Copyright 2000, SPE/PS-CIM International Conference on Horizontal Well Technology This paper was prepared for presentation at the 2000 SPE/Petroleum Society of CIM Inter- national Conference on Horizontal Well Technology held in Calgary, Alberta, Canada, 6-8 November 2000. This paper was selected for presentation by an SPE/PS-CIM Program Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the Society of Petroleum Engineers or the Petroleum Society of CIM and are subject to correction by the author(s). The material, as presented, does not necessarily reflect any position of the Society of Petroleum Engineers, the Petroleum Society of CIM, their officers, or members. Papers presented at SPE/PS-CIM meetings are subject to publication review by Editorial Committees of the Society of Petroleum Engineers and Petroleum Society of CIM. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435. Abstract Horizontal wells are becoming a very important component in the thermal recovery of heavy oil reservoirs. The success of a cyclic steam injection project depends strongly on the selection of key parameters, such as cycle length and amount of steam injected. The numerical simulation of horizontal wells, especially under non-isothermal conditions, is computationally demanding. When optimization is combined with numerical simulation, the computing time requirement may be prohibitive and it is not guaranteed that the optimal conditions will be found. In this research, a new methodology has been developed for optimizing the cyclic steam injection process for vertical and horizontal wells. The procedure integrates oil production characterization using numerical simulation, net present value maximization through a Quasi-Newton method, and model validation/tuning. The three-stage procedure provides the optimum number and/or duration of cycles, the optimal amounts of steam to be injected in each cycle and the optimal value of the overall economic indicator. The optimization algorithm was successfully validated with published results obtained from the discrete maximum principle. The methodology was then applied to determine the optimal conditions of cyclic steam injection for a horizontal well located in Bachaquero field, Venezuela. Introduction Thermal stimulation of heavy-oil producing wells by cyclic steam injection has received attention since the early 1960’s. Currently, steam stimulation is being applied on a commercial scale, particularly in Venezuela, California and Canada. With the arrival of horizontal well technology, the production from heavy and extra heavy oil reservoirs has been considerably improved. One of the prospective areas for using horizontal wells is thermal recovery using steam. Horizontal wells represent an indispensable technology for the production of bitumen or extra heavy oil formations. Process like SAGD, HASD drive, and Vapex have been specially designed using horizontal wells for recovery of oil that is immobile at original reservoir conditions. Today, these processes represent the most feasible alternatives to produce relatively deep bitumen formations. For conventional heavy oil reservoirs, the selection of horizontal wells is not a simple issue. Horizontal wells have been successfully applied in areas where gas and/or water conning is the major problem. However, factors such as vertical and horizontal permeability anisotropy, reservoir thickness, and sand production have strong influence in the production performance of this type of well. Under specific reservoir scenarios, the use of horizontal wells does not always represent the best alternative. In thermal oil recovery like cyclic steam injection and steam drive, horizontal wells have notable advantages over vertical wells such as better heat distribution and lateral transportation of fluids. In addition, the number of wells necessary to produce a pattern decreases in reservoirs with close well spacing. Nevertheless, the success of the steam injection process strongly depends on ensuring a uniform placement of the steam along the total well length. Success in the combination of cyclic steam injection with horizontal wells will depend upon an appropriate technical and economic design. To the best of our knowledge, no optimization methodology has been developed to support design decisions about thermal stimulation of horizontal wells. Among the complications associated with this task are the lack of long field experience under a wide range of conditions, and lack of an analytical solution to predict the oil recovery from a thermally stimulated horizontal well. Thermal simulation of cyclic steam injection with horizontal wells involves large amounts of time. Therefore, it is an interesting challenge and an imminent necessity to SPE/Petroleum Society of CIM 65525 Optimization Methodology for Cyclic Steam Injection With Horizontal Wells E. Escobar, SPE, PDVSA INTEVEP, P. Valkó, SPE, Texas A&M, W.J. Lee, SPE, Texas A&M, M.G. Rodríguez, SPE, PDVSA E&P

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Copyright 2000, SPE/PS-CIM International Conference on Horizontal Well Technology

This paper was prepared for presentation at the 2000 SPE/Petroleum Society of CIM Inter-national Conference on Horizontal Well Technology held in Calgary, Alberta, Canada, 6-8November 2000.

This paper was selected for presentation by an SPE/PS-CIM Program Committee followingreview of information contained in an abstract submitted by the author(s). Contents of thepaper, as presented, have not been reviewed by the Society of Petroleum Engineers or thePetroleum Society of CIM and are subject to correction by the author(s). The material, aspresented, does not necessarily reflect any position of the Society of Petroleum Engineers, thePetroleum Society of CIM, their officers, or members. Papers presented at SPE/PS-CIMmeetings are subject to publication review by Editorial Committees of the Society of PetroleumEngineers and Petroleum Society of CIM. Electronic reproduction, distribution, or storage ofany part of this paper for commercial purposes without the written consent of the Society ofPetroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstractof not more than 300 words; illustrations may not be copied. The abstract must containconspicuous acknowledgment of where and by whom the paper was presented. WriteLibrarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

AbstractHorizontal wells are becoming a very important component inthe thermal recovery of heavy oil reservoirs. The success of acyclic steam injection project depends strongly on theselection of key parameters, such as cycle length and amountof steam injected. The numerical simulation of horizontalwells, especially under non-isothermal conditions, iscomputationally demanding. When optimization is combinedwith numerical simulation, the computing time requirementmay be prohibitive and it is not guaranteed that the optimalconditions will be found.

In this research, a new methodology has been developedfor optimizing the cyclic steam injection process for verticaland horizontal wells. The procedure integrates oil productioncharacterization using numerical simulation, net present valuemaximization through a Quasi-Newton method, and modelvalidation/tuning. The three-stage procedure provides theoptimum number and/or duration of cycles, the optimalamounts of steam to be injected in each cycle and the optimalvalue of the overall economic indicator.

The optimization algorithm was successfully validatedwith published results obtained from the discrete maximumprinciple. The methodology was then applied to determine theoptimal conditions of cyclic steam injection for a horizontalwell located in Bachaquero field, Venezuela.

Introduction

Thermal stimulation of heavy-oil producing wells by cyclicsteam injection has received attention since the early 1960’s.

Currently, steam stimulation is being applied on a commercialscale, particularly in Venezuela, California and Canada.

With the arrival of horizontal well technology, theproduction from heavy and extra heavy oil reservoirs has beenconsiderably improved. One of the prospective areas for usinghorizontal wells is thermal recovery using steam.

Horizontal wells represent an indispensable technology forthe production of bitumen or extra heavy oil formations.Process like SAGD, HASD drive, and Vapex have beenspecially designed using horizontal wells for recovery of oilthat is immobile at original reservoir conditions. Today, theseprocesses represent the most feasible alternatives to producerelatively deep bitumen formations.

For conventional heavy oil reservoirs, the selection ofhorizontal wells is not a simple issue. Horizontal wells havebeen successfully applied in areas where gas and/or waterconning is the major problem. However, factors such asvertical and horizontal permeability anisotropy, reservoirthickness, and sand production have strong influence in theproduction performance of this type of well. Under specificreservoir scenarios, the use of horizontal wells does notalways represent the best alternative.

