RUUKKI RD ® PILE WALL www.ruukki.com RETAINING WALL SOLUTION FOR ALL CONDITIONS

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

RUUKKI RD® PILE WALL

www.ruukki.com

REtaining wall solution foR all conditions

2 Ruukki RD® pile wall2 Ruukki RD® pile wall

Ruukki RD® pile wall 3

ExpERtisE in stEEl and foundation constRuction

Ruukki is one of the leading suppliers of steel founda-tion structures in Europe. Our domestic market includes the Nordic countries and the Baltic Sea Region, but ow-ing to our effective logistics we are also able to deliver solutions for demanding projects elsewhere in Europe. Ruukki is your skilled partner. The solutions we offer are economically competitive and technically advanced. They are based on versatile expertise and responsible operating procedures. For us, partnership with the cus-tomer means not only commitment to high reliabili-ty and promptness of delivery but also consulting in the design and implementation stage, if required. The RD® pile wall is Ruukki’s new retaining wall solution based on RD® piles. The RD pile wall is specially designed for

challenging conditions, for instance, for faster imple-mentation of retaining walls and other foundation structures.

You can always find the correct pile size and steel grade from Ruukki’s extensive RD pile and steel grade range, which allows you to implement a retaining wall or foundation structure with the best overall economy for all soil conditions and loading situations. By select-ing Ruukki’s delivery package you will also get all oth-er steel components, systems and overall solutions for your project’s foundation engineering with ease from one supplier.

4 Ruukki RD® pile wall

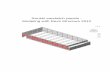

Figure 1. Principle of the RD® pile wall.

1. Rd® pile wall and applications general principle

The RD pile wall is based on Ruukki’s spirally or longitu-dinally welded steel pipe piles and interlocking sections attached by welding at the mill. The piles are drilled by the centric drilling method. The interlocking sections of the steel pipe piles were especially developed for the purpose by Ruukki. The matching dimensions of ring bits and interlocking sections allow installing RD pile walls by drilling through stones and boulders and even into bedrock, if necessary. A larger than normal ring bit is used to drill a hole larger than the outer diameter of the pile in soil, stones and bedrock.

4 Ruukki RD® pile wall

Ruukki RD® pile wall 5

permanent structures

The RD pile wall is best suited for permanent structures that require high vertical and horizontal load-bearing capacity. RD pile walls can also be installed reliably un-der challenging conditions, whereby the solution brings considerable savings in construction time and produc-es an end result of good overall economy. RD pile walls may even completely eliminate the need to build tem-porary retaining walls.

temporary structures

As a construction-period retaining wall structure the RD pile wall is particularly suitable for challenging soil conditions where the implementation of conventional retaining wall structures is difficult or impossible.

Horizontally loaded structures

The RD pile wall is an excellent solution for projects that require a higher bending stiffness and resistance than conventional sheet pile walls can offer. An RD pile wall built using large diameter RD piles provides high bending stiffness and resistance.

Vertically loaded structures

If the piles are extended to bedrock, the vertical load-bearing capacity of the RD pile wall is very high. Thus the structure can act as a horizontally loaded wall sub-ject to earth pressure and a foundation structure able to bear high vertical loads at the same time.

Ruukki RD® pile wall 5

6 Ruukki RD® pile wall

2. application examples

Building with a basement

The RD pile wall may be used to good advantage in buildings with one or more basement storeys. At these projects the RD pile wall serves as a permanent joint structure for vertical and horizontal loads. The solution is cost-effective because separate retaining wall struc-tures are not needed. The RD pile wall can be surface treated and allowed to remain an exposed wall struc-ture, for example, in a parking garage in a basement without internal cladding.

Ruukki RD® pile wall 7

Building with a column frame

The RD pile wall may consist of piles of variable length. Part of the piles of the RD pile wall can be extended to bedrock to ensure horizontal support for the lower end of the wall structure and to act as foundation piles that transmit column loads. The RD pile wall may also be built as a so-called Combi wall whose sheet piles are installed between the RD piles by driving them by per-cussion or vibration after the installation of the pipe piles.

construction-period retaining wall

The RD pile wall is an effective solution for construction period retaining wall structures if the soil contains lay-ers that are difficult to penetrate, high water tightness is required of the retaining wall, it is desired to mini-mise the number of support levels, or the retaining wall should be extended to rock. Installation of RD pile walls usually causes less vibration in the penetration of com-pact soil layers than the installation of sheet pile walls, which makes the RD pile wall very suitable for installa-tion close to vibration-sensitive structures.

Retaining walls of varying shapes

RD pile walls may be used for building wall entities of different geometric shapes. For instance, the walls can be circular or make angles of various degrees. If neces-sary, different pile sizes can be combined in the RD pile wall. Thus the wall structure can be optimised accord-ing to actual loads.

