-

8/12/2019 Report 4correction

1/90

Flux optimization for indirect vector control of induction motor

i

Abstract

The industrial sector is the largest users of energy around the world and induction motor

uses a major fraction of it. Adjustable speed drive system is very important in energy saving

viewpoint. In this project, the rotor flux oriented indirect vector control with flux optimization

is implemented. An indirect vector control method has a good dynamic performance due to

the inherent decoupling between d-axis (flux producing component) and q-axis (torque

producing component) components of current, similar to a separately excited DC machine.

The Induction motor gives maximum efficiency at full load condition, but generally motor is

not fully loaded. The efficiency is less at low load condition. The motor can be operated with

maximum efficiency even at low load condition by altering the flux value. At each load

condition the value of flux can be estimated so that iron and copper losses would remain

same. According to the flux optimization theory, we get the maximum efficiency even at

light load condition by making both copper loss and iron loss equal. Vector control of

induction motor enables the independent control of flux and torque as in dc machine which is

superior. Indirect vector control has very good dynamic performance. The simulation results

of the flux optimization scheme of indirect vector controlled induction motor shows the

validity of the proposed system. The hardware implementation is done for a fractional horse

power motor using DSP, a high speed processor.

-

8/12/2019 Report 4correction

2/90

Flux optimization for indirect vector control of induction motor

ii

Contents

Abstract ........................................................................................................................................ i

List of tables .............................................................................................................................. iv

List of Figures ............................................................................................................................ iv

Abbreviations / Notations / Nomenclature ............................................................................... vii

Chapter 1 .................................................................................................................................... 1

Introduction ................................................................................................................................ 1

1.1 Literature survey ............................................................................................................... 1

Chapter 2 .................................................................................................................................... 3

Mathematical modeling of Induction motor ............................................................................... 3

2.1 Working ............................................................................................................................ 3

2.2 Axes Transformation ........................................................................................................ 4

2.3 Mathematical Model of Induction Motor ......................................................................... 6

Chapter 3 .................................................................................................................................... 9

Vector or Field Oriented Control ............................................................................................... 9

3.1 Introduction ....................................................................................................................... 9

3.2 Working .......................................................................................................................... 10

3.3 Equivalent Circuit and Phasor Diagram ......................................................................... 11

3.4 Principle of Vector Control ............................................................................................. 13

3.5 Indirect Vector Control ................................................................................................... 14

3.6 Flux Optimization Scheme ............................................................................................. 17

Chapter 4 .................................................................................................................................. 20

Matlab Simulation and Results ................................................................................................. 20

4.1 Pulse Width Modulation (PWM) .................................................................................... 20

4.1.1Carrier Based PWM .................................................................................................. 214.1.2 Space Vector PWM .................................................................................................. 21

4.1.3Duty cycle ................................................................................................................. 25

4.2 Space vector PWM Simulation ....................................................................................... 27

4.3 Matlab Simuation ............................................................................................................ 28

4.4 Result .............................................................................................................................. 34

Chapter 5 .................................................................................................................................. 35

Hardware implementation ........................................................................................................ 355.1 .Schematic Block Diagram of the System ...................................................................... 36

-

8/12/2019 Report 4correction

3/90

Flux optimization for indirect vector control of induction motor

iii

5.2 Design of Three Phase Inverter ...................................................................................... 37

5.3 Design of Gate Driver Circuit ......................................................................................... 39

5.4. Design of PCB Layout for Inverter and Gate Driver using CadSofts Eagle software . 40

5.5. Design of Voltage and Current Sensing Circuit ............................................................ 42

5.6 Laboratory Setup of the Complete System ..................................................................... 44

5.7.1Features of the controller........................................................................................... 47

5.7.2 Block diagram of TMS320F28069 .......................................................................... 47

5.7.3 General-Purpose Input /Output (GPIO) ................................................................... 48

5.7.4Event Manager .......................................................................................................... 48

5.7.5ADC .......................................................................................................................... 49

5.7.6 PWM ........................................................................................................................ 49

5.7.7 Calculating PWM Period and Frequency ................................................................. 50

Chapter 6 .................................................................................................................................. 52

HARDWARE RESULTS ......................................................................................................... 52

6.1 Calculation of TBPRD for ePWM module of TMS320F28069 ......................................... 52

6.2:Testing and Calibration of Current and Voltage Sensing Board .................................... 53

Chapter 7 .................................................................................................................................. 57

Conclusion and future scope..................................................................................................... 57

Conclusion ............................................................................................................................ 57

Future Scope ......................................................................................................................... 58

References ............................................................................................................................. 59

Published paper ..................................................................................................................... 60

Appendix I - LEM Current Sensor data sheet ....................................................................... 77

Appendix IIIGBT data sheet ............................................................................................. 78

Acknowledgement ................................................................Error! Bookmark not defined.

-

8/12/2019 Report 4correction

4/90

Flux optimization for indirect vector control of induction motor

iv

List of tables

TABLE. 1:The switching time of the active vector for each sector...................................................... 25

TABLE. 2:Duty time for each sector.................................................................................................... 26

TABLE. 3: Power At Different Load Condition............................................................................ 34

TABLE. 4:Components used for hardware setup of three phase inverter............................................. 38

TABLE. 5:Specifications of the power circuit...................................................................................... 39

-

8/12/2019 Report 4correction

5/90

Flux optimization for indirect vector control of induction motor

v

List of Figures

Fig.2. 1 : Stationary frame a-b-c to ds-qs axes transformation................................................................5

Fig.2. 2:Stationary frame ds - qs to synchronously rotating frame d e - qe transformation.....................6

Fig.2. 3: Equivalent two-phase transformation........................................................................................7

Fig.2. 4: Equivalent circuit of Induction Machine in de- q

eframe...........................................................8

Fig.3. 1: Separately excited dc machine................................................................................................ 10

Fig.3. 2: Vector-controlled induction machine..................................................................................... 11

Fig.3. 3:Complex (qds) equivalent circuit in steady state..................................................................... 12

Fig.3. 4:Steady-state phasor diagram with increase of (a) torque component of current (b) flux

component of current............................................................................................................................ 12

Fig.3. 5:Vector control implementation principle with machine de-qe model..................................... 13

Fig.3. 6 :Phasor diagram with stator flux oriented control.................................................................... 14

Fig.3. 7:Block diagram of indirect vector control of induction motor.................................................. 16

Fig.4. 1: The reference vector in the two and three dimensional plane................................................. 22

Fig.4. 2: Space voltage vectors in different sectors............................................................................... 23

Fig.4. 3:Simulink model of SV PWM technique.................................................................................. 27

Fig.4. 4: Sector selection of SVPWM................................................................................................... 28

Fig.4. 5: Time period of SVPWM (Ta)................................................................................................. 28

Fig.4. 6:MATLAB simulink model of flux optimization of indirect vector control of induction motor

............................................................................................................................................................... 30

Fig.4. 7: Simulink model of Theta and flux calculator......................................................................... 30

Fig.4. 8: Matlab simulink model of reference value of current............................................................. 31

Fig.4. 9:Actual and reference speed (1430 rpm)................................................................................... 32

Fig.4. 10: Actual and reference torque (At 5Nm)............................................................................. 32

Fig.4. 11: Reduction in the rotor flux after flux optimization at 2.5 sec for torque 5 Nm.................... 33

Fig.4. 12: Reduction in the input power after flux optimization at 2.5 sec for torque 5 Nm................ 33

Fig.5. 1:Block diagram of implemented control algorithm................................................................... 36

Fig.5. 2: Opto-coupler based IGBT Gate driver HCPL-3120............................................................... 39

Fig.5. 3: Gate driver circuit for inverter switches................................................................................. 40

