-

8/21/2019 Send Tqm Mcq

1/48

Total Quality Management

Questions

Besterfield, Quality Control

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

-

8/21/2019 Send Tqm Mcq

2/48

Part I: multiply choice question

1. What does the transcendent view imply for highquality?It is something everlastingIt is something timeless and enduringIt is something pricelessIt is something perfect

2. Help to evaluate the level of product quality thata customer want or need means :Mareting

!esign engineering"rocurement"rocess design

#. Which of the following is not a tenet of $ros%y? $onformance to requirements. &ero defects. 'itness for use. (uality is free. )ll of the a%ove

*. Which of the following is not one of thecommitments of +otal (uality management?

+echnical quality understanding and improving the organi,ation-s

rocesses data%ased decision maing

employee involvement

/. !uring which century0 the manufacturers %eganto include quality processes in quality practices?1th century1th century13th century20th century

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2

-

8/21/2019 Send Tqm Mcq

3/48

4. Which of the following is not part of the +otal(uality )pproach?

holistic thining

focus on shortterm 5nancial performance focus on desira%ility team thining6

. +aguchi suggested that loss in a process isincreased with increase in which of the following?7peci5cations7tandards$ompetitionVariability

. +he products manufactured during 188s wereunique. Howquality was ensured in this era?

+hrough renovationThrough inspection +hrough calculation +hrough repair

3. Which of the following is typically viewed to lie%etween fully vertically integrated 5rms?

Supply chain management"roduction chain management

9alue chain management!emand chain management

18. Which of the following is not a %ene5t oflongterm suppler relationships?

supplier involvement in designinformation system linages to customer facilitiescapacity and facility plans favora%le to their

customers

all of the above are benets

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

-

8/21/2019 Send Tqm Mcq

4/48

11. +he maority of advertisers appeal the pu%licon the%asis of which of the following?

Quality of product(uality of sta; Inferiority of productInferiority of service

12. Which of the following models valuesta%ility?

randson and grandfather

1*. Which of the following was developed %yMotorola to improve its processes %y minimi,ingdefects?

I7< 3888

Six sigma(7 3888 +(M

1/. What was the primary concern of managersduring 138s?

!etectionStrategic impact$ontrol

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!

-

8/21/2019 Send Tqm Mcq

5/48

$oordination

14. ou can as direct questions to quiet peopleand try to control talative people@0 for which of

the following purpose?

Mobiliing the groupAeeping the group focusedBestating purpose7tarting punctually

1. 7ome organi,ations emphasi,es the use ofquality tools %ut failed to do which of the

following?

'ocus on what is truly important to thedistri%utorsIncorporate continuous improvement e!ortsMae fundamental changes in their processes andculture'ocus on what is truly important to the customer

1. Cearn how to tell when nothing can %egained from further discussion. +his refers towhich of the following discussion sills inmeetings?

)cting as gateeepers$losing the discussion

)sing for clari5cation +esting for consensus

13. Which of the following models has theviewpoint that change and learning are valued inthemselves?

-

8/21/2019 Send Tqm Mcq

6/48

"ultural model +otal (uality model

28. Mareting research carried out to nowwhether the particular area should %e covered inthis course. What the course instructor shoulddevelop?

The course meeting re#uirements of theuniversity +he course meeting requirements of theinstructor

+he course meeting requirements of the students +he course meeting requirements of the%ooseller

21. Which of the following statements is +BDEa%out !emingFs philosophy?

It is %ased on improving products and services %yreducing uncertainty and varia%ility in the designand manufacturing processesQuality is either or not present in the $holeorganiation% that #uality is theresponsibility of everyone in theorganiationIncreasing conformance to speci5cations throughelimination of defects0 supported eGtensively %y

statistical tools for analysisIncreasing loss0 for the producer0 the customer0and society0 associated with increasing varia%ilityfrom a target value

22. )ll of the following are the elements of a +(M system E$E"+:

Ceadership$ommunications

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

#

-

8/21/2019 Send Tqm Mcq

7/48

Measurement&etentions

2#. +he standards for output %ased on quality

and customer service requirements that originateat the organi,ational and process levels includerequirements for all of the following E$E"+:)ccuracyInnovation +imelinessTurnover

2*.

-

8/21/2019 Send Tqm Mcq

8/48

'ailure costs(ll of the given options

2. the o% characteristic of quality professionals

is:Educating others)chieving personal targets$onsultative wor with other departments)one of the above

23. Why the factory managers createdinspection departments?

To 'eep defective products aside* ensuringthey do not reach the customers +o ensure quantity of goodsJservices +o count0 grade0 and rewor)ll of the a%ove

#8. +he K'atherF of statistical quality control is:

'. W. +aylor Loseph M. Luran"hilip $ros%y+alter She$hart

#1. =onconformance is an eGpense of:

"ro5t of quality!efects of quality

(uality of product"ost of #uality

#2. $ros%yFs approach to management is:

) pro%lem that can never %e solved(bsolutes of Quality ManagementInterim ManagementI7<

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

$

-

8/21/2019 Send Tqm Mcq

9/48

##. EGample of prevention costs is:

Quality improvement pro,ects!owngrading

+o lin outcomes to usesWarranty claims

#*. ig ( is:(uality of services(uality of people(uality of processes(ll of the above

#/. Which of the following documentNsO is NareOincluded in the quality system?

( #uality policy $ustomer focus $ommitment)ll of the given options

#4. is a graphic tool for de5ning therelationship %etween customer desires and the5rmJproduct capa%ilities.