In thermal oil recovery like cyclic steam injection andsteam drive, horizontal wells have notable advantages oververtical wells such as better heat distribution and lateraltransportation of fluids. In addition, the number of wellsnecessary to produce a pattern decreases in reservoirs withclose well spacing. Nevertheless, the success of the steaminjection process strongly depends on ensuring a uniformplacement of the steam along the total well length.

Success in the combination of cyclic steam injection withhorizontal wells will depend upon an appropriate technical andeconomic design. To the best of our knowledge, nooptimization methodology has been developed to supportdesign decisions about thermal stimulation of horizontal wells.Among the complications associated with this task are the lackof long field experience under a wide range of conditions, andlack of an analytical solution to predict the oil recovery from athermally stimulated horizontal well.

Thermal simulation of cyclic steam injection withhorizontal wells involves large amounts of time. Therefore, itis an interesting challenge and an imminent necessity to

SPE/Petroleum Society of CIM 65525

Optimization Methodology for Cyclic Steam Injection With Horizontal WellsE. Escobar, SPE, PDVSA INTEVEP, P. Valkó, SPE, Texas A&M, W.J. Lee, SPE, Texas A&M, M.G. Rodríguez, SPE,PDVSA E&P

2 E. ESCOBAR, P. VALKÓ, W.J. LEE, M.G. RODRÍGUEZ SPE/PS-CIM 65525

develop a systematic methodology that combines numericalsimulation with an optimization method to obtain, inreasonable time, the optimum design conditions representedby the amount of steam to inject in each cycle, the respectiveproduction times and the number of cycles.

In this research, a new methodology has been developedfor optimizing the cyclic steam injection process for verticaland horizontal wells. The procedure integrates three stages: oilproduction characterization, net present value maximizationand model validation/tuning. The three-stage procedureprovides the optimal number and/or duration of cycles, theoptimal amounts of steam to be injected in each cycle and theoptimal value of the overall economic indicator.

Cyclic Steam Injection ProcessCyclic steam injection, also referred to as thermal stimulation,steam soaking or the huff-and-puff steam injection process, isa single-well process usually applied to heavy oil reservoirs.

The primary objective in a cyclic steam injection process isto provide thermal energy in the vicinity of the wellbore, usingthe steam as the heat transport medium and allowing the rockto act as a heat exchanger for storage of the injected energy.This heat may then be used effectively to decrease theviscosity of the oil flowing through the heated region.

The process involves three phases: the rapid, buttemporary, injection of wet steam (quality around 70 to 85%)for a specific period of time (1 to 6 weeks) into a producingwell; a short soak period (3 to 6 days), in which most of thelatent heat of the steam is transferred into the formationsurrounding the well; and finally, a period where the well isput back on production for several months.

During the last period, the production rate of hot fluidsstarts higher than that of the primary cold production.However, the rate declines with time to near the pre-stimulation values, as heat is removed with produced fluidsand dissipated into nonproductive formations. These threephases are repeated cycle by cycle, until the process becomesunprofitable.

From a technical point of view, two main factors arenecessary for the success of this kind of process: a significanteffect of temperature on the viscosity of the heavy crude oil, toreduce the flow resistance around the producing well; and anatural production mechanism or a driving force present in thereservoir initially. Typically, gravity drainage and solution-gasdrives are the most important mechanisms in providingdriving forces during the production phase. In addition, rockcompaction might be particularly effective when an extensivearea of the reservoir is subjected to thermal operations.1

From an operational point of view, cyclic steam injectionwas immediately accepted because the application of theprocess is simple: a single steam generator may service a largenumber of wells. In addition, if the process is successful,increased oil production happens immediately, since the oilremains hot as it flows to the well.

Cyclic Steam Injection Using Horizontal Wells. In general,thermal oil recovery processes have been improved with theincorporation of horizontal wells. The main advantages of thehorizontal wells are improved sweep efficiency, increasedproducible reserves, increased steam injectivity, and decreasednumber of wells required for field development.2

Some numerical simulation studies applied to specificreservoirs,3,4 along with conceptual cases representative ofnon-depleted, conventional heavy oil,5 have noted theimprovement in recovery obtained with the application ofcyclic steam injection in horizontal wells. However, for thecase of bitumen, a conceptual study6 showed a betterperformance of cyclic steam injection on a pattern of verticalwells than with horizontal wells. Recently, a simulation studyof a depleted zone in Bachaquero field7 reported a similarconclusion. However, these works did not attempt to comparethe optimal technical and economical injection conditions forthe competing patterns.

Some field applications of cyclic steam injection usinghorizontal wells have been reported in the literature.3,4,8,-12

Even though most of these applications have shown favorableperformance, rigorous conclusions will be available only aftera longer evaluation period.

Optimization of the Cyclic Steam Injection. Cyclic steaminjection is a good example of a multistage, multidimensionaloptimization problem. Each cycle represents a stage in whichthe amount of steam injected (defined as volume of equivalentwater), W j, and the production time, ∆tp

j, corresponding toeach cycle are the control or decision variables. The objectivefunction is represented by the cumulative discounted netincome at the end of the final cycle, CDNIn, that has to bemaximized, using operational costs and the amount of oilproduced in each cycle as the state variables. Both theobjective function and the constraints involve a large numberof technical and economic parameters that have to be providedas input to the optimization algorithm.

The literature shows many examples that illustrate thediversity of optimization methods and their applications inalmost all branches of petroleum engineering.

Some models have been proposed to optimize the processof cyclic steam injection with vertical wells. However, to date,little work has been done in the area of cyclic steam injectionwith horizontal wells.

Trebolle et al.13 used numerical simulation together with asensitivity analysis to optimize the cycle-steam operatingstrategy for the Bachaquero-01 reservoir in Venezuela. Thestudy provided numerical simulation support for the optimaldesign of the steam cycles, compared with the current practicewhich was based on field experience and on the stimulation ofover 500 cycles in 30 years. The study concluded that theoptimization could improve economic efficiency. It alsorecommended the use of horizontal wells.

Mehra et al.14 developed operating guidelines for cyclicsteam injection in a water-underlain, oil-sands reservoir inCold Lake, Canada. Their study involved a stochastic

SPE/PS-CIM 65525 OPTIMIZATION METHODOLOGY FOR CYCLIC STEAM INJECTION WITH HORIZONTAL WELLS 3

simulation to quantify risks associated with fracturing intowater sands. The authors conducted a numerical simulation toobtain correlations among the cumulative production volumesand selected operating variables. Also, they developed aneconomic model to maximize profits under differentconstraints. The study concluded that, rather than uniqueconditions, a wide range of operating conditions can maximizethe project profitability.

Dunn15 used an exponential decline approximation tocharacterize the production history of a steam-stimulated well.He provided an incremental analysis of production todetermine the length of the cycle and the selection of the wellto be thermally stimulated.

Curry et al.16 improved the approach developed by Dunn.15

They proposed a simple method to optimize the profit fromcyclic steam injection and to design the well schedules forsteaming on the basis of the availability of the steamgenerators and the steaming priority of specific wells.