Fig.5. 4:PCB layout of inverter section................................................................................................. 41

Fig.5. 5: Photograph of hardware of three phase inverter and gate driver with isolated supply........... 41

Fig.5. 6: PCB layout of sensing board.................................................................................................. 43

Fig.5. 7 :Component view of sensing board.......................................................................................... 44

Fig.5. 8 : Laboratory setup.................................................................................................................... 45

Fig.5. 9:Flow chart of program for Vector control................................................................................ 46

-

8/12/2019 Report 4correction

6/90

Flux optimization for indirect vector control of induction motor

vi

Fig.5. 10: Block Diagram of TMS320F28069...................................................................................... 47

Fig.5. 11: Image of experimental kit of TMS320F28069..................................................................... 48

Fig.5. 12 : Sub-modules of an ePWM Module...................................................................................... 50

Fig.6. 1: (a) PWM pulse of 1A& 1B with frequency of 10 KHz and (b) expanded view of pulse....... 53

Fig.6. 2:Level shifted waveforms at no load condition of Induction motor a) sensed voltageb)sensed

current................................................................................................................................................... 54

Fig.6. 3:(a) Sensed current waveform b ) Sensed voltage waveform................................................... 55

Fig.6. 4: (a) Space Vector Modulated PWM gate pulses (b) Motors single phase output terminalvoltages after filtering........................................................................................................................... 55

Fig.6. 5: CCS-4 Screen shot indicating sector selection of space vector modulation........................... 56

Fig.6. 6:CCS-4 Screen shot indicating torque and flux estimation based on measurement of actual

motor terminal voltages and currents.................................................................................................... 56

-

8/12/2019 Report 4correction

7/90

Flux optimization for indirect vector control of induction motor

vii

Abbreviations / Notations / Nomenclature

S,r=Stator and rotor indices

X : Components in the stationary frame axes

Xdq: Components in the synchronous reference frame dq axes

X* : Reference value

Rs,Rr : Stator and rotor resistances

Ri : Iron loss resistance

Ls,Lr :Stator and rotor inductances

Lls, Llr: Stator and rotor leakage inductancer: Rotor time constant (r= Lr/Rr): Leakage flux total coefficient ( = 1Lm2/ LsLr )

Lm: Magnetizing inductance

s, r : Stator and rotor fluxm : Magnetizing fluxs : Stator pulsation (rd/s)

r : Rotor speed (rd/s)

p: Number of pairs poles

s : slip

sl: Slip frequency (rd/s);

J : Motor Inertia

fvis : Viscous Coefficient

TL: Load torque

Tem : Electromagnetic torque

Pcs, Pcr : Stator and rotor copper losses.

Pi : Iron losses.

IFOC : Indirect Flux Oriented Control

IM: Induction Motor

-

8/12/2019 Report 4correction

8/90

Flux optimization for indirect vector control of induction motor

1

Chapter 1

Introduction

1.1 Literature survey

Induction motors are mostly used in industrial application due to their high performance,

robustness, efficiency and cost. More than 40% of the total electric energy generated isconsumed by electric motors. Recently, the concern about the enormous use of electrical

energy and its adverse impact on the environment is growing. Generally induction motor is

designed to have maximum efficiency near full load. At light load condition, the copper loss

is less compared to iron loss and the efficiency is poor [1]. So an attempt is made to increase

the efficiency of an induction motor even at light loads by the flux optimization method.

An indirect vector control method has a good dynamic performance due to the

inherent decoupling between d-axis (flux producing component) and q-axis (torque producing

-

8/12/2019 Report 4correction

9/90

Flux optimization for indirect vector control of induction motor

2

component) components of current, similar to a separately excited DC machine. Efficiency of

the motor can be increased by means of loss reduction which can be done by the following

methods; 1) Appropriate motor selection and design; 2) Improved waveform supplied by the

inverter; 3) Using suitable control method. Generally, motor is designed to have maximum

efficiency at rated conditions [2]. Mostly motor operates at other than rated conditions. Under

these conditions, it is not possible to improve the machine efficiency by machine design or by

waveform shaping technique; hence it is necessary to go for the suitable control algorithm [2].

The control method or the control strategy to improve the efficiency can be divided

into two categories 1) Search controller 2) Loss model based controller [3]. The basic

principle of search controller is to measure the input power and then iteratively search the flux

until the minimum power is detected for given torque and speed [4]. For this vector drive, the

flux is reducing in small steps to reach the optimum condition, and the problem is an increase

in the time of convergence and the torque pulsation during the search process. In fuzzy logic

based search controller method, we speed up the convergence time, but we want to use

compensator for torque pulsation problem [5]. In the Golden section based search algorithm,

we can improve the convergence time, but the problem is selecting the upper and lower limit

of flux producing current before the algorithm start. To get acceptable dynamic performance

and to increase the speed of search, prior knowledge of drive system is required [6].

The advantage of loss model based approach is that it is faster than the other method.

Optimum flux is decided by the machine model and extra filter and sensor not required to get

the power input. Torque ripple is less compared to the other method [6].

-

8/12/2019 Report 4correction

10/90

Flux optimization for indirect vector control of induction motor

3

Chapter 2

Mathematical modeling of Induction motor

This chapter covers the mathematical model of induction motor in synchronously

rotating reference frame.

2.1 Working

When 3-phase stator winding is energized from a 3-phase supply, a rotating magnetic

field is set up which rotates round the stator at synchronous speed Ns (= 120 f/P).The rotating

field passes through the air gap and cuts the rotor conductors, which as yet, are stationary.

Due to the relative speed between the rotating flux and the stationary rotor, e.m.f.s are

induced in the rotor conductors. Since the rotor circuit is short-circuited, currents start flowing

in the rotor conductors. The current-carrying rotor conductors are placed in the magnetic field

-

8/12/2019 Report 4correction

11/90

Flux optimization for indirect vector control of induction motor

4

produced by the stator. Consequently, mechanical force acts on the rotor conductors. The sum

of the mechanical forces on all the rotor conductors produces a torque which tends to move

the rotor in the same direction as the rotating field.

2.2 Axes Transformation

In many applications, the dynamic behavior of the induction machine has an important

effect upon the overall performance of the system. The dynamic performance of an ac

machine is complex because the three phase rotor windings move with respect to the three

phase stator windings. The machine model can be described by differential equations with

time varying mutual inductances, but such a model tends to be very complex. The three phase

machine can be represented by an equivalent two-phase Machine i.e. a-b-c to d-q

transformation. In the1920s, to overcome the problem of time varying parameters, R.H. Park

proposed a new theory of electrical machine analysis. He transformed or referred the stator

variables (voltages, currents and flux linkages) to a synchronously rotating reference frame

fixed on the rotor. Later, in the 1930s, H.C. Stanley showed that time varying inductances in

the voltage equations of an induction machine due to electric circuits in relative motion can be

eliminated by transforming the rotor variables to variables associated with fictitious stationary

windings. Later, G. Kron proposed a transformation of both stator and rotor variables to a

synchronously rotating reference frame that moves with the rotating magnetic field. A proper

model for the three phase induction machine is essential to simulate and study the complete

drive system.