-ouse of Quality)Pnity diagram)rrow diagram=one of the give option

#. )onconformance is an expense of "ro5t of quality !efects of quality (uality of product "ost of #uality

#. "rosby.s approach to management is

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

%

-

8/21/2019 Send Tqm Mcq

10/48

) pro%lem that can never %e solved (bsolutes of Quality Management Interim Management I7<

#3. /est price or ero cost is

+o eep defective products aside0 ensuring theydo not reach the customersrerogative cost +o count0 grade0 and rewor$ost leadership

*8. +he process of evaluating overall proectperformance on a regular %asis to provide con5dencethat the proect will satisfy the relevant qualitystandards is called:

1. Quality (ssurance2. (uality $ontrol

#. (uality "lanning*. (uality Beview

*1. +he process of monitoring speci5c proect resultsto determine if they comply with relevant qualitystandards is called:). (uality )ssurance. Quality "ontrol

$. (uality "lanning!. (uality Beview

*2. ) histogram ordered %y frequency of occurrencethat shows how many results were generated %y eachidenti5ed cause is:). 7tatistical Histogram. 1uran -istogram$. 'ish%one !iagram

!. "areto !iagram

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

&'

-

8/21/2019 Send Tqm Mcq

11/48

*. +ools and techniques used during the (uality"lanning process include:). ene5t J cost analysis

. enchmaring$. (uality audits!. a and bE. all of the a%ove

*#. +he overall intentions and direction of anorgani,ation with regard to quality as formallyeGpressed %y top management is a:

). (uality "lan. (uality 7tatement$. Quality olicy!. +(M

**. $I" is:). $ontinuous improvement process. ) sustained0 gradual change$. Includes constancy of purpose and commitment to

quality as part of its focus!. a and %E. all of the above

*/. +he practice of ceasing mass inspections andending awards %ased on price is credited to:). d$ard &eming. "hilip $ros%y

$. Luran!. "areto

*4 (uality is:). &ero defects found. $onformance to requirements$. +he totality of features and characteristics of aproduct or service that %ear on its a%ility to satisfystated or implied needs

!. b and c

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

&&

-

8/21/2019 Send Tqm Mcq

12/48

E. all the a%ove

*4. +he concept of maing a giant leap forwardfollowed %y a period of maturity is:

). Innovation. $ontinuous improvement$. Lust in time!. "aradigm

*. +he concept that it is easier and less costly to dothe wor right the 5rst time is called:). &ero defects

. $ontinuous improvement$. &T3T3T4T!. +he customer is the neGt person in the process

*. +he a%ility of a product to %e used for di;erentpurposes at di;erent capacities and under di;erentconditions determines its:). Dsa%ility. 4lexibility

$.

-

8/21/2019 Send Tqm Mcq

13/48

!. a and %E. all of the above

/1. What percentage of sales is estimated to %e the

cost of nonquality?). #/Q. 526207$. #8*8Q!. 4Q

/2. ) series of consecutive points on the same side ofthe average is called:

). 3un. +rend$.

-

8/21/2019 Send Tqm Mcq

14/48

//. ) structured tool0 usually industry or activityspeci5c0 used to verify that a set of required steps has%een performed is called:). (uality "olicy

. "hec' list$. +rend analysis!. "areto diagram

/4. ) tool that analy,es the Input to a process toidentify the causes of errors is called:). $ause and e;ect diagram. 7catter diagram

$. Ishiawa diagram!. "areto diagramE. a and c

/. +he concept of ,ero inventory is called:). 7iG sigma. $ontinuous improvement$. 1ust in Time!. &ero defects

/. )ll of the following statements a%out acceptancesampling plans are true eGcept:). )cceptance sampling plans are %ene5cial when thecost of inspections is high and the resulting loss ofpassing nonconforming units is not great. )cceptance sampling plans are necessary whendestructive inspections are required

$. (cceptance sampling plans are never ase!ective at re,ecting non6conforming units as500 percent inspection* even $hen theinspection process is very tedious!. )cceptance sampling plans do not directly controlthe quality of a series of lotsR they instead specify theris of accepting lots of given qualityE. )cceptance sampling plans are not very e;ectivefor inspecting small lots of custommade products

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

&!

-

8/21/2019 Send Tqm Mcq

15/48

/3. ) quality control N($O manager for amanufacturing 5rm is calculating the eGpectedstandard deviation NsO for the length of heG %olts %eingproduced on the assem%ly line. +here are two sources

of variation in the length of the heG %olts: productionvariation and easurement error. +he ($ managernows that the standard deviations from these twosources is 8.2* inch and 8.*# inch0 respectively.)ssuming that there are no other signi5cant sources of error0 what answer should the ($ manager calculatefor the total standard deviation of the length of theheG %olts?

). 8.18 inch. 8.13 inch$. 8.#* inch!. 8.*3 inchE. 8.4 inch

48. +he rule of seven is used %y quality controlengineers to determine whether a process is out ofcontrol. If a run of seven or more samples lays on one

side of the process mean0 the process issaid to %e out of control. What is the pro%a%ility that arun of seven on either side of the "rocess mean is dueto random variation?). 1*.#Q. #.12Q$. 2.#Q!. 1./4Q

E. 8.Q

41. $ontrol chart theory is %ased on the di;erences ofthe causes of variations in quality. 9ariations in qualitymay %e produced %y assigna%le causes. )ll of thefollowing are eGamples of assigna%le causes eGcept:). !i;erences among machines. !i;erences among worers$. !i;erences among materials

!. !i;erences in each of these factors over time

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

&"

-

8/21/2019 Send Tqm Mcq

16/48

E. )one of the above 8all are examples9

42. +he same quality control manager decides toincrease his daily sample si,e from three to siG. +he

si,e of the control %and will:). Increase. &ecrease$. Bemain unchanged!. =ot determina%le from given dataE. =one of the a%ove

