Proceedings of the 2009 IEEE International Conference on Mechatronics and Automation August 9 - 12, Changchun, China Electric Current measurement using AMR Sensor Array Xisheng Li, Jia You, Xiongying Shu and Ruiqing Kang School of Information Engineering University of Science and Technology Beijing Xueyuan 30, Haidian, Beijing, China [email protected] Abstract - Anisotropic magnetoresistive sensor can be used to measure DC and AC current by sensing the field near the conductor in a contactless way. In order to improve measurement accuracy, an analysis of the influence of the displacement of the examined wire is made. According to the result of the analysis, restriction on the displacement of the examined wire is given. Current measurement method based on current carrying wire position estimation is presented. Experimental results show that current measurement method based on current carrying wire position estimation is of higher accuracy than that of direct summation method. For example, for sensor circular of 25.4 mm radius around the measurement hole of 10 mm radius, the maximum relative error of wire position estimation method due to non-concentric wire is about 0.2%. electrical isolation and protection of the sensor and surrounding electronics. The use of the sensors' set/reset circuitry allows for ultra low offset and ultra low offset drift of current measurements. In order to improve measurement accuracy, an analysis of the influence of the displacement of the examined wire is made. According to the result of analysis, restriction on the displacement of the examined wire is given. Current measurement method based on current carrying wire position estimation is presented. Experimental results show that current measurement method based on current carrying wire position estimation is of higher accuracy than that of direct summation method. II. THEORETICAL ANALYSES FOR CENTERED CURRENT CARRYING WIRE (2) For the centered position of the wire, the summed output voltage of the device is NSf V OSU M = NV oi = NSH sA =-- 21lR In the following, we assume that the sensors (from 0 to N- 1) are strictly vectorial, reacting only to the magnetic component parallel to their sensitive axes. In addition, the sensitivities (S) will be considered to be identical for all the sensors. The sensors are placed in an ideal symmetry and equidistance around the measurement hole so that their centers are on one concentric circle (name it as "sensor circle"). The sensitive axis of each sensor is tangent to the circle at this point. The output of sensor i (from 0 to N-1) is responses to the respective magnetic field by a voltage V Oi = SHSA,i (1) where HSA,i is the magnetic field component parallel to the sensitive axe of sensor i. According to the Ampere's law, the magnetic field intensity at the distance d from a straight current line in a homogeneous space is H=_I_ 2nd (3) where N is the number of the sensors in the sensor array, R is the radius of the sensor circle. From (3), the current being measured is calculated as I. INTRODUCTION There are numerous methods used to measure current. The most common ways include the use of a sampling resistor, a transformer, or a contactless magnetic sensor. The voltage drop across the sampling resistor which is in series with the load is proportional to the current going through the resistor. This offers good accuracy and low offset, but does not provide electrical isolation and has high thermal drift. This allows transient spikes to ruin the sensor and potentially overload the electronics. The current transformer is made up of a primary and a secondary coil wrapped around a magnetic core. The primary coil carries the current to be sensed and induces a magnetic field in the core. A current is generated in the secondary coil that is proportional to the primary current scaled by the turns ratio. The current transformer offers electrical isolation, but only works for AC applications. Current transformers can also be large and bulky. Often used configuration of contactless current measurement devices comprise magnetic flux concentrators in the form of a ring around the hole, which the examined wire is led through. A Hall sensor with the sensitive axis perpendicular to the cross-section of the ring is placed into an air gap formed in the ring. This type of current measurement devices offers electrical isolation, but can also be large and bulky. Anisotropic Magneto-Resistive (AMR) sensors offer a high sensitivity, small size, solid state solution. Further, these devices may be used for contactless current sensing, meaning they won't break the electrical circuit [1, 2]. This allows for Index Terms - Anisotropic magnetoresistive sensor. Magnetic sensor application. Contactlesscurrent measuremen. Sensor array. Position estimation. 978-1-4244-2693-5/09/$25.00 ©2009 IEEE 4085 Authorized licensed use limited to: UNIVERSITY OF ALBERTA. Downloaded on August 16,2010 at 16:43:31 UTC from IEEE Xplore. Restrictions apply.