8 Ruukki RD® pile wall

Excavations and structures extended into bedrock

If the support of the bottom of the retaining wall, the excavation level or water tightness requires extend-ing the retaining wall securely into bedrock or sever-al metres into moraine containing stones and boulders, sheet pile walls cannot be used without special meas-ures such as pre-drilling, blastings, etc. A construction-period or permanent RD pile wall can be drilled to the desired level in bedrock. The rock bounded by the wall may be excavated up to the wall, whereby construc-tion work requires less space because a “rock shelf” on which the retaining wall rests is not needed.

Bridge abutments

The RD pile wall can be used as a bridge abutment. With the RD pile wall the vertical and lateral loads of the bridge and the horizontal loads of the embank-ment can be transmitted reliably to bedrock and soil. Use of the RD pile wall as an abutment allows building the bridge deck before excavation. Combined, for in-stance, with a method for moving the deck it minimises the traffic interruption during construction.

intermediate bridge supports

RD pile walls can be used for intermediate supports of bridges subject to heavy horizontal loads, such as im-pact loads, under difficult soil and environmental con-ditions. A closed frame extending into bedrock can be built with an RD pile wall under an intermediate col-umn and the soil removed from the top part for con-creting. The structure requires no separate construc-tion-period retaining structures and the foundation can be implemented in cramped conditions.

Ruukki RD® pile wall 9

Harbour wharves

RD pile walls can be used for building wharves in chal-lenging soil conditions. If necessary, the piles can be protected against corrosion, for example, by painting.The RD pile wall can be built of Ruukki’s high strength piles of grade S550J2H steel. The high strength steel grade provides the structure high bending resistance in relation to material consumption.

wind mill foundations

RD pile walls can be used to build integral foundation wall structures for off-shore facilities. The RD pile wall foundation is particularly suitable for conditions wherethe installation of large mono-piles requires special measures or, for example, a caisson foundation would require massive soil replacement. An RD pile wall foun-dation allows building wind mills also in shallow water under all soil conditions.

trough structures

RD pile walls can be used to implement water tight trough structures which allows, for example, build-ing a road below ground water level without lowering the surrounding ground water level. If the RD piles are extended water tightly into bedrock, there is no need to anchor the foundation slab of the trough struc-ture against buoyancy. In construction-period retain-ing walls pipe piles can be used as construction-period pump wells to keep the excavation dry.

10 Ruukki RD® pile wall

3. Rd® pile wall products

piles used in the Rd® pile wall

Pile sizes RD170 to RD1200 can be used in the RD pile wall. The piles are delivered in exact design lengths and bevelled, if necessary. The pile sizes available for the RD pile wall are presented in Table 1.

steel grades of piles

S440J2H and S550J2H produced by Ruukki for piling pur-poses can be used for RD pile walls. In pile walls us-ing RD400 or larger piles it is also possible to use steel grades S355J2H, X60 and X70. The selection of the steel grade has a marked impact on the structural resistance of the pile wall. Selecting a stronger steel grade such as S550J2H often allows using piles of smaller diameter or wall thickness. Available steel grades are presented in Table 1. The chemical and mechanical properties of the piles are presented in Table 2.

interlock types

In the RD pile wall the pipe piles are attached to each other by interlocking sections. Adjacent piles are always interlocked using a pair of interlocking sections, a nar-row and a wide one. Two different interlock types de-veloped for the RD pile wall are available: the Ruukki RM/RF interlock, Figure 2, and the Ruukki E21 interlock, Figure 3.

Ruukki’s new RM/RF interlock and the injection channel integrated in it ensure the water tightness of the bot-tom of the RD pile wall and its rigid contact with rock without separate injection pipes.

The Ruukki RM/RF interlock can be used with pile sizes RD170 to RD 1200. The Ruukki E21 interlock is suitable for pile sizes RD400 to RD600.

Pile Diameter Wall thickness [mm]

[mm] 8 10 12,5 14,2 16 18 20RD170 168,3

RD220 219,1

RD270 273,0

RD320 323,9

RD400 406,4

RD500 508,0

RD550 559,0

RD600 610,0

RD700 711,0

RD750 762,0

RD800 813,0

RD900 914,0

RD1000 1016,0

RD1200 1220,0

Steel grades S355J2H, S440J2H, S550J2H, X60 and X70

Steel grades S355J2H and S440J2H

Steel grades S440J2H and S550J2H

Figure 2. Ruukki RM/RF interlock Figure 3. Ruukki E21 interlock

Table 1. Pile sizes and steel grades.

manishkumarsingh

Highlight

Ruukki RD® pile wall 11

Sufficient water tightness of the section is ensured e.g. by bitumen-based sealing compound.

waterproof Rd® pile wall

Bottom of RD pile wall embedded in rock. The space between the bedrock and pile can be injection sealed e.g. through the injection channel of the RM/RF interlocking section.