4#. )ll of the following statements a%out control charts

are true eGcept:). $ontrol charts can %e used to esta%lish as well asmaintain process control. $ontrol charts are used to determine acceptancelimits when no limits are stipulated %y the productspeci5cationR otherwise0 one should use the limitsdictated %y the speci5cation$. )ll data points outside the control chart limits arevariations eGplained %y

!. ) and E. / and "

4*. Lapanese quality control has improved dramaticallyin the last #8 years for all of the following reasonseGcept:

). +he use of quality control circles

. 7mall0 continuous improvements in quality control$. +he use of worer suggestion systems!. +he use of quality control chartsE. 4ocusing #uality control e!orts on productionoutput

4/. (uality management deals with all of the followingtopics eGcept:). $onformance to requirements J speci5cations

. 7atisfying the needs of the customer

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

-

8/21/2019 Send Tqm Mcq

17/48

$. Ma'ing products more desirable and luxurious!. ) and $E. and $

44. Which of the following statements a%out the costof quality are true?). The cost of #uality is the expense of non6conformance to re#uirements and specications. +he costs of quality are mostly the directresponsi%ility of worers who are manufacturing theproduct$. (uality control programs should only %e

implemented when the costs of quality is low!. ) and E. ) and $

4. +he ,ero defects concept). is a performance standard for management. is a motivational technique that promotes @doing itright the 5rst time@$. is used %y management to communicate to all

employees that everyone should do things right the5rst time!. ( and "E. and $

4. (uality assurance). refers to the prevention of product defects: is an auditing function that provides feedbac'

to the pro,ect team and client about the #ualityof output being produced$. is the technical process that includes theconstruction of control charts which specifyaccepta%ility limits for conforming output!. ) and E. and $

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

&7

-

8/21/2019 Send Tqm Mcq

18/48

43. 'inancial compensation is the primary motivationaltool for which of the following management theories orprograms?). &ero !efects program

. Theory ; management$. +heory management!. (uality $ontrol $irclesE. ) and $

8. In the proect environment0 the individualultimately responsi%le for quality control is:

). +he line worers who must strive @to do things rightthe 5rst time@ to avoid quality pro%lems. +he company-s quality control manager who mustwor with the proect mem%ers to ensure the qualitycontrol program is e;ective$. +he head of the production department who retainsultimate quality control responsi%ility for all thecompany-s proects!. The pro,ect manager $ho has ultimately

responsibility for the entire pro,ect E. +he customer who must ensure that he is receivinga quality product from the vendor

1. )n acceptance control chart has limits that are%ased on the speci5cation limits for the product ratherthan limits which di;erentiate %etween random andassigna%le causes. Dnder

which if the following circumstance should a ($manager consider using an acceptance control chart?

). When the engineering tolerance on a dimensiongreatly eGceeds the natural dispersion of themanufacturing process. When the num%er of samples outside the currentcontrol chart limits %ecome too costly andcum%ersome to investigate

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

&$

-

8/21/2019 Send Tqm Mcq

19/48

$. When a process is su%ect to constant %ut sta%letool wear!. ) and E. ( and "

2. +he maority of product defects could %eprevented in most processes if manufacturers woulddo the following:). Increase the use of acceptance control chartsinstead of standard threesigma control charts. Ma'e a concerted e!ort to eliminate thepotential for product defects in the design stage

$. $reate a quality control department!. ) and E. ) and $

#. (uality attri%utes). are used to determine how e;ectively theorgani,ation accomplishes its goals. can %e o%ective or su%ective in nature$. are speci5c quality characteristics for which a

product is designed0 %uilt0 and tested!. ) and E. / and "

*. Most quality pro%lems). originate in the quality department where theultimate responsi%ility for quality rests. originate on the shop Soor %ecause of waste and

product rewor$. are the result of management

-

8/21/2019 Send Tqm Mcq

20/48

concerning a particular service or manufacturingprocess should %e corrected. Which of the followingstatements %est represents the philosophy employed%y this principle?

). In order to minimi,e 5nancial losses from qualitycontrol pro%lems0 all pro%lems which have ameasura%le cost associated with them should %ecorrected. The ma,ority of defects are caused by a smallpercentage of the identiable problems:Improvement e!orts should be reserved for

those fe$ vital problems$. In order to achieve ,ero defects0 all quality controlpro%lems0 including those which do not have a direct5nancial cost should %e corrected!. >enerally0 8Q of the quality control pro%lems are usti5a%le for correction via cost%ene5t analysis. +heremaining 28Q are not 5nancially worthy ofimprovement e;ortsE. ) and !

4. +he Lapanese (uality $ontrol N($O $irclemovement motivated its participants in many ways.Which of the following represents the most importantmotivation for the ($ circle participant:). Improving the performance of the company. 7elfImprovement$. 'inancial Incentives

!. Becognition among coworersE. 7trengthening of relationships %etween coworers

. In order to achieve longterm qualityimprovements0 management must do the following:). Motivate the employees with seminars0 contests0and institution of programs such as @(ualityImprovement@ day

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2'

-

8/21/2019 Send Tqm Mcq

21/48

. $reate a quality control department and give thehead of the department ultimate responsi%ility forquality improvement$. Implement a formal #uality control program

$ith $or'er and management involvement!. Esta%lish 5nancial incentive pacages for worersE. ) and !

. (uality assurance is). top management-s intention regarding quality. functions determining implementation of the qualitypolicy

$. actions to provide condence of satisfying#uality re#uirements!. responsi%ilities and processes which implementquality managementE. all of the a%ove

3. (uality is). ,ero defects. a pro%lem

$. a specication!. a costE. )0 $0 and !

8. Which are the %est two charts to show trends in aprocess?). "areto and $ontrol. "ontrol and 3un

$. Histogram and Bun!. >antt and "ertE. >antt and $"M

1. If the acceptance sampling attri%ute for a lot is#8Q0 this means that). #8Q of all lots must %e tested. #8Q of all lots must pass the test$. any given lot must have #8Q or fewer defects

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2&

-

8/21/2019 Send Tqm Mcq

22/48

!. a sample of a given lot must have =07 orfe$er defects to pass the entire lotE. $ and !

