SANDWICH PANELS FOR W A LLS AND R O O F S BUILDING LIFETIME EFFICIENCY

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 1/24

SANDWICH

PANELS

FOR WALLS AND ROOFS

BUILDING LIFETIME EFFICIENCY

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 2/24

www.ruukki.com/sandwichpanels

Focus on green efficiency. And save money.

Ruukki®

energy panels

Airtight top technology The new Ruukki energy panel solution consists of airtight Ruukki energy panels,

structural details, accessories, airtightness instructions and installation services.

Save up to 30% in yearly energy costsThe new energy panel solution creates savings in heating costs, leading in turn

to significantly reduced carbon dioxide emissions generated by the use of the

building. A building that utilizes the energy panel solution will also receive higher

LEED* and BREEAM* credits.

Ruukki’s airtightness promise seals the dealAs the only manufacturer, Ruukki is able to promise an exact airtightness level for

a building. The guarantee is agreed upon case-by-case in a separate contract.

Choosing Ruukki’s airtight energy panel solution will increase the value of

your property.

* Voluntary certificates assessing the environmental impact of a building

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 3/24

One panel – many options

for customer buildingsRuukki sandwich panel comes in different core

materials (PU, PIR, W and S) and thicknesses, va-

rious profiling shapes and coatings, many standardand non-standard colours, as well as options for the

vertical or horizontal installation of wall panels.

All this gives our customers freedom to choose the

wall and roof cladding they want according to their

project requirements.

Comprehensive panel system

delivery and much moreRuukki, as one of only a few sandwich panel pro-

ducers, can provide a customer with a total panelpackage – starting from design tailored to the

customer’s needs, through selection of the right

panel type, freedom of choosing a range of product

features and specifying essential accessories to a

speedy and efficient installation service.

Safety - first and foremostRuukki sandwich panels offer excellent fire safety

properties, especially the panels with a mineral wool

core, which boast exceptional fire safety properties,

as well as acoustic insulation. The most recent

Ruukki’s achievement: our PIR wall sandwich panels

have EI 30/EW 60 ratings, one of the best results in

terms of fire safety in the European market!

Time-constant thermal insulationRuukki panels provide excellent thermal insulation.

Air-tight cladding reduces the maintenance costs of

a building, such as heating, cooling and air condi-

tioning, and consequently the release of CO2 into

the atmosphere.

For a building to lastRuukki panels, thanks to their high quality core and

cladding materials, and innovative glueing system,

boast excellent durability, corrosion resistance,

thermal insulation and mechanical properties. Our

calculated strength tables allow the quick and easy

selection of panels suitable for a particular build-

ing. With Ruukki panels even dark colours can be

successfully used. Our panels as first on the market

have achieved the highest atmospheric-corrosivity

category C5-M. With our panels customers’ buildings

will live longer.

Sandwich panels for walls and roofs

New energy panel solution ENERGY The main advantage of new energy panels is

their higher airtightness and thermal insula-

tion comparing to traditional sandwich panels.

High class joint tightness is achieved thanks

to the use of special ENERGY gasket and

production process with minimal engineering

tolerances.

Special attention is also paid to production

quality control in order to achieve superior

airtightness up to passive house standard.

New energy panels are offered in three airtight-ness classes defined as Basic, Plus and Premium

levels. Ruukki energy panels are the basis of Plus

and Premium levels, for which air leakage figures

are respectively n50

≤ 0,9 l/h and n50

≤ 0,6 l/h.

For these two levels Ruukki gives a promise that

specified values will not be exceeded. In case of

Basic level, Ruukki’s traditional sandwich panels

are used and air leakage figure is n50

≤ 1,3 l/h.

New group of sandwich panelswith mineral wool coreIncreasingly stricter requirements as to thermal

insulation of buildings force construction mate-

rial manufacturers to search for new solutions

and focus on further improvement of their

products.

In order to meet these requirements and to fulfill

our customers’ expectations we developed a new

offer of sandwich panels with the core made ofmineral wool - SP2D WE and SPB WE. These new

panels feature a core with lower density. The

core’s physical and mechanical properties ensure

proper strength, what is reflected in relevant

strength tables.

Very low thermal conductivityλ allows to im-

prove significantly thermal parameters of walls

made with the use of new sandwich panels.

New panels with mineral wool core are a perfect

solution for envelopes that must meet highrequirements as to energy efficiency.

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 4/24

4

Ruukki SP2D PU 1. Large bend radii on facings ensure that none of the protective coat

properties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Double lock from outer and inner sides increases fire-tightness andfacilitates assembly.

4. Rigid, HCFC-free, self-extinguishing, environmentally and ozone friendly

polyurethane foam core provides excellent thermal insulation parameters.

5. Auxiliary groove allows for precise assembly.6. Concealed panel fixings ensure aesthetic facade appearance.

7. Properly profiled edges improve thermal insulation and joint tightness.

8. Continuous polyurethane seal ensures proper thermal insulation and

joint tightness.9. Aluminium foil prevents gas diffusion and penetration of vapour into

a polyurethane core (constant thermal parameters of panels).10. Gas permeable polyurethane seal.

Ruukki SPF PU 1. Large bend radii on facings ensure that none of the protective coat

properties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Double lock from outer and inner sides increases fire-tightness and facili-

tates assembly.4. Properly profiled edges improve thermal insulation and joint tightness.

5. Auxiliary groove allows for precise assembly.

6. Concealed panel fixings ensure aesthetic facade appearance.

7. Rigid, HCFC-free, self-extinguishing, environmentally and ozone friendly

polyurethane foam core provides excellent thermal insulation parameters.8. Continuous polyurethane seal ensures proper thermal insulation and

joint tightness.

9. Aluminium foil prevents gas diffusion and penetration of vapour into

a polyurethane core (constant thermal parameters of panels).10. Narrow, almost invisible 1 mm gap.

1 the surface of plain profile can be slightly corrugated – min. facing thickness 0.50 mm.2 other colours according to RAL system, available on special order, following additional arrangements. External

panel facings in dark colours (from standard colour range RAL 3013, 5005, 7016 and 9007), due to considerablethermal loads, higher than that of lighter colours, can be deformed. In order to minimize this phenomenon, itis advisable to apply only single-span systems for wall panels; for roof panels limitation to maximal lengthsresulting from calculations that take into cosideration thermal loads; in doubtful cases please consult con-struction department of panels producer.

