NEWSLETTER OF THE WORTHING & DISTRICT SOCIETY OF MODEL ENGINEERS Number 151 www.worthingmodelengineers.co.uk Autumn 2020 IN THIS ISSUE: A (bigger) Burrell Black Propaganda A garden railway Answers to that quiz Some Club News Report from the Chair The Hon. Sec Scribes The Treasurer writes Engineering Report Not Much Else THE SOCIETY’S OFFICERS Patron: Peter Webb President Andrew Breese Chairman: Larry Avard Vice Chair: Mike Roberts Secretary: Leigh Gibbins Treasurer: Martin Laker Engineering: Geoff Symes Programme: Neil Furze Membership: Paul Parsons Publicity: Geoff Bashall Boiler Liaison: Brian Hunt Comm. 1*: Glen Payne Comm. 2*: Graham White Comm. 3*: Barry Partridge *See foot of page 2 THE WORTHING & DISTRICT SOCIETY OF MODEL ENGINEERS LOCATED AT FIELD PLACE, THE BOULEVARD, WORTHING BN13 1NP www.worthingmodelengineers.co.uk GLAD TO BE BACK AT WORK … but obeying the rules! In recent weeks, as the lockdown has relaxed, there has happily been much increased activity at the club. My pics clockwise, show Geoff B at the workshop main doors having taken the precaution of adding Dettol to his paint pot. Mostyn is busy producing anti-viral swarf and Jim L checks his next passenger carriage repaint, as he ponders how to make the seat self-cleaning. Outside, Big Geoff and Mike R deep clean the track as Martin, Brian and Larry (all at a distance) replace contaminated boards on the garden shed. Glen, Graham and Leigh at the carriage store have a trial run of their hand built fogging machine (seen at Graham’s feet). It should have produced a disinfectant mist, but as you can see from their faces, it gave off laughing gas instead. Finally, some things never change … one part of our site as I found it early one morning recently … no comment needed from me!

NE SN EWWSLLEETTTTERR OOFF TE TH HE ......Geoff Bashall 11 Trinity Way, Littlehampton, 2:00 BN17 5SR THURS Tel: 01903 722973 E-mail: [email protected] Membership Secretary

Jul 15, 2020

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

NNEEWWSSLLEETTTTEERR OOFF

TTHHEE WWOORRTTHHIINNGG && DDIISSTTRRIICCTT

SSOOCCIIEETTYY OOFF MMOODDEELL EENNGGIINNEEEERRSS

Number 151 www.worthingmodelengineers.co.uk Autumn 2020

IINN TTHHIISS IISSSSUUEE::

A (bigger) Burrell

Black Propaganda

A garden railway

Answers to that quiz

Some Club News

Report from the Chair

The Hon. Sec Scribes

The Treasurer writes

Engineering Report

Not Much Else

TTHHEE SSOOCCIIEETTYY’’SS

OOFFFFIICCEERRSS

Patron: Peter Webb

President Andrew Breese

Chairman: Larry Avard Vice Chair: Mike Roberts Secretary: Leigh Gibbins Treasurer: Martin Laker

Engineering: Geoff Symes Programme: Neil Furze

Membership: Paul Parsons Publicity: Geoff Bashall

Boiler Liaison: Brian Hunt Comm. 1*: Glen Payne

Comm. 2*: Graham White Comm. 3*: Barry Partridge

*See foot of page 2

THE WORTHING & DISTRICT SOCIETY OF MODEL ENGINEERS LOCATED AT FIELD PLACE, THE BOULEVARD, WORTHING BN13 1NP

www.worthingmodelengineers.co.uk

GGLLAADD TTOO BBEE BBAACCKK AATT WWOORRKK …… bbuutt oobbeeyyiinngg tthhee rruulleess!!

In recent weeks, as the lockdown has relaxed, there has happily been much increased activity at the club. My pics clockwise, show Geoff B at the workshop main doors having taken the precaution of adding Dettol to his paint pot. Mostyn is busy producing anti-viral swarf and Jim L checks his next passenger carriage repaint, as he ponders how to make the seat self-cleaning. Outside, Big Geoff and Mike R deep clean the track as Martin, Brian and Larry (all at a distance) replace contaminated boards on the garden shed. Glen, Graham and Leigh at the carriage store have a trial run of their hand built fogging machine (seen at Graham’s feet). It should have produced a disinfectant mist, but as you can see from their faces, it gave off laughing gas instead. Finally, some things never change … one part of our site as I found it early one morning

recently … no

comment needed

from me!

Editor Dereck Langridge

Distributed by Jim Alderman

Key Contributors The Members

All Complaints to The Chairman

Contributions to the newsletter are most welcome. Please submit to:

Dereck Langridge 173 Upper Brighton Rd.,

WORTHING BN14 9JS

Tel: 01903 202661 E-mail: [email protected]

Society Secretary Leigh Gibbins

45 Lavington Rd., WORTHING BN14 7SL

Tel: To be advised Email: [email protected]

Publicity Rep. Geoff Bashall

11 Trinity Way, Littlehampton,

BN17 5SR Tel: 01903 722973

E-mail: [email protected]

Membership Secretary Paul Parsons

37 Shootingfield, STEYNING BN44 3RQ

Tel: 01903 815350 E-mail: [email protected]

COMMITTEE DUTIES:

The three ‘untitled’ Committee posts carry the following responsibilities:

Committee Post 1:- As Committee Post 2:- determined by Committee Post 3:- the committee.

www.worthingmodelengineers.co.uk

2 W&DSME

YOUR BOARDROOM PAGE

STARTS HERE! A quick note from the editor … my thanks to the members who have contributed to this issue; but your excellent articles have squeezed the space, and with Hon. Officers being their usual vociferous selves, there’s hardly any room for me. (No comments please!) DL

A NOTE FROM THE CHAIR

Larry presents his report …

I hope everyone is keeping safe and well, especially as many of us are in the ‘vulnerable’ group. Our public running and social gatherings are cancelled for the rest of this year, but if the rules

change we will of course let our members know.

In the meantime I would like to thank those who have continued to help maintain our facilities, especially the two grass cutting teams who have kept the site immaculate. In addition, the usual weekly gang has which split into two groups, meeting on either Wednesdays or Thursdays to carry on other essential work such as shed repair, outside painting, track upgrade, steel door fabrication, carriage painting’ and not to forget our tea-maker and electrical engineer.

Contd page 3

THE NEWSLETTER DIARY DATES? … ask Boris

Chairman contd.