2. +he pillars of quality is NareO). (uality is free. !oing it right the 5rst time$. &ero defects!. "rocess improvementE. / and "

#. When a product or service completely meets a

customer-s requirements:). #uality is achieved. cost of quality is high$. cost of quality is low!. the customer pays the minimum priceE. ) and

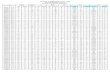

*. Dsing "areto-s Bule0 and given the data in thefollowing ta%le0 where should corrective action focus?

>rigin of roblem 7 of roblems!esign 8Q!evelopment 2Q"rototype 3Q +esting 4Q'a%rication #Q). &esign. !esign0 development0 and prototype

$. !esign and prototype!. !evelopment0 prototype0 and fa%ricationE. =one of the a%ove

/. $ost of quality is a concept that includes:). the cost necessary for ensuring conformanceto re#uirements. the life cycle cost of the proect$. al research and development costs related to the

proect

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

22

-

8/21/2019 Send Tqm Mcq

23/48

!. only the cost of the quality control functionE. ) and

4. +he process of determining that technical

processes and procedures are %eing performed inconformance with scope requirements and qualityplans is called quality:). management. assurance$. process review!. controlE. checs

. (uality control is:). identifying which quality standards are relevant tothe proect and determining how to satisfy them: monitoring specic pro,ect results todetermine if they comply $ith relevant #ualitystandards and identifying $ays to eliminatecauses of unsatisfactory performance$. evaluating overall proect performance on a regular

%asis to provide con5dence that the proect will satisfythe relevant quality standards!. taing action to increase the e;ectiveness andePciency of the proect so as to provide added%ene5ts to %oth the performing organi,ation and theproect customerE. assuming the production of goods that meet thehighest standards of luGury

. (uality planning is:). identifying $hich #uality standards arerelevant to the pro,ect and determining ho$ tosatisfy them. monitoring speci5c proect results to determine ifthey comply with relevant quality standards andidentifying ways to eliminate causes of unsatisfactoryperformance

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2

-

8/21/2019 Send Tqm Mcq

24/48

$. evaluating overall proect performance on a regular%asis to provide con5dence that the proect will satisfythe relevant quality standards!. taing action to increase the e;ectiveness and

ePciency of the proect so as to provide added%ene5ts to %oth the performing organi,ation and theproect customerE. assuring the production of goods that meet thehighest standards of luGury

3. (uality management includes forming anddirecting a team of people to achieve a qualitative

goal within an e;ective cost and time frame thatresults in:). a proect completed in the shortest possi%le time. a product or service that conforms to there#uirement specication$. an awardwinning product that %rings pu%licrecognition to the proect!. an innovative proect that esta%lishes thequali5cations of the proect team

E. and $

38. )ccording to current quality management thining0which of the following approaches to qualityimprovement is least liely to produce positive results?). increased inspection. continuous improvement$. quality circles

!. statistical quality controlE. use of worer suggestion systems

31. +he concept that states: @the optimal quality levelis reached at the point where the incremental revenuefrom product improvement equals the incrementalcost to secure it@ comes from:). quality control analysis: marginal analysis

$. standard quality analysis

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2!

-

8/21/2019 Send Tqm Mcq

25/48

!. conformance analysisE. systems analysis

32. Which of the following %est characteri,es the

results of an increase in quality?): increased productivity* increased cost6e!ectiveness* and decreased cost ris' . reduced productivity and no change to coste;ectiveness or cost ris$. reduced productivity and an increase in overallproduct or service cost!. increased productivity and coste;ectiveness

E. increased productivity0 decreased coste;ectivenessand increased cost ris

3#. Which of the following statements regardingquality is false?). (uality improvements depends upon %etterde5nition and increased awareness of therequirements speci5cations. 4uture gains in #uality $ill often rely on

advanced technology$. Becognition of ey actions required of each teammem%er is necessary to meet quality o%ectives!. $omputeraided design systems can improvequality0 %ut only a the eGpense of an increase in thecost of designE. ) and $

3*. ou are sampling items from a %atch and plottingthe results on a control chart. how will an increase inthe num%er of items sample a;ect the value of thestandard deviation used to set the control limit?). increase it. decrease it$. no e;ect on it!. 5rst increase it0 then decrease itE. 5rst decrease it0 then increase it

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2"

-

8/21/2019 Send Tqm Mcq

26/48

3/. If the level of con5dence directly increases as aresult of new processes0 di;erent resources0 orchanged methods0 the required cost of monitoring isliely to:

). increase as well. remain the same$. decrease!. decrease initially then increase slightlyE. increase then tend to level o;

34. +he primary driverNsO %ehind the demand forcontinual qualify improvement is J are:

). an increase in the num%er of proects %eing wored. the government cost improvement reports thathave created widespread pu%lic interest in quality$. the prevalence of media reports on quality circlesand other quality improvement techniques!. the need to %oth reduce costs and ensureconsistency in the performance of products andservicesE. / and &

3. +he concept of quality is %ased on:). meeting luGury goods standards. producing eGcellent products that are superior toother similar items$. conforming to the re#uirements specications!. maintaining uniformity of designE. ) and $

3. )n assigna%le variance tells us:). our equipment is %ecoming o%solete. top management should initiate increased worertraining$: there is an identiable problem that must bexed!. schedule variances will %e reducedE. our use of quality circles is inadequate

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2#

-

8/21/2019 Send Tqm Mcq

27/48

33. 'rom a high level perspective0 quality:). is ensured %y having inspectors. cannot %e quantitatively measured$. and productivity are inconsistent o%ectives