Hong and Jensen17 developed a most complete analyticalmethod to optimize the cyclic steam injection process withvertical wells. Their method uses field data to calibrate aconstant percentage or a harmonic decline model to estimatethe oil production rate during each cycle. Also, they propose arelationship between the amount of steam injected in eachcycle and the overall production. Each cycle is finished whenthe stimulated oil production rate is equivalent to the coldproduction rate at the end of the preceding cycle. The optimalcycle length and steam volume in each cycle are obtainedusing an optimization algorithm based on the discretemaximum principle. The algorithm generates a system ofnonlinear equations, whose unknowns are the optimal valuesof the design variables. The algorithm maximizes thecumulative discounted net income at the end of the final cycle,using an incremental economic analysis that takes as areference the cold production conditions.

Cyclic Steam Injection - Oil Recovery Estimation.Modeling the cyclic steam injection process is one of the mostchallenging tasks in reservoir engineering. Abrupt heat andfluid flow reversals, temperature sensitive permeability,permeability hysteresis, and multiple and changing reservoirmechanisms all complicate the solution.17

The recovery of a well stimulated with steam can bepredicted using analytical and numerical models. Analyticalmodels are separated into two groups: models based onestimation of heat distribution around the wellbore (verticalwells only) and models based on production decline curves.All of these techniques need, to more or less extent, somecalibration with field production data to increase theconfidence range of the prediction.

The problem is more complex for cyclic steam injectionwith horizontal wells. At this time, the petroleum industrylacks an analytical method to predict the oil production of ahorizontal well thermally stimulated with steam.

Numerical simulators are the most reliable and accuratetools for predicting the behavior of thermal process. However,

computational stability is the main difficulty with this kind ofsimulators. The combination of numerical simulation, cyclicsteam injection and horizontal wells require longcomputational time, but represent the only alternative to studythis process.

Optimization MethodologyIn this work, a new three-stage characterization-optimization-tuning scheme was developed to obtain the optimal designconditions for a cyclic steam injection process.

The methodology developed for the optimization of acyclic steam injection project consists of three stages.

Production Characterization. In this phase a set ofnumerical simulation runs are conducted at different injectionconditions, using data that represent, with reasonableaccuracy, the typical behavior of a specific reservoir. Theanalysis of these runs allows us to identify the appropriateproduction decline model and its corresponding fittingparameters that best represent the actual production behaviorin the range of conditions investigated.

Commercial reservoir simulators are available to study thethermal process performance. The thermal numericalsimulator used in this work was Eclipse-500 (Schlumberger-GeoQuest),18 version 98-a.

Optimization. The parameters of the production model,obtained in the previous stage, are the input data to theoptimization program. From this algorithm the optimalamount of steam injected, together with the production lengthof each cycle, are estimated.

Tuning (feedback). Finally, a tuning stage is run to verifythe conditions predicted by the optimization algorithm. In thisstage, the optimal values obtained in the previous stage areintroduced into the numerical simulator. The results obtainedare compared with the input data, and, if there is a significantdiscrepancy, the process is repeated to convergence within areasonable tolerance. In this case, however, thecharacterization stage will be run only for a narrow range ofdecision variables representing a restricted neighborhood ofthe current estimate of the optimal conditions.

Production Decline Models. The optimization algorithm hasto be able to estimate the oil rate and the total oil production,at cold and hot conditions in a wide range of amounts of steamto be injected. To do that, we introduce into the algorithmproduction decline models, whose parameters have beendetermined previously, to represent the production conditionsof a specific stimulated reservoir.

At thermal stimulation conditions, we can assume that theinitial flow rate corresponds to the maximum value. We willcall this value qsj

max. As Hong and Jensen17 proposed, thesuperscripts s and j will be used to denote steamed conditionsat a generic cycle j.

The production time for cycle j, ∆tpj, is expressed by

jI

jjjp tttt −−=∆ −1

(1)

4 E. ESCOBAR, P. VALKÓ, W.J. LEE, M.G. RODRÍGUEZ SPE/PS-CIM 65525

and represents the elapsed time between the end of the soaktime of cycle j, and the start of injection in the next cycle, j+1.

In Eq. 1, tj represents the total time from the projectbeginning, t j-1 is the total time at the end of the cycle j-1 andtI

j is the time during the injection and soak stages. Theinjection time can be variable in most cases.

Three production decline models were considered.Constant Percentage Decline

( )jI

jjh tttDsjsj eqtq −−− −

=1

max)( (2)

and

sjp

sjfin

sjmaxj

h N

qqD

−= . (3)

Where Dhj is the decline factor, qsj

fin is the final productionrate at the end of the cycle j, and Np

sj is the overall productionof the cycle j.

Harmonic Decline

( )[ ] 111)(−− −−+= j

Ijj

hsjmax

sj tttDqtq (4)

and sjfin

sjmax

sjp

sjmaxj

h qq

Nq

D ln= . (5)

Hyperbolic Decline

[ ] jbjI

jjjh

sjsj tttbDqq1

11max )(1

−−− −−×+= (6)

and

( )( ) ( )

−

−=

−− jj bsjfin

bsjmaxsj

pj

sjmaxj

h qqNb

qD

11

1 . (7)

For the case of hyperbolic decline, it is necessary to obtaina relationship between the factor bj in Eqs. 6 and 7 and Wj. Wedeveloped the following correlation, which fits the values of bj

with reasonable precision.

( ) jGWGj Gebjjj

3* 21 += +

(8)

In Eq. 8, G1j, G2

j, and G3j, are parameters that are

determined using a nonlinear regression technique19.

Criterion to Stop the Cycle. In general, a cycle is stoppedwhen the production rate is comparable with thecorresponding cold production. Hong and Jensen17 suggestedusing an oil rate equal to the cold production rate at the end ofthe cycle j-1, as a criterion to finish cycle j. Accordingly,

)()( 1−= jjsjfin tqtq , (9)

where q(tj-1) represents the cold production rate or oil primaryproduction rate at the end of cycle j-1.

The cold production rate can be obtained through aproduction decline model, as presented in Eqs. 2 to 7. The

model selected must be previously tuned with field data orwith data provided by a numerical simulator that properlyrepresents the cold production behavior of the field.

As an example, Eq. 10 represents the exponential declinemodel for the cold production. The subscript c in the declinefactor D means cold production. Equations equivalent to Eqs.4 and 6 can be also written for wells in which cold productionis better represented by harmonic or hyperbolic declinemodels.

( )0

)()( 0 ttDcetqtq −−= , (10)

where q(t0) is the cold production rate at time t0.

Overall Production Estimation. Hong and Jensen17

suggested the following mathematical relationship betweenthe amount of steam injected in each cycle, W j, and the over-all cumulative production Np

sj:

( )( )[ ]j

minjj

n WWd

sjminp

sjmaxp

sjminp

sjp

e

NNNN

−×−−

×−+=

1 . (11)

Again, the parameters Npsj

min, Npsj

max, dnj and W j

min areobtained by applying a nonlinear regression technique, usingas input data the information estimated from simulation runswhere different amounts of steam are injected.

Eq. 11 has the advantage of smoothing throughout theentire range of values of W j. Additionally, it is limited to aNp

sjmax when W j goes to infinity, and Np

sjmin when W j goes to

zero. Finally, it represents well the behavior observed in manycases. This expression was retained in our optimizationalgorithm.

Estimation of qsjmax. We observed that in general the

maximum oil rate for a cycle has a linear relationship with theamount of steam injected. So a straight-line equation (Eq. 12)was used.

jjjsj bWmq intmax * += , (12)

where mj and bintj are parameters to be fitted with the

simulation data.