It would be helpful if we could set up another small working team, perhaps on Tuesdays, to get more of the outside work done before the weather deteriorates, as autumn will soon be with us.

Our new ticket office/patio furniture store has been delivered after some confusion with the manufacturer who supplied panels with the door in the wrong place. It will be modified with a booking/payment window and painted in the workshop before erection just north of the clubhouse entrance.

Finally, on a sad note, we lost another member, Mike King on July 31st. May he rest in peace.

Larry.

THE TREASURY

Martin Laker reviews our current financial position:

As you are aware from my last report, our financial outlook for the year was not looking good; however, the situation has now

changed completely. We have recently received a very generous Government grant to support us during this time of “shut-down”. This means we will not have to use the reserve fund for our running costs, but of course we still need to keep a tight control of all spending. I would like to thank those members who have generously donated funds, goods or supplies during recent months to keep us going; the committee really appreciates your generosity.

With the shut-down in place the treasurer’s job has been very quiet, I would love to be counting the cash from public running!

At home earlier in the year we were busy potting-up cuttings and plants for sale on public running days, I was getting worried what to do with these plants. Pat suggested we set up a table on our drive and see if we could sell them, plus a few other odds & ends. I am pleased to report that so far we have sold £80 of plants and goods to boost club funds.

On a personal level now the lock-down has lifted a little, we have been able to have a few day-trips around Sussex, and I have been able to start playing golf again – but at present we continue to avoid large groups and busy places, we have decided not to go away this year at all.

I have now steamed my Garrett traction engine a couple of times; with the help and advice of Brian Hunt a number of adjustments have been made to improve its running. The engine is basically “as-new” being built 10 years ago and never used when the owner passed away a few months after purchasing it. As it is unlikely I will be attending any rallies this year, I am going to delay the hydraulic and steam tests until next year, but continue to work on minor changes and further fettling.

Martin.

SECRETARIAL SCRIBING

Leigh Gibbins’ reports …

We are well aware that many model engineers, soon to include myself, are classed as vulnerable in the context of the current CV-19 virus and sadly there have been some

who have been greatly affected. While avoiding infection ourselves we have lost other club members, family members or good friends. Our thoughts go out to those coping with bereavement.

With the decision to cancel further public running for the foreseeable future, we are all so looking forward to the time when we can get together again to put the world to rights in the clubhouse over a mug of tea or coffee. It will also be wonderful to invite other clubs and friends from whom we’ve been separated for far too long.

Field Place had booked contractors for the tennis court refurb and this will cramp some of our activities but on the bright side it has probably come at the best time. Fortunately, Field place is home to other activities so when government guidelines began to be relaxed we were able to regain access to enable us to carry out maintenance and repairs. Then, following these guidelines the committee prepared some rules to ensure strict adherence to social distancing and cleanliness by everyone that visits the club site. With this in mind we have implemented the following:

• Record all your attendances.

• Record the reasons for any action that you take.

• Carry out risk assessments for any proposed activity that take into account all recommended steps (such as distancing, PPE, cleanliness, etc.) and make sure any actions we take are communicated to all members.

• Advise members of their responsibilities to themselves and each other, especially for those in at-risk groups. There are many factors that will affect each club’s situation including member’s age, risk and location, therefore these rules will change as time wears on and the impacts of previous actions will be analysed.

We have also focused on our Health & Safety guidelines, and with this in mind the Committee have decided to implement a review of our H&S policy and risk assessments. We have formed a small sub-committee to oversee some necessary changes which will reflect the guidance in a new document issued by combined model engineering clubs, associations and the 71/4-gauge Society. This document, HS2020 is fully endorsed by the Health & safety Executive and covers the running of miniature passenger carrying railways. A copy of this document will be available in the Club House for inspection.

We are ever grateful to those who have been maintaining our facilities, managing the club…..

3

W&DSME

cont. page 4

Leigh, cont. from page 3

………....publishing our newsletters and supplying information on our website and social media platforms.

That’s all for now folks so stay safe and get those jobs finished that you have been putting off for the last few months!

Leigh

ENGINEERING REPORT

In isolation from the world, deep in the tunnel, Geoff Symes our CME reports.

The first sign of any sort of the new norm was when Chairman Larry called an outdoor committee

meeting on Wednesday 10th of June. It was decided that working parties could be formed consisting of a maximum of six persons per team in accordance with Government guidance. Since Wednesday is normally reserved for grass cutting, I decided to meet on Thursdays for our track and passenger car maintenance sessions. THE TEAM – Myself, Head of everything; Mike Roberts, Chief Blame Taker; John Olley, Consulting Engineer; Jim Ledger, Carriage Paint Shop superintendent; Pete Quick Coat Quigley, Track and General Steelwork Protective Coatings Specialist, and Mostyn Thompson, Sequestered from the Building Maintenance.

First job, the long-awaited removal of our accumulated scrap metal pile. This was due before lockdown and Barry Partridge was ready with his trailer and poised for action, only to be stood down. The old barbeque, water heater, rusty track frame steel, and quite a large quantity of random junk metal from the workshop could now be taken to the recycle facility. Many thanks Barry.

Another job patiently waiting was the refurbished braked passenger car that Jim Ledger had repainted and was due for recommissioning with a track test to check the brakes and the ride quality of the reprofiled wheels. This had also been on hold since March. By a happy coincidence I contacted Barry again who seemed keen to have a run on the track with his 0-4-0 electric loco, a sort of payback for shifting all that metal. What could be more convenient? The only run so far this season, what could possibly go wrong? Well....

Loco coupled to passenger car, level access gates shut and locked, carriage store gate shut and locked, tunnel doors opened and locked back; track looks clear of damage and or obstructions. OK Barry, off you go, “It’s OK Geoff, you have a drive round first”. Now this could alert the reader to a sense of impending doom. So off I go with caution, at a pedestrian pace while peering ahead with eyes locked on the track in case of some track fault lying in wait to cause an unsuspected derailment. One circuit of the track completed without a hitch, set off again with Mike Roberts on board to investigate a noisy rail joint near the carriage store and disaster strikes; front of loco lifts and swings to the right derailing the front axle and bringing us to an abrupt halt.

What the ****? It was now time to realise, to my embarrassment, that the pendant control cable had found its way into the gap between the loco and the driving car with the inevitable result of becoming run over by the left front wheel of same. An investigation by the Transportation Safety Board was not needed to establish the cause of this unfortunate incident nor whom was to blame. Clearly it was the ineptitude of my passenger in failing to alert me to the danger of an excessively long control cable becoming fouled. Thanks are due to Neil Furze for repairing the now foreshortened cable and sorting out the fault which was affecting the locos inability to proceed.