Ruukki SP2D PU

Declaration of conformityCE acc. to EN 14509Hygienic CertificateHC/97/779/104/2011

R28 ribbedL linear

P embossedF flat1

M microprofiled

L linearF flat1

RL, RF, PL, PF,ML, MF, LL, LF,

FL, FF

1015, 3013, 5005, 6011,7016, 7035, 9002, 9006,

9007, 9010

9002, 9010

11.0 11.710.3

see point2

60 80 100

0.35 0.26 0.21

≥24

1050

18,5

1000

0.50

Ruukki SPF PU

rigid polyurethanefoam

Declaration of conformityCE acc. to EN 14509Hygienic CertificateHC/97/779/104/2011

S sinusoidal

SL, SF

9006

9010

98 / 80

15.3

0.022 0.022

see point2

L linearF flat1

0.23

B-s3, d0

≥25

18.5

963.5

900

0.60

0.55

core

thickness[mm]

weight[kg/m2]

λ value[W/mK]

U value[W/m2K]4

reaction to fire

soundinsulation [dB]

maximum length[m]

total width[mm]

modular width [mm]

external facingthickness [mm]

certificatesand approvals

external facingprofiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL5

standard colours ofinternal facing

RAL

other colours

internal facingthickness [mm]

internal facingprofiling

rigid polyurethanefoam

B-s2,d0

0.40

18.5

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 5/24

Sandwich panels for walls and roofs

3 only for partition walls.4 U value includes impact of linear thermal bridge appearing on panel joint.5 Facing colour groups is in the table on page 19.

Ruukki SP2E PU 1. L arge bend radii on facings ensure that none of the protective coat

properties is lost.

2. 3 mm gap enables additional joint closure with durably elastic mass (p.8).

3. Precisely milled labyrinth core edge eliminates thermal bridges.

4. Doubl e lock from outer and inner sides increases fire-tightnes s andfacilitates assembly.

5. Butyl sealing compound eliminates air and moisture penetration, applied at

building site.

6. Facing profile conforming with the standards applicabl e to cooling and foodindustries ensures uniform facade appearance.

7. Rigid, HCFC-free and self-extinguishing environmentally and ozone friendly

polyurethane foam core of excellent thermal insulation.

8. Durably elastic sealing compound (compulsory for ceilings, optional for walls),

applied at building site.

Ruukki SP2B PU 1. L arge bend radii on facings ensure that none of the protective coat

properties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Double lock from outer and inner sides increases fire-tightness and faci-

litates assembly.4. 3 mm gap enables to meet sanitary and hygienic requirements (food,

cooling, pharmaceutical industries etc.).

5. Properly profiled edges improve thermal insulation parameters and joint

tightness.

6. Rigid, HCFC-free, self-extinguishing, environmentally and ozone friendlypolyurethane foam core provides excellent thermal insulation parameters.

7. Aluminium foil prevents gas diffusion and penetration of vapour into

a polyurethane core (continuous thermal parameters of panels).

8. Continuous polyurethane seal ensures thermal insulation and jointtightness.

Ruukki SP2B PU

eclaration of conformityCE acc. to EN 14509Hygienic CertificateHC/97/779/104/2011

R28 ribbedL linear

P embossedF flat1

M microprofiled

R28 ribbedL linear

P embossedF flat1

M microprofiled

RL, RF, PL, PF,ML, MF, LL, LF,

FF3

015, 3013, 5005, 6011,016, 7035, 9002, 9006,

9007, 9010

see point2

9002, 9010

L linearF flat1

60 80 100

9.1 9.9 10.6

0.35 0.26 0.21

≥24

1120

18.5

1100

0.50

0.40

Ruukki SP2E PU

Declaration of conformityCE acc. to EN 14509Hygienic CertificateHC/97/779/104/2011

RL, RF, PL, PF,ML, MF, LL, LF,

FF3

1015, 3013, 5005, 7035,9002, 9006, 9007,

9010

see point2

9002, 9010

L linearF flat1

120 160 180 200

11.9 13.4 14.1 14.8

0.17 0.13 0.11 0.10

≥25

18.5

1120

1100

0.50

0.50

rigid polyurethanefoam

rigid polyurethanefoam

core

thickness[mm]

weight[kg/m2]

reaction to fire

soundinsulation [dB]

maximum length[m]

total width[mm]

modular width [mm]

external facingthickness [mm]

certificatesand approvals

external facingprofiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL5

standard colours ofinternal facing

RAL

other colours

internal facingthickness [mm]

internal facingprofiling

0

.4

50

B-s2,d0 B-s2, d0

0.0220.021

(temp. 0°C)

λ value[W/mK]

U value[W/m2K]4

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 6/24

Ruukki SP2D PIR 1. Large bend radii on facings ensure that none of the protective coat

properties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Double lock from outer and inner sides increases fire-tightness andfacilitates assembly.

4. Rigid, HCFC-free, self-extinguishing, environmentally and ozone friendly

polyisocyanurate foam core provides excellent fire insulation parameters.

5. Auxiliary groove allows for precise assembly.6. Concealed panel fixings ensure aesthetic facade appearance.

7. Properly profiled edges improve thermal insulation and joint tightness.

8. Continuous polyurethane seal ensures proper thermal insulation and

joint tightness.9. Aluminium foil prevents gas diffusion and penetration of vapour into

a polyurethane core (constant thermal parameters of panels).10. Gas permeable polyurethane seal.

1 the surface of plain profile can be slightly corrugated – min. facing thickness 0.50 mm.2 other colours according to RAL system, available on special order, following additional arrangements. External

panel facings in dark colours (from standard colour range RAL 3013, 5005, 7016 and 9007), due to considerablethermal loads, higher than that of lighter colours, can be deformed. In order to minimize this phenomenon, itis advisable to apply only single-span systems for wall panels; for roof panels limitation to maximal lengthsresulting from calculations that take into cosideration thermal loads; in doubtful cases please consult con-struction department of panels producer.

Ruukki SP2C PU 1. Large bend radii on facings ensure that none of the protective coat pro-

perties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Rigid, HCFC-free, self-extinguishing, environmentally and ozone friendlypolyurethane foam core provides excellent thermal insulation parameters.

4. Aluminium foil prevents gas diffusion and the penetration of vapour

into a polyurethane core (continuous thermal parameters of panels).

5. Auxiliary groove allows for precise assembly.6. Properly profiled edges improve thermal insulation and joint tightness.

7. Specially shaped micro-chamber protects against water capillary pe-

netration.