Production Time by Cycle. As we can observe in the declinemodel equations (Eqs. 2, 4 and 6), if we introduce the declinefactor, the maximum production rate, the overall productionby cycle (and also the parameter b for the hyperbolic model),and the criterion to stop the cycle given by Eq. 9, then thecorresponding production time can be obtained. Hence, up tothis stage, the optimization algorithm will optimize only theamount of steam to inject by cycle, and we will consequentlyobtain the corresponding production time for the cycle. Thatmeans that we will not use the variables ∆tp

j as decisionvariables. Rather, they will be state variables. The way to alsooptimize the production time will be discussed later.

Optimization Algorithm. The cyclic steam injection processis very specific for the reservoir and the conditions of the wellthat is stimulated. For this reason, a priority in the

SPE/PS-CIM 65525 OPTIMIZATION METHODOLOGY FOR CYCLIC STEAM INJECTION WITH HORIZONTAL WELLS 5

development of our optimization algorithm was to obtain amodel that is simple to apply and easy to modify.

Hong and Jensen17 suggested an optimization algorithmbased on the discrete maximum principle. The application ofthis mathematical method produces a system of complex,nonlinear equations. For the specific case of a cyclic steaminjection process, the unknowns of the system are the optimalvalues of steam to inject, W j, and the production time ∆tp

j foreach cycle.

The optimization algorithm that we propose to solve theoptimization problem of a cyclic steam injection process isbased on a Quasi-Newton method and a finite-differentialgradient approximation. This algorithm is simpler to applythan the discrete maximum principle algorithm. Additionally,this method provides flexibility to introduce modificationsmore easily, because it works directly with the objectivefunction and does not require that we create and solve a largesystem of nonlinear equations.

Objective Function. The objective function that we wantmaximizes is represented by the cumulative discounted netincome at the end of the final cycle, CDNIn (Eq. 13). Thederivation of this equation was given by Hong and Jensen17.

( )

[ ] }{

( )[ ]js

jjI

jc

j

Itjt

jptj

Itjt

jIt

jt

sjc

jptIt

jtjn

WCCttqabi

dtatqtqab

iCDNICDNI

++−+

−−−−

++=

−

+−

−

∆++−

+−

∆++−

−−

∫

11

365

1

1

1 21

365

1

1

)()1(

)()()(

*1

(13)

where

jI

jj tttt ∆++= −1 (14)

and

CDNI n = 0 . (15)

The optimization algorithm maximizes the objectivefunction through two consecutive optimization loops, using asdecision variables the amount of steam injected, Wj (first loop)and the production time, ∆tp

j (second loop), both in each cycle.

Eq. 13 gives us flexibility to introduce specific economicparameters for each project to be considered, such asadditional or different operational costs and taxes. Sometimesthe cyclic steam injection involves the application of additives,like organic solvents or surfactants, to improve the steamdistribution inside the reservoir. Eq. 13 can be easily modifiedto incorporate the additional costs, and the optimizationalgorithm proposed could be applied to obtain the optimal

injection conditions (steam and additive amounts) for thisspecific problem.

Eq. 13 is defined to estimate the cumulative discounted netincome from an incremental analysis. That means that we areevaluating the incremental benefits of the steam injection overcold production. For some heavy oil reservoirs, it is commonthat the wells are drilled exclusively for thermal applications,because the primary production is uneconomical. For thesekinds of mutually exclusive projects, Eq. 13 can be easilymodified19 to represent the cumulative discounted net incomewithout comparing with the cold production, which is given inEq. 16. In that case, the drilling costs of the well areincorporated at the beginning of the project, and the benefitsare calculated without subtracting the primary production.

[ ]

[ ]365

)1(

11

365

)1(

1 21

)1(

*)()(

)1(

)()(

Itjt

js

jI

jfc

jptIt

jt

jt

Itjt

sjc

j

i

WCCttqab

i

dtatqabCDNI

+−−

−

∆++−

−

+−

+

+−−−

+

−−=

∫

( 16)

Algorithm Description. To maximize the objective function,an optimization algorithm based on a quasi-Newton methodand a finite-difference approximation of the gradient was used.

The optimization of a multivariable function such as givenby Eqs. 13 or 16 requires the evaluation of the Hessian matrix.The Hessian consists of the second partial derivatives of theobjective function with respect to the decision variables.

The gradient is a directional derivative of the objectivefunction. In our algorithm, the gradient is estimatednumerically, using a finite-difference approximation.

The quasi-Newton method20 is based on an estimation ofthe direct path to the optimum, using an iterative proceduresimilar to Newton’s method. However, this method avoidsusing the Hessian of the objective function. This is anadvantage, because most of the time these derivatives aredifficult or inconvenient to compute analytically. Instead, thequasi-Newton method uses another matrix that is constructedonly from the first partial derivatives of the objective function.The approximation matrix is updated in each iteration. Themethod is called quasi-Newton because we use anapproximation to the true Hessian matrix.

In our optimization algorithm, the amount of steam toinject in each cycle, W j, and the production length, ∆tp

j, willalways be positive numbers, so these variables are bounded as

ntojW j 1;0 =≥ , and

ntojt jp 1;0 =≥∆ . (17)

6 E. ESCOBAR, P. VALKÓ, W.J. LEE, M.G. RODRÍGUEZ SPE/PS-CIM 65525

The objective function represented by Eqs. 13 or 16 areoptimized by using the IMSL50 mathematical library21.Specifically, the subroutine DBCONF50 is suitable for solvingthis problem. A Fortran90 program was written to optimizethe objective function.

The algorithm has two consecutive optimization loops. Inthe first one, the optimal values of Wj are obtained. In thisstage, the production stage of a generic cycle j is finishedwhen the hot production rate is equal to the cold production attime t j-1. For these conditions, the values of overall productionfor each cycle are obtained from Eq. 11. The correspondingvalues of ∆tp

j are obtained through Eqs. 2, 4, or 6, afterestimating the decline factors through Eqs 3, 5, or 7, and qsj

fin

using Eq. 9.

However, it has been noted that the optimal conditions arenot always obtained while waiting for the well to come back tocold production. For this reason, an optional, secondoptimization loop is run. In this stage, the optimal values ofWj, with their corresponding production characterizationparameters, such as Dh

j and qsjmax (and bj for the hyperbolic

model) are kept constant from the first optimization loop. ∆tpj

is converted to a decision variable and the same subroutineDBCONF21 is used to obtain the optimal values of thesevariables. For this case, new values of Np

sj and qsjfin are

estimated in the process through Eqs. 2 to 8. The final set ofWj and ∆tp

j should define the optimal injection conditions for aparticular steam stimulation process.

Optimization Algorithm Verification

The proposed optimization algorithm was compared with thediscrete maximum principle method used by Hong andJensen.17 The methods were compared to each other using thedata and the three examples reported by Hong and Jensen.17

Example 1, Four Cycles. For a four-cycle stimulation project,determine the optimal set of steam volumes and cycle lengthsthat maximizes the cumulative discounted net income at theend of the fourth cycle.

As we can observe from Tables 1 and 2, our optimizationmethod gave values comparable to the results reported byHong and Jensen17 using the discrete maximum principlemethod.

Example 2, Project Life = 1,460 days. With the project lifespecified as 1,460 days (4 years), determine the optimumnumber of cycles and the optimum set of control variables thatmaximizes the cumulative discounted net income over thegiven project life.

