1 SAP MM/ WM PRESENTATION SAP MM/ WM PRESENTATION VISIT US AT www.sap-topjobs.com

MM - Master Data & PR

Dec 18, 2015

MM - Master Data & PR

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

-

SAP MM/ WM PRESENTATION

VISIT US AT www.sap-topjobs.com

-

MM ConfigurationMaster Data and PRObjective

To understand

MM Module data flowMM Module Master DataRequisitionRFQ QuotationRelease Strategy

-

MM Module Data flow

-

Data flow ..contd..1.MRP run triggers the requirements Purchase requisition is released 2. If quota is used, source is identified 3. vendor is selected4. Prepare Purchase Order5. Follow up with vendor for supply6. Receive goods7. Receive Invoice and pay vendor

-

Data in SAPWe have seen the data flow in MM, to perform those activities, certain data are required.

Lets discuss about the data before we go to the MM specific master data.

-

Data in SAPthere are two important types of data in SAP

Master DataTransaction data

-

Master DataMaster data is the backbone for each transaction.

Without master data transactions can not be performed.E.g. Material masterVendor masterPurchasing info recordSource listQuota arrangement

-

Transaction dataTransaction data are created when performing a transaction.

Transaction data are created with the input from master data.

e.g.Purchase requisitionPurchase orderGoods receipt Invoice verification

-

MM Specific Master dataFollowing are the MM module specific master data.

Material Master Vendor MasterSource ListQuota arrangementPurchasing Info recordPurchasing group

-

Material MasterMaterial master contains entire information about the material related all department of an organization.

Purchasing related information are stored in a purchasing view.

-

Material master - PurchasingPurchasing view of material master specifies

Person responsible to procure Base unit of measurePlant specific material statusGR processing timeUse of quota arrangementUse of source listBatch Management

-

Vendor MasterVendor master contains all the information required to do business with a vendor.

Name and addressBank detailsContact personPayment terms

-

Vendor Master RecordGeneral dataAccount number Description AddressBus. volumes1994Bus. volumes1995Purchasing dataPurchase order currency Inco termsAccounting dataControl account Terms of payment Bank detailsTransaction figures

-

Roles of a VendorPurchase orderGoods receiptPaymentVendorPurch.BankInvoicePurc. order?=Invoice verificationMaterialInvoicing PartyPayeeOrder RecipientGoods Supplier

-

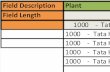

Source ListList of available sources of supply for a material and plant combination.

It facilitates the Determination of source.Automatic assignment of source to the purchase requisitionSource list contains validity period for each vendor.

-

Source ListManualmaintenanceMaintenance from outlineagreementMaintenancefrom purchasinginfo recordAutomatic generationDefault source of supplyin requisition via sourcedetermination Check in purchase order+ requisition for admissibility

-

Source determinationFollowing is the order of priority to search the source.1. Quota arrangement 2. Source List3. Purchasing Info record / outline agreement.

-

How to Determine the Source?

-

Quota arrangementQuota arrangement helps to automatically identify the vendor and allocate the quantities to the vendor.

It containsVendor Quota %Min / Maximum lot size Validity period of quota

-

Quota arrangement -calculationVendor will be determined on the basis of lowest rating result of the following formula

Rating = Base qty +Quota allocated qty--------------------------------------------Quota

-

Base quantity & PrerequisiteQuota base quantity is to regulate the quota arrangement without changing the quota.

Prerequisite:-

Quota usage must be maintained in the material master purchasing view

-

Purchase info recordIt is created for the combination of material, vendor and purchase organization.

-

Purchasing Info Record DataGeneral data Vendor data Origin data Order unitTextsPrices and conditions Gross priceDiscount FreightControl data Delivery time Minimum quantity TolerancesPrice history Ordering statistics Change history

-

Purchasing groupPurchasing group is responsible for specific purchasing activities.It represents buyerIt is used for reporting

-

Purchase RequisitionPR is the request for Material and services. It is the first trigger to the buyer to arrange for procurement.

It is generated automatically or manually.Item category and account assignment are important in PR

-

Item categoryItem category controlsRequirement of material numberAccount assignmentWhether to place in stock or notRequirement of GR / IR

-

Item Category

-

Account assignmentAccount assignment will directly debit the cost of procurement to those object.

E.g. If the account assignment is F to indicate production order, cost of procurement will be debited to the production order.