8. Continuous polyurethan e seal ensures thermal insulation and jointtightness.

Ruukki SP2D PIR

Declaration of con-formity CE acc. to EN

14509Hygienic

CertificateHC/97/779/104/2011

L linearF flat1

L linearF flat1

RL, RF, PL, PF,ML, MF, LL, LF,

FL, FF

1015, 3013, 5005,6011, 7035, 9002,9006, 9007, 9010

9002, 9010

11.2 12.010.4

see point2

60 80 100

0.34 0.25 0.20

≥24

1050

18.5

1000

0.50 or 0,60

0.40

Ruukki SP2C PU

rigid polyurethanefoam

core

thickness[mm]

weight[kg/m2]

reaction to fire

soundinsulation [dB]

maximum length[m]

total width[mm]

modular width [mm]

external facingthickness [mm]

certificatesand approvals

external facingprofiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL6

standard colours ofinternal facing

RAL

other colours

internal facingthickness [mm]

internal facingprofiling

rigid polyiso-cyanurate foam

T trapezoidal

TL, TF

1015, 3013, 5005,6011, 7035, 9002,

9006, 9010

80/40

9.5

see point2

0.46

B-s2,d0

18.54

1083

1000

0.50

0.40

100/60 120/80 140/100

10.3 11.0 11.7

0.31 0.24 0.20

≥24

9002, 9010

Declaration of conformityCE acc. to EN 14509Hygienic CertificateHC/97/779/104/2011

BROOF (t1)external fireexposure –

160/120 210/170

12.5 14.3

0.17 0.13

R28 ribbedL linear

P embossedF flat1

M microprofiled

λ value[W/mK]

U value[W/m2K]4

0.022 0.021

60-80 B-s2,d0100 B-s1,d0

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 7/24

Sandwich panels for walls and roofs

3 only for partition walls.4 on special request up to 21.0 m.5 U value includes impact of linear thermal bridge appearing on panel joint.6 Facing colour groups is in the table on page 19.

Ruukki SP2E PIR 1. L arge bend radii on facings ensure that none of the protective coat

properties is lost.

2. 3 mm gap enables additional joint closure with durably elastic mass (p.8).

3. Precisely milled labyrinth core edge eliminates thermal bridges.

4. Doubl e lock from outer and inner sides increases fire-tightnes s andfacilitates assembly.

5. Butyl sealing compound eliminates air and moisture penetration, applied at

building site.

6. Facing profile conforming with the standards applicabl e to cooling and foodindustries ensures uniform facade appearance.

7. Rigid, HCFC-free and self-extinguishing environmentally and ozone friendly

polyisocyanurate foam core of excellent fire insulation.

8. Durably elastic sealing compound (compulsory for ceilings, optional for walls),

applied at building site.

Ruukki SP2B PIR 1. L arge bend radii on facings ensure that none of the protective coat

properties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Double lock from outer and inner sides increases fire-tightness and faci-

litates assembly.4. 3 mm gap enables to meet sanitary and hygienic requirements (food,

cooling, pharmaceutical industries etc.).

5. Properly profiled edges improve thermal insulation parameters and joint

tightness.

6. Rigid, HCFC-free, self-extinguishing, environmentally and ozone friendlypolyisocyanurate foam core provides excellent fire insulation parameters.

7. Aluminium foil prevents gas diffusion and penetration of vapour into

a polyurethane core (continuous thermal parameters of panels).

8. Continuous polyurethane seal ensures thermal insulation and jointtightness.

Ruukki SP2B PIR

eclaration of conformityCE acc. to EN 14509Hygienic CertificateHC/97/779/104/2011

R28 ribbedL linear

P embossedF flat1

M microprofiled

1015, 3013, 5005, 6011,7035, 9002, 9006,

9007, 9010

see point2

9002, 9010

L linearF flat1

60 80 100

9.3 10.1 10.9

0.34 0.25 0.20

≥24

1120

18.5

1100

0.50 or 0.60

Ruukki SP2E PIR

Declaration of conformityCE acc. to EN 14509 Hygienic CertificateHC/97/779/104/2011

RL, RF, LL, ML, LF,MF, FF3

1015, 3013, 5005, 6011,7035, 9002, 9006,

9007, 9010

see point2

9002, 9010

L linearF flat1

R28 ribbedL linearF flat1

M microprofiled

120 160 180 200

12.4 14.0 14.8 15.6

0.16 0.12 0.11 0.10

≥25

18.5

1120

1100

0,50 or 0.60

0.50

rigid polyisocyanuratefoam

rigid polyisocyanuratefoam

core

thickness[mm]

weight[kg/m2]

reaction to fire

soundinsulation [dB]

maximum length[m]

total width[mm]

modular width [mm]

external facingthickness [mm]

certificatesand approvals

external facingprofiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL6

standard colours ofinternal facing

RAL

other colours

internal facingthickness [mm]

internal facingprofiling

0

.5

49

40-80 B-s2,d0100 B-s1,d0 B-s1,d0

RL, RF, PL, PF,ML, MF, LL, LF,

FL, FF3

––

external fireexposure

0.40

λ value[W/mK]

U value[W/m2K]4

0.021 0.020(temp. 0°C)

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 8/24

Ruukki SP2C PIR 1. Large bend radii on facings ensure that none of the protective coat pro-

perties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Rigid, HCFC-free, self-extinguishing, environmentally and ozone friendly

polyisocyanurate foam core provides excellent thermal insulation parameters.

4. Aluminium foil prevents gas diffusion and the penetration of vapourinto a polyurethane core (continuous thermal parameters of panels).

5. Auxiliary groove allows for precise assembly.

6. Properly profiled edges improve thermal insulation and joint tightness.

7. Specially shaped micro-chamber protects against water capillary pe-netration.

8. Continuous polyurethan e seal ensures thermal insulation and joint

tightness.

1 other colours according to RAL system, available on special order, following additional arrangements. External

panel facings in dark colours (from standard colour range RAL 3013, 5005, 7016 and 9007), due to considerablethermal loads, higher than that of lighter colours, can be deformed. In order to minimize this phenomenon, itis advisable to apply only single-span systems for wall panels; for roof panels limitation to maximal lengthsresulting from calculations that take into cosideration thermal loads; in doubtful cases please consultconstruction department of panels producer.

Ruukki SP2D W 1. Core made of rigid, environmentally friendly mineral wool provides

excellent fire resistance.

2. Properly milled core improves thermal insulation.

3. Large bend radii on facings ensure that none of the protective coat

properties is lost.4. Facing profiling ensures uniform facade appearance.

