignore color)

-

End Stops & Wiring

End Stop Holder

Electronics Board Connector

Switch

Use these connections

1. Solder or otherwise connect the end stop wires to the

two tabs closest to the fulcrum of the switch (See photo).

These two contacts are designed to have the switch open

in the normal position. When the limit switch is activated

the switch will close and a current can flow.

2. Connect the switch to the end stop holder using two

2.5mm x 20 mm bolts. The X and Z axis can be attached

as pictured above. For the Y axis the switch should be

inverted to provide a better connection with the print

bed frame.

-

End Stops & Wiring

Switch

Use these connections

Attach Ohm meter across both wires. Resistance reading

should be infinity.

Meter Check

Manually close the switch. Resistance reading should drop to

almost zero.

If the above tests do not check out correctly then ensure that the wires are soldered to the correct pins on the switch.

-

End Stops & Wiring

X AXIS

Z AXIS Y AXIS

FRONT

BACK

3. Bolt on the end stops in the positions shown. Positions of the stops will be adjusted later.

-

Now the Wiring

Reversing +/- polarity or otherwise incorrectly connecting power can destroy your electronics and cause fire hazard. Incorrectly inserting stepper drivers will destroy your electronics and cause a fire risk. Always make sure power and USB is disconnected when removing or adjusting stepper drivers. Always make sure to insert drivers in correct orientation and in the socket correctly.

-

Note: Kit electronics are provided in a pre-assembled kit . The

following few pages dealing with assembly of the board have

been left for reference. The kit contains ready made leads for

stepper motors (4 Pin), end stops (3 Pin) and Thermistor

connections (2 Pin)

The color code of stepper motor coil connections tends to

change between suppliers and does not always agree with

the convention of the electronics kit. When connecting 4

pin wires from the electronics kit to the stepper motors the

same order of wires on the motor plug should be repeated

on the kit extender wire. Color has no significance.

-

RAMPS 1.4 ( Reprap Arduino Mega Pololu Shield)

Arduino Mega Micro Controller Board

Stepper Motor Driver (Extruder)

Stepper Motor Drivers (X,Y & Z)

Pololu Shield

Kit Comes Pre-assembled. This is for information only. You do not need to separate the Arduino from the shield board.

-

4. Place the Pololu Shield on top of the Mega and firmly but carefully press into

place. Ensure that all pins are located in their slots before applying pressure.

-

Extruder Stepper motor driver (see picture on next page)

Install Extruder Stepper motor driver

-

Variable Potentiometer

Or Pot

POWER END OF BOARD

5. Insert one of the stepper motor drivers. Note the Pot is oriented to the right

away from the power end of the board. THIS IS IMPORTANT.

Install Extruder Stepper motor driver

Pot

-

X, Y & Z Stepper motor drivers

Install X, Y & Z Stepper motor drivers

X Y Z

-

Variable Potentiometer

Or Pot

POWER END OF BOARD

5. Insert the X, Y and Z stepper motor drivers. Note the Pot is oriented to the right

away from the power end of the board. THIS IS IMPORTANT.

Pot

Install X, Y & Z Stepper motor drivers

-

6. Place the RAMPS board on the tray in preparation for

running wires. Do not bolt down yet as it is easier to run wires

if the board can be moved.

-

7. Wire Extruder and Hot End

Extruder Stepper Motor

Hot end Heater Note: Heater is a 6.8 ohm

resistor which is not

sensitive to polarity.

Hot End Thermistor To T0 on board

Note: Thermistor is a

resistance and not

sensitive to polarity

See meter check on next page

-

7.0 Wire Extruder and Hot End (Meter Check)

Hot end Heater Hot End Thermistor To T0 on board

Resistance Should be minimum

6.5 Ohm

Resistance Should be between 50 and 150 K Ohm

(100k at 25 degrees Celsius)

-

8.0 Wire Heated Bed

Bed Heater to D8 on Board

Bed Thermistor to T1 on board

Note: Thermistor is a

resistance and not

sensitive to polarity

Resistance Should be minimum

1.25 Ohm

Resistance Should be between 50 and 150 K Ohm

(100k at 25 degrees Celcius)