Groundwater pressure

Steel grade Carbon equivalent Chemical composition max. Mechanical properties

Impact strength

CEV max. C Mn P S fy min fu A5 min T KV min

[%] [%] [%] [%] [%] [MPa] [MPa] [%] [°C] [J]

S355J2H 0,45 0,22 1,6 0,03 0,03 355 470-630 20 -20 27

S440J2H 0,39 0,16 1,6 0,02 0,02 440 490-630 17 -20*) 27

S550J2H 0,43 0,12 1,9 0,02 0,02 550 605-760 14 -20*) 27

X60 0,43 0,19 1,75**) 0,03 0,03 415 ≥520 18 0 27

X70 0,43 0,19 2,00**) 0,03 0,03 485 ≥570 18 0 27

**) Manganese content can be increased if carbon content is decreased. API 5L/ISO 3183 Table 4, Note b.*) At wall thicknesses exceeding 12.5 mm impact strength values are determined separately.

Table 2. Chemical and mechanical properties of piles.

12 Ruukki RD® pile wall

4. design

general

RD pile walls can be designed either according to the Eurocode design standards or the national code of building regulations. The RD pile wall is dimensioned as a conventional retaining wall structure. If the RD pile wall is subjected to significant vertical loads, the de-sign and dimensioning practices of pile foundations are applied in the design.

Engineering requires adequate input data about the following: soil conditions at the wall and a sufficient distance from it, the groundwater conditions, effects of the environment and the preconditions set by the envi-ronment such as foundation types of nearby structures, the size and nature of the structure to be supported, the loading and design life of the RD pile wall.

Ruukki´s extensive pile size and steel grade range is available for the design of RD pile walls, which allows cost effective structural design.

Piles can be drilled through all soil layers and extend-ed into bedrock, if necessary. The positional deviations and curvatures of piles are small.

geotechnical and structural design

Ground investigations are used in the design stage of a RD pile wall to discover the geotechnical properties of the soil and the groundwater conditions in order to determine the earth pressures on the support struc-tures. Ground investigations are also used to determine pile installation level, so that piles can be ordered cut to length to avoid unnecessary waste. If the pile wall is to be extended into bedrock, the variations and quali-ty of the bedrock surface are established by a sufficient number of percussion drillings.

Piles extended into bedrock should be drilled at least 500 mm into it, irrespective of the working principle of the wall. Piles transmitting vertical loads and piles whose lower ends are subject to significant moment loads and/or shear forces are recommended to drill into solid rock to a depth 3 times the pile diameter. For piles over 300 mm in diameter, sufficient drilling depth is determined case by case, but drilling more than 1500 mm into solid bedrock is not necessary in regular Nor-dic bedrock.

If the RD pile wall is designed according to the Euroco-des as a support structure, the design and dimension-

ing principles of EN 1997-1, Section 9, are observed. If the RD pile wall serves as the foundation of a building, vertical equilibrium must be checked according to the principles of EN 1997-1, Section 7. When installed in sol-id bedrock, the geotechnical resistance of the pipe pile wall is always higher than the resistance of the wall structure.

The structure of an RD pile wall can be designed as a steel structure or as a steel-concrete composite struc-ture. If the pile wall is subject to normal force in addi-tion to bending moment, the pile wall must be dimen-sioned for the combined stresses. The corrosion of steel piles must be considered in the case of long-term and permanent structures if the piles are not corrosion pro-tected.

Table 3 presents some sectional properties and bend-ing moment resistances of RD pile walls with no cor-rosion allowance. A Combi wall dimensioning program can be downloaded from Ruukki’s Toolbox, software.ruukki.com, which also allows calculating the bending stiffness and moment resistance of the wall as a steel structure with various corrosion allowances.

Tekla components can also be downloaded from Ru-ukki’s Design Toolbox for the design of an RD pile wall. They make the design work that involves tolerances and order forms easy.

manishkumarsingh

Highlight

manishkumarsingh

Highlight

manishkumarsingh

Highlight

Ruukki RD® pile wall 13

RD pile wall

Pile Sectional properties and bending moment resistances of RD pile wall,corrosion O mm

D[mm]

t[mm]

Weight[kg/m2]

b[mm]

Wel[cm3/m]

EI[kNm2/m]

S355J2HMel

[kNm/m]

S440J2HMel

[kNm/m]

S550J2HMel

[kNm/m]