5. Double lock from outer and inner sides increases fire-tightness and faci-

litates assembly.

6. Auxiliary groove allows for precise assembly.7. Concealed panel fixings ensure aesthetic facade appearance.

8. Butyl sealing compound (applied at building site) protects against waterand moisture penetration.

core

thickness[mm]

weight[kg/m2]

reaction to fire

maximum length[m]

total width[mm]

modular width[mm]

external facingthickness [mm]

internal facingthickness [mm]

certificatesand approvals

external facingprofiling

internal facingprofiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL4

standard colours ofinternal facing

RAL

other colours

Ruukki SP2C PIR

rigid polyisocyanuratefoam

T trapezoidal

TL

1015, 3013, 5005,6011, 7035, 9002,

9006, 9010

80/40

9.7

see point1

L linear

0.46

18.52

1083

1000

0.50

0.40

100/60 120/80 140/100

10.5 11.3 12.1

0.31 0.24 0.20

≥24

9002, 9010

Declaration of conformity CEacc. to EN 14509

Hygienic CertificateHC/97/779/104/2011

Ruukki SP2D W

R28, R250, R500L linear

M microprofiled

L linearF flat

RL, ML, LL,RF, MF, LF

1015, 5005,7035, 9002, 9006,

9007, 9010

9002, 9010

see point1

≥32

1054

12.0 12.0 12.0 10.0

1000

0.60

0.50

100

21.5

0.43

A2-s2, d0

120 140

23.8 26.1

0.35 0.31

Declaration of con-formity CE acc.

to EN 14509Hygienic CertificateHC/97/779/104/2011

hard mineralwool

soundinsulation [dB]

external fireexposure BROOF (t1) –

160

28.3

0.27

160/120210/170

12.9 14.9

0.17 0.13

λ value[W/mK]

U value[W/m2K]4

0.021 0.043

80/40-120/80 B-s2,d0140/100-210/170 B-s1,d0

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 9/24

Ruukki SPC W 1. Core made of rigid, environmentally friendly mineral wool provides excel-

lent fire resistance.

2. Hump made of environmentally friendly, hard mineral wool.

3. Properly milled core improves thermal insulation and joint tightness.

4. Large bend radii on facings ensure that none of the protective coat pro-

perties is lost.5. Facing profiling ensures uniform facade appearance.

6. The lock from inner side increases fire-tightness and facilitates as-

sembly.

7. Specially shaped micro-chamber protects against water capillary pene-tration.

8. Auxiliary groove allows for precise assembly.

9. Butyl sealing compound (applied at building site) protects against wa- ter and moisture penetration.

Sandwich panels for walls and roofs

2 on special request up to 21.0 m.3

U value includes impact of linear thermal bridge appearing on panel joint.4 Facing colour groups is in the table on page 19.

Ruukki SPB W 1. Large bend radii on facings ensure that none of the protective coat proper-

ties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Double lock from outer and inner sides increases fire-tightness and facili-

tates assembly.4. 3 mm gap enables to meet sanitary and hygienic requirements (food,

cooling, pharmaceutical industries, etc.).

5. Butyl sealing compound (applied at building site) protects against water

and moisture penetration.6. Properly milled core improves thermal insulation and joint tightness.

7. Core made of rigid, environmentally friendly mineral wool provides

excellent fire resistance.

Ruukki SPB W

R28, R250, R500for 1000 mm modular width)

R275, R550 (for 1100 mmmodular width)L linear, F flat

M microprofiled

RL, ML, LL, FL,RF, MF, LF, FF

1015, 5005,7035, 9002, 9006,

9007, 9010

see point1

9002, 9010

L linearF flat

L linearF flat

100

7 21.0 23.3

1 0.41 0.34

1018 lub 1118

1000 lub 1100

0.60

0.50

120 140

25.6

0.30

≥32

12,0 12,0 10,0 10,0

Ruukki SPC W

TL, TF

1015, 5005, 7035,9002, 9006, 9010

see point1

9002, 9010

T trapezoidal

140/100 190/150

22.0 27.8

0.41 0.28

≥34

12.0

1059

1000

0.60

0.50

hard mineralwool

Declaration of conform-ity CE acc. to Hygienic

CertificateHC/97/779/104/2011

Declaration of conform-ity CE acc. to EN 14509

Hygienic CertificateHC/97/779/104/2011

core

thickness[mm]

weight[kg/m2]

reaction to fire

soundinsulation [dB]

maximum length[m]

total width[mm]

modular width[mm]

external facingthickness [mm]

internal facingthickness [mm]

certificatesand approvals

external facingprofiling

internal facingprofiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL4

standard colours ofinternal facing

RAL

other colours

hard mineralwool

external fireexposureBROOF (t1)–

A2-s2, d0 A2-s2, d0

160 200

27.9 32.5

0.26 0.21

λ value[W/mK]

U value[W/m2K]4

0.043 0.043

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 10/24

1 other colours according to RAL system, available on special order, following additional arrangements. External

panel facings in dark colours (from standard colour range RAL 3013, 5005, 7016 and 9007), due to considerablethermal loads, higher than that of lighter colours, can be deformed. In order to minimize this phenomenon, it isadvisable to apply only single-span systems for wall panels; for roof panels limitation to maximal lengths resultingfrom calculations that take into cosideration thermal loads; in doubtful cases please consult constructiondepartment of panels producer.

Ruukki SP2D WE 1. Core made of soft, environmentally friendly mineral wool provides

excellent fire resistance.2. Properly milled core improves thermal insulation.

3. Large bend radii on facings ensure that none of the protective coat

properties is lost.

4. Facing profiling ensures uniform facade appearance.5. Double lock from outer and inner sides increases fire-tightness and faci-

litates assembly.

6. Auxiliary groove allows for precise assembly.

7. Concealed panel fixings ensure aesthetic facade appearance.

8. Butyl sealing compound (applied at building site) protects against waterand moisture penetration.

Ruukki SPB WE 1. Large bend radii on facings ensure that none of the protective coat proper-

ties is lost.

2. Facing profiling ensures uniform facade appearance.3. Double lock from outer and inner sides increases fire-tightness and facili-

tates assembly.

4. 3 mm gap enables to meet sanitary and hygienic requirements (food,

cooling, pharmaceutical industries, etc.).5. Butyl sealing compound (applied at building site) protects against water

and moisture penetration.