Consider a symmetrical three-phase induction machine with stationary as-bs-cs axes at

2/3-angle apart as shown in Figure 2.1. We have to transform the three phase stationary

reference frame (as-bs-cs) variables into two-phase stationary reference frame ( ds - qs )

variables and then transform these to synchronously rotating reference frame (de - qe ), and

vice versa. Assuming that the ds - qs axes are oriented at angle, as shown in Figure 2.1, the

voltages Vdss andVqs

scan be resolved into as-bs-cs components and can be represented in the

matrix form as

-

8/12/2019 Report 4correction

12/90

Flux optimization for indirect vector control of induction motor

5

qs-axis

ds-axis

as

cs

bs

vbs

vcs

vas

Fig.2. 1 : Stationary frame a-b-c to ds-qs axes transformation

=

The corresponding inverse relation is

Where Voss is added as the zero sequence component, which may or may not be

present. We have considered voltage as variable. The current and flux linkages can be

transformed by similar equations. Figure 2.2 shows the synchronously rotating de qe axes,

which rotate at synchronous speed ewith respect to the dsqs axes and the angle e=e t.

-

8/12/2019 Report 4correction

13/90

Flux optimization for indirect vector control of induction motor

6

ds

de

qs

qe

V

e

e =et

e

Vds=-Vm sin()

Vqs=Vm cos()

Vqs=Vm cos(e+)

Vqs=-Vm sin(e+)

Fig.2. 2:Stationary frame ds - qs to synchronously rotating frame de - qe transformation

The two-phase ds - qs windings are transformed into the hypothetical windings

mounted on the d e - q e axes. The voltages Vdss and Vqs

s can be resolved into de - qe

components and can be represented in matrix form as

[] [ ] [ ]

For convenience, the superscript e has been dropped from the synchronously rotating

frame parameters. The corresponding inverse relation is

[ ] [ ] []

2.3 Mathematical Model of Induction Motor

When the motor operates in both steady and transient states, the standard induction

motor equivalent model can be used to calculate machine variables such as stator current,

-

8/12/2019 Report 4correction

14/90

Flux optimization for indirect vector control of induction motor

7

rotor current, developed torque, etc. The induction motor can be modeled with stator current

and flux. In FOC the motor is modeled in synchronously rotating reference frame i.e. =e

Consider the two-phase machine shown in Figure 2.3, we need to represent both (d sqs) and

(d rqr) circuits and their variables in a synchronously rotating (deqe) frame.

ds-axis

r

dr-axis

qr-axis

qs-axis

Fig.2. 3: Equivalent two-phase transformation

We can write the following stator circuit equations

(2.1)sqsdt

dsR

sqsI

sqsv

(2.2)sds

dt

dsR

sds

Isds

v

Wheresds and

sqs are q-axis and d-axis stator flux linkages. When these equations are

converted to de-qe frame:

(2.3)eds

eeqsdt

dsR

eqsIv

eqs

(2.4)eqseedsdt

dsR

eds

Ieds

v

Where, all variables are in rotating form. If the rotor is not rotating, r= 0, the rotorequations are:

-

8/12/2019 Report 4correction

15/90

Flux optimization for indirect vector control of induction motor

8

(2.5)edre

eqrdt

dRr

eqrI

eqrv

(2.6)eqreedr

dt

dRr

edr

Iedr

v

Where, all variables and parameters are referred to the stator. In de-qe frame, the rotor

equations are:

)7.2(edr

)r

ej(eqr

dt

drR

eqrIv

eqr

)8.2(eqr)rej(

edr

dt

drR

edr

Ivedr

The flux linkage equations in terms of the currents are:

(2.9))eqr

Ieqs

(Im

Leqs

Ils

Leqs

(2.10))edr

Ieds

(Im

Leds

Ils

Leds

(2.11))eqr

Ieqs

(Im

Leqr

Ilr

Leqr

(2.12))

e

drI

e

ds(ImL

e

drIlrL

e

dr

The torque equations of induction motor are given by:

(2.13)rdt

dJ

lT

eT

(2.14)esd

Iesq

esq

Iesd

2

P

2

3

eT

Where, Tl is load torque, r is electrical speed. Fig 2.4 shows de-qe equivalent model of

induction motor .

Fig.2. 4: Equivalent circuit of Induction Machine in de- q

eframe

R

qd

qd

Lie-

V d

I d

V dr

-

8/12/2019 Report 4correction

16/90

Flux optimization for indirect vector control of induction motor

9

Chapter 3

Vector or Field Oriented Control

This chapter includes the working principle of indirect vector of induction motor

followed by the flux optimization technique of induction motor

3.1 Introduction

The scalar control technique is simple to implement, but due to inherent coupling

effect i.e. both torque and flux are functions of voltage or current and frequency, gives

sluggish response due to which the system becomes easily prone to instability because of

higher order system effect. This problem can be solved by vector or field-oriented control. By

this control technique the induction machine can be controlled like a separately excited dc

machine. Because of dc machine-like performance, vector control is also known as

-

8/12/2019 Report 4correction

17/90

Flux optimization for indirect vector control of induction motor

10

decoupling, orthogonal, or transvector control. Vector control is applicable to both induction

and synchronous machine drives.

3.2 Working

Consider the separately excited dc machine as shown in Figure 3.1. The developed

torque is given by

Ia

If

y

yf

aIa

If

Decoupled yafTe=kt =k'tIaIfy

Torque

ComponentField

Component

Fig.3. 1: Separately excited dc machine

Te=KtIaIf

Where Ia= armature current and If=field current. The construction of dc machine is

such that the field flux f produced by current If is perpendicular to the armature flux a,

which is produced by armature current Ia. These space vectors, which are stationary in space,

are orthogonal or decoupled in nature. This means that when torque is controlled by

controlling the currentIa, the flux f is not affected.

DC machine-like performance can also be extended to an induction motor if the

machine control is considered in a synchronously rotating reference frame ( de and qe), where

the sinusoidal variables appear as dc quantities in steady state. Figure 3.2 shows the induction

machine with the inverter and vector control with the two control current inputs, i ds* and

-

8/12/2019 Report 4correction

18/90

Flux optimization for indirect vector control of induction motor

11

iqs*With vector control, ids is analogous to field current If and iqs is analogous to armature

currentIaof a dc machine.

ids

yr

we

Te=k'tidsiqs

Iqs*

Ids*

Vector

control Inverter IM

Torque

ComponentField

Component

Fig.3. 2

Fig.3. 2: Vector-controlled induction machine

Therefore, the torque equation can be expressed as

Te=Ktr iqs

or

Te=Ktidsiqs

The dc machine like performance is only possible if the ids is aligned in the direction

of r and iqs is established perpendicular to it. This means that when iqs* is controlled, it

affects the actual iqs current only, but does not affect the flux r . Similarly when ids*is

controlled, it controls the flux only .does not affect the iqscomponent of current.

3.3 Equivalent Circuit and Phasor Diagram

Consider the de-qe equivalent circuit diagram of induction motor in steady state

condition as shown in fig.3.3 The rotor leakage inductance Llr is neglected for simplicity,

-

8/12/2019 Report 4correction

19/90

Flux optimization for indirect vector control of induction motor

12

which makes the rotor flux r the same as the air gap flux m. the stator current Is can be

expressed as

( )ids= magnetizing component of stator current flowing through the inductanceLm and iqs=torquecomponent of stator current flowing in the rotor circuit. Figure 3.4 shows phasor diagrams in

deqe frame with peak value of sinusoids and air gap voltage Vmaligned on the qe axis. The

in-phase or torque component of current iqs contributed active power across the air gap,

whereas the reactive or flux component of stator current contributed only reactive power.fig

3.4(a) shows an increase of the iqscomponent of stator current to increase the torque while

maintaining the flux rconstant whereas fig 3.4(b)shows weakening of flux by reducing the

idscomponent.

