20 – ¾” 3,000psi x 13-5/8” 5000psi 26” x 18-5/8” x 13-3/8” Casing 9-5/8” x 5-1/2” Tubing Hanger North Sea Platform Wellhead Isolation History / Introduction: Failed test issues as reported in 2001(SBMS-II, ‘S’ Seal) Reference Kittiwake Wellhead Integrity Testing report August 2003 (2001) KCI evaluation and sealant deployment method. Tubing Hanger Body Seals Locking Device 20-3/4” x 13-3/8” Mandrel Neck Seal Case History

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

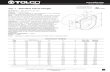

20 – ¾” 3,000psi x 13-5/8” 5000psi

26” x 18-5/8” x 13-3/8” Casing

9-5/8” x 5-1/2” Tubing Hanger

North Sea Platform

Wellhead Isolation

History / Introduction: Failed test issues as reported in 2001(SBMS-II, ‘S’ Seal)

Reference Kittiwake Wellhead Integrity Testing report August 2003 (2001)

KCI evaluation and sealant deployment method.

Tubing Hanger Body Seals Locking Device

20-3/4” x 13-3/8” Mandrel Neck Seal

Case History

Tubing Hanger Review:

Lower hanger body cavity, test port Nos.10 & 11 (between metal seal & resilient seal)

Port 11

Resilient Seal

Port 10

Lower Hanger

Body Cavity

Polypack Seal

Metal to Metal

Seal

Tubing Neck

Test Port 16

T.B.A.

Tubing hanger neck seal, metal to metal, low pressure / monitoring test port 16.

Tree/ Spool Gasket

Metal to Metal

Tree spool gasket, metal to metal,

Void Test

Port 15

Hanger Void

Monitoring / Bleeding

Port 14

Hanger Void

Hanger void, monitoring / bleed port, test port 14 & 15.

Resilient Seal

Tubing Hanger

Locking Device

Tubing hanger locking device, resilient seals in OD & ID

Port 12

Hanger Body

Metal to Metal

Seal

Hanger Body Cavity

Hanger body cavity, test / monitoring port No.12 ( between resilient seal & metal seal)

Tubing Hanger Evaluation: Hanger Body Cavity

Test Fluid: Light Oil or Water Based Fluid

Review: KCI Evaluation

Fill void with test fluid i.e. inject test fluid through test port 14 and displace through port 15, close port 14

Vent / bleed hanger void, and ports 15,12, 11 & 10.

Inject test fluid in through port 10 and displace through port 11. Close port 11 and lock in 2,000psi

Inject a set volume of (1 Litre) test fluid through port 12 (500psi) and monitor leak rate and fluid displacement at port 15.

Bleed / vent port 12, apply 2000psi within void through port 15 and monitor leak rate through port 12 (confirmation).

Void Test Port 15

Void Monitoring/

Bleed Port 14 Port 12

Port 10 Port 11

Potential Leak Paths:

1/ Locking device resilient

seal ID & OD.

2/ Metal seal above port 10 & 11

Inject a set volume of Mac-Seal 06 ( 1.5 Litres)

Sealant

Port 12

Port 11 Port 10

Void Monitoring/

Bleed Port 14

Void Test Port 15

Inject a set volume of (1.5 Litres) sealant

through port 12 (500psi) and monitor leak

rate and fluid displacement at port 15.

Allow 3 hours to cure.

Vent / bleed ports 10 & 11

Mac-Seal 06 Application

Testing: inflow only:

Pressure between ports 10 & 11 2000psi

and sting / vent void port 15.

13-3/8” Hanger, Neck Seal and Pack-off Review:

Port 6

Test Port 6: Supported by upper polypack seal and lower metal seal

PolyPack Seal

Metal Seal

Port 7

Test / monitor port 7: Supported by upper metal seal and S-Seal resilient seal ( ID & OD Seals)

Resilient Seal

Port 4

Port 3

Port 5

Test port 5: Void communicating with test ports 3 & 4 (drain ports)

Port 2

Port 1

Test port 1 & 2 Pack-Off

Port 4

Port 2

Port 6

Port 3

Port 5

Port 1

Port 7

Test Fluid: Light Oil or Water Based Fluid

13-3/8” Hanger, Neck Seal and Pack-off Review: Neck Seal Port 6

Review:

Vent/bleed both annuli above and below

Fill void with test fluid i.e. vent port 5 and close port 3. Inject test fluid through port 4 and displace through port 5

Close port 4

Sting and vent ports 6, 7, 5

Inject test fluid and maintain pressure (1000psi) through port 6 and vent / monitor port 7 for any fluid displacement.