Interlock type Ruukki RM/RF

RD170168,3 10,0 228,7 232 800 14 138 - 352 440168,3 12,5 267,4 232 956 16 890 - 421 526

RD220219,1 10,0 232,0 283 1 160 26 693 - 511 638219,1 12,5 274,8 283 1 401 32 228 - 616 770

RD270273,0 10,0 234,3 337 1 555 44 580 552 684 855273,0 12,5 280,1 337 1 891 54 198 671 832 1 040

RD320323,9 10,0 235,9 388 1 935 65 822 687 852 1 064323,9 12,5 283,8 388 2 363 80 376 839 1 040 1 300

RD400406,4 8,0 197,1 470 2 079 88 723 738 915 1 144406,4 10,0 237,8 470 2 561 109 267 909 1 127 1 408406,4 12,5 288,1 470 3 142 134 065 1 115 1 382 1 728

RD500508,0 10,0 239,4 572 3 340 178 134 1 186 1 469 1 837508,0 12,5 291,7 572 4 113 219 382 1 460 1 810 2 262508,0 14,2 327,0 572 4 625 246 708 1 642 2 035 2 544

RD600

610,0 10,0 240,5 674 4 127 264 359 1 465 1 816 2 270610,0 12,5 294,2 674 5 096 326 387 1 809 2 242 2 803610,0 14,2 330,5 674 5 740 367 668 2 038 2 526 3 157610,0 16,0 368,7 674 6 411 410 595 2 276 2 821 3 526

RD700

711,0 10,0 241,3 775 4 911 366 623 1 743 2 161 2 701711,0 12,5 296,0 775 6 074 453 446 2 156 2 673 3 341711,0 14,2 333,0 775 6 850 511 412 2 432 3 014 3 768711,0 16,0 372,0 775 7 660 571 850 2 719 3 370 4 213

RD800

813,0 10,0 241,9 877 5 704 486 960 2 025 2 510 3 137813,0 12,5 297,4 877 7 065 603 086 2 508 3 109 3 886813,0 14,2 335,0 877 7 975 680 800 2 831 3 509 4 386813,0 16,0 374,7 877 8 926 761 990 3 169 3 928 4 909

Interlock type Ruukki E21

RD400406,4 8,0 190,2 502 1 947 83 072 691 857 1 071406,4 10,0 228,2 502 2 398 102 307 851 1 055 1 319406,4 12,5 275,1 502 2 942 125 526 1 044 1 294 1 618

RD500508,0 10,0 231,3 604 3 163 168 696 1 123 1 392 1 739508,0 12,5 280,7 604 3 895 207 759 1 383 1 714 2 142508,0 14,2 314,0 604 4 380 233 638 1 555 1 927 2 409

RD600

610,0 10,0 233,5 706 3 940 252 376 1 399 1 734 2 167610,0 12,5 284,6 706 4 865 311 593 1 727 2 141 2 676610,0 14,2 319,2 706 5 480 351 003 1 945 2 411 3 014610,0 16,0 355,5 706 6 120 391 984 2 173 2 693 3 366

Table 3. Sectional properties and bending moment resistances of the RD® pile wall.

Run of pile

Column b

a b dc

14 Ruukki RD® pile wall

Figure 4. Improving the water tightness of an RD® pile wall with a sealing agent (Figure a) or grouting (Figure b) andensuring water tightness by welding (Figures c and d).

water tightness and groundwater management

The water tightness of the RD pile wall is usually suf-ficient, and under some conditions the wall is almost watertight without any special measures. The water tightness of the RD pile wall is affected strongly by the properties of the soil. It can be said generally that at low water permeability of the soil (fine-grained soils) and moderate differential water pressure across the wall (<50 to 80 kPa), the amount of water penetrat-ing the interlock is negligible. With increasing differen-tial water pressure and highly water-permeable soils, the probability of leaks through the interlock increases. Due to the installation method, no significant stresses are exerted on the interlocking sections during instal-lation and no leakage points form in them due to de-formations of the sections.

If necessary, the water tightness of the RD pile wall can be improved by applying on site a hot bitumen-based sealing agent onto the wider interlocking section, Fig-ure 4a. Water tightness can also be improved by using sealing compound that expands in contact with wa-ter or by injecting the area at the interlock behind the wall, Figure 4b.

The best possible water tightness of the RD pile wall can be achieved by welding shut the space between the interlocking section and the pipe pile after the exca-vation has been completed, Figure 4c. If water leaking through the interlocking section prevents closing the interlocking section by welding, a flat bar can be weld-ed in front of the interlock, Figure 4d.