Rs

Lm

iqs

ids

Fig.3. 3

Fig.3. 3:Complex (qds) equivalent circuit in steady state

'

de axis

qe

axis

i'qs

iqs

i'sis

'

deaxis

iqsids

i's

is

qeaxis

(a) (b)

Fig.3. 4:Steady-state phasor diagram with increase of (a) torque component of current (b) fluxcomponent of current

-

8/12/2019 Report 4correction

20/90

Flux optimization for indirect vector control of induction motor

13

3.4 Principle of Vector Control

The fundamental of vector control implementation can be explained with the help of

Figure 3.5.where the machine model is represented in a synchronously rotating reference

frame. The inverter is omitted from the figure, assuming that it has unity current gain, that is,

it generates currents ia, ib, and ic as dictated by the corresponding command currents ia*,ib

*and

ic*from the controller. A machine model with internal conversion is shown on the right. The

machine terminal phase currents ia, ib, and ic are converted to ids and iqs components by 3

to2 transformation. These are then converted to synchronously rotating frame by the unit

vector components cose and sinebefore applying them to the de- qe machine model as

shown. The controller makes two stages of inverse transformation, so that the control currents

ids*and iqs*correspond to the machine currents ids and iqs respectively. In addition, the unit

vector assures correct alignment of ids current with the flux vector rand iqsperpendicular to

it. There are essentially two general methods of vector control. One, called the direct or

feedback method, was invented by Blaschke and the other known as the indirect or feed-

forward method was invented by Hasse. These two methods are different essentially by how

the unit vector is generated for the control.

Inverse

transformation

Transformation

Control Machine

Ids

IqsIqss*

Idss*

Ia*

Ib*

Ic*

Ia

Ib

IcIqss

Idss

Cose sine sineCose

ds-q

s

To

a-b-c

de-q

e

To

ds-q

s

a-b- c

To

ds-q

s

ds-q

s

To

de-q

e

Machine

de-q

e

model

Machine

Terminal

Fig.3. 5:Vector control implementation principle with machine de-qe model

-

8/12/2019 Report 4correction

21/90

Flux optimization for indirect vector control of induction motor

14

3.5 Indirect Vector Control

The indirect vector control method is essentially the same as the direct vector control,

except that the rotor angle e is generated in an indirect manner (estimation) using the

measured speed r and the slip speed sl. Figure 3.6. explains the fundamental principle of

indirect vector control with the help of phasor diagram. The ds-qs axes are fixed on the stator,

but the dr-qr axes, which are fixed on the rotor, are moving at speed r as shown in fig .3.6.

Synchronously rotating axes de-qe is rotating ahead of the dr-qr axes by the positive slip angle

sl corresponding to slip frequency sl. Since the rotor pole is directed on the de axis and

e=r+sl,

slrrslee dt www )( (3.1)

The phasor diagram suggests that for decoupling control, the stator flux component of

current ids should be aligned on the de axis, and the torque component of current iqs should be

on the qe axis as shown in Figure.

Fig.3. 6 :Phasor diagram with stator flux oriented control

The rotor circuit equation can be written as

0)( qrredrrdr iR

dt

dyww

y

(3.2)

-

8/12/2019 Report 4correction

22/90

Flux optimization for indirect vector control of induction motor

15

0)( drreqrrqr

iRdt

dyww

y

(3.3)

Where Rris rotor resistance ,

The rotor flux linkage equation can be written as

dsmdrrdr iLiL y (3.4)

qsmqrrqr iLiL y (3.5)

Where Lr is rotor inductance, Lm is magnetizing inductance.

From the above we can write

ds

r

m

r

dr

dr iL

L

Li

y

(3.6)

qs

r

m

r

qr

qr iL

L

Li

y

(3.7)

From (3.2) to (3.7), we can write

0 qrsldsrr

m

dr

r

rdr iR

L

L

L

R

dt

dywy

y

(3.8)

0 drslqsrr

m

qr

r

rqr iRL

L

L

R

dt

dywy

y

(3.9)

Where idsand iqsis dq axis equivalent stator current, idrand iqr is dq axis equivalent rotor

current

For decoupling, we can write

0qry (3.10)

rdr yy (3.11)

0dt

d qry

(3.12)

So that rotor flux ry is directed on deaxis.

Substitute (3.10) ,(3.11),and (3.12) in (3.8) and (3.9), then we get,

)1( s

iL

r

dsmr

y

(3.13)

-

8/12/2019 Report 4correction

23/90

Flux optimization for indirect vector control of induction motor

16

Electromagnetic torque can be calculated by

)(22

3qsdr

r

m

e iL

LpT y

(3.14)

The calculation of iq* and id* as reference current torque and flux component respectively is

as following

)(22

3 **qs

r

m

e iL

LpT

dry

(3.15)

m

rd

Li y

* (3.16)

r

e

m

r

qT

L

L

pi

y

** 232

(3.17)

From the above equations, we can implement the indirect vector control of induction motor

SVPWM

INVERTERIM

Optimum

flux

dq to abc

Iabc

Iq

Id

IdFlux

Flux

Te*Te

*r

*

r

r

Flux

Id* PI-2

PI-3

Id

Iq TL

Iabc

r

Te

+

+

-

-r*

PI-1

Fig.3. 7:Block diagram of indirect vector control of induction motor

In the above given scheme the whole control structure consists of a speed control loop

and two current control loops. In the speed control loop the rotor speed is compared with the

reference speed and the speed error is then fed to the PI-controller (PI-1) which generates the

reference torque T*. according to equation (3.15) we get the reference iqs* from reference

torque Then in the current control loop the current error is generated by comparing the current

-

8/12/2019 Report 4correction

24/90

Flux optimization for indirect vector control of induction motor

17

iqswith its reference value and the error is then given to a PI controller (PI-3) . The output of

PI-3 gives the reference quadrature axis voltage command vqs*. Similarly for the direct axis

current control loop the reference value for rotor flux is generated from the optimum

mathematical model optimum flux. According to equation (3.16) we get the reference

command ids*. The direct axis current error is generated by comparing ids with its reference

value and the error is then fed to a PI controller (PI-2). The output of controller PI-2 gives the

reference direct axis voltage command Vds*.

3.6 Flux Optimization Scheme

Operation of the induction motor is efficient at rated load and rated flux, but at light

load condition the efficiency of the motor is less. So to improve the efficiency of the machine

it is necessary to apply the optimal rotor flux reference value which satisfies the condition, the

copper loss equals the iron loss. Optimal rotor flux can be calculated based on the machine

model by equating the derivative of the total losses with respect to the rotor flux to zero.

From the equivalent circuit of induction motor, the total machine losses can be written as

follows [8][9].

Stator cu loss= )(2

33 222 qsdsSsscs iiRIRP

(3.18)

Rotor cu loss= )(3 22 qrdrrcr iiRP (3.19)

Iron loss = ))((2

33 222 qmdm

i

emiiii ii

R

LRIRP

w

(3.20)

icrcs ppplosses (3.21)In synchronously rotating frame we get

dsmdrrdr iLiL y (3.22)

qsmqrrqr iLiL y (3.23)

The perfect decoupling is achieved by

0qry (3.24)

-

8/12/2019 Report 4correction

25/90

Flux optimization for indirect vector control of induction motor

18

rdr yy (3.25)

Then from rotor field oriented indirect vector control of induction motor we can write

0dri (3.26)

qs

r

mqr i

L

Li

(3.27)

Put value of iqr, idrin the losses equation, then we get

))((2

3)(3)(

2

3 222222qmdm

i

emiqsdsrcrqsdsS ii

R

LRiiRPiiRlosses

w (3.28)

where Rsis stator resistance, Ri is iron loss resistance.

The stator dq current components are

qm

lr

rr

i

eqs i

L

L

Ri y

w

(3.29)

qm

i

emr

m

ds iR

L

Li

wy

1

(3.30)

Substitute (29) and (30) in (28), then

][)(2

3)(

2

3)()[(

2

3 22

222222

qm

m

r

i

emiqm

lr

mrqm

lr

rr

i

eqm

i

em

m

rS i

LR

LRi

L

LRi

L

L

Ri

R

L

LRLosses ywywwy

(3.31)

Where Llr is rotor leakage inductance.