Another braked passenger car, ‘E’, has been taken in for refurbishment in line with our goal to re paint the entire fleet. and will be re-liveried in maroon and treated to the usual wheel-reprofiling, brake and running gear inspection and the seat re-covered.

Track maintenance continues to be an important ongoing project and the main push at the moment is the replacement of the holding down bolts that secure steel frames to the concrete ‘A’ frames. The existing bolts have corroded over time and cannot be retightened. When the piers become loose, they tend to rotate causing possible contact with passenger cars. Opportunity is taken to adjust track levels by removing the bits and pieces of slate and metal from under the legs of the A frames and replacing it with strips of roofing felt between the top of the piers and the steel underframe. With the new 12mm bolts being well lubricated with grease, future maintenance and track level adjustments should be easier.

In addition to our efforts on Thursdays, other vital work is progressing on Wednesdays, I refer particularly, to the replacement doors for the carriage store. The old wooden doors had served us well but had done what wooden doors normally do. Hence the need for some new ones made of steel that do what steel normally does, last forever with a bit of paint. Glen Payne and Graham White have completed the project with fitting the locks and brackets to hold all of the paraphernalia normally attached to their insides. This is a very secure and professional job and is being complemented by the steel cladding of the rear door to further improve security.

Finally, I come to a rather emotive subject. The old traverser. It is obvious that we need to tidy up the patio in front of the clubhouse. Health and safety concerns dictate that we must reasonably eliminate risks to our visitors; trip hazards and hard edges must be eliminated as much as possible. To this end Committee has discussed the removal of the above-mentioned item. Many of the older members, that’s just about all of us come to think of it, will have historical attachment to this gnarly old piece of kit. No, not the previous Chair. It may give rise to some outpouring of sorrow and emotion as we remove it, but I ask you all to be strong and resist the temptation of the usual hate mail associated with these highly charged but necessary actions.

Geoff.

CHRIS AND JULIE DEVENISH

HAVE BEEN BUSY DURING

THE LOCKDOWN ! Julie and I decided late last year to build a Gauge 1 railway in our modestly sized back garden at our house on Romney Marsh, Kent. Survey pegs were used to mark out the initial plan back in November, but before I could proceed any further we had to buy a new Summerhouse - well we needed to have somewhere for a tea urn and cakes for visitors - and this was supplied and erected in

February, shortly thereafter, the next week in fact, I got someone to bash in the Metpost bases for me as my back was not up to it - he put all 38 in, in under 3 hours - I did help, I held the spirit level !

I then collected together all the wood and materials, with the 24 X 3.6 metre lengths of decking being delivered by Travis Perkins just days before the Lockdown. Actual construction started on Wednesday 18th March and it was finished on Saturday. I used all 24 lengths of the Travis Perkins decking and could have used more, luckily, I had a few spare lengths of Wickes’ decking, not quite the same size, but with some packing managed to incorporate it into the base. I have been enjoying running some trains for a week or so now and a shot is included. Finally, a neighbour took an aerial drone picture of the railway (at top left) part way through the track laying.

I had only intended to get one track running by the Autumn, but the current situation, along with three very fortunate purchases of track from eBay has enabled the rapid progress. The outer circuit is Peco Streamline Code 200, and

the inner circuit is Cliff Barker Code 180, mostly stainless except for the end curve which is in gauge widened (45.5mm) brass. It's not billiard table smooth but seems to run very well and I am delighted that I now have somewhere to play trains during the Lockdown and hopefully for many years to come as well !

Chris Devenish.

CAN ANY ONE HELP JOHN PLEASE?

The other day I became custodian of the pictured engine. Jean Picken asked me what it was and of course I did not know, so she asked if I would like to have it. How could one refuse? In any case at over 5kg it was hardly an ornament for a lady's boudoir. Two knowledgeable and reliable members were unable to help but the Editor did, and offered to print a bit. I am very

pessimistic about Government Circles attaching real priority to resuming Model Engineers' Thursday evening meetings, so the Editor may have allowed a precedent or thin end of the wedge for Bits & Pieces to morph in to a regular Newsletter item. Before I tell you what I can about it let's have the sting in the tail questions: does anyone know what it is? Did Geoff ever bring it to the club or discuss it with anyone? Was it a freelance Geoff design? or based on some published design or article about the prototype? Can one do a Google search starting with a picture instead of a keyword? We can observe that it is a 4 cylinder single acting oscillating engine. There is no pipework, but passages are drilled or milled into massive solid parts. “Massive” is illustrated by the base being 71/2 x 33/8 x 3/8 and the central “frame” 71/2 x 31

/8 x 5/8 inches. There is no sign of a plan to export power or torque from the ends of the central shaft.

If you are able to assist in my enquiries, I can be contacted at [email protected] or 01243 552290 Thanks, John Stoton.

5 W&DSME

BLACK PROPAGANDA DURING WW2, PART 1 …………...….. LEIGH GIBBINS

“BLACK PROPAGANDA IS INTENDED TO CREATE THE IMPRESSION THAT IT WAS CREATED BY

THOSE IT IS SUPPOSED TO DISCREDIT.”

I have always had an interest in the development of wireless or radio during the war. I was brought up in Northamptonshire and so I naturally visited the surrounding area knowing there were sites of wireless listening and transmitting stations from WW2.

Inevitably a visit to Bletchley Park in Buckinghamshire ensued and there was a display of some of the equipment used by the “Y” service. It was fortunate and a privilege for me much later to meet some of the people who worked at Bletchley when I was working at St. Dunstan’s, now Blind Veterans UK.

Wireless Interception, known as ‘Y’ (W.I.) had been used to eavesdrop on radio transmissions from foreign embassies before the first world war. The Navy set up a listening station at Hunstanton on the East coast in 1914 to intercept German wireless traffic across the North Sea. After an initial lack of funding in this country, the “Y” service became the mainstay of radio traffic being sent to Bletchley Park for decoding from all over the world.

The inspiration for this article came from a reference to a transmitter called “Aspidistra” being set up in Crowborough. In his book “Most Secret War” R.V. Jones refers to it being used for various wireless countermeasures. This included an attempt code named “Silent Minute” to deflect the V2 rocket attack on London by jamming the guidance system. (This is not to be confused with the practice during the war of a minute’s silence at 9pm during the Blitz.) Why was it called Aspidistra ? It was the biggest in the world! named after the Gracie Field song of the same name. We shall discover how and why the Crowborough transmitter played such an important role during the war.