To solve this problem, a new optimization algorithm wasdeveloped. The variables to optimize were switched from Wj

to the production length of the cycles, ∆tpj. A new IMSL

subroutine (DLCONF)21 was used to optimize the objectivefunction. This subroutine has the flexibility to use linearequality or inequality constrains. This advantage is used tointroduce the project life as the following linear equalityconstraint

jI

n

j

jp tntlifeprojectt *0

1

−−=∆∑=

. (18)

Only one optimization loop was used to solve thisproblem, where the production lengths for each cycle, ∆tp

j,were used as decision variables in the optimization algorithms.For the exponential case represented in Example 2 and usingthe usual constraints represented by Eq. 17, values of declinefactors, Dh

j, were obtained from Eq. 2; the correspondingoverall production, Np

sj, were obtained from Eq. 3; and finallythe values of Wj were obtained from Eq. 11. Eqs. 2, 3, 11, 13,and 18 were coupled with the optimization algorithm to obtainthe optimal values of ∆tp

j that maximize the cumulative netincome at the end of the last cycle.

We could observe19 a significant difference between thetwo approaches. The reason for the discrepancy is the lack of asecond loop to optimize Wj, because in our model, we do notconsider ∆tp

j and Wj as independent variables. We only use∆tp

j as control variables for this case. W j can be calculatedfrom the rest of the available data. To check this observation,we repeated Example 2, keeping W j and ∆tp

j independent.Results are shown in Tables 3 and 4.

The results are almost the same. However, we believe thatit is better to use the procedure with two optimizations loops,because there is an exact relation between ∆tp

j, W j, and Nps j,

and for the first optimization loop we do not neglect Eq.9.

However, these results show that it is possible to obtain thesame results using different optimization algorithms. Also, thisis an indirect way to validate our new optimization algorithm.

Example 3, Free Number of Cycles and Project Life.Neither the number of cycles nor the project life is specified. Itis desired to determine the optimal set of control variablescorresponding to the optimal number of cycles and optimalproject life that maximizes the cumulative discounted netincome.

For this example we applied the same algorithm used forExample 1. The results (Table 5 and 6) obtained with ouralgorithm match very well with the results of the Example 3reported by Hong and Jensen.17

As a summary of the results obtained in this section, wecan infer the following points:

• A new optimization algorithm has been developed tooptimize the cyclic steam injection.

• The algorithm combines a decline production model, arelationship between the amount of steam and the overalloil production, an objective function represented by thecumulative discounted net income, and a quasi-Newtonmethod to obtain the optimal design parameters, which arethe amount of steam to inject in each cycle and thecorresponding production times.

• The method was successfully validated by comparison ofthe results with the results obtained with the discretemaximum principle.

SPE/PS-CIM 65525 OPTIMIZATION METHODOLOGY FOR CYCLIC STEAM INJECTION WITH HORIZONTAL WELLS 7

Field Application - Reservoir Bachaquero-01

In this section, we present an application of our optimizationmethodology to a cyclic steam injection project in a heavy oilreservoir located in Bachaquero field on the eastern side ofLake Maracaibo, Venezuela.

The Bachaquero-01 reservoir was selected for thisevaluation because of an available recent production historymatch13 of a prospective zone using Eclipse-500. In addition,there is an operational interest of knowing the optimalconditions of cyclic steam injection with horizontal wells inthis area.

In 1999, Rodríguez7 conducted a 3D thermal simulation ofthe Bachaquero-01 reservoir to evaluate the performance ofcycling steam injection compared to steamflooding. This studywas done in three areas of Bachaquero-01 reservoir (LLHW1,LLHW2, and LLHW3) that contained a horizontal wellrecently drilled.

The Rodríguez research7 concluded that steamfloodingshould be the process to be used in this reservoir because ithad a higher recovery factor and thermal efficiency, togetherwith an effective repressurization of the reservoir, in contrastto the traditional cyclic steam injection process that had beenapplied in the field for more than 20 years.

Because of the high investment cost involved in switchingfrom cyclic steam injection to steamflooding and the recenteconomic crisis caused by the low oil prices, it is very possiblethat the change of technologies in Bacaquero-01 will not bedone in the near future. For this reason, it is of great interest toinvestigate what should be the performance of the cyclic steaminjection under optimal conditions. Specifically, we wish toevaluate the optimal design variables for a horizontal well inthis zone.

Reservoir Characteristics. Bachaquero-01 is a Miocenereservoir of unconsolidated sands, with a sedimentaryenvironment of fluvio-deltaic origin7. It is a monocline,dipping 20 to 30 to the southwest. The average depth is 3,000-ft. The reservoir is bounded on the south, west, and northwestby an aquifer of moderate strength.

Bachaquero-01 reservoir covers 19,450 acres with about7.037 BSTB OOIP. The oil gravity is 11.70 API with aviscosity of 365 cp at original region conditions of 1,360 psiaand 1280F.

Area LL-HW1 Description. To evaluate our optimizationmethodology we chose to work with the Area LL-HW1 and toestimate the optimal design variables for the horizontal WellLLHW1. Fluid and rock properties were available for thisanalysis.7,19

Area LL-HW1 is the least developed of Bachaquero-01. Itcovers a semi-rectangular area of approximately 110 acres,1,920 ft by 2,500 ft, with an average thickness of 360 ft. Thetop of the sand is at a depth of 2,940 ft. The area is composedof five layers: AP-1, 2 and 3, HH, and GG. The average rockpore volume compressibility is approximately 60 * 10-6 psia-1.

The simulation runs were done using two-hydrocarboncomponents, a light component with properties very similar tomethane and a heavy component with properties very similarto the heptanes plus.

Area LL-HW1 contains 6 wells, five verticals (LLVW1,LLVW2, LLVW3, LLVW4, and LLVW5) and one horizontalwell, LLHW1, drilled in May 1997 with a length of 1,000 ft.From these wells only LLVW3 (which has been producingsince 1955), LLVW4, LLVW5, and LLHW1 have had asignificant contribution to the oil production of the area.

Wells LLVW4, LLVW5, and LLHW1 have beenthermally stimulated. In March 1997, Well LLVW4 was in itssecond cycle. Well LLVW5 was in its third cycle and thehorizontal Well LLHW1, which was steamed immediatelyafter its drilling, was still in the first cycle. Table 7 shows thecharacteristics of each cycle.

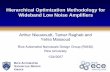

Grid Definition. We used a Cartesian grid composed of 1,200blocks distributed as 12 in the x direction, 20 in the ydirection, and 5 in the z direction, with local grid refinement inWells LLVW3, LLVW4, and LLHW1. Fig. 1 shows the area(plane x-y) and cross-section (plane x-z) for this model, withthe location of the 6 wells and their corresponding completionintervals.

Cold Production Characterization. In Area LL-HW1, onlyWells LLVW3 and LLVW4 have enough history ofproduction without steam stimulation to characterize the coldproduction stage. The hyperbolic decline model was selectedas the option to represent the cold-production conditions forboth wells.

Fig. 2 shows the results for Well LLVW4, and Table 8 thecorresponding parameters for characterizing the coldproduction with a hyperbolic decline model for Wells LLVW3and LLVW4.

Economic Analysis for the Steamed Vertical Wells. Table 9shows the economic data used in our evaluation. These valuesrepresent averages of 1999 economic conditions.