6. Properly milled core improves thermal insulation and joint tightness.

7. Core made of soft, environmentally friendly mineral wool providesexcellent fire resistance.

core

thickness[mm]

weight[kg/m2]

reaction to fire

maximum length[m]

total width[mm]

modular width[mm]

external facingthickness [mm]

internal facingthickness [mm]

certificatesand approvals

external facingprofiling

internal facing

profiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL3

standard colours ofinternal facing

RAL

other colours

soundinsulation [dB]

external fireexposure

Ruukki SP2D WE

R28, R250, R500,L linear

M microprofiled

L linear

F flat

RL, ML, LL,RF, MF, LF

1015, 5005, 7035,9002, 9006,9007, 9010

9002, 9010

see point1

≥29

1054

12.0

1000

0.60

0.50

100

19.0

0.40

A2-s1, d0

120

20.8

0.33

Declaration of conformityCE acc. to EN 14509Hygienic CertificateHC/97/779/104/2011

soft mineralwool

–

140 160

22.6 24.4

0.29 0.25

Ruukki SPB WE

soft mineralwool

R28, R250, R500(for 1000 mm modular width)

R275, R550 (for 1100 mmmodular width)L linear, F flat

M microprofiled

RL, ML, LL, FL,RF, MF, LF, FF

1015, 3013, 5005,7035, 9002, 9006,

9010

80

16.8

see point1

L linearF flat

0.48

A2-s1, d0

8.0

1018 or 1118

1000 or 1100

0.60

0.50

100 120 140

18.6 20.4 22.2

0.39 0.32 0.28

≥29

9002, 9010

Declaration of conformity CEacc. to EN 14509

Hygienic CertificateHC/97/779/104/2011

-

160 200

24.0 27.6

0.24 0.20

12.0 10.0 10.012.010.012.012.0

λ value[W/mK]

U value[W/m2K]4

0.040 0.040

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 11/24

Ruukki SPB S 1. Large bend radii on facings ensure that none of the protective coat pro-

perties is lost.2. Facing profiling ensures uniform facade appearance.

3. Double lock from outer and inner sides increases fire-tightness and faci-

litates assembly.

4. 3 mm gap enables to meet sanitary and hygieni c requirements (food,

cooling, pharmaceutical industries, etc.).5. Butyl sealing compound (applied at building site) protects against water

and moisture penetration.

6. Properly milled core improves thermal insulation and joint tightness.

7. Core made of environmentally friendly polystyrene.

Ruukki SPC S 1. Large bend radii on facings ensure that none of the protective coat

properties is lost.

2. Facing profiling ensures uniform facade appearance.

3. Properly milled core improves thermal insulation and joint tightness.

4. Butyl sealing compound (applied at building site) protects against waterand moisture penetration.

5. Auxiliary groove allows for precise assembly.

6. Core made of environmentally friendly polystyrene.

7. Specially shaped micro-chamber protects against water capillarypenetration.

8. Hump made of environmentally friendly, natural polystyrene.

Sandwich panels for walls and roofs

core

thickness[mm]

weight[kg/m2]

reaction to fire

maximum length[m]

total width[mm]

modular width[mm]

external facingthickness [mm]

internal facingthickness [mm]

certificatesand approvals

external facingprofiling

internal facing

profiling

possibleprofiling

combinations

standard colours ofexternal facing

RAL3

standard colours ofinternal facing

RAL

other colours

soundinsulation [dB]

external fireexposure

T trapezoidal

Ruukki SPC S

TL

1015, 6011, 7035,9002, 9006, 9010

see point1

9002, 9010

140/100

11.0 12.0

0.34

1059

1000

0.50

190/150

0.23

≥26

18.5

polystyrene

L linear

Declaration of confor-mity CE acc. to EN 14509

Hygienic CertificateHC/97/779/104/2011

BROOF (t1)

B-s3, d0

0.50

Ruukki SPB S

L linear

LL, ML

1015, 6011, 7035, 9002,9006, 9010

9002, 9010

see point1

≥24

1118

2.0

1100

0.50

10.5.5 10.0

0.2458

100

0.35

B-s2, d0

L linearM microprofiled

18.5 18.5 18.5

polystyrene

140 2000

11.0

0.17

9.8

80

0.44

1.0

Declaration of conform-ity CE acc. to EN 14509

Hygienic CertificateHC/97/779/104/2011

-

0.50

λ value[W/mK]

U value[W/m2K]4

0.037 0.037

2U value includes impact of linear thermal bridge appearing on panel joint.3

Facing colour groups is in the table on page 19.

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 12/24

Airtight top technology

Thanks to decades of expertise in sandwich panel pro-

duction, intensive R&D, and comprehensive field mea-

surements, we have succeeded in developing a new

airtight energy panel solution. Utilizing the solution

in a building will result in improved energy efficiency

and savings in maintenance costs.

The energy panel solution consists of new, airtight

Ruukki energy panels, structural details, accessories,

airtightness instructions, as well as installation car-

ried out by a certified Ruukki partner, and comes with

Ruukki’s airtightness promise.

Our energy panels feature high-class joint tightness.

The panels are manufactured with minimal engi-

neering tolerances, and special attention is paid to

production quality control in order to achieve superior

airtightness up to passive house standard. Our energy

panel solution is an excellent choice for industrial andcommercial buildings, logistics centers, and warehouses,

for instance. After the installation, final measure-

ments will verify the airtightness of your building.

Financial and ecological benefits

The new energy panel solution creates savings in

heating costs, leading in turn to significantly reduced

carbon dioxide emissions generated by the use of the

building. Projects that are constructed in compliance

with the principles of sustainable development will

receive higher LEED* and BREEAM* credits. In addi-

tion to this, the indoor air quality will improve, as the

temperature becomes stabilized with no cold draft.

The value of your property will increase with environ-

mental responsibility and image, high quality, and

lower running costs.

Ruukki’s airtightness promise seals the deal

We have absolute faith in the airtightness of our en-

ergy panel solution. As the only manufacturer, Ruukki

is able to promise an exact airtightness level for a

building. The guarantee is agreed upon case-by-case

in a separate contract.

* Voluntary certificates assessing the environmental impact

of a building.

12

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 13/24

PREMIUMair leakage

rate

n50≤0.6 1/h

PLUSair leakage

rate

n50≤0.9 1/h

BASICair leakage

rate

n50≤1.3 1/ h

Potential savings with Ruukki energy panel solutionValues based on a building located in Poland

H e a t e n e r g y c o n s u m p t i o n ( € / y e a r )

n50

= 3 l/h based ontechnical conditions tobe fulfilled by buildingsand their location;buildings with naturalventilation.