From (3.26) and (3.27) we can write,

qmr

lr

mqrrqsr

r

mem i

L

Lpipi

L

LpT yyy (3.32)

where p is number of pair poles.

After simplification, we get,

2

2

2 ))(()()()(r

emeemere

TcTbalosses

ywwyw

(3.33)

where

])([2

3)(

2

2

2

i

eis

m

ss

RRR

L

Ra

ww

,

-

8/12/2019 Report 4correction

26/90

Flux optimization for indirect vector control of induction motor

19

S

esS

pR

Rb

ww

3)(

])([2

3

)( 22

22

1

222

2

i

er

rS

r

m

rS

S Rp

l

RRp

R

Lp

LR

c

w

w

To get the optimum flux, partial derivative of (3.33) with respect to rotor flux

01

)(2)(20)(

3

2

r

emere

r

TcaLosses

ywyw

y

Then

emr Ty (3.34)

Where

4

a

c

The flux value is a function of the electromagnetic torque and the coefficient, which

depends on the machine parameters. So the optimum flux can be estimated as a function of

torque and speed of the machine.

-

8/12/2019 Report 4correction

27/90

Flux optimization for indirect vector control of induction motor

20

Chapter 4

Matlab Simulation and Results

This chapter throws light on the Matlab simulation of the system and the comparative

result of with optimization and without optimization of flux for indirect vector control. The

voltage source inverter and the control technique of different pulse width modulation is

explained in the following..

4.1 Pulse Width Modulation (PWM)

The main purpose of these topologies is to provide a three phase voltage, where the

amplitude, phase, and frequency are always controlled. The voltage source inverter converts

dc power to three-phase ac power by means of switching power electronic switches. The

power flow in each phase is controlled by duty cycle of the PWM pulses. To obtain a suitable

duty cycle an appropriate pulse width modulation technique is used. The harmonic content of

the voltage (current) and electromagnetic interference generated in the inverter fed drive

-

8/12/2019 Report 4correction

28/90

Flux optimization for indirect vector control of induction motor

21

depends on the modulation technique selected. The advantage of PWM is that power loss in

switching device and harmonics content in output voltage is low .The different types of PWM

methods are as follows:

4.1.1Carrier Based PWM

In this method, the sinusoidal signal is compared with a carrier wave. This method is

the most widely used method of pulse width modulation and is also known as sinusoidal

PWM. In this method three reference sinusoidal signals are compared with triangular carrier

signal Vt which is common to all three phases. In this way the logical signals SA, SB, SC are

generated, which define the switching instants of the power transistors. To generate a

sinusoidal output voltage waveform at a desired frequency a sine wave at desired frequency is

compared with triangular waveform. The frequency of inverter is same as that of the

triangular waveform. The modulation index m is defined as:

VtVmm

Modulation index m can be varied between 0 and 1 to give a linear relation between

the reference and output wave. At m=1, the maximum value of fundamental peak voltage is

Vdc/2 which is 78.55% of the peak voltage of the square wave where, V m is peak value of

modulating wave and Vt is peak value of carrier wave. Comparing with the Sine PWM, the

output voltage utilization is more in SVPWM. Harmonic contents are also less in SVPWM sothat Space Vector PWM is preferred

4.1.2 Space Vector PWM

Space vector technique is rotating voltage vector. The 3-phase voltage output of the

inverter could be represented by equivalent vector Vrefwhich is represented in a plane this

-

8/12/2019 Report 4correction

29/90

Flux optimization for indirect vector control of induction motor

22

two phase stationary reference plane which is transformed from 3 phase abc plane. Location

of Vrefin plane decides the switching position of the inverter (ON ,OFF) . Magnitude ofVref is equal to magnitude of the inverter output voltage. Time taken by V refto complete one

revolution is fundamental time period of the output voltage .

For balanced load condition

0 coboao VVV (4.1)

The instantaneous phase voltages are

)sin( tVV ma w (4.2)

)120sin( tVV mb w (4.3)

)120sin( tVV mb w (4.4)

Transformation of abc plane to two phase stationary reference frame

)

22

(

3

2 bba

VVVV

(4.5)

)(3

1cb VVV (4.6)

Vref

V

V

Va

Vb

VC

Fig.4. 1: The reference vector in the two and three dimensional plane

Magnitude and angle of reference voltage is

-

8/12/2019 Report 4correction

30/90

Flux optimization for indirect vector control of induction motor

23

22

VVVref (4.7)

)(tan1

V

V

(4.8)

Switches can be ON or OFF means 1 or 0.lower switches are complimentary of upper

switches, so possible combinations of switching states 000,001,010,011,100,101,110,111. V0

is 000 means all lower switches(4,2,6) are ON and v7is 111 means all upper switches (1,3,5)

are ON . SVPWM has eight vectors in which six are active vectors (V1-V6) and two are null

vectors (V0,V7). After joining all the six vectors a regular hexagon is formed as shown in fig

4.9

Fig.4. 2: Space voltage vectors in different sectors

TC is the sampling period of Vref. Sampling period is divided into tree intervals

T1,T2,T0. Suppose V1amount of voltage is applied for T1 sampling period and V2amount of

voltage is applied for T2sampling period and zero voltage is applied for rest of the sampling

period T0=Tc-T1-T2

Theta is the position of Vrefwith respect to V1. Volt sec balance produced by vector V1,V2are

same as those produced by Vref

002211 *** TVTVTVVref (4.8)

-

8/12/2019 Report 4correction

31/90

Flux optimization for indirect vector control of induction motor

24

ccc

crefT

TV

T

TV

T

TVTV 00

22

11 **** (4.9)

The total cycle is given by:

021 TTTTc (4.10)

The position of Vref,V1,V2and V0can be described with its magnitude and angle:

j

refref eVV * dcVV *

3

21

,

32 **

3

2

j

dc eVV

00V (4.11)

Calculation of each duration time

dcdcrefC VTVTVT *3

1**

3

2*)cos(** 21

(4.12)

dcrefC VTVT *3

1*)sin(** 2

(4.13)

After simplification we get T1and T2time as

)3

sin(**)3

sin(**3

*1

aTV

VTT c

dc

ref

c

(4.14)

)sin(**)sin(**3

*2 aTV

VTT c

dc

ref

c (4.15)

The general calculation to get the duty times in the rest of the sectors is given by

)]sin()3

cos()cos()3

[sin(**)*3

1

3sin(**1

nnaT

naTT cc

(4.16)

)]sin()3

1

cos()cos()3

1

sin([**)3

1

sin(**2

nn

aT

n

aTT cc (4.17)

-

8/12/2019 Report 4correction

32/90

Flux optimization for indirect vector control of induction motor

25

210 TTTT c (4.18)

Choosing nas the number of the sector (n=1,2,3,4,5,6) the calculations for the time duration

in each sector can be calculated

TABLE. 1:The switching time of the active vector for each sector.

SECTOR T1 T2 T0

1V

V

TT

d

C 31 )3(

2

32 VV

V

TT

d

C

TO=TC-T1-T2

2 )3(2

31 VV

V

TT

d

C )3(2

32 VV

V

TT

d

C TO=TC-T1-T2

3V

V

TT

d

C 31 )3(

2

32 VV

V

TT

d

C TO=TC-T1-T2

4 VV

TT

d

C 31 )3(2

32 VV

V

TT

d

C TO=TC-T1-T2

5 )3(2

31 VVV

TT

d

C

)3(23

2 VVV

TT

d

C

TO=TC-T1-T2

6V

V

TT

d

C 31 )3(2

32 VV

V

TT

d

C TO=TC-T1-T2

4.1.3Duty cycle

For each sector there are seven switching states for each cycle. It always starts and

ends with a zero vector. For sector 1 it goes through these switching states: 000-100-110-111-

110-100-000, one round and then back again. This is during the time Tc and it has to be

divided into the seven switching states, three of them being zero vectors.