For reference purposes, we estimated the cumulativediscounted net income for the vertical wells that werestimulated with steam (LLVW4 and LLVW5)19.

Analysis of the injection and production data showed thatthe vertical wells had an abnormal performance behavior,because the overall oil production increased with the numberof cycles. Maybe better operational conditions, such as ahigher steam quality or an improvement in the wellcompletions, could be the reasons for this behavior. Inaddition, we noted that the production time within the cycleswas irregular. The reported range of 4 to more than 7 years isunusually large. While such discrepancies are usuallyinevitable when introducing a new technology, they certainlyobscure the economic analysis.

Using the cold production data from Well LLVW4 shownin Table 9 we conducted an incremental economics analysis19

for wells LLVW4 and LLVW5. The results led to thefollowing observations:

8 E. ESCOBAR, P. VALKÓ, W.J. LEE, M.G. RODRÍGUEZ SPE/PS-CIM 65525

• The two first cycles of Wells LLVW4 and LLVW5 hadproduction equivalent to or lower than the cold production.With this result, the economic indicators represented bythe cumulative discounted net income are negative.

• The worst case is represented by Well LLVW5, which hasnegative indicators after three cycles or 14 years of thermaloil recovery.

From these results, we can infer that cyclic steam injectionhas not been an efficient method of oil recovery in Area LL-HW1.

Horizontal Well Optimization – Problem Definition. Thefollowing factors were taken into the account to define ouroptimization problem.

We started our simulation work from the first cycle. Thatmeans that we took the results of the history matching up tothe moment that the horizontal well (LL-HW1) beganproduction (Jan/54 – May/97). From this point, we allowedone month of cold production before starting the steamstimulation.

In the field, Well LLHW1 was stimulated after drillingwithout allowing any time for cold production. Consequently,we decided to do the optimization design for this well usingthe option of mutually exclusive projects, discussed before.That means we cannot use cold production as a reference basefor an incremental economics analysis.

The cost of drilling a horizontal well in Area LLHW1 isapproximately $2 million; this amount was entered into ourdata file.

On the basis of experience in the field, we decided to use adrawdown pressure of 300 psia. Additionally, we set acriterion to stop the production cycle at a rate of about 150 to200 STB/D. The minimum reservoir pressure was fixed atabout 400 psia.

The maximum steam injection rate available in the zone is2,500 STB/D water equivalent and the steam quality in thesand face is about 75%. These parameters were kept constantin our simulation runs.

The next step was to model and analyze the hotproduction.

Optimization of Cyclic Steam Injection for Well LLHW1.A series of runs was done with Eclipse-500. For all the cycles,a hyperbolic decline model was used to represent the wellperformance under thermal conditions.

The first cycle was run in a range of steam injection of25,000 to 150,000 STB. When all the parameters forcharacterizing the production of this first cycle were obtained,we ran a first optimization of this cycle. The optimal amountof steam for the first cycle was about 100,000 STB ofequivalent water injected. Because there are operationallimitations, we had to fix the amount of steam to inject in thefirst cycle at 70,000 STB.

With this value fixed for the first cycle, together with itscorresponding production time, we repeated the general

procedure to characterize the second cycle. When we obtainedall the parameters to characterize the second cycle, we ran ouroptimization algorithm for two cycles and obtained theoptimal values for the second cycle. With the amount of steamto inject in the first and the second cycle fixed, together withtheir respective production times, we characterized the thirdcycle. We repeated this procedure cycle by cycle. Finally, wefound that for a fifth cycle, the cumulative discounted netincome was lower than the corresponding one for the fourthcycle. At this point, we finished our optimization work. Fig. 3shows the hot production characterization results for the fourcycles.

The correlations used to describe the relationship of qsjmax,

Npsj, and bj with the amount of steam injected, W j, provided

excellent fits.

The initial oil rate and the overall production decrease withthe number of cycles. This is a direct result of the pressuredepletion in the reservoir.

Table 10 presents the parameters used to characterize theoil production under thermal stimulation. Table 11 presentsthe optimal design parameters for cyclic steam injection ofwell LLHW1.

Fig. 4 shows the results of the tuning stage, where theoptimal values of W j and ∆tp

j were introduced in the Eclipse-500 run. An excellent match was obtained.

The average fluid temperature in the complete area was notaltered by heating in the horizontal well. The averagetemperature was kept constant at 128 0F.

Reservoir pressure depleted at an average rate of 45psi/year, with grater depletion rates in the first cycle. Thiscycle produced an average of 478,102 STB.

Low steam/oil ratios (0.15 - 0.39) were obtained in all thecycles. This result suggests excellent thermal efficiency in theprocess. Trebolle et al.13 reported values of 0.32 from aparametric study done in the field.

The relation of energy injected to total thickness was in therange of 70 to 17 MMBtu/ft. Trebole et al.13 reported valueson the order of 142 STB of steam (equivalent water)/ft. In ourcase, we are in the range of 194.4 for the first cycle to 47 STBof steam/ft for the fourth cycle.

The results obtained in the previous section show that theoptimization method appears to work well for a real case.However, we cannot say that these results should be applied tothe field directly. To do that we need to have more fieldinformation to accurately represent the production behavior ofthe well.

In the definition of the problem, we applied generalinformation about the production criteria used in the field.These data should be more specific for the area around thewell. Information about well skin was not available. It ispossible that the effective length of this well is shorter than1,000 ft.

SPE/PS-CIM 65525 OPTIMIZATION METHODOLOGY FOR CYCLIC STEAM INJECTION WITH HORIZONTAL WELLS 9

Conclusions

1. A new methodology to obtain the optimal design valuesin a cyclic steam injection process for vertical and horizontalwells has been developed, evaluated, and applied in theBachaquero-01 reservoir. This method integrates acommercial thermal simulator, a production characterizationmethodology, and an optimization algorithm that uses asobjective function the discounted net income at the end of thefinal cycle.

2. The algorithm based on a quasi-Newton method withfinite-difference gradient approximation was effective andstable. This procedure represents an advantage overoptimization methods based on the application of the discretemaximum principle, because it avoids the generation of a largesystem of nonlinear equations.

3. We found the hyperbolic production decline model to bethe best option to represent the production behavior ofthermally stimulated wells. We developed and evaluated anew correlation to obtain the relationship of the parameter b ofthe hyperbolic model with the amount of steam injected,together with the procedure to obtain their correspondingparameters.

4. The success of the method depends on how accuratelythe actual production performance can be predicted. Weobserved that a satisfactory match with simulation resultscould be obtained. Additionally, the method gives enoughflexibility to adapt specific injection or production conditionsand economical parameters.

5. These results also show that, for mature reservoirs withlow pressure, the injection of high amounts of steam in thefirst cycles ia better option then simply repeating the samecycles..

6. The application of cyclic steam injection in horizontalwells at the conditions represented in Area LLHW1 ofBachaquero field does not appear to be economicallyattractive. However, we recommend an update of the availableinformation to obtain a better numerical representation of theproduction behavior for this well and its economicenvironment.

7. The methodology developed works reliably in fieldapplications and it can be applied to evaluate various scenariosas additional information becomes available and/or theeconomic environment changes.

8. We recommend the extension of the optimizationmethodology for applying in other thermal processes as steaminjection with additives, and steam drive.