!: is primarily 8?@ 6 A@79 a managementproblemE. pro%lems are usually caused %y unmotivatedemployees

188 Which is not a commonly used qualitymanagement tool?). 'ish%one diagram

. $77B report$. "areto chart!. $ontrol chartE: )one of the above Nall are commonly usedO

181 (uality is often inSuenced %y all of the followingeGcept:). fa%rication processes and methods. supervision

$. inspection!. cost of materialsE. design

182 +he of a product or service mostlya;ects its relia%ility and maintenancecharacteristics.). design

. concept$. fa%rication!. performanceE. cost

18# Bandom variance in a process0 as measured %ythe standard deviation0 can %e directly reduced %y:). improving the overall system of production. increasing the num%er of quality inspectors

$. maing use of run charts

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

27

-

8/21/2019 Send Tqm Mcq

28/48

!. maing %etter use of "areto chartsE. identifying patterns of variance using controlcharts

18* ) proect manager notices that all themeasurements recorded on a control chart lie withinthe control %and range. However0 most of themeasurements are %elow the midpoint NnegativevarianceO. (uality management practice o;ers uswhat guidance in dealing with this situation?). The pro,ect manager should apply the Brule of sevenB

. +here is no pro%lem as long as the variances liewithin the control %and$. =egative variance indicates a pro%lem which should%e remedied!. +hese variances are most liely caused %y randomfactorsE. Increased worer ownership should %e encouraged

18* +he proect management team-s for quality

should:). extend beyond the completion of the pro,ect. stop at the point of delivery$. %e signi5cantly reduced %y a good warranty!. %e ignored %y the proect managerE. ) and $

18/

-

8/21/2019 Send Tqm Mcq

29/48

defects liely to %e most useful?). When destructive testing is required. When the cost of 188Q inspection is high$. When we %elieve there are not many defects

!. )0 0 and $E. ( and /

18 ) fundamental tenet of modern qualitymanagement holds that quality is most liely to %eachieved:). by planning it into the pro,ect. %y developing careful mechanisms to inspect for

quality$. %y developing prestigious products and processes!. %y striving to do the %est o% possi%leE. %y conducting quality circle activities

18. "oor quality in a design proect is liely to directlya;ect costs.). manufacturing J %uilding. advertising

$. overhead!. postcompletion supportE. ( and &

183 'rom the proect perspective0 quality attri%utes:). are used to determine how e;ectively theperforming organi,ation supports the proect. can %e o%ective or su%ective in nature

$. are speci5c characteristics for which a product isdesigned0 %uilt0 and tested!. / and "E. ) and 118 'rom the proect manager-s viewpoint0 qualityassurance involves:). conducting studies to determine if design methodswill support quality requirements. identifying applica%le laws0 ordinances and

regulations that the proect must comply with

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2%

-

8/21/2019 Send Tqm Mcq

30/48

$. monitoring inspection activities to ensure that thewor is performed as speci5ed!. )0 0 and $E. ( and "

111 Lustintime NLI+O is the concept of reducinginventories to:). 2/Q of former stoc. Cess than half of former stoc$. /Q of pea stoc!. ero stoc' E. 1/Q of the cost of the product for a planned stoc

112

-

8/21/2019 Send Tqm Mcq

31/48

$. histograms!. areto chartE. run chart

11/ 'rom the proect manager-s perspective0 qualitymanagement is limited to assessing theattri%utes of the tools provided to do the wor.). always. usually$. not!. seldomE. intermittently

114 +he primary responsi%ility for esta%lishing designand test speci5cations should rest with). senior management. procurement or purchasing$. engineering!. manufacturingE. quality control

11 Which of the following is least liely to contri%uteto developing an e;ective proect team supportive ofquality?). $ommitment to the proect. +eam mem%er SeGi%ility$. 4re#uent turnover of personnel!. +eam interest in wormanshipE. $learly de5ned goals

11 "rimary responsi%ility for quality management inthe proect rests with the:). proect engineer. purchasing agent$. quality manager!. pro,ect managerE. company president

113 +he I7< 3888 series is:

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

&

-

8/21/2019 Send Tqm Mcq

32/48

). a set of instructions for preparing control charts. a set of guidelines for quality$. a set of forms and procedures to ensure quality!. an international standard that describes a

recommended #uality systemE. intended to %e applied only to manufacturedproducts

128 Dnless evidence indicates otherwise0 a process isassured to %e:). in control. out of control

$. woring at full capacity!. woring at less than full capacityE. operating within required engineering tolerances

121 Which of the following statements %estcharacteri,es the quality management practice called%enchmaring?). +he I7< term for progress measurement. "omparing planned pro,ect practices to those

of other pro,ects$. ) technique used to test certain types of electronicequipment!. +he di;erence %etween grade and qualityE. +he measurement of customer satisfaction

122 (uality management is de5ned as the process ofensuring that a proect meets the of the

proect-s clients0 participants0 and shareholders.). speci5cations and statements of wor. legal and 5nancial o%ligations$. eGpectations and desires!. needs and expectationsE. legal and moral requirements

12# +he primary components of quality managementare quality .