The water tightness of the lower end of the RD pile wall depends strongly on the groundwater conditions and the water permeability of the bedrock and the soil layer

directly above it. With conventional sheet pile walls it is often difficult to achieve sufficient water tightness of the lower end of the wall without a concrete beam and/or grouting the soil and bedrock, because the retain-ing wall cannot be extended to follow tightly the bed-rock surface which allows water to flow across the sur-face under the wall.

When the piles of the RD pile wall are extended into bedrock, they block the direct flow route of wa-ter through the lower end of the wall, which consid-erably reduces, or may completely prevent, the filtra-tion of water into the area inside the wall. When the RD pile wall extends into bedrock, the water tightness of its lower end can be ensured, if necessary, by grouting the space between the piles and bedrock. If the exca-vation is extended to the rock surface using an RD pile wall, it is possible to insert a concrete beam at the in-terface between the wall and bedrock. If necessary, ground water flow across the bedrock can be prevent-ed by sealing the bedrock under the retaining wall by grouting it through the pile piles.

If the lower ends of the piles in the RD pile wall are open, they may be used as pump wells to lower the ground water table, if necessary.

grouting

The injection channel of the Ruukki RF interlock can be made use of in injecting the bottom of the RD pile wall. It allows injecting the area underneath the bottom ends of the interlocks. By connecting horizontal injec-tion channels installed at the lower ends of piles to the injection channel of the RF interlock, the water tight-ness of the tips of piles can be ensured reliably and the contact between piles and rock made rigid.

a b

Ruukki RD® pile wall 15

Figure 5. Grouting behind the RD® pile wall.

Different types of post-injections can also be used on the unexcavated side of the RD pile wall e.g. to improve water tightness of the structure or to compact or rein-force the soil behind the wall. Injection of the back-ground of an RD pile wall can be implemented by drill-ing or driving injection pipes behind the wall or to the joints of piles after the wall piles have been installed, Figure 5.

If necessary, injection pipes can also be attached to pile pipes before pile installation. With Ruukki’s E21 inter-

locking sections, injection pipes can be used to ensure contact between the bottom of a pile wall and rock and water tightness.

Water tightness of the section below excavation lev-el can also be improved by performing an injection on the excavation side of the RD pile wall below excava-tion level. The bedrock below the wall can be inject-ed through the piles of the RD pile wall. Injection can be performed using e.g. cement- or bentonite-based grouts.

16 Ruukki RD® pile wall

support of Rd® pile walls

The lower end of an RD pile wall can be supported on bedrock by drilling all or part of the piles into it. The lower end can also be supported on bedrock by drilling separate anchors, rock dowels or smaller drilled piles through the pile pipes into the bedrock. When the piles are installed in bedrock, a concrete beam in the low-er end of RD wall is not normally needed to support the lower end of the wall. If the RD pile wall is not extend-ed into bedrock, it is supported by passive earth pres-sure like a conventional retaining wall structure. Owing to the high bending stiffness of the RD pile wall, the distance between the support levels can be made long-er compared, for instance, to a sheet pile wall. By ex-tending the RD pile wall sufficiently into bedrock and by grouting behind the interlocking sections, if nec-essary, the retaining wall can be made to act partly as a mast structure of high bending moment stiffness, which reduces the need of support levels. The RD pile wall can be supported by internal or external supports.

The RD pile wall structure may be supported internally by bracing if the opposite RD pile wall or other structure providing support is sufficiently close. In permanent structures, for example, a ground slab, the intermedi-ate floors of a building or the deck structure of a trough may act as horizontal braces.

The RD pile wall can be supported externally by soil or rock anchors, or by tension rods attached to an-chor plates like with other retaining wall structures. If external support is needed, anchors can be installed through the interlocking part of the RD pile wall, if the diameter of the hole needed for the anchor bar does not exceed 60 mm with the RM/RF interlock type or 90 mm with the E21 interlock type. If the hole needed for the anchor bar is larger, the bars are installed through a pile. If the support level can be located at the upper end of the RD pile wall, it is possible to make a separate console structure to avoid making holes for the bars in the piles.

soil deformations near the Rd® pile wall

Soil deformations near RD pile walls are affected most by soil properties but also by the drilling system, the implementation of the drilling work and the interlock type. RD pile walls are installed using oversized ring bits so as to leave a theoretical empty space outside the pile piles. The size of the empty space depends on the used pile size and interlock type.

In compact frictional soils only little soil deformations occur near the RD pile wall. If compressed air flush-ing is used in the drilling, the empty space caused by

Ruukki RD® pile wall 17

Figure 6. Examples of making a 90 degree angle in anRD® pile wall

the oversized ring bit is filled partly or entirely by drill cuttings. If the aim is to minimise deformations, com-pressed air and percussion force should be used only to the extent that flushing works and the drilling pro-gresses at a suitable rate.