Ruukki Basic

Ruukki Plus

Ruukki Premium

Ruukki energy panel solution

• Ruukki energy panels

- SP2B PU/PIR ENERGY

- SP2D PU/PIR ENERGY

- SP2E PU/PIR ENERGY

- SPB W ENERGY, SPB WE ENERGY

- SP2D W ENERGY, SP2D WE ENERGY

• Structural details and accessories

• Airtightness instructions

• Installation carried out by a specialist firm certified by Ruukki

Airtightness levels

Premium and Plus levels are based on the new energy

panel solution, for which an airtightness promise is

given. The Basic level air leakage rate is n50

= 1.3 1/h.

This can be achieved by using Ruukki’s ordinary panel

system.

13

40 000

35 000

30 000

25 000

20 000

15 000

10 000

5000

0Floor area (m2)

1000m2 2000m2 3000m2 4000m2 6000m2 8000m2 10000m27000m2

Sandwich panels for walls and roofs

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 14/24

Fire resistance

Ruukki SP2E PU

120 160 180 200

EI 151

EW 302

EI 153

EW 203

EI 151

EW 302

EI 153

EW 203

EI 151

EW 302

EI 153

EW 203

EI 151

EW 302

EI 153

EW 203

Ruukki SP2D PU

60

E 151

80

EI 153

EW 304

100

EI 153

EW 304 EW 304

EI 152

Ruukki SP2B PU

40 60 80 100

EW 301

EI 152

EI 153

EW 301

EI 153-

EI 153-

fireresistance

thickness[mm]

rigidpolyurethane foam

1 fire resistance of load bearing structure min. R30; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;2 fire resistance of load bearing structure min. R15; max. distance between supports 11.3 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;3 fire resistance of load bearing structure min. R15; max. distance between supports 4.0 m – horizontal assembly arrangement and 8.6 m – vertical assembly arrangement; panel's facings made of stainless steel;

fireresistance

thickness[mm]

from

inside

fromoutside

1 the inside is exposed to fire; fire resistance of load bearing structure min. R15; max. distance between supports 11.6 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;2 the inside is exposed to fire; fire resistance of load bearing structure min. R15; max. distance between supports 4.0 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;3 the inside is exposed to fire; fire resistance of load bearing structure min. R15; max. distance between supports 6.3 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;4 the outside is exposed to fire; fire resistance of load bearing structure min. R30; max. distance between supports 4.0 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;

fireresistance

thickness[mm]

1 fire resistance of load bearing structure min. R15; max. distance between supports 10.0 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;

2 fire resistance of load bearing structure min. R30; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;3 fire resistance of load bearing structure correspondingly min. R15or R20; max. distance between supports 4.0 m – horizontal assembly arrangement and 12.0 m – vertical arrangement assembly; panel's facings made

of stainless steel;

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 15/24

Sandwich panels for walls and roofs

Ruukki SP2C PU

Ruukki SPF PU

98/80

EI 151

EW 301

EW 602

E 1202

fireresistance

thickness[mm]

1 fire resistance of load bearing structure correspondingly min. R15 or R60; span bending moment Md ≤ 0.0672 kNm/m; support bending moment Md ≤ -0.1200 kNm/m; snow load 0.2xS must be taken into considerationwhen doing calculations;

2 fire resistance of load bearing structure correspondingly R20 or R30; span bending moment Md ≤ 0.0697 kNm/m; support bending moment Md ≤ -0.1245 kNm/m; snow load 0.2xS must be taken into considerationwhen doing calculations;

3 fire resistance of load bearing structure min. R30; span bending moment Md≤ 0.0896 kNm/m; support bending moment Md ≤ -0.1600 kNm/m; snow load 0.2xS must be taken into consideration when doing calcula-tions;

fireresistance

thickness[mm]

from

inside

fromoutside

1 the inside is exposed to fire; fire resistance of load bearing structure correspondingly min. R15 or R30; max. distance between supports 3.0 m – vertical and horizontal assembly arrangement;2 the outside is exposed to fire; fire resistance of load bearing structure correspondinglymin. R60 or R120; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;

80/40

REI 151

RE 601

REI 202

RE 302

100/60

REI 151

RE 601

REI 202

RE 302

120/80

REI 151

RE 601

REI 303

160/120140/100

REI 303REI 303

REI 151

RE 601

REI 151

RE 601

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 16/24

Ruukki SP2C PIR

Ruukki SP2E PIR

120

EI 151

EI 302

EW 302

160

EI 151

EI 302

EW 302

180

EI 151

EI 302

EW 302

200

EI 303

EW 303

EI 604

EW 604

Ruukki SP2D PIR

60

EW 301

80

EW 301

El 152

EW 202

EI 154

EW304

100

EW 301

EI 153

EI 154

EW304

EI 154

EW304

Ruukki SP2B PIR

40 60 80 100

EI 153

EI 304

EW 304

EI 152

EW 302EW 301EW 301fire

resistance

thickness[mm]

rigidpolyisocyanurate foam

1 fire resistance of load bearing structure min. R30; max. distance between supports 3.0 m – vertical and horizontal assembly arrangement;2 fire resistance of load bearing structure correspondingly min. R15 or R30; max. distance between supports 3.0 m – vertical and horizontal assembly arrangement;3 fire resistance of load bearing structure min. R15; max. distance between supports 11.9 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement; providing that butyl sealing compound is used on both locks of

the panel;4 fire resistance of load bearing structure min. R30; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement; providing that butyl sealing compound is used on both locks of the panel;

fireresistance

thickness[mm]

from

inside

fromoutside

1 the inside is exposed to fire; fire resistance of load bearing structure min. R30; max. distance between supports 3.0 m – vertical and horizontal assembly arrangement;2 the inside is exposed to fire; fire resistance of load bearing structure correspondingly min. R15 or R20; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;3 the inside is exposed to fire; fire resistance of load bearing structure min. R15; max. distance between supports 8.8 m – vertical assembly arrangement and 4.0 horizontal assembly arrangement;4 the outside is exposed to fire; fire resistance of load bearing structure correspondingly min. R15 or R30; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;

fireresistance

thickness[mm]

2 fire resistance of load bearing structure min. R15; max. distance between supports 12.0 m – vertical and horizontal assembly arrangement;2fire resistance of load bearing structure min. R30; max. distance between supports 8.0 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;3fire resistance of load bearing structure min. R30; max. distance between supports 12.0 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;4

fire resistance of load bearing structure min. R60; max. distance between supports 9.1 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement

fireresistance

thickness[mm]