4222224

0120120 TTTTTTTTC (4.18)

-

8/12/2019 Report 4correction

33/90

Flux optimization for indirect vector control of induction motor

26

TABLE. 2:Duty time for each sector

SECTOR UPPER SWITCH DUTY TIME LOWER SWITCH DUTY TIME

1

S12

021

TTT

S2

2

0T

S32

0

2

TT

S4

2

0

1

TT

S52

0T

S6

2

021

TTT

2

S120

2 TT

S220

1 TT

S32

021

TTT

S4

2

0T

S52

0T

S6

2

021

TTT

3

S12

0T

S2

2

021

TTT

S3

2

021

TTT

S4

2

0T

S52

0

2

TT

S6

2

0

1

TT

4

S12

0T

S2

2

021

TTT

S32

0

2

TT

S4

2

0

1

TT

S52

021

TTT

S6

2

0T

5

S12

0

2TT

S2

2

0

1TT

S32

0T

S4

2

021

TTT

S52

021

TTT

S6

2

0T

6

S12

021

TTT

S2

2

0T

S32

0T

S4

2

0

21

TTT

-

8/12/2019 Report 4correction

34/90

Flux optimization for indirect vector control of induction motor

27

S52

0

2

TT

S6

2

0

1

TT

4.2 Space vector PWM Simulation

Fig 4.3 shows simulation block diagram of SVPWM implemented in simulink model

of MATLAB to control the inverter. Fig.4.4 shows the sector selection of inverter circuit.Fig.4.5 shows time period of switching instant of inverter

Fig.4. 3:Simulink model of SV PWM technique

-

8/12/2019 Report 4correction

35/90

Flux optimization for indirect vector control of induction motor

28

Fig.4. 4: Sector selection of SVPWM

Fig.4. 5: Time period of SVPWM (Ta)

4.3 Matlab Simuation

The control system block diagram is shown in fig. 3.7 simulated for induction motor

in MATLAB /simulink (version 7.1 R2010a). The simpower system is used for modelingwork. Simpower system has libraries of electrical machine and power electronics circuits.

-

8/12/2019 Report 4correction

36/90

Flux optimization for indirect vector control of induction motor

29

Motor parameter used for simulation:

Rated Power = 4000 W,

Rated Voltage = 400 Volts,Frequency = 50 Hz,

Number of poles =4,

Stator Resistance = 1.405 ,

Stator Leakage Inductance = 0.005839 Henry,

Rotor Resistance referred to stator = 1.395 ,

Rotor Inductance referred to stator = 0.005839 Henry,

Mutual Inductance = 0.1722 Henry.

With reference to the Fig.4.6 the whole model can be divided into Induction motor

model, Two level inverter ,Space vector modulation ,Torque and flux estimation .The torque

and flux value estimated from the equation (3.14) and (3.13) and compared with reference

value .The error is passed through the PI regulator to get the reference voltage Vabc and that

reference value is used to trigger the inverter switches with SVPWM control technique.

Fig 4.7 shows simulink model of theta calculator and actual flux value. Sensed current is

converted into two phase rotating frame (id and iq component). From equation 3.13 we can

calculate actual flux and theta using relation of id, iq and speed. Fig.4.8 shows the Matlab

simulink model to calculate the reference value of current using relation of equation 3.16 and

3.17.

-

8/12/2019 Report 4correction

37/90

Flux optimization for indirect vector control of induction motor

30

Fig.4. 6: MATLAB simulink model of flux optimization of indirect vector control of induction motor

Fig.4. 7: Simulink model of Theta and flux calculator

-

8/12/2019 Report 4correction

38/90

Flux optimization for indirect vector control of induction motor

31

Fig.4. 8: Matlab simulink model of reference value of current

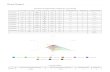

Results of above control technique are given below. Fig.4.9 shows the simulated speed

response of rotor. The green line color shows the speed reference (1430 rpm) while the blue

line color shows the actual speed of motor. After 2.5 second optimum flux is applied to get

the maximum efficiency.

Fig.4.10 shows torque response of motor at 5Nm load condition with conventional

technique PI and Fig.4.11 shows rotor flux applied to the motor with and without flux

optimization system. Fig.4.12 shows the input power consumption of the motor with and

without flux optimization system at 5Nm load torque.

-

8/12/2019 Report 4correction

39/90

Flux optimization for indirect vector control of induction motor

32

Fig.4. 9:Actual and reference speed (1430 rpm)

Fig.4. 10: Actual and reference torque (At 5Nm)

-

8/12/2019 Report 4correction

40/90

Flux optimization for indirect vector control of induction motor

33

Fig.4. 11: Reduction in the rotor flux after flux optimization at 2.5 sec for torque 5 Nm

Fig.4. 12: Reduction in the input power after flux optimization at 2.5 sec for torque 5 Nm

-

8/12/2019 Report 4correction

41/90

Flux optimization for indirect vector control of induction motor

34

4.4 Result

Table.3 shows the result of indirect vector control of induction motor with flux

optimization and without flux optimization at rated speed (1430 rpm) for different load

torque condition.

TABLE. 3: Power at Different Load Condition

Test

Condition

Power Input

Power

Reduction(Input)Without F lux Optimization With F lux Optimization

No load 1275 W 185 W 85 %

3 Nm 2044 W 1498W 26 %

5Nm 2513 W 1895W 25 %

7Nm 2964 W 2619w 11 %

10Nm 3826 W 3733W 2.43

-

8/12/2019 Report 4correction

42/90

Flux optimization for indirect vector control of induction motor

35

Chapter 5

Hardware implementation

The implementation of vector control or any high performance control requires a

complex and fast controller. A microprocessor/microcontroller/ digital signal processor forms

an integral part of such a controller. A fast controller provides a faster sampling rate as

needed, to ensure stable and successful control. PC- based implementation of the vector

control for voltage source inverter-fed induction motor is considered here. So this chaptercovers the description of the system and its operation. This is followed by the design of the

various stages such as driver stage, power supply section, inverter section and sensing circuit.

The controller used in this project is Experimental kit of TMS320F28069 Digital Signal

Controller from Texas Instruments.

-

8/12/2019 Report 4correction

43/90

Flux optimization for indirect vector control of induction motor

36

5.1 . Schematic Block Diagram of the System

The complete induction motor vector control system is basically designed according

to the MATLAB simulation System blocks diagram shown in Fig. 4.1. Due to practical

limitations some modifications are made during the implementation stage. Hardware is

implemented for 0.373kW motor instead of 4 kW motor which is simulated in MATLAB.

Only two phase currents isa and isb are measured instead of all three phase currents. For

balanced condition, three phases are balanced and hence one phase current can be calculated

from the other two phase currents. Same is applicable to the voltage. Fig.5.1 shows the

complete block diagram of the hardware implementation.