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Proceedings of the 2009 IEEEInternational Conference on Mechatronics and Automation

August 9 - 12, Changchun, China

Electric Current measurementusing AMR Sensor Array

Xisheng Li, Jia You, Xiongying Shu and Ruiqing Kang

School ofInformation EngineeringUniversity ofScience and Technology Beijing

Xueyuan 30, Haidian, Beijing, China

Abstract - Anisotropic magnetoresistive sensor can be used tomeasure DC and AC current by sensing the field near theconductor in a contactless way. In order to improvemeasurement accuracy, an analysis of the influence of thedisplacement of the examined wire is made. According to theresult of the analysis, restriction on the displacement of theexamined wire is given. Current measurement method based oncurrent carrying wire position estimation is presented.Experimental results show that current measurement methodbased on current carrying wire position estimation is of higheraccuracy than that of direct summation method. For example, forsensor circular of 25.4 mm radius around the measurement holeof 10 mm radius, the maximum relative error of wire positionestimation method due to non-concentric wire is about 0.2%.

electrical isolation and protection of the sensor andsurrounding electronics. The use of the sensors' set/resetcircuitry allows for ultra low offset and ultra low offset drift ofcurrent measurements.

In order to improve measurement accuracy, an analysis ofthe influence of the displacement of the examined wire ismade. According to the result of analysis, restriction on thedisplacement of the examined wire is given. Currentmeasurement method based on current carrying wire positionestimation is presented. Experimental results show that currentmeasurement method based on current carrying wire positionestimation is of higher accuracy than that of direct summationmethod.

II. THEORETICAL ANALYSES FOR CENTERED CURRENT

CARRYING WIRE

(2)For the centered position of the wire, the summed output

voltage of the device is

NSfVOSUM = NVoi = NSHsA =--

21lR

In the following, we assume that the sensors (from 0 to N1) are strictly vectorial, reacting only to the magneticcomponent parallel to their sensitive axes. In addition, thesensitivities (S) will be considered to be identical for all thesensors. The sensors are placed in an ideal symmetry andequidistance around the measurement hole so that their centersare on one concentric circle (name it as "sensor circle"). Thesensitive axis of each sensor is tangent to the circle at thispoint.

The output of sensor i (from 0 to N-1) is responses to therespective magnetic field by a voltage

VOi = SHSA,i (1)

where HSA,i is the magnetic field component parallel tothe sensitive axe of sensor i.

According to the Ampere's law, the magnetic fieldintensity at the distance d from a straight current line in ahomogeneous space is

H=_I_2nd

(3)where N is the number of the sensors in the sensor array,

R is the radius of the sensor circle.From (3), the current being measured is calculated as

I. INTRODUCTION

There are numerous methods used to measure current.The most common ways include the use of a samplingresistor, a transformer, or a contactless magnetic sensor. Thevoltage drop across the sampling resistor which is in serieswith the load is proportional to the current going through theresistor. This offers good accuracy and low offset, but doesnot provide electrical isolation and has high thermal drift. Thisallows transient spikes to ruin the sensor and potentiallyoverload the electronics. The current transformer is made upof a primary and a secondary coil wrapped around a magneticcore. The primary coil carries the current to be sensed andinduces a magnetic field in the core. A current is generated inthe secondary coil that is proportional to the primary currentscaled by the turns ratio. The current transformer offerselectrical isolation, but only works for AC applications.Current transformers can also be large and bulky.

Often used configuration of contactless currentmeasurement devices comprise magnetic flux concentrators inthe form of a ring around the hole, which the examined wire isled through. A Hall sensor with the sensitive axisperpendicular to the cross-section of the ring is placed into anair gap formed in the ring. This type of current measurementdevices offers electrical isolation, but can also be large andbulky. Anisotropic Magneto-Resistive (AMR) sensors offer ahigh sensitivity, small size, solid state solution. Further, thesedevices may be used for contactless current sensing, meaningthey won't break the electrical circuit [1, 2]. This allows for

Index Terms - Anisotropic magnetoresistive sensor. Magneticsensor application. Contactless current measuremen. Sensor array.Position estimation.