Note: Bed heater is a

resistance and not

sensitive to polarity

-

IMPORTANT NOTE FOR PRUSA 12 x 12 XL

The 12 X 12 XL comes with two power packs and two bed heaters. Only one bed heater should be wired to the D8 output on the board. The other bed heater should be wired directly to the second power supply and is used as a temperature booster. It should be permanently on when high temperatures are needed and the heater wired through D8 will thermostatically control the temperature. WIRING BOTH BED HEATERS THROUGH D8 WILL OVERLOAD AND DAMAGE

THE BOARD

-

9. Wire X & Y Axis

X Axis Stepper Motor

Y Axis Stepper Motor

-

10. Wire Z Axis Stepper Motors

Z Axis Stepper Motors Wired in Parallel

-

11. X,Y and Z Endstops

X,Y and Z end stops

X Y Z End stops are simple switches

And not sensitive to polarity Connect to S and Minus

Pins on board

All end stop wire pairs should be

infinite resistance

-

12. Power Supply Warning

DANGER !

YOU ARE ABOUT TO ASSEMBLE CONNECTIONS WHICH CARRY A LETHAL VOLTAGE OF ELECTRICITY. IF YOU DO NOT HAVE SUITABLE TRAINING YOU SHOULD SEEK THE ASSISTANCE OF A QUALIFIED ELECTRICIAN. - NEVER OPERATE THIS EQUIPMENT UNNATENDED - ALWAYS HAVE A SUITABLE FIRE EXTINGUISHER TO HAND - PLACE SMOKE DETECTOR IN PROXIMITY TO WORKING EQUIPMENT - NEVER LET CHILDREN OPERATE WITHOUT ADEQUATE SUPERVISION - NEVER OPERATE WITHOUT GROUNDING EQUIPMENT.

-

Power Supply

13. Set the power supply switch to the appropriate voltage for your country. For example the United States is 115 V . If you do not know what the

mains voltage is for your country then return to step 12.

14. Obtain the appropriate electrical plug for your country together with 2 to 3 m of 3 strand wire. That is wire which has a Live, Neutral and Ground

capability. Use a three pin plug with a ground (earth) connection. THIS IS IMPORTANT BECAUSE THE POWER SUPPLY CASE IS METAL AND A

COMPONENT FAILURE MAY MAKE THE CASE LIVE AND DEADLY WITHOUT A GROUND CONNECTION.

3 Pin Good YES

2 Pin BAD NO

-

Power Supply

L N E AC Mains Voltage

DC 12 Volts (Positive )

DC 12 Volts (Negative )

15. Connect wires securely to the tabs as indicated above. Never operate without the earth (ground) wire connected.

-

Power Supply Safety Cover

15. Before plugging in to the mains power make sure the cover is located in the down position. The power unit should be placed in a position

that is not accessible to children, household pets or persons not knowledgeable in its operation. When not in use the unit should be

unplugged from the mains power.

Safety cover up

Safety cover down

-

Establish a Strict Color Protocol for Wires !

Direct Current (DC) Positive (+) = RED WIRE

(+)

(-)

Direct Current (DC) Negative (+) = BLACK WIRE

-

Power Supply to Board

DC 12v +

DC 12v +

DC 12v -

DC 12v -

-

Temporary Fan Mount

Fan

16. The fan is necessary to cool the stepper motor drivers and

can be fixed to the temporary fan mount using a small drop of

super glue or Kapton Tape.

17. The new fan mount can be printed after software

installation and calibration . The permanent mount is not

essential but can be helpful to tidy up the wires.

-

Amendment: Special Note on Fan Placement

DC 12v +

DC 12v +

DC 12v -

DC 12v -

Extruder

X Driver Y Driver

Most of the heat is generated by the X,Y and Extruder stepper motor drivers. The fan should be located as close as possible to these three components

if you are operating the printer in a hot environment. All fans should be powered directly from the DC power supply and not the board. This is because

fans should run all the time even when stepper motors are energized but stationary. The software control of fans through the board is normally used

for a nozzle mounted cooling fan with the purpose of cooling prints between layers.

-

Reference

SD Ramps Card: Permits printing without computer attached:

http://www.reprap.org/wiki/Sdramps

These 2 pins hang off The end of the board

-

Reference

SD Ramps Card: Permits printing without computer attached:

http://www.reprap.org/wiki/Sdramps

http://reprap.org/wiki/RAMPS_1.4

Ramps Board :