Maintain test pressure within port 6 and apply fluid test pressure through port 7 (500psi T.B.A) monitor leak rate

through port 5.

Potential Leak Paths:

1/ Resilient casing neck seal.

2/ Metal seal

Test / Monitor:

Inflow test, pressure port 6

Sting and monitor port 5.

Reverse the process.

Close ports 3 & 4

Pressure test though port 5

Sting and monitor port 6 Port 4

Port 2

Port 6

Port 3

Port 5

Port 1

Port 7

Inject a set volume of Mac-Seal 02 (750mls)

Sealant

Maintain test pressure within port 6 and apply 750mls of Mac-Seal 06 through port 7 (500psi T.B.A). Allow 3 hours to cure

Bleed / Vent port 6

K I Kinetics Controls & Innovation Ltd

C

Mac-Seal Products: Viscosities, 01, 02, 04, 06

Mac-Seal is a two-part sealant i.e. compound and hardener. The sealant is deployed as a fluid

and converts to a solid but flexible self-energising seal structure within the void / cavity of the

wellhead. The Mac-Seal sealant is designed as an emergency seal and is deployed as a

temporary or permanent isolation across a number of applications.

The Mac-Seal product is provided as a kit i.e. compound and hardener, with a set volume of

hardener for a pre-determined curing time and to support on-the-job review and deployment

procedures.

Mixing Instructions:

The product is provided in two parts:

1/ Compound,

2/ Hardener,

Both products combined provides a package to meet a specified setting time.

Note: The hardener measure is subject to curing time requirements and can be adjusted –

please contact KCI for advice on this if required.

Standard setting times 2 to 12 hours -Surface

Standard setting times 12 to 45hours -Subsea

Review information label attached to both compound and hardener.

Mixing:

Use in well ventilated area.

Do not mix in other containers as this may interfere with quality of product.

KCI provides a large container (compound) to allow for mixing.

Empty hardener fluid into compound and stir gently but thoroughly with a clean spatula or

other device until mixed.

Deployment: Subject to Viscosity

1/ Hand-held hydraulic injection gun.

2/ Pneumatic or hydraulic injection gun (large volumes).

3/ Cylinders

4/ Spatula

Follow procedure (work scope) in accordance with the application and its environment.

Note: This product is required to be deployed by KCI trained and registered personnel or

trained and registered sub-contractors.

K I Kinetics Controls & Innovation Ltd

C

3 Litres

Cylinder Cap Cap Piston

3 Litre Deployment Tool

3 Litre Assembly Deployment Tool

3Litre

s

3 Litres of

Mac-Seal 02

Mixed with

Hardener

3Litres

Deployment Tools

Cylinders are provided as the method of deploying the sealant. These are designed as a

simple process for preparation / handling, deployment (diver assist) and refurbishment.

The cylinders have been designed to operate with seawater

Mixing Instructions

The Mac-seal is a two-part product i.e. compound and hardener. The product has been

provided with set volumes of up to 3 litres of compound (white) and a set volume of hardener.

Pour the set volume of hardener into the 3 litre tub (example) of compound and mix until the

sealant becomes. Pour the mixed compound into the cylinder and attach to the deployment

package.

Note: Prepare all cylinders to receive

the sealant prior to mixing

Sealant curing time:

3 hours subject to temperature

Sealant deployment time:

1 hour after mixing.

Cylinder Support

Stand Protect Fitting

3/8” Control (Feed) Line

Hydraulic Hand Pump

Deployment

Manifold

Injection Fitting

Mac-Seal Deployment Tool Assembly

3 Litres

3 Litre

Deployment Cylinder 10K

10Litre

Related Documents