IM

IC-HCPL 3120Optocoupler Drivers

Gate signals

Is Is Vs Vs

Controlled

Rectifier

Inverter

CT1

CT2

PT1

PT2

Voltage and Current

Sensing Circuit

LEM HX-

03

230/3V

Step Down

IC-74LS573

A0 A1 A2 A31A 1B 2A 2B 3A 3B

PWM

LC Filter

ADC

IGBT-IRG4PH50UD

Digital Signal Processor

3-

0.5 hp

230 V

230 V

AC

Speedsensor

A4

Flux estimator

r

Id

*

PI

PI

Id

++

--

Iq

*

PI

Vector Rotator

&

- to a,b,c

transformation

a,b,c to -

transformation

&

Vector Rotator

Iq

*r

-+

ds qsUnit Vector

++

V*ds V*qs

PI

PI

r*

Lm

e

Sin(e)

Cos(e)

sl

Fig.5. 1:Block diagram of implemented control algorithm

-

8/12/2019 Report 4correction

44/90

Flux optimization for indirect vector control of induction motor

37

5.2 Design of Three Phase Inverter

The parameters of the induction motor are given below. The two level (3 leg) inverter is used

for controlling the induction motor.

Motor parameter used for hardware:

Rated Power = 373 W,

Rated Voltage = 415 V,

Frequency = 50 Hz,

Number of poles =4,

Stator Resistance = 23.405 ,

Stator Leakage Inductance = 0.0874665 Henry,

Rotor Resistance referred to stator = 38.1155 ,

Rotor Inductance referred to stator = 0.0874665 Henry,

Mutual Inductance = 0.92526 Henry.

The inverter design is based on the voltage rating, current rating and switching

frequency. High switching rates of modern power semiconductors lead to rapid changes in

voltage in relatively short periods of time. Steep-fronted waves with large dV/dt or very fast

rise times lead to voltage overshoots and other power supply problems .These effects can

damage the motors insulation and severely shorten its useful operating life so that The

switching frequency in drives application is typically selected between 2 kHz to 20 kHz. Here

the switching frequency of the inverter is selected as10 kHz.

DC Link voltage, Vdc= 2*VLL=311 V

Due to high DC voltage, high dv/dt voltage spikes are produced which causes the

voltage of the motor winding to exceed the insulation limit which will damage the motor. On

230 volts AC system the voltage spikes are around 1200 - 1500volts.The switch voltage rating

is 1200V and hence a lower DC link voltage of 120V-150V is selected and the step up

transformer with delta/star or delta/delta connected at voltage of 110V/415Vor 110V/230V is

-

8/12/2019 Report 4correction

45/90

Flux optimization for indirect vector control of induction motor

38

used to run the motor (star (415 V) or delta (230 V). The net power capacity of the inverter is

calculated as below

Power rating of motor

Power rating of inverter = ------------------------------------------------------------------

(Efficiency of motor x efficiency of the inverter)*pf

Assuming efficiency of inverter as 85 %, the power rating of the inverter is calculated as

= 370W/(0.6 x0.85*0.8)

= 800 VA

The gate driver selected is IC HCPL- 3120 suitable to drive the IGBT IRG4PH50UD.

The required isolated power supplies for the gate driver ICs is derived from 230 V / 16 V

transformer with ten windings, out of which six are rated for 200mA continuous current rating

two for 500 mA and two are 500mA with 230 V/6 V rating . The six power supplies are used

for the driver of the inverter and the remaining for auxiliary circuits like level shifter, current

sensor in sensing board and buffer IC. The buffer IC used between the DSP controller and thegate driver is 74LS573. The important components of hardware setup for three phase inverter

are shown in Table 4. The summary of operational specifications of the inverter is given in

Table 5.

TABLE. 4: Components used for hardware setup of three phase inverter

Sr. No Component Type

1. Switches IGBT-IRG4PH50UD

2. Gate Driver HCPL3120

3. Buffer 74LS573

4. Regulator LM 7815/7805

5 Rectifier DB107

-

8/12/2019 Report 4correction

46/90

-

8/12/2019 Report 4correction

47/90

Flux optimization for indirect vector control of induction motor

40

HCPL312074LS

573

330 ohm

10 ohm

IN4148

TO GATE

TO EMITTER

GND Vcc

INPUT

FROM

DSP

1

2

3

46

7

5

8 10uF/63v

Fig.5. 3: Gate driver circuit for inverter switches.

To turn ON the IGBT, gate to source voltage should be greater than the threshold

voltage. If the gate to source voltage is less than the threshold voltage, then the IGBT will be

turned off. Generally the threshold voltage is of +5 volts. Gate signals require isolation from

power circuit which is achieved by means of opto-coupler circuit. The gate control signals are

low voltage level signals .The low level PWM signal from DSP is isolated and amplified by

the driver circuit. Six such circuits have been fabricated with individual power supplies for

driving the IGBTs of inverter.

5.4. Design of PCB Layout for Inverter and Gate Driver using

CadSofts Eagle software

The single sided PCB layout of three phase inverter is as shown in Fig 5.4. The PCB is

designed with the help of CadSofts EAGLE software (version 5.6.0) for power supply

section, driver section and inverter section. In driver circuit section, six gate driver ICs are

used to drive six IGBT switches. The driver IC requires +15 volt power supply which is

derived from the isolated transformer with rectifier, filter circuit and voltage regulator

(LM7815) IC. Current handling capacity of the power circuit track is 6 A.

-

8/12/2019 Report 4correction

48/90

Flux optimization for indirect vector control of induction motor

41

Fig.5. 4:PCB layout of inverter section

Fig.5.5 shows the photo of inverter circuit with common heat sink driver circuit, and auxiliary

power supply circuit.

Fig.5. 5: Photograph of hardware of three phase inverter and gate driver with isolated supply

POWER

SUPPLY

BUFFER

74LS573

SWITCHES

CONTROL

CIRCUIT

SWITCHES WITH

COMMON HEAT

SINK

POWER

SUPPLY

BUFFER

74LS573

CONTROL

CIRCUIT

-

8/12/2019 Report 4correction

49/90

Flux optimization for indirect vector control of induction motor

42

The step down transformer has ten isolated secondary winding out of which six

secondary windings of 16 V, 200mA is used for supply of driver circuit. Two 16 V, 500mA

isolated windings of the transformer are used to provide auxiliary supply for current sensing

amplifier circuit. Another two isolated windings of the transformer is giving 6 V, 200mA

AC. One is rectified and given to the regulator which regulates output voltage to 1.5 volts.

The regulator used is LM317. This 1.5 DC voltage is used to provide DC phase shift for the

input signals of the processor. 5 V DC which is used for buffer IC is also generated.

5.5. Design of Voltage and Current Sensing Circuit

The single sided PCB layout of voltage and current sensing circuit is shown in

fig.5.6.Two LEM HX-03 type of current sensors are used to sense the currents of two phases

of the induction motor driven by the inverter. Output of LEM current sensor is in the form of

voltage which is in the range of -4V to 4V for the current range of 0-3 A, Two step-down

transformers are used to sense voltages of the induction motor .Two phase voltages are sensed

by potential transformers. The line to line voltage across the motor terminals is stepped down

to 3 V with the help of transformers of 230V / 3V, 500mA ratings.

The ADC of DSP is unidirectional and can handle only 3.3 V maximum so that all

input sensed signals are adjusted below 3.3V with the help of potentiometer and shifted by

+1.5 V DC. The pot used is of 10 k. Both sensed voltage and current signals after suitable

processing are fed to DSP processor ADC pins. Fig.5.7 shows the photo of current sensor,

voltage sensor and auxiliary power supply fabricated on one board

-

8/12/2019 Report 4correction

50/90

Flux optimization for indirect vector control of induction motor

43

Fig.5. 6: PCB layout of sensing board.

POWER

SUPPLY

CURRENT

SENSOR-

(LEM-03HX) PT-230V/3V

-

8/12/2019 Report 4correction

51/90

Flux optimization for indirect vector control of induction motor

44

Fig.5. 7 : Component view of sensing board

5.6 Laboratory Setup of the Complete System

The laboratory setup with a step up transformer and filter is as shown in Fig.5.8. Setup

consists of 0.37kW inductions motor which is fed by Voltage Source Inverter (VSI). The two

current sensors-LEM HX-03 and two potential transformers are used to sense the currents and

voltages respectively.