In loose frictional and made-up ground and soft cohe-sive soils settlement may take place in the immediate vicinity of the wall. The settlement may be caused by the filling of the empty space with the subsoil next to the wall. It may also be due to compressed air escaping outside the pile and the resulting loosening and distur-bance of soil layers.

Noticeable settlements may occur within half the pile length from the wall line. The extent of the settlement depends strongly on the soil. To minimise settlements, it is recommendable to use the RM/RF interlock type and a drilling system that allows the least amount of compressed air to escape into the soil around the pile.

Settlement of soft cohesive soils can be avoided by a technique where soil layers are penetrated by pressing or vibrating the open pipe pile with a variable frequen-cy vibrator to the bottom of soft soil layers. Thereafter, pile installation is continued by drilling. This technique requires the use of a so-called integrated ring bit. When installing a micropile wall (RD170-RD270) a water-powered hammer with so-called external flushing can be used, which causes the empty space to be filled by drill cuttings and keeps soil deformations small.

On sites sensitive to settlements and displacements, where special attention is to be paid to the manage-ment of settlements, it is recommended to start the work by performing tests away from the structures to be minded or to perform a pilot installation before the actual one for reliable assessment of settlements.

shapes, joints and tolerances

The necessary angle changes in the RD pile wall line are implemented by welding the interlocking sections at the desired angle, Figure 6.

Interlocking sections welded on opposite sides of a pile in line with each other do not allow angular devia-tion from a straight wall line. Angular deviations must be implemented by welding interlocking sections at the desired angle.

The theoretical run of a pile wall are presented in Ta-ble 3. The actual run of a wall, however, varies slight-ly due to pile deformation during installation, the out-ofroundness of pile pipes and the play of interlocking sections. The average width of a pair of joined inter-locking sections equipped with Ruukki RM/RF interlocks is 64 mm and play about ±4 mm, while with Ruukki E21 interlocks the respective values are 96 mm and about 3 mm. According to standard SFS-EN 10219, the out-of-roundness tolerance of a structural pipe is 2 % of its outside diameter. By special order, the out-of-round-ness tolerance of spirally welded piles (≥RD400) with interlocks may, however, be made smaller.

The sizes of tolerances transverse to the wall line are affected most by shifts in position during installation. These shifts in position can be limited by using a suf-ficiently sturdy guide frame with respect to pile size through which the piles are installed.

Both wall tolerances and installation tolerances must be considered in design. In the design and implemen-tation of wall lines tolerances must be taken into ac-count especially if the wall incorporates frame columns. As a rule, the implementation of installation and the installation sequence ought to be considered already at the wall design phase so as to keep the number of wall ends that need to be joined to each other at a mini-mum. Data presented in the designs are presented in Figure 11 on Page 23.

18 Ruukki RD® pile wall

stallation tolerances for drilled piles are observed in in-stallation.

The RD pile wall can be joined to a sheet pile wall if the interlocking sections of the latter match those of the RD pile wall. If the interlocking sections of the walls to be joined are different, a joint profile must be used to con-nect the interlocks of different types. When a sheet pile wall is extended by an RD pile wall, a wide interlocking section is attached to the RD pile used at the joint. If an RD pile wall is extended by a sheet pile wall, a narrow interlocking section is attached to the RD pile.

surface treatments and linings

The piles for an RD pile wall may be delivered corrosion protected, Figure 9. The corrosion protection is provided by a protective paint system according to standard EN ISO 12944-5. Surface preparation, implementation and super-vision of painting as well as tests on the coating are done in accordance with standard EN ISO 12944. The interlocking sections and possible sheet piles of the Combi wall may also be painted against corrosion. If protective painting is done before installation, the painted surface may get damaged during installation depending on the prevailing conditions.

An RD pile wall can be equipped with various lining struc-tures as necessary. Internal thermal insulation can be im-plemented, for instance, by polyurethane foam. Structures that need not be completely water tight can be lined, for instance, by shotcrete accompanied by installation of ver-tical drainage systems at the interlocking sections.

When the RD pile wall is used as a bearing structure that may take a fire load, such as in an underground parking garage, fire protection rules and regulations must be fol-lowed in the design and implementation of such a struc-ture.

Due to the longitudinal tolerances of the wall, imple-mentation of a closed wall, i.e. a wall where the last pile is joined by an interlock to the starting pile, is dif-ficult. The exact pile spacing of a closed wall is not known before other phases of the installation have been completed. The joining of wall ends can be ac-complished by overlapping the end piles, Figure 7. Piles of smaller diameter are used in the overlapping. The number of overlapped piles may be one or more, and the piles can be welded together at the point of over-lap. Wall ends may also be overlapped using a pile that has no interlock but has a normal size ring bit. The pile is placed on the unexcavated side of the wall and is supported by installed wall piles, Figure 8. Ensuring the water tightness of overlapping solutions may require grouting of the soil around joints. It is recommendable to take into account the end joints and the RD piles re-quired for them already during the RD pile wall design phase.