Nomenclaturea1 = oil lifting and treating costs, $/STBa2 = fixed operating charge, $/daybc = crude price, $/STBbj = correlation factor in hyperbolic model,

dimensionlessbj

int = Intercept with y axis of linear relationshipbetween qmax

sj and Wj, STB/D

Cd = cost of well drilling, $Cj = well preparation cost, $Cr = effective rock compressibility, psi-1

Cs = cost of steam, $/STB of feed waterCDNI = cumulative discounted net income, $dj

n = constant used in the relationship for Npsj, Eq.

11, STB-1

Dc = decline factor for cold production, day –1

Djh = decline factor for hot production of cycle j,

day –1

Gji = correlation parameters for determining bj in

Eq.8, subscript i = 1 to 3Hi = Hessian matrix evaluated at the iteration ii = annual discount rate, fraction/yearmj = slope of linear relationship between qmaxsj

and W j, day-1

n = number of cyclesNp = overall oil primary production, STBNp

sj = overall oil production of cycle j, STBNp

sjmax = maximum limiting value of Np

sj, STBNp

sjmin = minimum limiting value of Np

sj, STBq(t) = primary oil production rate at time t, STB/Dqsj(t) = stimulated oil rate of cycle j at time t, STB/Dqsj

fin = final oil rate at the end of cycle j, STB/Dqmax

sj = initial oil rate at the beginning of cycle j,STB/D

r j = ratio of the initial response to the primary rateat time t j-1, dimensionless

t = cumulative time, daytinjec = injection time, daytI = downtime required for steam injection and

soaking, dayst0 = time at which q(t0) is known, dayW j = amount of steam injected as equivalent

volume of water, STBWj

min = minimum limiting value of W j, STB∆tp

j = length of the jth cycle, not including downtimetI, day

AcknowledgmentsWe thank PDVSA for providing support, that has made thepreparation and presentation of this paper possible.

References1. Prats, M.: Thermal Recovery, Monograph Volume 7, Henry L.

Doherty Series, SPE Inc, Richardson, TX (1982).2. Joshi, S.D.: “Thermal Oil Recovery With Horizontal Wells,” JPT

(November 1991) 1302-1304.3. Fernández, B. and Zerpa, L.B.: “Numerical Simulation of Two

Horizontal Wells Drilled in a Heavy Oil Reservoir Located inMaracaibo Lake, Venezuela,” paper SPE 37105, Proc.,International Conference on Horizontal Well Technology,Calgary (November 1996) 569-579.

4. Zerpa, L.B.: “Numerical Simulation of Horizontal Wells inHeavy Crude Reservoir in Venezuela,” paper SPE 30282 Proc.,International Heavy Oil Symposium, Calgary (June 1995) 345-357.

5. Petit, H.J-M, Renard, G., and Valentin, E.: “Technical andEconomic Evaluation of Steam Injection With Horizontal Wells

10 E. ESCOBAR, P. VALKÓ, W.J. LEE, M.G. RODRÍGUEZ SPE/PS-CIM 65525

for Two Typical Heavy-Oil Reservoirs,” paper SPE 19828, Proc.,64th SPE Annual Technical Conference and Exhibition, SanAntonio, TX (October 1989).

6. Sarkar, A., and Deo, M.D.: “Comparison of Thermal EORProcesses Using Combinations of Vertical and HorizontalWells,” paper SPE 25793, Proc. Thermal Operations & HeavyOil Symposium, Bakersfield, CA (February 1997) 175-181.

7. Rodríguez M.: “Bachaquero Field, Venezuela-Increasing OilProduction by Switching from Cyclic-Steam Injection toSteamflooding using Horizontal Wells,” MS thesis, Texas A&MU., College Station, TX (1999).

8. Escobar, M.A., Valera, R.E, and Pérez, R.E.: “A Large Heavy OilReservoir in Lake Maracaibo: Cyclic Steam InjectionExperiences,” paper SPE 37551, Proc., Thermal Operations &Heavy Oil Symposium, Bakersfield, CA (February 1997) 337-347.

9. Partidas, C.: “Horizontal Drilling in Miocene Thin Sand of theLake Maracaibo,” paper SPE 50426, Proc., InternationalConference on Horizontal Well Technology, Calgary (November1998) 353-359.

10. Reina, M.: “Horizontal Wells in Melones Heavy Oil Field” paperSPE 39085, Proc., Fifth Latin American and CaribbeanPetroleum Engineering Conference and Exhibition, Río deJaneiro, (August 1997).

11. Araque-Martínez, A. and Rattia, A.: “Experience on HorizontalWell Applications for Heavy Oil Fields,” paper SPE 37400,Proc., International Conference on Horizontal Well TechnologyCalgary (November 1996) 569-579.

12. González, R., Brunings, C., and Toussaint, L.:”ESP’s in CyclicSteam Injection Wells,” paper SPE 39084, Proc., Fifth LatinAmerican and Caribbean Petroleum Engineering Conference andExhibition, Río de Janeiro (August 1997).

13. Trebolle, R.L., Paz, M.C., and Martínez, D.E.: “Parametric Studyof the Design Factors for Cyclic Steam Injection in LakeMaracaibo Oil Fields,” paper SPE 25810, Proc., ThermalOperations & Heavy Oil Symposium Bakersfield CA (February1993) 331-341.

14. Mehra, R.K., Ding, L.Y., Coles, G., and Donnelly J.K.: “Risk-Weighted Optimization for Cyclic Steam Stimulation of Water-Underlain Reservoirs,” paper SPE 21770, Proc., WesternRegional Meeting, Long Beach, CA (March 1991) 197-210.

15. Dunn, K.: “Use of Incremental Analysis in the Operations ofCyclic Steam Projects,” paper SPE 2258, Proc., 43rd SPE AnnualFall Meeting of AIME,- Houston (September 1968).

16. Curry, G.L., Chang, G.Y., and Harper, R.G.: “OptimalScheduling for Cyclic Steam Injection Projects,” paper SPE2627, Proc., 44th SPE Annual Fall Meeting of AIME, Denver,CO (September 1969).

17. Hong, K.C., and Jensen, R.B.: “Optimization of MulticycleSteam Stimulation,” paper SPE 2328, Proc., 39th SPE AnnualCalifornia Fall, Meeting, Bakersfield, CA (1968), SPE ReprintSeries No. 7, Thermal Recovery Processes (1985) 227-237.

18. Eclipse-500 Thermal Simulator, GeoQuest ReservoirTechnology, Schlumberger (UK) Ltd., 1998.

19. Escobar E.: "Optimization Methodology for Cyclic SteamInjection With Horizontal Wells," PhD thesis, Texas A&M U.,College Station, TX (1999).

20. Chapra S.C. and Canale R.P., Numerical Methods for Engineers,Third Edition, WCB/McGraw-Hill, Boston (1998).

21. “Fortran Subroutines for Mathematical Applications,” IMSLMath/Library Vol.2, Visual Numeric, Inc. (1994).

TABLE 1 - HONG AND JENSEN, EXAMPLE 1 RESULTS17

Cycle

j

W j

STB∆∆tp

j

days

t j

days

1 18,720 375 399

2 17,140 361 784

3 15,130 328 1,136

4 12,450 268 1,428

The cumulative discounted net income at the end of the fourthcycle is $19,760.