1 fire resistance of load bearing structure correspondingly min. R15 or R90; span bending moment Md ≤ 0.0940 kNm/m; support bending moment Md ≤ -0.1680 kNm/m; snow load 0.2xS must be taken into considera-

tion when doing calculations;2 fire resistance of load bearing structure correspondingly min. R20 or R30; span bending moment Md ≤ 0.1160 kNm/m; support bending moment Md ≤ -0.2070 kNm/m ; snow load 0.2xS must be taken into conside-ration when doing calculations;

3 fire resistance of load bearing structure correspondingly min. R30 or R60; span bending moment Md ≤ 0.1210 kNm/m; support bending moment Md ≤ -0.2150 kNm/m; snow load 0.2xS must be taken into conside-ration when doing calculations;

80/40 100/60 120/80 160/120140/100

REI 303

RE 603

REI 303

RE 603

REI 151

RE 901

REI 151

RE 901

REI 151

RE 901

REI 303

RE 603

REI 151

RE 901

REI 202

RE 302

REI 151

RE 901

REI 202

RE 302

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 17/24

Sandwich panels for walls and roofs

EI 602

EI 904

fireresistance

thickness[mm]

Ruukki SP2D W

1 the inside is exposed to fire; fire resistance of load bearing structure min. R60; max. distance between supports 11.1 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;2 the outside is exposed to fire; fire resistance of load bearing structure min. R60; max. distance between supports 11.1 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;3 the inside is exposed to fire; fire resistance of load bearing structure min. R60; max. distance between supports 4.0 m – horizontal assembly arrangement and 10.5 m – vertical assembly arrangement;4 the outside is exposed to fire; fire resistance of load bearing structure min. R1200; max. distance between supports 4.0 m – horizontal assembly arrangement and 11.0 m – vertical assembly arrangement;5 the outside is exposed to fire; fire resistance of load bearing structure min. R1200; max. distance between supports 4.0 m – horizontal assembly arrangement and 10.7 m – vertical assembly arrangement;

from

inside

from

inside

fromoutside

fromoutside

fireresistance

thickness[mm]

Ruukki SPC W

140/100 190/150

REI 601

RE 1801

1 fire resistance of load bearing structure correspondingly min. R60 or R180; span bending moment Md ≤ 0.1512 kNm/m, support bending moment Md ≤ -0.2700 kNm/m; snow load 0.2xS must be taken into considerationwhen doing calculations;

REI 601

RE 1801

fireresistance

thickness[mm]

Ruukki SPB W

1 fire resistance of load bearing structure min. R30; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;2 fire resistance of load bearing structure min. R60; max. distance between supports 11.9 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;3 fire resistance of load bearing structure min. R90; max. distance between supports 10.2 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;4 fire resistance of load bearing structure min. R120; max. distance between supports 9,9 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;

hard mineralwool

100

EI 601

EI 904

EI 601

EI 904

EI 601

EI 904

120 160140

EI 601

EI 602

EI 453EI 453

EI 904

EI 453

EI 904

EI 453

EI 904

EI 904

EI 1205

EI 904

EI 1205

EI 904

EI 1205

EI 904

EI 1205

or

80 100 120 200160140

EI 602

EI 903

EI 1204

EI 602

EI 903

EI 1204

EI 602

EI 903

EI 1204

EI 602

EI 903

EI 1204

EI 602

EI 903

EI 1204

EI 301

EI 602

EI 904

EI 602

EI 904

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 18/2418

Ruukki SPC S

140/100

RE 601

190/150

RE 601

Ruukki SPB S

60

-

80

EW 601

100

EW 601

140

EW 601

200

EW 601fireresistance

thickness[mm]

rigid polystyrene

1

fire resistance of load bearing structure min. R60; max. distance between supports 3.0 m – vertical and horizontal assembly arrangement;

fire

resistance

thickness[mm]

1 fire resistance of load bearing structure min. R60; span bending moment Md ≤ 0.0672 kNm/m, support bending moment Md ≤ -0.1200 kNm/m; snow load 0.2xS must be taken into consideration when doingcalculations;

fireresistance

thickness[mm]

Ruukki SPB WE

80 100 120 140

EI 151

El 302

El 603

El 1204

El 603

El 1204

El 603

El 1204

El 603

El 1204

El 603

El 1204

1 fire resistance of load bearing structure min. R15; max. distance between supports 12.0 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;2 fire resistance of load bearing structure min. R30; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;3 fire resistance of load bearing structure min. R60; max. distance between supports 4.0 m – vertical and horizontal assembly arrangement;4 fire resistance of load bearing structure min. R120; max. distance between supports 9.9 m – horizontal assembly arrangement and 4.0 m – vertical assembly arrangement;

soft mineralwool

fireresistance

thickness[mm]

Ruukki SP2D WE

100

EI 301

El 902

El 1203

120

EI 301

1 fire resistance of load bearing structure min. R30; max. distance between supports 4.0 m – horizontal assembly arrangement and 11.5 m – vertical assembly arrangement;2 fire resistance of load bearing structure min. R90; max. distance between supports 4.0 m – horizontal assembly arrangement and 11.0 m – vertical assembly arrangement;3 fire resistance of load bearing structure min. R120; max. distance between supports 4.0 m – horizontal assembly arrangement and 10.8 m – vertical assembly arrangement;

from

inside

fromoutside

160 200

160140

EI 30EI 301

El 902

El 1203

El 902

El 1203

El 902

El 1203

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 19/2419

Sandwich panels for walls and roofs

I

II

III

colourscolour group

RAL 1015, 7035, 9002, 9010

RAL 9006 RR 20, 21, 24, 30, 40

RAL 3013, 5005, 6011, 7016, 9007 RR 22, 23, 29, 34, 35, 36, 41

Facing colour groups

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 20/24

Accessories Corrosion resistance Facings and coatings

Steel flashings Standard length: 3000 mm.

Material: zinc-coated steel sheet.

Protective coating: polyester varnish.

Additional protection: foil.

Note: there is a possibility of making individual flashings

up to 6000 mm in length.

FastenersSelf-drilling:

• for hot-rolled structure (walls' thickness – 3-12 mm),

• for cold-bent structure (thickness – 1.5-5 mm).

Note: fasteners are available in galvanized or lacquered -

white versions. On special demand it is possible to provide

hoods or fasteners in external facing colour of a sandwich

panel.

Seals

• seals for Ruukki panels.