Special attention must be paid to the verticality of the piles of the wall if the wall is to be made into a closed structure or if there is some other reason for setting tighter requirements for the verticality of the wall than normal installation tolerances for drilled piles.

If the ends of the wall do not join other structures or verticality otherwise is of no concern, the normal in-

Figure 9. Coating of an RD® pile wall by painting.Figure 8. Joining of wall ends by a loose pile.

Figure 7. Joining of wall ends by overlappingSteelPrimerFinish

Ruukki RD® pile wall 19Ruukki RD® pile wall 19

20 Ruukki RD® pile wall

Figure 10. Ending of interlocking section when it is desired to install a pile at a lower level than the previous one.

5. installation

drill bits

The RD pile wall is installed with the centric drilling method using ring bits of a larger diameter than stand-ard bits. The ring bit drills a hole larger than the pile to accommodate the pile’s interlocks. The recommend-ed ring bit diameters for different piles and interlocking sections are presented in Table 4.

There are two basic types of ring bits: a solitary type not locked into the casing shoe, and a type integrat-ed into it. Both types can be used for the RD pile wall. The ring bit and the casing shoe will remain part of the pile’s load-bearing structure, which means that they must be able to take the stresses exerted on them.

installation equipment

The installation of an RD pile wall places no special de-mands on the features of the installation equipment which means that normal pile drilling equipment can generally be used. However, it must be ensured that jaws and other parts of the equipment can accommo-date the interlocking sections welded to the sides of piles. It is recommended that the jaws have a support that comes against the interlocking section to prevent the pile from rotating during installation.

Use of the longest possible pile sections to minimise splice welds facilitates pile wall installation.

installation

An RD pile wall can be installed either in the direction of the wall line by backing up the drilling rig, or from the side, depending on the equipment used. The wall can be installed from either side or in either direction. However, installation is always done so that a narrow interlocking section is on the side of direction of instal-lation. The first pile of an RD pile wall must not have a wide interlocking section. Installation may also begin from the middle of the wall line or from a corner using a pile onto which two similar narrow interlocking sec-tions have been attached.

When an RD pile encounters a large stone, boulder or bedrock, the pulldown force is kept low and rotation speed is increased. That reduces the tendency of the pile to change direction during drilling. It also ensures a reliable installation process as stresses on the inter-locking sections and friction remain low.

On a slanting bedrock surface it is advisable to install the piles of an RD pile wall in the direction of upward sloping bedrock so that the interlocking sections can be extended close to the tip of the pile pipe. If it is as-sumed that the bedrock surface declines in the direc-tion of installation, and a pile has to be driven deep-er than the previous one, the wide interlocking section must not extend to the tip of the pile, Figure 10. If a wide interlocking section extends to the tip of a pile, it collides with the ring bit of the previous pile preventing installation at a lower level than the previous pile. In the case of pile walls whose lower section is subject to water-tightness requirements, the interlocking sections must extend as low as possible.

For instance, if it is desired to install a pile 3 metres deeper than the previous one, the interlocking section must end at least 3 metres before the pile end, Fig-ure 10. Since that requires installing the pile for the first 3 metres without the pile being joined to the previous one by an interlocking section, it is recommendable to

RD-paaluseinä

Ruukki RD® pile wall 21

use an installation frame to keep the piles aligned and to allow connecting the interlocking sections.

During the installation of the first pile it must be en-sured that the interlocking profiles stay aligned as planned and the pile pipe does not rotate. Each sub-sequent pile is always supported by the previous one which ensures better alignment. If highly accurate alignment is required, it is recommendable to install the piles through a guide frame built at ground level.

Work safety must be ensured at all stages of piling. Pressure may build inside installed piles during drilling, and its sudden discharge up along the pipe constitutes a hazard. Pile ends must be closed securely against pressure shock and due to risk of falling.

splicing and cutting of piles

RD piles with interlocks can be spliced by welding if the required pile length exceeds the standard length pile that can be installed using the available pile drilling equipment. Splicing is done as normally with RD piles. The piles intended to be spliced are to be specified al-ready when placing the order so that they can matched and marked as pairs. This makes splicing of piles on site much easier. National codes present the requirements for splice welding. In connection with pile splicing, it must be ensured that no angle change occurs between pile sections. Splice welding of the interlocking sec-tion area on-site requires special attention. If neces-

PilePile diameter

[mm]

Interlock type

Ruukki RM/RF Ruukki E21

Ring diameter [mm] Ring diameter [mm]

RD170 168,3 222 -

RD220 219,1 273 -

RD270 273,0 327 -

RD320 323,9 378 -

RD400 406,4 460 500

RD500 508,0 562 602

RD600 610,0 664 704

RD700 711,0 765 -

RD800 813,0 867 -

RD900 914,0 968 -

RD1000 1016,0 1070 -

RD1200 1220,0 1274 -

Table 4. Recommended outer diameters of ring bits

sary, bevels can be cut in the interlock on site so that the pile can be reliably welded also at the interlocking section.