Naturally I had heard of the Crowborough site being used by the BBC until it closed in 1982, but what was it used for in the 1940s, being the most powerful medium wave transmitter in the world? There seems to be confusing elements as to the reason why this 3rd station at Crowborough was commissioned and when it was initially used. First, I need to describe the interesting layout and use of the first 2 stations. In November 1941 transmitters at Gawcott in Buckinghamshire and Potsgrove near Woburn were set up by Section 8, part of MI6’s Propaganda Section to further the allied cause by sowing alarm and despondency amongst the enemy.

Each station was equipped with 2 American 110-volt RCA 7.5kW transmitters because due to lack of funding and development, the British had no comparable sets. Gawcott station’s transmitters were named Geranium and Gardenia. Those at Potsgrove were named Poppy

and Pansy and both stations had Ruston or Crossley diesel generators for power. In the control room, connected to the short-wave transmitters were large record turntables, these were for playing pre-recorded messages and music recorded in most European languages. The discs were made of shellac about 18 inches in diameter and played at 33⅓ RPM.

The various language discs also contained information for broadcasting to resistance groups in occupied territories, and morale-boosting speeches from their leaders in exile in Great Britain. Twice a week there would be a church service, and suggested sabotage methods and targets were also included. The programmes were immaculately timed so as to simulate a live broadcast and were transmitted usually in the evening or at night to use the Heavyside layer in the atmosphere to help propagate the signal.

Later on, the transmitters would be linked directly by landline to the recording studios doing away with the record discs. The studios were situated in the tiny village of Milton Bryan in Buckinghamshire and this clandestine wireless station had, during the war years, the most up to date sound studios bettering even those of the BBC at the time. The site was chosen because it was within the boundary of Woburn Abbey estate which then housed department EH of the Foreign Office propaganda section.

The man responsible for setting up this operation was Sefton Delmer, a journalist, who could have an article written exclusively about him and his exploits. This man, born in Germany of Australian parents who could speak immaculate German, worked initially at the BBC in 1940 then went on to direct his own propaganda station with the sanction of MI6. He coined the term Black Propaganda and went on to write several books about Propaganda and Psychology in later life.

Delmer’s idea was to set up a spoof German radio station called “Gustav Seigfreid Eins” In German military phonetics - GS1. In modern phonetics Golf Sierra One. It meant nothing except to have a military ring to it.

May 1941 saw the first broadcast which was recorded on disc and sent to be transmitted by Gawcott and Potsgrove. German radio interception would know instantly that it was broadcast from England but Delmer reasoned that a casual listener would not. Transmissions continued with pretend coded messages and made up ‘inside’ information about leading German military personnel. Intertwined with the messages was genuine information taken from German newspapers which gave further credence to the programmes.

The transmissions were repeated every hour and after 18 months, transmissions came to an end when a staged shut down by the Gestapo was recorded along with gunfire onto discs to be played on air.

6 W&DSME

Cont. page 13

Works and D.O. .......................with Mike

LOCOMOTIVE BALANCING IN

THE BIG WORLD

Among the magazines and newsletters that regularly pass through my letterbox, one recent society publication touched on the matter of balancing steam engines. Of course, I could not resist putting together a few words about this matter in an attempt to untangle what is rather a difficult subject but one that luckily does not affect us modellers as scale is on our side and the forces experienced in the big world become insignificant for us. Quite simply the forces needing to be balanced in an engine are caused by the acceleration and deceleration of rotating and reciprocating masses which in 5” gauge diminish by the cube of 11.3, about 1/1500, although of course the weight of a scale model (dead to scale and using the same materials as in full size) is reduced in the same proportion, so it might be thought the forces would still have some significance.

What we must remember is a model running at the right visual speed, i.e. correct revs per minute, (not like some of you speed merchants) also has its piston speed reduced by the scaling factor, and likewise its acceleration, so that the forces in 5” G models decrease by another 11.3 down to 1/16,000. So balance weights are of no consequence for us, well not quite, dummy balance weights are needed to make the model look realistic, but be careful to note where they are actually placed, they vary considerably according to the prototype and between wheel position as well as the year for which the prototype is portrayed!

On full size engines balance weights are put into coupled wheels either as cast-in crescents or as steel side plates attached across several spokes at the rim and filled with lead. This is similar to the small lead weights put on to the wheel rims of our cars but rather more complicated. Steam engines suffer from out-of-balance forces as a result of masses that rotate such as the coupling rods, plus a proportion of the connecting rods, but additionally from other forces originating from the reciprocating masses of the piston-crosshead-connecting rod assemblies as they accelerate and decelerate during each revolution. An engine will run very roughly indeed if steps are not taken to balance forces, increasing to a dangerous level as speed increases.

The rotating mass of coupling rods, plus part connecting rods is easily balanced by adding counter-weights diametrically opposite to achieve balance, but the fore-and-aft acceleration forces of the piston assembly are quite a different matter. Although these can be dealt with by increasing the size of the balance weights this introduces another problem since the extra weight is fine when it acts horizontally opposing the reciprocating masses, but when moving vertically it pulls the axle up and down. This is the so-called “hammer blow”, created by the Chief Mechanical Engineer trying to balance his

engine but much disliked by the Civil Engineer responsible for the permanent way. As always in engineering a compromise is made, in this case by balancing only a proportion of the reciprocating mass, usually around 60 or 50%, even less with some large “modern” engines, and accepting the surging caused by the unbalanced remainder.

If this looks complicated just hang on a minute because the rotating and reciprocating forces acting on the crank pins lie in a plane outside the wheel but the counter weight is put within the wheel itself (Fig 1).

Imagine an assembly like a bicycle crank with similar weights strapped to each pedal: statically this is

balanced but when spun around the weights pull in

opposite directions trying to twist the shaft in the bearing. This twisting torque itself rotates and on an engine, it

causes a swaying movement. It was often ignored on older lighter engines but it is usually compensated by using more balancing mass in the wheels located a few degrees beyond the 180° position: have a good look at the wheels of a “modern” outside 2-cylinder engine and note how the balance weights are not directly opposite the crank pins.