-

Account categoriesAsset Sales order Production order Cost centre Project All auxiliary account assignments Unknown account assignment

-

Account Assignment

With account categoryAccount assignmentwith material master recordAutomatic account assignment Data from material master recordStock materialStock account

-

How to Create a Purchase Requisition

-

Processing PRPurchaseOrderRFQReleaseOrderIdentifySupplier(Automatically)ReleaseProcedureAllocate andProcessRequisitionPlannedOrderMRPPurchase RequisitionManualCreation

-

RFQ (Request for quotation)Quotation is used in purchasing to compare different vendors before placing an order.

It contains entire information similar to PO.

-

Structure of an RFQHeader Messages VendorHeader Quotation Texts deadlineItemsRequest forquotation(RFQ)

-

Processing Quotations Vendor C, B - Rejection- Thank you for your offer. Unfortunately,we cannot place anorder at this time ..... Steel 2 t Price Quotation 1Quotation 2Quotation 3Mean valuequotation 160/t220/t250/t263/t

-

Release StrategyRelease strategy helps to control further processing.

Based on conditions, different person or department can be authorized to release in sequence

It can be applied for PR, RFQ and for PO.

Item level release can be applied for PR

It can be with or without classification

-

Release ProcedureRelease ConditionsValueMaterial GroupPlantDoes a Strategy Apply?Release IndicatorReleased/Blocked for OrderingReleased/Blocked for RFQFixed for MRPWhat can the Requisition be Released to?Release StrategyWho is Authorised to Release?In what Order must the Releasing Occur?What is the Release Indicator?Who can do what?Release CodeTwo digit code associated witha user IDWho is Authorised to release?

-

Release Procedure W/out ClassificationRelease ConditionsValueMaterial GroupAccount Assgt. CategoryPlantDoes a Strategy Apply?ReleaseStrategy

-

Release Procedure With Classification

-

Releasing Requisitions

-

Summary

You must have understood MM Module data flowMM Module Master DataRequisitionRFQ QuotationRelease Strategy

La catgorie du poste dtermine :

- le type dapprovisionnement pour le poste en question

requires a material number requires account assignment is to be placed in stock requires a goods receipt and/or invoice receipt. La catgorie du poste dtermine :

- le type dapprovisionnement pour le poste en question

requires a material number requires account assignment is to be placed in stock requires a goods receipt and/or invoice receipt.In the SAP system, Requisitions can be created in the following twoways:Directly, someone from the requesting department enters a purchase requisition manually. The person determines what and how much to order and the delivery date.Indirectly via materials planning and control, networks and plant maintenance orders. Networks - from the SAP component PS Plant maintenance orders - from the SAP component PM

A purchase requisition is an internal request to purchasing. You ask the buyer to provide a certain quantity of a material or service on a certain date.A purchase requisition can be created automatically by MRP or manually created. The MRP controller can also convert a planned order into a purchase requisition.Source determination is a separate function. The buyer receives proposals if, for example, fixed vendors or outline agreements exist for the material.A release procedure for purchase requisitions can be set up. According to certain conditions, you can determine that a purchase requisition item can only be approved for an RFQ or purchase order once it has been released in sequence by certain persons or departments.If a purchase requisition item complies with the release conditions, it is assigned a release strategy when it is created. Thus, for a requisition, the release strategy is assigned at the ITEM LEVEL.The release strategy identifies who must approve a requisition and in what sequence.The release indicator determines the release status. The indicator designates whether an RFQ or purchase order can be created for this item, whether or not the item is fixed for MRP, and what should happen if changes are made to the requisition.The four options that are available regarding whether a new release strategy should be applied when a purchasing document is changed during or after the release process:Cannot be changedChangeable, no new determination of strategyChangeable, new release under new strategyChangeable, new release under new strategy or with value changeThe release code is a two digit code associated with the user profile. It designates the person or group with authorisation to release a requisition item.For requisitions, the release procedure can be created with or without classification.In without classification, there are only four fields from the requisition that can be used as release conditions in determining which strategy to apply. These fields are: Value, Material Group, Plant, and Account Assignment Category. Also, when setting up release procedures without classification, authorisation is set up on the basis of release codes only. Authorisation for this type of requisition release is defined under the object M_BANF_FRG.There are two distinguishing features of setting up your release procedures with classification:You can define your own release conditions using the classification systemYou can set up release procedures for requisitions as well as other purchasing documentsIn the with classification method, classes are created in the classification system to be used for release of the purchasing documents. The class type for these classes is 032 - Release Procedure. The characteristics in a release class are comprised of fields from the purchasing document. When a purchasing document is created/changed, the purchasing document field values are passed to the release class characteristics via a communications structure. The release strategy is selected if its characteristics values match those of the purchasing document. Otherwise, no strategy is selected.One requisition can be released at a time or else several requisitions can be released at once.

Related Documents