When the RD pile has reached its target level, the pile section remaining above ground can be cut off. The need to cut depends on the used drilling equipment. If the next pile can be installed in the previous one’s in-terlock that may extend quite high above ground lev-el, there is no need to cut the previous pile to facilitate the work.

The final cutting of piles is done at planned levels per-pendicularly. Piles may be cut, for instance, by a flame cutter or a plasma cutter.

Reuse of piles

The piles of an RD pile wall installed in temporary structures may be reused several times. If necessary, RD piles are to be filled with soil before extracting them so as to avoid major settlements or hazards. After the extraction of a temporary RD pile wall, the underlying subsoil and possible structural layers must be compact-ed to the density required by the site. The extraction may be done, for instance, by a vibratory hammer.

The impact of a possible integrated ring bit on pile ex-traction should be considered in the case of RD pile walls to be extracted.

22 Ruukki RD® pile wall

6. production, quality controland delivery terms of products

production and quality control

Ruukki follows in its operations procedures that comply with the requirements of ISO 9001:2008 quality manage-ment system and ISO 14001:2004 environmental manage-ment system. Quality management systems ensure the functioning of processes from raw materials procurement to delivery of the end product to the customer.

Ruukki steel pipe piles are made of the high grade steel produced at the company’s Raahe Steel Works. Large diameter (RD400) steel pipe piles are manufactured by spiral joint welding and small diameter piles (RD320) by longitudinal welding.

Interlocking sections are welded simultaneously to both sides of spirally welded RD piles on an automated pro-duction line. Special attention has been paid to control of deformations of steel pipes due to the welding of in-terlocking sections.

The quality of large diameter RD piles based on stand-ard EN10219-1 and accessory work of the piles made by Ruukki are certified by the CE marking.

The steel piles used in Ruukki´s RD-pilewall are CE marked products and they have been granted an European technical approval ETA-12/0526.

technical delivery conditions

The technical delivery conditions of piles comply with standard EN 10219-1. Dimensions and tolerances comply with standard EN 10219-2. A material certificate in ac-cordance with EN 10204 type 2.2 or 3.1 for the pile ma-terial is provided.

Ruukki RD® pile wall 23

Figure 11. Data included in RD® pile wall designs.

The pile situation plan for the RD pile wall must show:

• Piles with individual identifiers; code or colour• Installation starting points• Direction of installation• Possible wall-end joints and details

Dis

tan

ce o

f w

ide

inte

rloc

k fr

om h

ead

of

pile

Dis

tan

ce o

f on

-si

te m

ade

splice

fro

m h

ead

of

pile

Ove

rall len

gth

of

wid

e in

terl

ock

Dis

tan

ce o

f w

ide

inte

rloc

k fr

om t

ip o

f p

ile

Dis

tan

ce o

f n

arro

w

inte

rloc

k fr

om h

ead

of

pile

Ove

rall len

gth

of

nar

row

in

terl

ock

Dis

tan

ce o

f n

arro

w

inte

rloc

k fr

om t

ip o

f p

ile

Ove

rall p

ile

len

gth

Angle between interlocks

Top view of pile

In deviation from the assumption:Narrow interlockNo interlock

Pile identifier:

Pile size:

Wall thickness:

Pile steel grade: S355J2H

S440J2H

S550J2H

X60

X70

Interlock type: Ruukki RM/RF Ruukki E21

Splicing on site: yes no

Necessary end bevels must be made known when placing order.

Pile accessories: Grouting pipes Other accessories

A plan of all accessories must be presented.

Starting point

Starting point

Joint

Joint

Direction of installation

Direction of installation

Basic principle:

In deviation from the assumption:No interlock

Energy-efficient steel solutions for better living, working and moving.

Ruukki Construction Oy, Harvialantie 420, 13300 Hämeenlinna, FinlandTel. +358 20 5911, Fax +358 20 592 5656, www.ruukki.com

Copyright © 2012 Rautaruukki Corporation. All rights reserved. Ruukki, Rautaruukki, Living. Working. Moving.

and Ruukki’s product names are trademarks or registered trademarks of Rautaruukki Corporation

CFI 03.0

20EN

/05.20

13/PR/H

K

Related Documents