So far I have been visualising engines with outside cylinders but those with their cylinders between the frames differ slightly since the weights of the connecting rod and coupling rods can be partly offset by locating the outside and inside crankpins opposite each other at 180ᵒ thereby reducing the balance weight needed. A typical British inside cylinder 4-4-0 has small weights on the trailing wheels more or less opposite the cranks (to balance the coupling rods) but the weights on its driving wheels are aligned with the cranks, not opposite them, thereby adding to the coupling rod mass so as to balance the forces of the inside connecting rod and reciprocating masses.

Cont. page 8

THE GARDENS AT THE GARDENS.............WITH DIANE LEWINS

The strong winds in June wrecked the roses but having dead headed and pruned back the damage they seem to be holding their own with plenty of nice red shoots promising a secnd flush of blooms lasting well into the summer and beyond. The tomatoes and courgettes in the large pots are doing pretty well - they certainly taste OK. Had loads of juicy strawberries (though no Wimbledon to go with them). Again, much tastier than those from the shops. Potatoes and broccoli still to come, also blackberries from behind the workshop. Might be able to make bramble jelly this year. Already made strawberry jam so here's hoping for a bumper crop. As always, the newts have charge of both ponds. Two baby seagulls were safely fledged up on our chimney and we were certainly pleased to see the back of them, they have been so noisy, more so this year than ever before. Sparrows and robins a plenty have been getting quite frequent visitors to the lower garden. They have entertained us with their antics

when we have been sitting outside with our cuppas. Magpies and crows have given us some death-defying aerobatics, vying with each other and with the seagulls. Found some old packets of seeds tucke d away in a drawer and as the garden centres have been closed I thought why not give them a go, they will either come

up or they won't. Well, they did come up and we've had lots of nasturtiums and yellow poppies brightening up the patio pots. Last year when the geraniums had finished I turned the pots on their side and stashed them under the large hydrangea. After the worst of the weather earlier in the year, I got them out, gave them a trim and a feed and they have been glorious. Also, the pinks have done us proud. Who needs the garden centre after all? Cheers, Diane

MIKE CONT. FROM PAGE 7

A few designers of inside cylinder engines set the adjacent outside and inside cranks in line with each other so extra-large weights were needed in the wheels to balance both the outside rods and the inside motion.

Stroudley favoured this arrangement on the LBSCR which, although seeming counterproductive, has an advantage in reducing the forces (and wear) on the axle boxes of the driving wheels but at the expense of additional axle load: bully for him if the Civil Engineer did not figure out what was happening to his track.

It was recently pointed out to me by a modeller that some engines did not have the reciprocating forces balanced and he quoted an academic engineering thesis citing an example. However, for the class of engine mentioned it is not correct to interpret the absence of balance weights for the reciprocating masses as lack of balancing since it is one of several cases in which the total effect of the reciprocating forces happens to be zero, so effectively they are naturally balanced. This means that no additional weights were required in the wheels, not that they were omitted despite being needed.

This situation can occur in multi-cylinder engines where the reciprocating mass of one cylinder is balanced others. The 4-cylinder LNWR Claughton, whose features I came to know very well when making my miniature version, comes to mind with the adjacent cylinders on each side of the engine having similar pistons, crossheads and connecting rods acting at 180° to each other thereby being in balance without the need for additional weights in the wheels other than a small amount just to offset the swaying moment

caused by the cylinders in each pair being separated horizontally. The most common case of self-balance is the 3-cylinder arrangement having all drives to the same axle (equal connecting rod lengths) and distributed at 120°. On the LNER Gresley’s 3-cylinder engines were of this type (neglecting the slight inequality due to the inclination of the middle motion), and the same layout was perpetuated by Bulleid on the SR in his Pacifics which do not have additional balance weight. The SR “Schools”, the example of an engine without reciprocating balance mentioned in the thesis, also has a self-balancing layout but there is mention of a modification made to them in Bulleid’s time stating that the “additional balancing” was removed to improve riding. This seems to indicate that Clayton, the SR Designer, put in unnecessary weight which I find unlikely.

Careful examination of photographs when new and also in BR times (overturned “Blundells” in 1949 is quite revealing) does not show any alteration to the actual balance weights so the reference to it is doubtful. However, a simple comparison of the balance weights on the driving and trailing wheels shows that those of the drivers are considerably larger. Obviously the balance on the trailing axle is quite small as it deals with just the rotating mass of half of the coupling rod, but if the reciprocating masses of the three motions sum to zero why would so much more weight have been put into the driving wheels? The position of the weights takes care of the swaying moment but they do seem too big. Come on you Southern experts, please let us into the secret.

Mike Wheelwright.

MY PEPPERCORN A1……more progress than usual ….

So, 2020 continues to be a somewhat “special” year which I guess none of us expected. In the last few weeks I have finally started working from the office again, however flying abroad remains strictly off the agenda. An update on the A1 project; well some progress to report from the workshop and some sourcing update on the boiler front, firstly in the workshop. I have plumbed the air feed lines to the cylinders using some small-bore heating tubing and 8mm compression fittings, not very elegant but effective. In preparation for setting the valve timing I of course needed a set of rollers for the wheels, these I made using some bearings I already had, and some 1-inch steel angle bolted to some pieces of MDF. Again, not the most elegant solution, but good enough to do the job. The valve timing is now underway with the first task to put the glands in place. I must confess that the timing adjustments are not yet completed, and I think I need a clear day to really get stuck into this.

If any of you read my last update back in April you will have heard that the boiler was a topic of discussion. I had discounted the buy option for both economic and to some extent personal satisfaction reasons, also, the kit option seemed excessively expensive, how difficult could it be to source the materials? For sure, the copper tubes should be no issue, ½” o/d 17 ½” long no problem, but looking at all the usual suppliers I discovered they all sell either 12” or 24” lengths! And when you need 24 of them that is a lot of waste. Finally, I found Macc models selling 18” lengths, problem solved. However, the main boiler body as per the drawings is made up of two tubes, one at 6 ¾” o/d and one at 6 ¼” o/d. This proved to be a much greater challenge, with none of the model engineering suppliers offering anything over 6” o/d. Would rolling a tube out of flat be an option? Well yes, but a quick exchange of emails with our boiler experts made me realise that this would maybe not be the best option, so back to sourcing the tube. I found one guy online who indeed had both sizes in stock, but the larger was double the price of the smaller, which made it over £25 per inch!! And I needed 18”, ouch. Surely it must be a mistake in his price list? I contacted him fully expecting a “sorry that is wrong”, but NO, he said “oh we price it depending on what we pay for it, so this bit must have been more expensive!” I was now starting to feel this was going to be impossible, or incredibly expensive. After numerous other calls and emails, I finally found a supplier who could source exactly the correct tube at a reasonable (well not eye watering) price. In the picture you can now see the main tubing, the ½” tubes and the 3mm copper sheet cut to size for the firebox wrapper and ends. Still to buy is the 4mm sheet for the rear bulkhead and smokebox end, along with the larger tubes.