TABLE 2 - PROPOSED ALGORITHM, EXAMPLE 1 RESULTS

Cycle

j

W j

STB∆∆tp

j

days

t j

days

1 18,659 380 404

2 17,103 365 793

3 15,109 332 1,150

4 12,447 273 1,447

The cumulative discounted net income at the end of the fourthcycle is $19,867

TABLE 3 - HONG AND JENSEN, EXAMPLE 2 RESULTS17

Cyclej

W j

STB∆∆tp

j

dayst j

days

1 17,740 327 351

2 16,080 305 680

3 13,970 265 969

4 11,200 206 1,199

5 7,300 128 1,351

6 4,780 85 1,460

The cumulative discounted net income at the end of thefourth cycle is $21,010.

SPE/PS-CIM 65525 OPTIMIZATION METHODOLOGY FOR CYCLIC STEAM INJECTION WITH HORIZONTAL WELLS 11

TABLE 4 - EXAMPLE 2 RESULTS – WJ AND ∆∆tpj AS

DECISION VARIABLESCycle

jW j

STB∆∆tp

j

dayst j

days

1 17,737 328 352

2 16,076 305 680

3 13,973 265 969

4 11,199 206 1,199

5 7,299 128 1,351

6 4,784 85 1,460

The cumulative discounted net income at the end of the fourthcycle is $21,209.

TABLE 5 - HONG AND JENSEN, EXAMPLE 3 RESULTS17

Cyclej

W j

STB∆∆tp

j

dayst j

days

1 18,630 370 394

2 17,040 355 773

3 15,020 321 1,118

4 12,340 261 1,403

5 8,530 173 1600

6 6,080 124 1748

7 2,830 64 1,836

The cumulative discounted net income at the end of thefourth cycle is $21,400.TABLE 6 - PROPOSED ALGORITHM, EXAMPLE 3 RESULTS

Cyclej

W j

STB∆∆tp

j

dayst j

days

1 18,555 375 399

2 16,993 359 781

3 14,992 325 1,130

4 12,231 265 1,419

5 8,519 177 1620

6 6,071 127 1771

7 2,829 66 1,861

The cumulative discounted net income at the end of thefourth cycle is $21,455.

TABLE 7 - AREA LL HW1 CYCLE CHARACTERISTICS(from Rodríguez7 )

Well Inj.

date

Inj.Period

SoakPeriod

iw j W j

j day day STB/D STB

3/26/85 1 19 10 1,712 31,831LLVW4

8/14/92 2 12 8 2,256 27,581

8/10/84 1 18 11 1,712 31,356

2/5/91 2 15 6 2,237 34,450

LLVW5

3/2/94 3 14 5 1,768 25,013

LLHW1 6/8/97 1 20 7 2,500 50,700

TABLE 8 - AREA LL-HW1 - COLD PRODUCTIONCHARACTERIZATION PARAMETERS

Well LLVW3 LLVW4

q(t0) (STB/D) 512 301

t0 (days) 0 0

Dc (days)-1 0.0069 0.0313

b 2.91 4.89

TABLE 9 - ECONOMIC DATA – BACHAQUERO-01

Description Symbol Units Value

Annual discountrate

i fraction/year 0.1

Oil lifting andtreating costs

a1 $/STB 1.64

Fixed operatingcharge

a2 $/day 0.

Crude price bc $/STB 7.2

Cost of steam Cs $/STB offeed water

3.75

Well preparationcosts

C j, j > 1 $ 329,000

TABLE 10 - HOT PRODUCTION CHARACTERIZATIONPARAMETERS

Cycle j 1 2 3 4 5

Npsj

max

STB999*103 239*103 190*103 182*103 88*103

Npsj

min,STB

311*103 95*103 90*103 75*103 21*103

dj 3.80*10-6 1.68*10-5 1.68*10-5 9.80*10-6 2.81*10-5

qjmax_m

STB/D6.02*10-3 4.23*10-3 2.05*10-3 1.14*10-3 5.59*10-4

qjmax_b

STB/D1.62*103 5.34*102 4.11*102 3.14*102 1.97*102

Gjb1 -2.47*10-5 -2.65*10-5 -2.05*10-5 -6.79*10-5 -5.87*10-5

Gjb2 4.13*10-1 5.79*10-1 2.25*10-1 1.86 2.08

Gjb3 0.62 1.00 1.30 1.25 3.00

TABLE 11 - OPTIMAL DESIGN VALUES-WELL LLHW1

Cycle

j

W j

(STB)∆∆tp

j

(day)

t j

(day)

Npsj

(STB)

CDNI j

($)

1 70,000 870 905 471,122 -226,869

2 69,142 544 1,484 183,785 -18,548

3 34,715 521 2,025 134,107 101,039

4 16,903 430 2,469 91,482 132,771

12 E. ESCOBAR, P. VALKÓ, W.J. LEE, M.G. RODRÍGUEZ SPE/PS-CIM 65525

Fig. 1 - Grid definition, well location, and completionintervals. (from Rodríguez7)

Fig. 2 Cold Production Characterization, WellLLVW4.

Fig. 3 - Hot production characterization WellLLHW1.

Fig. 4 - Tuning stage – Well LLHW1.

-

500

1,000

1,500

2,000

2,500

30-A

pr-9

7

30-A

pr-9

8

30-A

pr-9

9

29-A

pr-0

0

29-A

pr-0

1

29-A

pr-0

2

29-A

pr-0

3

28-A

pr-0

4

28-A

pr-0

5

qo

s (S

TB

/D)

0.0E+00

2.0E+05

4.0E+05

6.0E+05

8.0E+05

1.0E+06

Np

s (S

TB

)

qos_Optimization qos_Eclipse

Nps_Optimization Nps_Eclipse

AREA LL- 3487 - Well LL- 2527

-

200

400

600

800

Nov

-81

Oct

-84

Oct

-87

Oct

-90

Oct

-93

Oct

-96

Oct

-99

Oil

Pro

du

ctio

n R

ate

(ST

B/D

)

0.0E+00

2.0E+05

4.0E+05

6.0E+05

8.0E+05

Np (

ST

B)

qo_real qo_fit Np_real Np_fit

1 2 3 4 5 6 7 8 9 10 11 12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

LL VW 5 LL VW 4 LLVW 1LL VW 3 LL HW 1 LL VW 2

AP1 ++ + +

2 AP2 + + + ++ + +

AP3 + + ++ + ++ + +

HH + + ++ + ++ + ++

GG +

1 2 3 4 5 6 7 8 9 10 11 125

4

3

1

LL VW 5

LL VW 1

LL VW 2

LLVW 4

LLVW 3

LL HW 1

-

200,000

400,000

600,000

800,000

- 25,000 50,000 75,000 100,000

W j (STB)

N

psj(S

TB

)

Cycle 1 Cycle 2 Cycle 3 Cycle 4 Cycle 5

-

500

1,000

1,500

2,000

2,500

- 25,000 50,000 75,000 100,000

Wj (STB)

qm

ax

sj (ST

B/D

)

Cycle 1 Cycle 2 Cycle 3 Cycle 4 Cycle 5

-

2.0

4.0

6.0

8.0

10.0

- 25,000 50,000 75,000 100,000

W j (STB)

b_H

yper

bo

lic

Cycle 1 Cycle 2 Cycle 3 Cycle 4 Cycle 5

Related Documents