Current sensor

(LEM HX-o3P)

Power supply

-

8/12/2019 Report 4correction

52/90

Flux optimization for indirect vector control of induction motor

45

Fig.5. 8 : Laboratory setup

5.7 Description of TMS320F28069

Thecomplete application is processed using the DSP software. The flowchart for the same is

shown in fig 5.9. The three main operations are voltage and current measurements of

induction motor, vector control and the PWM generation. With the help of ADC, we measure

the voltage and current. The flux and actual torque is calculated from the sensed voltage and

current using the voltage model. The implementation of vector control is done as explained in

chapter 3.

STEP-UP

TRANSFORMER

(80V/230V)

MOTOR (0.5HP)

FILTER

CAPACITOR &

INDUCTOR

DSP PROCESSOR

28069

EXPERIMENTALBOARD

SENSING

CIRCUIT

POWER

SUPPLY

DSO

-

8/12/2019 Report 4correction

53/90

Flux optimization for indirect vector control of induction motor

46

Read ADC

channel4 (Output

of speed Encoder )

TransformStationary

2-phase dq into

Rotating refrance

frame

Transform 3 phase

abc into

2-phase dq

Read Sampled

value of Current &

voltage from ADC

channel

Calculate rotor flux

torque and theta

angle

Obtain error in speed

by comparing speed

ref. with measured

speed

Calculate

Reference Torque

by Speed PI

Controller

Calculate Current

Iq*

Obtain Vq*from

Current PI

controller

Calculate Id* from

Reference flux

Obtain Vd*from

Current Pi

controller

Transform Vd* and

Vq* into stationary

reference frame

Transform

stationary reference

frame voltage into

abc frame

Return from ISR

Obtain error in

current by comparing

ref. current withactual current

Obtain error in

current by comparing

ref. current with

actual current

A

ASTART

Fig.5. 9: Flow chart of program for Vector control

The Texas Instrument Experimental kit TMS320F28069 has many features making it suitable

for power electronics applications

-

8/12/2019 Report 4correction

54/90

Flux optimization for indirect vector control of induction motor

47

5.7.1Features of the controller

1. High-Efficiency 32-Bit CPU (TMS320C28x)

2.

80 MHz Clock (12.5-ns Cycle Time)

3. 16 x 16 and 32 x 32 MAC Operations

4. 16 x 16 Dual MAC

5.

Harvard Bus Architecture

6. Atomic Operations

7. Fast Interrupt Response and Processing

8. Unified Memory Programming Model

9. Code-Efficient (in C/C++ and Assembly)

5.7.2 Block diagram of TMS320F28069

It is 32-bit fixed point microcontroller which is used for controlling purpose in industries for

automation, lighting, robotics, power supplies.

Fig.5. 10: Block Diagram of TMS320F28069

The TMS320F28069 also supports many communication protocol making it very suitable for

various industrial applications. The dedicated ePWM (enhanced PWM) blocks make CPU to

work efficiently for control algorithm. The Fig 5.11 shows the image of experimental kit ofTMS320F28069

-

8/12/2019 Report 4correction

55/90

Flux optimization for indirect vector control of induction motor

48

Fig.5. 11: Image of experimental kit of TMS320F28069

5.7.3 General-Purpose Input /Output (GPIO)

The GPIO MUX registers are used to select the operation of shared pins on the 280x

devices. The pins are named by their general purpose I/O name i.e. GPIO0 - GPIO34. These

pins can be individually selected to operate as digital I/O, referred to as GPIO, or connected to

one of up to one of three peripheral I/O signals (via the GPAMUX1, GPAMUX2 and

GPBMUX1 registers). If selected for digital I/O mode, registers are provided to configure the

pin direction (via the GPADIR and GPBDIR registers).

5.7.4Event Manager

The event-manager (EV) modules provide a broad range of functions and features thatare particularly useful in motion control and motor control applications. The EV modules

include general-purpose (GP) timers, full-compare/PWM units, capture units, and quadrature-

encoder pulse (QEP) circuits. The two EV modules, EVA and EVB, are identical peripherals,

intended for multi-axis/motion-control applications EVA and EVB timers, compare units, and

capture units function identically. However, timer/unit names differ for EVA and EVB.

-

8/12/2019 Report 4correction

56/90

Flux optimization for indirect vector control of induction motor

49

5.7.5ADC

The ADC module has 16 channels, configurable as two independent 8-channel

modules to service event managers A and B. It has built in dual sample and hold. It provides

simultaneous sampling and sequential sampling modes. It has fast conversion time up to12.5

MSPS. it has 2X8 channel multiplexed inputs. The start of conversion can be given by

external pin .analog input range is 0 to 3.3 V. The digital value of the input analog voltage is

derived by:

Digital Value =4096*((analog input voltage-ADCLO)/3.3)

The two independent 8-channel modules can be cascaded to form a 16-channel module.

Although there are multiple input channels and two sequencers, here is only one converter in

the ADC module. The two 8-channel modules have the capability to auto sequence a series of

conversions, each module has the choice of selecting any one of the respective eight channels

available through an analog MUX. In the cascaded mode, the auto sequencer functions as a

single 16-channel sequencer. On each sequencer,once the conversion is complete, the selected

channel value is stored in its respective RESULT register.

5.7.6 PWM

An ePWM module represents one complete PWM channel composed of two PWM

outputs: EPWMxA and EPWMxB, ePwm sub-module are as shown in Fig. 4.11. Each ePWM

module supports the following features:

Dedicated 16-bit time-base counter with period and frequency control

Two PWM outputs (EPWMxA and EPWMxB) that can be used in the following

configurations:

Two independent PWM outputs with single-edge operation

Two independent PWM outputs with dual-edge symmetric operation

One independent PWM output with dual-edge asymmetric operation

-

8/12/2019 Report 4correction

57/90

Flux optimization for indirect vector control of induction motor

50

Fig.5. 12: Sub-modules of an ePWM Module

Asynchronous override control of PWM signals through software. Dead-band generation

with independent rising and falling edge delay control.

PWM output signals (EPWMxA and EPWMxB): The PWM output signals are made

available external to the device through the GPIO peripheral described in the system

control and interrupts guide for your device.

ADC start-of-conversion signals (EPWMxSOCA and EPWMxSOCB): Each ePWM

module has two ADC starts of conversion signals. Any ePWM module can trigger a start

of conversion. Which event triggers the start of conversion is configured in the Event-

Trigger sub-module of the ePWM.

5.7.7 Calculating PWM Period and Frequency

The frequency of PWM events is controlled by the time-base period (TBPRD) register and the

mode of the time-base counter. The time-base counter has three modes of operation selected

by the time-base control register (TBCTL):

-

8/12/2019 Report 4correction

58/90

Flux optimization for indirect vector control of induction motor

51

Up-Down-Count Mode: In up-down-count mode, the time-base counter starts from

zero and increments until the period (TBPRD) value is reached. When the period

value is reached, the time-base counter then decrements until it reaches zero. At this

point the counter repeats the pattern and begins to increment.

Up-Count Mode: In this mode, the time-base counter starts from zero and increments

until it reaches the value in the period register (TBPRD). When the period value is

reached, the time-base counter resets to zero and begins to increment once again.

Down-Count Mode: In down-count mode, the time-base counter starts from the period

(TBPRD) value and decrements until it reaches zero. When it reaches zero, the time-

base counter is reset to the period value and it begins to decrement once again.

For the project to generate the PWM pulses updown count mode is selected because