Whilst all this was going on, I got some 10mm flat steel plate to make the formers. After marking them out it was time to cut them out, new hacksaw blade fitted and away we go. Well after 1cm I realised that this indeed going to be hard work, time to get my old bandsaw out. I cleaned off the cobwebs and luckily it already had a

metal blade fitted, this was going to be much easier. Well at least that is what I thought, after less than 10 seconds there was a strange noise and the blade stopped. Closer investigation revealed that the rubber tyres on the wheels had perished and fallen off. So, onto eBay for replacements, which arrived within a couple of days, now we can go. No, within less than a minute of fitting the new tyres, the drive belt broke! Back onto eBay again, new belt ordered, delivered and fitted. It was at this point I found out that the blade was blunt! So back onto eBay new blade ordered and fitted, this time it worked! So much quicker than cutting by hand. The picture shows the formers I have cut so far ready for forming the copper.

I have also included for intertest a picture showing the chassis and tender on a piece of track, I thought I had better check that it all fitted OK before I went much further. Seeing it together also gives you a renewed boost of energy to push towards the final finishing line

Clive.

9 W&DSME

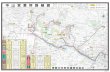

WAS IT SOMETHING DIFFERENT FOR THOSE IDLE HOURS? So how did you do? Just one member reported that he and his wife had answers for all fifty-six questions … they’ve been waiting for this to check them. When I gave the quiz a try, for number seven I put down ‘Handcross’. Well it fits doesn’t it? So, I ended up with the same answer for both numbers seven and twenty-two. Does that count as a failure of Q7?

1 Quiet Refuge Peacehaven 29 What one does with sails Firle

2 Arsenal 1 Chelsea 4 Winchelsea 30 Crossing the river at Shoreham Three Bridges

3 A shallow river crossing Ford 31 Fido will do this to a bone Bury

4 A decaying parson Rottingdean 32 A female horse’s home Maresfield

5 What’s to be done if little Willie tears his trousers

Patcham 33 A container and shady area Box Grove

6 How to support collapsing buildings Shoreham 34 What you do after a good performance

Clapham

7 A portable crucifix Cross in Hand

35 Where free chickens roam Henfield

8 A nasty habit of bulls Goring 36 A freshly cut tree Newtimber

9 A drastic remedy for boils Lancing 37 How to propel a punt Poling

10 Creepy Crawley 38 The fruit is ready to pick Ripe

11 A lawn for game Partridge Green

39 A dazzling century Brighton

12 Part of a fish and a Spanish gentleman

Findon 40 Where to cross the salty water Seaford

13 A Grain Rye 41 This falling ice is false Hailsham

14 Chews cud and sheep enclosure Cowfold 42 Chef’s pasture Cuckfield

15 Found in a church Hassocks 43 God’s hospice Christs Hospital

16 A large-scale fight Battle 44 Lemon flavoured shallow river crossing

Kirdford

17 What a smoky lamp needs Newick 45 Old clothes Warnham

18 A replete monarch Fulking 46 Nice ham soup Pease Pottage

19 Wide and wet Broadwater 47 Find a stake and make a call Dial Post

20 Done to roads before the stones go down

Tarring 48 Athletic Charlton

21 A crossing for chefs Cooksbridge 49 Starboard fire eater Dragons Green

22 An equestrian measure and angry Handcross 50 A little for the unemployed Hove

23 A tart and a little village Pyecombe 51 Actually Small Dole

24 Dried grass and what a bee does Hastings 52 Tilting beach Camber Sands

25 Trees in a line Forest Row 53 Value of a four legged friend Petworth

26 Good value Worth 54 Uncomplicated birth Easebourne

27 Bob’s card game Robertsbridge 55 D.C. Washington

28 A compass point and part of a candle Southwick 56 Toothpaste for whiter teeth Colgate

10 W&DSME

NOW TRY THIS QUICK TEASER … No calculator allowed !

You are driving a number 700 bus from Worthing to Brighton and begin the trip with seventeen passengers. In Lancing, six get off the bus and nine get on. In Lancing, it’s two off and four on. At Shoreham, eleven leave and sixteen join. Next, at Southwick, three get off and five get on. Nearly there, and in Hove six alight and three board.

You then arrive in Brighton.

Now … without going back to review, how old is the bus driver?

(Answer on the backpage.)

Life of John Stoton ....................by John Himself I must apologise for the gremlin that resulted in my re-printing an incorrect second page of John’s article in the last Newsletter. We re-join him as he tries to collect an order from a shop in the USA. Ed.

I duly asked for what we had ordered and waved the order and cheque, to be met with a hail of questions like where did we steal the car from? In desperation I waved my passport at the woman with my finger pointing at the bit about Her Britannic Majesty requests your help for the bearer. It was soon returned as being not a State document, not even a Federal document. I was relieved to hear a male supervisor from behind a layer of steel work call out “Maisie, if they ain't pulled a gun on you yet they must be honest, for God's sake give them the calculator”. Then there are some language differences but I must save the Editor's blushes and censorship.

The life of leisure ended in redundancy at a time of depression in most industries and initial depression in me of course. However, it was to provide time to apply for Probate of my Father's Estate. The legal correctness of Bank and deviousness of a Solicitor were in marked contrast to the helpfulness of Civil Servants. We had for some time operated with an arrangement for me to sign Father's cheques but that was instantly void so I could not see the envelope in the vault presumed to contain his will, but I did persuade them that if the will were there, any likely executor would not be able to get started. They went into a huddle and returned to say they had not got the will. Next I went to try the Solicitor who I knew had conveyed their bungalow. The doorkeeper girl got me an instant appointment with someone upstairs. He took the will off his desk as he bade me sit down, saying he knew I would turn up sometime. I felt furious that he had made no attempt to find me despite the notices in the local paper nor even advised my Father to notify me of the whereabouts of the will.