). inspections0 certi5cations0 and validations

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

2

-

8/21/2019 Send Tqm Mcq

33/48

. philosophy* assurance* and control$. form0 5t0 and function!. relia%ility0 maintaina%ility0 and availa%ilityE. insurance0 assurance0 and warranty

12* (uality assurance is de5ned as the managerialprocess that determines that provide thecustomers with performance standards and feed%acon the performance.). time0 scope0 cost0 and resources. human resources0 dollars0 materials0 and duration$. time0 location0 duration0 and completion

!. organiation* design* ob,ectives* andresourcesE. management0 sta;0 worers0 and contractors

12/ (uality control is the technical processes that the proect-s progress against theperformance standards.). inspect0 certify0 and verify. examine* analye* and report

$. inspect0 eGamine0 and determine!. identify0 measure0 and reportE. reveal0 esta%lish0 and record

124 Besponsi%ility within the proect for quality must%e de5ned and promulgated to everyone contri%utingto the end product. 'irst and foremost0 the has the ultimate responsi%ility for conformance to

requirements when provided with the tools0 sills0nowledge0 and opportunities.). corporate president. director of proect management$. quality assurance manager!. proect managerE. individual

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

-

8/21/2019 Send Tqm Mcq

34/48

12 7elfinspection %y the individual performing thewor is used to achieve quality in a product. +headvantages of selfinspection include .). immediate feed%ac to permit adustments to the

process. early identi5cation of errors prior to furtherintegration$. minimi,ation of end product repairs and materialwaste!. reduction in the num%er of end product inspectionsand testsE. all of the above

12 &ero !efects is an element of the qualitymanagement philosophy that is a forall worers to %e achieved .). sloganR whenever possi%le. sloganR most of the time$. standard% at all times!. standardR whenever possi%leE. standardR during critical operations

123 7tatistical "rocess $ontrol is used in qualityprograms to determine whether repetitive operationsmeet predicta%le standards. +he process uses to permit accurate monitoring of theoperation.). 188 percent inspection and random reection. acceptance sampling and automatic reection

$. continuous sampling and error detection methods!. random sampling and corrective proceduresE. statistical sampling and control procedures

1#8 7tatistical !ecision Maing includes "areto)nalysis as a means of reducing errors in the totalproect process. "areto )nalysis . ). is a method of reecting errors or variances fromstandards following selfinspection

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!

-

8/21/2019 Send Tqm Mcq

35/48

. is a procedure for ran'ing the errors toidentify those contributing the most to failuresCM/>D p: /62E$. counts errors or failures to determine the added

cost of all operations that do not meet therequirements!. compares the error rate with the pass rate todetermine the allowa%le num%er of errors per 10888E. compares the error rate of individuals to determinethe compensation for %onuses

1#1 7tatistical sampling is a method to determine the

conformance to requirement for some element orproduct of a proect. +he advantage of statisticalsampling is that it .). does not require an eGpenditure of resources. is accurate enough with a sampling of less than onepercent$. does not re#uire 500 percent sampling of theelements to achieve a satisfactory inference ofthe population

!. needs to %e conducted only when there is apro%lem discovered with the end product or when thecustomer has some reectsE. is a good tool o gain customer con5dence during aperiod of high reects

1#2 7tatistical "rocess $ontrol uses diagrams called@$ontrol $harts.@ +hese charts depict hori,ontal0

parallel lines to represent standarddeviations.). siG. 5ve$. four!. threeE. two

1## When data is plotted on the control charts0 the

data is of two types: B and %ar. +he B data represent

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

"

-

8/21/2019 Send Tqm Mcq

36/48

points of a while the %ar data representpoints of aNnO .). random sampleR crossmatriG sample. real sampleR simulated sample

$. 188 percent samplingR 18 percent sampling!: sampling run% average of several runsE. random samplingR continuous sampling

1#* +he cost of quality has %een argued as %eingprimarily driven %y the worers. When items wereproduced that did not meet the customers-eGpectations0 the worers were @found@ to %e at

fault. $urrent thining is that management has at least percent of the responsi%ility for the cost ofquality.). ?@. /$. 4/!. //E. /8

1#/ 7tatistical sampling methods are valid for mostproects0 regardless of the lac of repetitive processes0%ecause .). pro,ects rely on external vendors for productsthat must meet contractual specications toconform to the re#uirements. purchased materials will never meet therequirements of the proect

$. services are amena%le to statistical sampling evenfor small lots!. it loos good to the customer when there is amathematical approach to qualityE. statistics provide a %asis for customer acceptanceof the proects1#4. ) quality program within a proect should %e%ased on of errors to improve productivityalong with quality levels.

). early detection

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

#

-

8/21/2019 Send Tqm Mcq

37/48

. early correction$. late detection!. late correctionE. prevention

1#. +he cost of quality is needed to identifyopportunities for improvement. +he cost of quality is0therefore0 de5ned as the dollar value associated with .). producing a product that meets the requirement. nonconformance to the re#uirement$. any cost for quality personnel and tools

!. any eGtra cost to hire a quality consultantE. all eGtra e;orts to implement a quality program

1#. In a proect0 the common parameters are cost0schedule0 and quality. In relationship to the others0quality should %e raned .). 5rst as the prime driver for a proect. second %ehind cost %ut ahead of schedule$. second %ehind schedule %ut ahead of cost

!. e#ual to cost and scheduleE. third %ehind cost and schedule

1#3. When errors that a;ect quality are discovered0the procedure to improve the situation should %e to .). identify the speci5c error. correct the speci5c error

$. determine the root causes of the error!. correct the root cause of the errorE. all of the above

1*8. ) quality audit is a powerful tool in any qualityimprovement program. 'or a proect that is starting aquality improvement program0 the initial audit is usedto .). identify all the faculty wor that has %een

completed

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

7

-

8/21/2019 Send Tqm Mcq

38/48

. identify all the wor that has %een correctlyaccomplished$. determine the single most urgent area forimprovement

!. determine the #uality baseline from $hichimprovements $ill be madeE. evaluate the quality audit-s e;ectiveness inidentifying errors

1*1. $ustomers are the driving force in any proectand determine the requirements to %e met. In dealingwith customers- complaints0 it is important to

.). avoid commitment to correction on an @out ofwarranty@ item. tal to them until they see the reason thecomplaints are trivial$. give them something more than they contracted toreceive to suppress any feelings of dissatisfaction!: provide them $ith the full scope of thecontracted product or service

