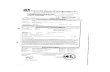

Neftegasdiagnostica group Non-destructive testing, technical diagnostics and industrial safety expert review

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Neftegasdiagnostica group

Non-destructive testing, technical diagnostics and industrial safety expert review

Main activities:

- Non-destructive testing, technical diagnostics, oil and

gas equipment industrial

- safety expert review

- Inline inspection

- Corrosion inspection, electrical

- Oil and gas pipelines diver inspection

- Geodetic surveys and cartography

- Pipeline repair using composite reinforcing sleeves

- Development and installation of pipeline and

equipment technical condition

- monitoring systems

- Research and development Standards, regulations

and specifications development.

Supervised facilities:

UNDERGROUND PIPELINES

TECHNOLOGICAL PIPELINES

OFFSHORE PIPELINES

TANKS and

PRESSURE VESSELS

SERVICES FOR TANKS, PRESSURE VESSELS, TECHNOLOGICAL PIPELINES

-Acoustic emission control including detection of leaks in tanks bottoms

-Ultrasonic thickness measurement, ultrasonic defect detection, testing by penetrates etc.

-Determination of geometric characteristics and structure elements, horizontal and vertical deviations

-Full set of calculations including the calculation of corrosion speed, strength, resistance, residual life

-Expertise of industrial safety

UNDERGROUND and TECHNOLOGICAL PIPELINES

Inspection of insulating coat condition: • Search and pipeline routing in the field with

establishing executive trimming;

• Locating potentially dangerous sectors and

insulation damage points and the points of

pipeline metal lifting by electric current;

• Inspection of pipeline cathodic protection;

• Calculation of residual life of the coat.

Neftegasdiagnostica group

Problems encountered when preparing and conducting in-line inspection Pipeline interior

hollow cleaning from all kind of debris

In-line diagnostics:

• ► Pipeline interior hollow cleaning from all kind of debris; • ► Providing of pipe reamer book at the stage of cleaning; • ► In-tube examination using magnetic memory method (detecting of metal • tension concentration areas); • ► Determination of pipeline interior profile and geometric defects; • ► Examination of the pipeline by Rosen intellectual gears 4 ч 56 inches. • Weld joints and base metal defect locating (cracks, including corrosion, metal • loss, pitting, in-cuts etc.) by magnetic method using MFL equipment of third • generation with high resolution (CDP). • ► AFD examination for detecting longitudinal defects with high resolution using • recent inspection pistons. • ► GYRO-examination for defining pipeline coordinates (XYZ)

configurations of sleeves are manufactured:

• Smart Lock – for external and internal defects repair with up to 100% metal loss;

• Smart Lock – А – for emergency repair of penetration defects.

Sleeve operating principle is compensation of pipeline internal pressure by creating external contact pressure which allows removing load from pipe wall defective area. May be installed without pipeline depressurizing with guaranteed quality unlike sleeves installed with no preload build, such as spiral sleeves. Sleeve consists of two half covers connected by a hinged joint on one side and by four bolted connections on the other. To fix the sleeve off-the-shelf stainless steel bolts are used.

Smart Lock SLEEVE DESIGN AND TECHNICAL PARAMETERS

Smart Lock external cover consists of two composite half-sleeves with a hinged joint.

Half-sleeves are fixed and coupled using bolt connection.

Bolt torque is calculated for each pipeline diameter and internal pressure and is

specified in the Product Passport.

Smart Lock is significantly lighter then similar metal structures. 530 mm diameter Smart Lock with bolts and insert weighs no more than 30kg.

To avoid negative mechanical

impact on welds Smart Lock

includes a split insert which is

slightly thicker than weld

reinforcement allowable by

regulations and standards.

Addition of insert to the sleeve

configuration allows to install

Smart Lock on seam and spiral

seam pipes and to use sleeves to

repair defects in the vertical weld

area and weld defects without

leveling them to pipe surface. With

the help of special tooling Smart

Lock may be used to repair

misalignment weld defect type.

Strength properties of Smart Lock plastic products material

Item No.

Parameter description Parameter value

1 Tensile strength, MPa, at least 800

2 Bending stress at failure, MPa, at least 200

3 Peripheral zone E modulus, MPa, at least 3.0 x 104

4 Density, kg/m3 1600 – 1800

5 Water absorption within 24 hours, %, no more than 0.2

Smart Lock is manufactured in U2 climatic modification, location category 2

as per GOST 15150 (ambient

temperature lower limit is minus 60˚С).

When Smart Lock is heated up to plus 110˚С no harmful volatile substances

are evolved.

Smart Lock fire and hygienic safety – GOST 12.1.044.

Smart Lock provides for operation of the repaired pipeline segment with no

maintenance and repair required

for at least 50 years.

-Smart Lock sleeves is certified as per ISO 9001 and GOST R system.

-The sleeve passed industrial safety expert review.

-Repair method using these

reinforcing sleeves is included in permanent repair methods.

-Sleeve service life is 50 years.

Smart Lock is operable at temperatures from -60˚С to +200 С ˚ It is possible to manufacture sleeves operable at temperatures up to +400 С˚ Smart Lock provides for operation of repaired pipeline segment without maintenance and repair for at least 50 years.

Smart Lock installation

Coating removal and pipe surface preparation

Adhesive compound application and insert installation

After repair is completed

process pockets and

holes shall be filled with a

sealing compound and

the sleeve becomes a

solid fiberglass

reinforced by embedded

stainless steel.

Smart Lock is successfully used to repair underground offshore pipelines. Applied adhesive polymerizes at up to 100% humidity level and pipe wall temperature down to minus 7 degrees. Sleeve material is not corrosive, metal parts are made of stainless steel, after repair process pockets and holes are filled with a special compound and the sleeve becomes a solid fiberglass reinforced by embedded stainless steel.

PARTNERS Rosen

Transneft

Gasprom

Sibneft

Yukos

Mosenergo

Sibur

Lukoil

TNK-BP

Saudi Aramco

Gubkin Oil&Gas Institute

Russian Engineering Academy

Sevmash

Rosneft

Mosoblgas

Kurchatovsky

Institute

Neftegasdiagnostika is a member of the following organizations:

• Commerce and Industry Chamber of the Russian Federation

• Committee of Industrial Development and High Technologies

• Subcommittee of Russian Industrial Products Export Support

• Russian Engineering Academy

• Scientific and industrial Alliance “RISCOM”

Related Documents