That little “dislike” of solicitors reminds me that I left a bit out of Part 6. We moved from Sunbury to a new house in Horsham. It was the days of ordering 'off plan' and 'stage payments' supported by a bank loan. Somewhere about first floor completion the mortgage company notified my solicitor that they would advance no more money unless the house was put right. The builder's reaction was that they could sell to someone else less fussy. I had the huge bank loan and a disappearing house and needed a plan. The conveyancing clerk in London knew nothing of Horsham but found the Senior Partner had once conveyed a big Estate outside Horsham and could remember the estate agent. Thus contact was made for a new survey. The actual surveyor turned out to be quite a senior fellow in a biggish south east firm and an active campaigner in the surveyors' ‘club against 'spec builders', and their treatment of customers. The report was sent to Horsham Council with “did they approve of houses being built not complying with their bye laws?” Similarly, did the Housebuilders' Federation know what their member was up to? It worked except that when our

surveyor got there he found the builder had done the neighbour's house. So he had to do it all again! When we came to sell years later, some surveyor came down out of the loft to ask how we got such a roof structure the like of which he had not seen before.

Relief from Redundancy

Just as I was getting to the end of being an executor, the outside world was picking up and the occasional advert appeared and I was called to an interview in Brighton. The Personnel guy soon explained that I had 2 technical interviews with a choice of the 2 positions. Immediately on my guard as this was a known trick, analogous to the donkey being starved to death located exactly midway between 2 identical carrots. All was well and I took the project engineering rather than the design offer. So I came to work for the consultants Ewbanks and do the boilers for Port Klang in Malaya. All the main contractors were Japanese. The unit size was 300MW, pretty well a world standard size then. Mitsubishi had 6 months to manufacture each turbine and generator. Even KKK the inspection authority in Japan were going spare, as no start was in sight until about 2½ months late, but they finished on time. What a contrast to CEGB and SSEB specials at 2 or 3 years.

The Civils were having fun with the piling, the site was riverside (stinking tropical) mud, the piles were 30 metres long and as usual, if not yet load bearing, they disconnected the driver to join another pile on. Low and behold the first pile had disappeared. Holding the piles up and repeating found load bearing at near 90 metres.

I can't remember anything exciting happening about the boilers. The turbine hall overhead crane did take on a hump back bridge or maybe it was a corner shop while being delivered and that unzipped several metres of brittle welding. Switch marking philosophy was interesting. I expect you start machines in your workshop with the green for go button. But red is for danger, machine running, green is for safe!

There were a couple of trips to Kuala Lumpur. Monsoon clouds were a fine sight from the aeroplane, offset by the smells and discomfort of climate on landing. Navigation in KL was a mystery just like Cardiff as the Malay majority had removed all English street signs which upset the police and the Indian and Chinese bus and taxi drivers as much as the international visitors. Most meetings were in KL but we did visit the site; I usually got into the back seat of the car. If you have ever driven at 2 chevrons separation, think what 0.02 of a chevron would be like. Once, we saw how the police concentrated on getting workers to work on time. A short bit of road had become dual carriage way and each side marked into 2 by a painted dotted line. Neatly along the line taking minimum space lay a corpse. On the hard shoulder lay a wrecked motor cycle, several police and their vehicles, patiently awaiting the rush hour to abate!

Cont. page 12

John cont. from Page 11

The useful bit of learning came when it was time to think about spare part lists and prices and how these would be indexed for the inflation of maybe 50 years ahead. This was usually a big ritual but the Japanese were not interested saying, you have all the 'as built' drawings as we contracted, why can't you get quotes from local suppliers, we do not want our factory interrupted with oddments of spares for old boilers. We asked what about your copyright? They asked what do you mean what is this word copyright? It reminds of how a former British Government held up British industry by allowing the shenanigans of patents for the simple crank, thus holding back for many decades all reciprocating engines and pumps before, during and after the expensive James Watt manufactory.

That construction was near the end and so redundancy must surely be just over the horizon, however luck was with me once again. Next came a head hunt. Better pay and a house move to Reading to work in a new-fangled group to do power plants within a firm used to doing oil refineries and the like. They were not the first to not understand that oil and water do not mix well and redundancy duly followed.

I was lucky to get an interview (and wondering why) with what I thought was an electronics firm – Toshiba. However, they had hired Ewbanks to do the recruiting and I met my old section head chairing the panel! Toshiba had had a bad case of arm twisting from the World Bank to do some exporting to help the Third World. The third of three jobs was far the biggest and to be the last, a power station with 300MW units at Assuit in Egypt. Most was being handled from Japan but the mechanical auxiliaries were to be handled through Toshiba's office in Stockley Park, just north of Heathrow and they had sub contracted much to the Belgian firm of Hamon Sobelco.

This turned out to be an “oddments” sort of job, probably called project engineering in posh circles. The company car was a good start but that had its downside, I didn't get a new one but had to take over a part used Vauxhall Astra which was really a Lotus in drag. 3” of foam cushion on the driver's seat improved it no end without slowing it. It later had more downsides in Calais and Reading, being attractive to young thieves. I had spent Sunday getting to Dover to sit on a ferry tied up waiting for the wind to abate (incoming ships got priority) and passing the time eating dinner and watching people’s antics in getting about. The jerks against the mooring warps confirmed the wisdom of remaining seated as long as possible and indeed of staying in harbour. Soon after reaching the Calais hotel I was asleep and soon after awakened to be told that they had frightened off an attempted theft of the car but there was some damage. The plans for an early start would have to be reviewed in the morning. A 'phone call to home base got our French speaking Italian girl on the case. The General Motors agent would collect the car and get it fit for travel by Friday afternoon. A local hire firm would deliver a car almost immediately. The downside was that the only last minute available car was a top of the range racy

Renault which was an invitation to race with the local young bloods. I was handicapped by left hand drive, one of those French gearboxes, not knowing the way and unprotected by the vital GB sticker on the back. They were furious.

Come Friday afternoon and with RH driver's doors unavailable off the shelf in France it was at least drivable and got me back to Reading where it was fortunately all unloaded ready for the night on the front drive. Then as we had a late supper, becoming aware of the sound of the car and looking out of the front door, it was no longer there! 'Phoning the police produced the information that Friday evenings were a busy time and they had more urgent work for the one and only patrol car left after the new fangled cuts so would I 'phone again in 2 or 3 hours. Several days later I got a call to go to the local station to collect the ignition leads and be given the address where the car had been abandoned. Over to the MT clerk. And the next 'pre-used' firm's car was to be a turbo-charged Saab which had a twitch of trying to trip over the outer front wheel on a tight corner. The servicing agents could find no fault. Then one day with a Japanese guest and others aboard, I was about to reverse into a roadside parking space near the Chinese restaurant when it sort of knelt down!