E. reali,e that customers as for too much and tochange their perceptions a%out the product or servicerequirements

1*2. In computing the cost of producing a qualityproduct0 the maor areas of costs contri%ute to thesale price of the product. +he ratio of the costs determine whether an e;ective program is fully

implemented.). direct0 indirect0 and overhead. onetime0 recurring0 and varia%le$. varia%le0 5Ged0 and semi5Ged!. prevention* appraisal* and failureE. %uild0 repair0 and test

1*#. +he 1*step process to quality improvement is aprogressive to total involvement of everyone in a

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

$

-

8/21/2019 Send Tqm Mcq

39/48

company toward the production of quality productsand services. +he 1*steps do not include .). management commitment. quality improvement team

$. quality measurement!. goal achievement measuresE. supervisor training

1**. +rend charts reSect the relative status of aprogram. +rend charts are e;ective means of .

). visibility reinforcing the gro$th of #ualityimprovements to the $or'ers. reSecting the precise status of quality failures$. identifying to customers the failure rates ofproducts!. setting standards and goals for accepta%le levels ofqualityE. showing that all goals have %een achieved

1*/. In many proects0 the end product is a @service@that does not have physical characteristics andattri%utes to %e measured to ensure conformance tothe requirement. When service is the endproduct of a proect0 measurements .). do not apply to the service0 %ut the criterion is passor fail. are always arti5cial and present only false

indications of progress$. can be established based on customerexpectations and the responsibility assigned toindividuals!. are not applica%le if the service is to an internalfunction of the proectE. relate only to the actual eGpenditures of funds orreceipt or revenues

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

%

-

8/21/2019 Send Tqm Mcq

40/48

1*4. Becognition of personnel achievements is animportant %uilding %loc to the attainment of asuperior quality program. +he form of recognitionshould %e .

). an annual %onus increase paid at the end of theyear. an immediate cash award that is commensuratewith the deed$: a non6monetary a$ard presented in a publicforum as soon as the deed is identied!. a nonmonetary award presented in privateE. a com%ination of monetary and nonmonetary

award presented in private

1*. (uality in a proect-s product is essential for theenhancement of the proect manager and the sellingorgani,ation. +o ensure that the customer perceives aquality product0 the proect manager must inform thecustomer of the to %e used so the customerwill not have a perception of .). materialsR inferior fa%rication

. standards% gold plating$. practicesR poor wormanship!. pricingR gougingE. warrantyR poor service after product sale

1*. )s one of its goal the proect organi,ation hasquality to speci5ed performance measures. Whencompared with the functional organi,ation0 the proect

organi,ation .). achieves higher levels of quality. is always tailored to meet the speci5c quality goals$. is less disciplined in the implementation of#uality!. is more disciplined in the implementation of qualityE. none of the a%ove

1*. +he technical performance of the proect is

derived from the quality program instituted %y the

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!'

-

8/21/2019 Send Tqm Mcq

41/48

proect manager. (uality control is one part of thequality program that .). de5nes requirements and performance standards. measures results of operations

$. compares measured results to performancestandards!. initiates corrective actions for variancesE: all of the above

1*3. (uality control includes inspections to ensure thestandards of performance are %eing met. Inspectionincludes eGaminations of .

). visual and nonvisualR processes and components. visual and auralR processes and materials$. visual and technicalR material and end products!. aural and tactileR materials and end productsE. aural and tactileR processes and procedures

1/8. (uality control methods eGtend %eyond theeGternal characteristics of the product or componentsof the product. +he types of testing of the product or

components include .). operator0 maintainer0 and environmental. stress0 destructive0 and operating$. in6house* public* and private!. la%oratory0 destructive0 and nondestructiveE. la%oratory0 fa%rication0 and product

1/1. Each proect needs a quality program plan tode5ne the parameters of the overall approach tomeeting quality requirements. )s a minimum0 thequality program plan addresses .). the required processes and procedures. the inspection plan$. the types of test to %e conducted!. the documentation re#uirements for actions

8testing* inspections* etc:9

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!&

-

8/21/2019 Send Tqm Mcq

42/48

E. all of the a%ove

1/2. In a quality management information system0there is a need to collect data and format such data

into an information output that is useful to the proectmanager. In developing such an information system0 itis good to remem%er that an optimum system doesnot supply all the information %ecause .). there is never enough information collected. the system is incapa%le of processing all therequired information$. some information costs more to collect than it is

worth!. some information is not availa%le for collection andinputE: most information relies on related data togenerate the proper output

1/#. (uality is one part of the three maor parametersof a proect. When the quality in a proect eGceeds thespeci5cations0 that is called .

). eGcellence. superior quality$: deviation plus #uality!. gold platingE. silver plating

1/*. In the quality area0 process control is %ecomingan important element of the manufacturing to rigorous

speci5cations to provide a consistently uniform output. +he control of a process is divided into controllingtemperatures0 pressures0 Sows0 0 and levelsin terms of rates and time.). directions0 elasticities. volumes0 distances$. speeds NvelocitiesO0 volumes!. distances* speeds 8velocities9E. lengths0 widths

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!2

-

8/21/2019 Send Tqm Mcq

43/48

1//. "rocess control is distinct and separate from thedata gathering function in a quality program. Whileprocess control regulates the functions0 data gatheringis used to .

). collect information on the relative performancestandards of the process so the output can %eenhanced through continuous adustments to theinput functions. validate the controlling function asperforming correctly and provide information one#uipment servicing intervals

$. provide the historical records for production lots asto the speci5cations and actual measurements of aproduct!. generate the control charts to determine thevariances in the product and the num%er on nonconforming productsE. ensure the products are within tolerances and toidentify those products that require reworing orscrapping

1/4. In the area of quality0 proect managers arestruggling with the training and indoctrination ofindividuals in the need to do the wor right the 5rsttime to conform to the requirement.

