-

Experience of Delhi Metro-Phase II

HV Receiving Substations with

IEC 61850 and its Incorporation in

Phase III

By:

Anoop Kumar Gupta, Director (Electrical)

Mahendra Kumar, Chief General Manager

-

2DELHI METRO RAIL CORPORATION (DMRC)

Set up in May95 under the Indian Company Act.

A joint venture between the GOI and theGNCT Delhi, with equal equity.

DMRC has the responsibility for construction andoperation of Delhi Metro.

A Master Plan had been drawn up for DelhiMetro expansion, consisting of 12 lines, covering

420 kms. to be completed by 2021 in four

Phases.

-

3DMRC PROGRESS/ ACHIEVEMENTS SO FAR

Phase-I 65 kms. Cost Rs.10,571 Cr ( $ 1.7 billion)

Completed in 7 years and 3 months (2 years & 9 months

ahead of schedule).

Phase-II 125 kms. Cost Rs.19,131 Cr ( $ 3.2 Billion )

Though double the length, completed in half the period

taken for Phase-I, and five months ahead of schedule.

Phase III - 136 km at Rs. 44000 Cr ( $ 7.5 Billion)

Sanctioned in Sept 11 and has been committed to the

Govt. for completion in 4.5 years.

-

STATUS OF PHASE-III

Further expansion by 136 kms. 110 km (50 km U/G) inDelhi & 26 km in Haryana (14 km) Line-6 Badarpur to YMCA

Chowk, Faridabad & (12 km) Mundka to Bahadurgarh.

The contracts are in place and the work is in progress.

For the first section Trial run was flagged off inDecember 2013 for the CTST- Mandi house corridor of

phase III

-

STATUS OF PHASE-III

5

Phase-III will be completed by March, 2016

On completion of Phase-III Delhi will have a

metro network covering 326 kms.

Delhi is the fastest growing metro network in

the world outside China.

-

6 DMRC is having 142 Stations and 190 Km in operation.This is including high speed Airport Express line having 6

stations and 23 km section.

About 2800 train trips a day with 208 train sets (1100Coaches) on 6 lines.

Each train used to consist of 4 coaches. With the increasein commuters, the trains are progressively being

lengthened to 6 coaches and finally to 8 coaches. We

have already near about 100 six car sets.

Average Ridership more than 2.4 million passengers perday. (meaning about 1,00,000 vehicles off the road)

Operation Highlights

-

Operation Highlights

Frequency during peak hours 2 m 40 sec on 2 out of 6lines (on other lines 3 to 5 mts).

DMRC has around 7,000 employees, besides contractstaff.

DMRC has assets of Rs 30,000 Cr ( US $ 5 billion) We earn around $ 170 Million from Operations and

spend around $ 104 M ( Op Ratio 62%)

Fare : From Rs.8/- to Rs. 30/-. The system is making anoperational profit from Day-1.

DMRC is able to service and pay back the loans despiteno subsidy from the Government and the Fare Structure

being lowest in the world except Kolkata.

-

8 20% of DMRCs revenue is from Non-operationalsources mainly real estate development andadvertisements.

The system is fully Barrier Free for Physicallychallenged.

The trains now operate from 6 AM to 11 PM.

DMRC has introduced feeder bus short loop servicesto help the commuters.

Punctuality measured with a least count of 60 Sec. andthe punctuality percentage has been above 99%.