Other• instruments for installation and lifting of Ruukki pa-

nels,

• sealing collars for sealing wire passage (for example venti-

lation) within Ruukki panels,

• transparent panels,

• socket, pads etc. for Ruukki SP2E PU panels.

Corrosion resistanceOn the basis of research carried out, application possibi-

lities for Ruukki sandwich panels with organic coatings/

facings were confirmed in the following environments:

• Polyester coating of 25 µm, C1 to C3 category acc. to

EN ISO 12944-2: 2001.

• PVDF coating of 25 µm, C1 to C3 category acc. to

EN ISO 12944-2: 2001.

• Foil coating PVC (F) of 120 µm, category C1 to C4 acc.

to EN ISO 12944-2: 2001.

• Facing made of stainless steel of 0.55 or 0.60 mm,

C1 to C5-M category acc. to EN ISO 12944-2: 2001.

• Special CSafe coating, up to C4 category acc. to EN ISO12944-2:2001, providing better scratching, corrosion, dirt and

UV resistance as well as improved chemical resistance against

ammonia and sodium hydroxide.

Facings and coatingsRuukki sandwich panels are made of a structural insulation

core (rigid, HCFC-free, self-extinguishing polyurethane

foam, mineral wool of very good fire resistance, or

polystyrene) and two facings made of steel sheet gal-

vanized on both sides with organic coating. Standardsteel sheet is covered with polyester coating of 25 µm

thickness in colour compliant to Ruukki sandwich panels

colour scheme. From interior side, steel sheet has a coating

that increases core adherence. On special order we offer

Ruukki sandwich panels made of zinc-coated steel sheets

with the following organic coatings:

• PVDF coating of 25 µm thickness, in white colour as

standard (other RAL colours on request). PVDF coating

has excellent corrosion resistance and resistance to

mechanical damage; the coating also provides long

term colour stability, even in temperature up to 120°C.• PVC (F) film of 120 µm thickness, in white colour is a

special coating of increased hardness, to apply in food

industry construction works and cold stores. PVC (F)

film is not susceptible to blurs, it is also easily washable

and resistant to most industrial cleaning agents.

On special order we also offer sandwich panels with fa-

cings made of stainless steel:

• Corrosion resistant steel applied either on one or on

both sides of Ruukki wall panels SP2B PU and Ruukki

panels for cold-storage SP2E PU; panels with stain-

less steel facings are used in pharmaceutical and food

processing industry.

20

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 21/24

Sandwich panels for walls and roofs

R250 R275 R500 R550

Sandwich panels for walls and roofs

Assembling during winterAssemblig of panels which facing colours are in

III colour group [RAL 3013, 5005, 6011, 7016, 9007 &

RR 22, 23, 29, 34, 35, 36, 41] ought to be carried out

with min temperature 10°C.

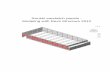

New span of ribbed profiling

In order to provide architects with additional

possibilities for creating interesting facades of

designed buildings we introduced new types of

ribbed profiling dedicated to external cladding

of wall sandwich panels with mineral wool core.

For Ruukki SP2D W and SP2D WE panel we offer

ribbed profiling with span of 250 mm and 500 mm.

For Ruukki SPB W and SPB WE - 1100 mm modular

width - we offer ribbed profiling with span of 275

mm and 550 mm. For Ruukki SPB W and SPB WE -

1000 mm modular width - we offer ribbed profiling

with span of 250 mm and 500 mm.

Features of ribbed profiling

Thickness of steel sheet used for external claddings

with new types of ribbed profiling is 0.60 mm.

It allows to achieve more interesting architectural

effect and also to provide sandwich panels with the

best fire resistance, thermal and acoustic insula-

tion parameters. Depth of ribbed profiling is ~1 mm,

ensuring thus clearly visible profiling result on

external cladding of facade panels.

Additional benefits

Sandwich panels with mineral wool core and new

types of ribbed profiling are a good alternative

for expensive solutions based on aluminum cas-

settes. Sandwich panels guarantee short instal-

lation time, easy selection of supplementary

elements, accessories and colours, maintaining

at the same time high quality look of designed

facade.

Ribbed profiling R250. Shopping center, Pila, Poland

21

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 22/24

For SP2D W and SP2D WE panels — ribbed profiling with span of

250 mm. Also available for SPB W panels with 1000 mm modular

width.

For SP2D W and SP2D WE panels — ribbed profiling with span

of 500 mm. Also available for SPB W panels with 1000 mm

modular width.

For SPB W and SPB WE panels with 1100 mm modular width —

ribbed profiling with span of 275 mm.

For SPB W and SPB WE panels with 1100 mm modular width —

ribbed profiling with span of 550 mm.

Details of ribbed profiling

~250

~ 1

~500

~ 1

~275

~ 1

~550

~ 1

22

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 23/24

Presented colours have a view character and maydiffer in tone from the exact RAL colour.

RAL coloursProf iling pattern

L Linear

S Sinusoidal

F Flat

P Embossed

R Ribbed

M Microprofiled

1 8

~90

~52 ~52 ~ 1

~ 1 ~28 (~250, ~275, ~500, ~550)

~16

9010

9002

9006*

1015

5005

6011

7035

7016

9007*

3013

* Due to the complexity of technological processes, manu-

facturers of sheets with organic coatings do not guarantee

uniform colour tints in successive delivery lots. It refers

particularly to steel sheets in metallic colours RAL 9006

and RAL 9007.

Therefore, in order to avoid any problems related to tint

differences and to maintain uniform colour of panel facing,

Buyer should agree with Seller in writing, prior to the con-

clusion of sales agreement, which part of the order/agree-

ment will refer to deliveries for one structure.

Once it is agreed by parties, Seller is obliged to fulfill

the order from one lot of input material. Otherwise Ruukki

Polska Sp. z o.o. bears no liability for possible differences

in colour tints.

In case of any questions please contact our Sales Depart-ment.

23

8/12/2019 Ruukki Sandwich Panels for Walls and Roofs

http://slidepdf.com/reader/full/ruukki-sandwich-panels-for-walls-and-roofs 24/24

C P L 02 1 E N / 0 5 .2 01 3

/ A r t &P r i n t S p .z o . o .

Ruukki Polska Sp. z o.o., Infoline 801 11 33 11

Customer service +48 46 85 81 600, +48 46 85 81 647, www.ruukki.comCopyright © 2013 Rautaruukki Corporation. All rights reserved. Ruukki is a trademark of Rautaruukki Corporation.

Related Documents