-

8/21/2019 Send Tqm Mcq

44/48

!. exceeding the specied re#uirement is$asting time and money at no value added tothe pro,ectE. the proect must %e rewored in other areas to

increase the level of @goodness@ to the same as the@over %uild@

1/. +he use of $)! Ncomputeraided designO isemerging as a new technology with the goal ofreducing the time and money spent to produce andupdate design drawings. In some cases0 the $)! is%eing used to control other computers and machines

to manufacture %asic components of equipment.ecause the $)! software has the capa%ility toperform checs of the design and mae changes todesigns as they are approved0 there has %een .). a signi5cant reduction in engineering errors. less rewor required %ecause of design errors$: improved updating of designs over the formermanual methods

!. more timely posting of changes to designsE. all of the a%ove

1/. +he ey to quality is to design and %uild to therequirements and avoid attempts to inspect qualityinto the product. +here is a need0 however0 to conductinspections a critical unctures in the assem%ly processto ensure defective items are identi5ed prior to

maing a costly interface or concealing a physicalattri%ute that cannot %e inspected at a later time. )ninspection plan will identify the points at whicheGaminations of processes0 materials0 or assem%liesare required.However0 inspection plans normally do not include .). eGamining the vendor-s quality procedures. eGamining surfaces

$. testing personnel sills

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!!

-

8/21/2019 Send Tqm Mcq

45/48

!. checing dimensionsE: $itnessing destructive and nondestructivetests

1/3. +he inspection of the proect through theimplementation phase is critical to ensure that qualitystandards are %eing met. +he use of vendors is mostoften required to o%tain critical materials0components0 or su%assem%lies. +o determine avendor-s capa%ilities to produce to the speci5cations0 a@shop survey@ or audit of the vendor may %e required. +he areas for the audit should include .

). facilities and shop space. eGperience and capa%ility with similar wor$. #uality assurance an control procedures!. organi,ation and quality of wor in processE. all of the a%ove

148. +he quality program may include the requirementfor @witnessed inspections@ of critical items for theproect. When a su%contractor or vendor is to conduct

a destructive test0 the proectmanager must ensure the test is validated NwitnessedO%y a quali5ed mem%er of his team. +he purchase orderor contract should contain a statement that requiresthe su%contractor or vendorperforming the test to .). give a #8day notice of when the test will %econducted and to provide a certi5cate of completion

within seven days following the test. notify the pro,ect manager* in $riting* of thedate and time for $itnessing the test$. retain the residue of the item destroyed for a periodof one year following completion of the proect!. have present at the test at least three independentsources NindividualsO who are quali5ed in destructivetesting procedures

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!"

-

8/21/2019 Send Tqm Mcq

46/48

E. report the results of the testing to an independentla%oratory for con5rmation and validation of theprocedures

"art II +rueJ'alse questions

5: +he very purpose of organi,ations is to meetcustomer needs and satisfy their eGpectations.T3FG4(HS

2: "rocess improvement is the foundation on whichcustomer satisfaction is %uilt. T3FG4(HS

=: With +(M0 the worer is viewed as a source ofprocess improvement. T3FG4(HS

: +he commitment to data%ased decision maingimplies a need to train all employees in the

appropriate use of statistics. T3FG4(HS

@: In the holistic approach to pro%lem solving0 compleGpro%lems are %roen down into independent su%pro%lems. T3FG4(HS

J: +(M focuses on accepta%ility. T3FG4(HS

K: +(M focuses on shortterm 5nancial performance.

T3FG4(HS

?: +(M sees proactive solutions for customersT3FG4(HS

A: Lapanese managers tend to place greater emphasison longterm maret share. T3FG4(HS

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!#

-

8/21/2019 Send Tqm Mcq

47/48

50: +he term service recovery refers to converting acustomer who is dissatis5ed with a service into onewho is satis5ed. T3FG4(HS

55: Loseph Luran is well nown for his fourteen pointphilosophy. T3FG4(HS

52: Luran-s four quality costs are not applica%le tothe service environment. T3FG4(HS

5=: +hining of quality in 5nancial terms helps topmanager see the importance of their ownparticipation in quality related functions.

T3FG4(HS

5: +he aldrige )ward is Lapan-s national qualityaward T3FG4(HS

5@: +he I7< 3888 standards have %een revised tofocus more on customer satisfaction and processimprovement. T3FG4(HS

5J: 9arious groups outside an organi,ation have no%earing on the quality of its product or service andits productivity. T3FG4(HS

5K: =onhuman resources and how they areprocessed are the primary concerns under theheading of internal inSuences. T3FG4(HS

5?: Besearch and development proects represent asi,a%le investment of time and money that help toguarantee an organi,ation-s future through a steadystream of customerpleasing goods and services.T3FG4(HS

5A: $areful coordination through regularinteractions with suppliers is vital to satisfyinginternal needs and eGternal customers.T3FG4(HS

Farid keyhani [email protected]

Master of Engineering Manufacturing Management

!7

-

8/21/2019 Send Tqm Mcq

48/48

20: Cocating manufacturing and distri%utionfacilities close to ineGpensive sources of rawmaterials can greatly increase a producer-s cost.T3FG4(HS

25: (uality can %e used as a strategic0 o;ensiveweapon rather than a defensive one. T3FG4(HS

22: "erformance is the pro%a%ility that a product willfail within a speci5ed time. T3FG4(HS

2=: $onformance relates to the num%er of productmodels andJor variations a company can o;er its

customers. T3FG4(HS

2: +he aldrige award is only for health care andeducational institutions. T3FG4(HS

2@: ) ey to employee involvement is quality at thesource. T3FG4(HS