Operation Highlights

-

DWARKA

LAX

MI N

AG

AR

YAM

UN

A B

AN

K

NIR

MA

N V

IHA

R

PR

EET

VIH

AR

KA

RK

AR

DU

MA

BOTANICAL GARDEN

GOLF COURSE

NOIDA CITY CENTRE

DHAULA KUAN

DELHI AEROCITY

DWARKA SEC 21

ASH

RA

M

SRIN

IVA

SPU

RI

`

KALINDI KUNJ

PALAM

DHSRATH PURI

DABRI MOR

BOTANICAL GARDEN

DELHI GATE

JAMA MASJID

LAL QUILA

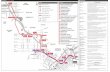

PHASEI = 65.1KmPHASEII = 125.0 KmPhaseIII = 136.0 KmTotal = 326.0 Km

-

Phase I

65 kms, 59 metro stations

6 Receiving HV Substations One at 220 kV and 5 at 66 kV

One substation i.e. at New Delhi RSS theprotocol at the substation was IEC 870-5-101

whereas at the other five it was RP 570

10

Contd.

-

The entire power supply at RSS, tractionsystem and the auxiliary system is monitored

& controlled through SCADA system.

The monitoring and control is exercisedthrough use of Remote terminal units.

11

Power Supply in Phase-I

-

Typical Layout for Phase I

12

NETWORK

RTU

Remote Terminal Unit

Power

Supply

Equipments

SCADA

Data Base

ECC Operating Room

ECC Technical Room

Remote VDU (optional)

PLC

Local Area Network

Terminal server

Operator VDU

Server Server (redundancy)

Printer

Filing

Mimic Display Panel Printer

Local console

(optional)

Manager Office

Front End Computers ECC Equipment

I/O (Field Data) I/O (Field Data)

Substation Level

PLC

PLC PLC

Example of SCADA architecture

-

Arrangement for Phase-I

13

-

PS AI DO DO DI ------ DI CPU

PS- Power Supply Card

AI- Analogue Input Card

DO- Digital Output

DI- Digital Input

CPU- Central Processing Unit

Communication between RTUs and Telecomrooms has been provided through one copper

cable only

A typical RTU consists of the following:

14

-

Limitations experienced in Phase I

Extension-Vendor specific

Limited flexibility

Increased time for installation, testing &

maintenance

-

Phase-II System on IEC 61850

IEC 61850 protocol for 8 HV Substations ofphase II

Substation Automation System (SAS) for all RSS(220kV/66kV/132kV - the incoming), 25kV TSS

(Traction) and 33kV AMS (Auxiliary Supply)

system

Communication between substation andOperation Control Centre ( OCC) through IEC

60870-5-101 protocol

16

-

System Architecture for SAS- in three levels

Bay Level

Station Level

OCC Level

17

-

Typical 66kV/33kV/25kV HV substation at Church Road

18

-

Each bay comprises of one circuit breaker and associateddisconnectors, earth switches and instrument transformers.

At bay level, the IEDs provide all bay level functions like control(commands outputs), monitoring (status indications, measuredvalues).

The IEDs are directly connected to the switchgear avoiding theneed for additional interposing of transducers.

Each bay control IED is independent of the others and itsfunctioning is not affected by any fault occurring in any of theother bay control units of the substation.

The data exchange among bay level IEDs, and between baylevel and substation level take place via dual fiber-optic inter baybus according to IEC 61850-8-1 protocol.

19

-

Station Level

Human Machine Interface enables local station control andmonitoring through the vendor software package compatible

with IEC 61850.

DMRC Substation bays are limited the bay bus arrangementprovides independent station-to-bay and bay-to-bay data

exchange.

Substation configuration language (SCL) facilitatesintegration of the system by the users/operators and can be

used without detailed knowledge of real-time systems.

An authorization mechanism has been provided to prevent system access to unauthorized users

-

OCC Level

IEC 61850 signals are converted to IEC 60870-5-101 signals through a software based

gateway for communication from the substation

to the OCC.

21

-

Functional description of SAS

The functions are allocated at bay level to achieve

the decentralized architecture:-

Bay control and monitoring functions

Bay protection functions

22

-

Phase-II-Typical Block diagram for the functional requirements

23

-

Achieving the functional requirements

One Ethernet switch is provided for two/three bays.

Connection from each IED of the bay to the switch is bya fiber optic link. The switches are connected in a dual

fault tolerant ring.