I promised more about how Japanese got on with Egyptians and so I must deliver. Quite obviously, as I became involved, the answer is simply 'in English'. It is the International Standard Communicating Medium. The Egyptians write the tender enquiry in English. The Japanese write the tender offer in English. The Contract Law is English. And so far, Englishmen are not involved! Sensibly though, ISO metric units are. So we were involved at international meetings, firstly to understand the question, then to understand the answer, otherwise what hope was there of an understanding between vendor and buyer. Patience, slow speech, no fancy long words and watch their eyes. Forget school stuff about shouting louder until the foreigners understand, or varying your words to colour your prose offerings. It's just a variant on control system design – colourfully vary a destination name and the computer thinks you are too daft to bother with.

The above-mentioned oddments were largely telephone calls, faxes and letters about the subcontracts of Hamon Sobelco which were mechanical bits like oil coolers being made in Europe. The Japanese were quite keen on face to face meetings and that suited me, I like to see if the item is really as they say. So some visits were whip cracking but many were to accept for shipment. A few highlights from my memory.

A factory in France making heat exchangers mainly for EdF including Nucs was located in a rural village. The original big mansion was now office and the grounds were filled with factory buildings.

To be continued John Stoton

12 W&DSME

AA NNEEWW ‘‘BBIIGG BBOOYYSS TTOOYY’’ JJOOIINNSS TTHHEE CCLLUUBB!! …… BByy BBrriiaann HHuunntt..

As many of you know I have been involved with full size and model steam since the early 70's, being lucky enough to become a firm friend of Derek Kilburn and being able to join him on many road trips with his Marshall Steam Tractor and later on his lovely 'Burrell' Britannia.

My Dutch concert organ is being housed in a nice barn not far from home along with two traction engines and a few living vans; I am able to go there to play and maintain it. Late last year I was there one Saturday afternoon doing some jobs on it and the steam guys were there working on their engines. Whilst we all sat down having a cuppa and a good old chinwag, I just mentioned that I should have had a full-size engine years ago to which one of them replied “it’s never too late”. Well, this got me thinking full size, mmm cost to buy one, running costs, storage cost, plus I'm not getting any younger, No I don't think so as much as I would love one.

On Boxing day I went to a get together at a pub in Slinfold and met up with people I know who have engines, and in conversation with one of them I was told that they had a half size Wallis and Stevens traction engine that the children are learning to maintain and operate. Half size eh! now that's a thought. In January I decided to browse various websites to see if there was anything available. One particular engine caught my eye, it looked like a well-proportioned 6" scale 'Burrell' agricultural engine and I was impressed with the description of it.

An appointment was made to view it and on the day I took Derek Kilburn with me as I value his opinion being a true 'Burrell' man.

When we arrived we could see it was a chunky piece of kit, engineering wise very well made but with several bits of detail missing as it was built on a budget by a steam engineering firm in Dorset. Sadly the previous owner is elderly now and poorly so had to part with it. Derek gave a favourable opinion of it and said if it could have all the missing parts made and fitted it would be a fine engine. I told the seller that I would go home and think about it and contact him the next day.

I think I knew in my mind then that I was going to have it. I made contact the next day and a deal was done; now, how do I get it home? A couple of weeks later I hired a trailer and along with my brother for extra muscle we collected it. The next task was to make a list of parts to be made and fitted which is quite long so I won't bother you with that. The first thing I did notice was that the cylinder block was painted the same colour as the rest of the engine, which is incorrect. I did make contact with the guy who built it and funny enough the first thing he said to me was “Paint that bloody cylinder block the correct colour.” I have spent the last few months making and fitting the missing parts and now I think she looks great, just one more job to do.

On 27th April it passed its boiler test which had to be done commercially, and now being road registered is taxed and insured so I can feel a few road runs coming on. I have taken it up and down the road where I live and am very pleased with the way it steams and rolls along.

The engine was completed in 2011 but has only had a couple of years use, so is in pretty good mechanical condition.

It was modelled on a very late 8 NHP 'Burrell' agricultural engine. In the last few years of their manufacture the orders were put together with whatever components they had in stock. Consequently the full sized version of this had a road locomotive boiler, road loco rear wheels with double drive and sprung front axle and would have run at 200psi. Mine red lines at 130psi, and I can assure you that's enough as she's quite lively at that pressure.

Brian Hunt

BLACK PROPAGANDA CONT. FROM PAGE 6

Unfortunately, the British operators could not understand German and played the disc again later in the day!

Just before the first spoof transmission in 1941, and unknown to Delmer, Churchill gave the go-ahead for a much more powerful transmitter to emulate the major

German radio stations and with further plans to disrupt the enemy.

In part 2, next issue, we look at the construction and equipping of the site at Crowborough.

Leigh

The Back Page…

AGITATE HUNG NOUGHT ASIA LAKE SHEARS ATLAS LANE SHEET BOUGHT LEAN SHOE COUGAR LORD SHOOT COUGH LURE SHOUT DEAD LOUGHBOROUGH SLOUGH DOUGH MEAT SOOT DROUGHT OBOE SPLASH EGG OUGHT STAR ELEVEN PATCH STEAM ENOUGH PIG STUD FUME PLOUGH SUGAR FURLOUGH PROD THATCHER GHOST RAIN THOROUGH GLOW RASH THROUGH GLUE REPTILE TOUGH GRANT ROAR TOWPATH GUESS ROUGH URCHIN GUTTER SADDLE WASP HEARTH SALT WHEEL HOLD SAUSAGE WROUGHT HORN SCOPE

14 W&DSME

DAVID’S WORD SEARCH...................compiled by David Lewins

THE BUS

DRIVER

Oh! For

goodness sake,

don’t you know your own age?!

You are driving the bus!

JOHN PARSONS WOULD LIKE TO SAY A BIG THANK YOU FOR THE MANY GOOD WISHES HE RECEIVED FROM MEMBERS ON HIS NINETIETH BIRTHDAY. See you back at the club soon John!

OFFERS INVITED!

1) Sturdy locally built hydraulic trolley;

2) Workshop trolley with braked and swivelling wheels. Club funds to benefit by 25%

of agreed prices. Contact Dereck L (see page 2)

FOR SALE BY THE

CLUB

Heavy duty folding aluminium wheelchair/access ramps. Get your trolley

in and out of the workshop with ease! Offers invited to our Hon. Treas. Martin on

01903 764056 or email [email protected]

Related Documents