Two Ethernet switches are used to connect theredundant HMI and other equipment for communication

redundancy.

The HV protection, monitoring & control solution isbased on the IEDs using numerical terminals likeRED670, RET670, REC670 and REB670 on a

distributed concept based on IEC 61850 protocol.

-

Achieving the functional requirements

All intra bay interlocks are software based andperformed by the BCUs

Substation wide interlocks are software based; thedata for the interlocks are transmitted using

GOOSE messages by the individual IEDs.

-

Experience of Phase II- based on IEC 61850

Common protocol for all vendors- Contract specificationswere not vendor specific.

Installation at site, testing & commissioning required lesstime compared to earlier arrangement of phase-I.

Reduced equipments for maintenance.

Increased flexibility i.e. in future one or more bays (up to6) can be controlled by using one BCU with dynamic

mimic display thereby making BCU a more cost effective

solution when compared to the conventional system.

Operation is faster at bay level

26

-

Issues encountered in phase II

Vendor provided one of the bay protection units(BPU) for distance protection i.e. REO 517 which

was non compliant to IEC 61850, hence it was

kept out of the Ethernet ring, and now it is learnt

that DPR in its different version has been made

compliant to IEC 61850 protocol.

This is proposed to be specified in phase-III.

27

Issues contd.

-

Location of IEDs and BCUs

The vendor did not place the IEDs and BCUs on the GISpanels of the 66kV or 25 kV panels due to non availability

of suitable equipment .It was provided at a varying

distance of 25-50 meters from the equipments in the

control room leading to a huge requirement of hardwired

copper control and monitoring cables.

This could have been saved by integrating IEDs andBCUs with the GIS (66 kV & 25 kV) panel leading to less

probability of failure and saving of cost and time during

installation.

This is proposed to be ensured in phase III.

28

-

The protocol at OCC between the front

end server and the HMI/Mimic display

is vendor specific and the assistance

of the same vendor is required for any

expansion. It is being studied/

discussed to avoid it.

29

-

Proposal for Phase-III

136 km network with 11 additional HVsubstations and augmentation of 2 HV

RSS

Traction system will be with 25 kV, ac,single phase, 50 HZ.

Auxiliary supply will be 33kV ring network stepped down to 400 volts for theauxiliary requirements

30

-

It is planned to have substations with substationautomation system using IEC 61850 complaint IEDs

BCUs and Bay Protection Units to be placed on the66kV/25kV GIS panels or near to the field equipment.

IEC 61850 compliant distance protection relays arespecified.

With increased number of substations for largenetwork, and need to transfer power supply from

sources, appropriate response time for operation will

need to be evaluated.

31

Phase III contd.

-

Though extension of existing phase II substationwas not envisaged earlier, now on account of

new corridors planned, it requires augmentation

of a few existing substation

Preliminary study indicated that addition of 2 baysrequired is feasible with the existing arrangement

based on IEC 61850.

A typical arrangement is shown in the next slide.

32

-

Schematic arrangement for Augmentation of HV RSS

33

-

TO CONCLUDE

Phase I -The systems were heavily dependenton on-site hard wiring and had its own demerits.

IEC 61850 based substation automation systemused in Phase-II had factory tested BCUs and

BPUs with reduced on-site wiring.

The reduction in wiring and the rationalization offunctionality in relays by substation automation

has enabled significant savings and enabled

improved reliability.

34

Conclusion contd.

-

In phase III placement of IEDs and BCUs on thepanels should also save space in substations ofphase-III.

With IEC 61850 continuously getting upgraded, itis expected that the systems and relays alreadyprovided in phase II and likely to be provided inphase-III would communicate with the latestversions of IEC 61850 in future.

The need is also felt to have an open protocoleven at the OCC level between the front endserver and the HMI/mimic panel.

35

-

36

Thank You

DMRC Ltd.Metro Bhawan,Fire Brigade Lane,Barakhamba Road, New Delhi - 110 003.