978-1-4244-2693-5/09/$25.00 ©2009 IEEE 4085

Authorized licensed use limited to: UNIVERSITY OF ALBERTA. Downloaded on August 16,2010 at 16:43:31 UTC from IEEE Xplore. Restrictions apply.

are

(7a)

(8a)

VOAN = SAN H Arsin( a)

d EA (7b)

V OBT =SBTHBR - r sin (a)

d EB (7c)

V OBN = SBN H B- r cos (a)

d EB (7d)

V OCT = SCT H CR + rcos( a)

d EC (7e)

V OCN = SCN H C- rsin( a)

dEC (7f)

V ODT = SDT H DR + rsin( a)

d ED (7g)

V - S H rcos( a)ODN - DN D d ED

(8b)where V01 SUM is the sum of the outputs of all tangentiallydirected sensors, Sm is the mean value ofSAT, S BT, S CT, S m '.

I IH A =--=----;============

2m1EA 21C~(R-rcos(a)Y +(O-rsin(a)Y . (6a)

I IH s = - -

2m1Es 21C f(O-rcos(a))2 +(R-rsin(a)Y'V . (6b)I I

H c = - -2ffdEC 21C~(-R-rcos(a)Y +(O-rsin(a)Y . (6c)

I IH D = - -

2ffdED 2Jr~(0-rcos(a)Y +(-R-rsin(a)Y . (6d)

The AMR sensors react only to the magnetic componentparallel to their sensitive axises, thus the outputs of theseAMR sensors are

_ S H R - rcos( a)VOAT - AT A -----'--.........:....

d EA

(7h)where SAT and SAN are the tangential direction sensitivity

and the normal direction sensitivity of sensor pair at point A,SB T and SBN are the tangential direction sensitivity and thenormal direction sensitivity of sensor pair at point B, S CT andS CN are the tangential direction sensitivity and the normaldirection sensitivity of sensor pair at point C, S [) T and SDN arethe tangential direction sensitivity and the normal directionsensitivity of sensor pair at point D, VOAT, VOBT, VOCT andVODT are the outputs of tangential direction sensor at point A,B, C, D respectively, VOAN, VOBN, VOCN, VO[)N are the outputsof normal direction sensors at point A, B, C, D respectively.

If the sum of the sensor output signals is taken for currentcalculation, then

VOTSUM = V OAT + V OBT + V OCT + V ODT

nR1M = -- VOTSUM = KVOTSUM

2Sm

(4)

(5c)

(5a)

(5b)

x

A

D

yB

c

(5d)Hence, the magnetic field intensities at points A, B, C, D

2nR1M =--VOSUM = KVOSUMNS

Fig. I Four-Point current measurement configuration

The coordinates of points A, B, C, D and E are (R, 0),(0, R), (-R, 0), (0, -R) and (r cos( a), r sin( a)). The distancebetween point E and points A, B, C, Dare

dEA =~(R-rcos(a)? + (O-rsin(a)?

d EB =~(O-rcos(a)? +(R-rsin(a)?

d EC =~(-R-rcos(a)? +(O-rsin(a))2

dED =~(O-rcos(aW +(- R-rsin(a))2

where K = 21lR is the calibration factor of the device forNS

centered current-carrying wire [3,4].

A. Current measurement based on the direct summation ofAMR sensor outputsWhen the wire is not centered, the outputs of all the

sensors are not identical, and generally the sum of them isn'tequal to that for the centered wire at the same current value.

Assume that four pairs of AMR sensor are used forcurrent measurement, the center of the sensor circle is 0, thecurrent-carrying wire is at point E, and four pairs of AMRsensor are equally distributed on the sensor circumference, atpoint A, B, C, and D (Fig. 1). One pair of AMR sensorconsists of two vertically placed HMC 1021S sensors. On theupside of printed circuit board, four HMC1021S sensors withtheir sensitive axises directed to tangential direction arelocated at point A, B, C, D respectively. We call these foursensors tangential direction sensors. On the downside ofprinted circuit board, four HMC1021S sensors with theirsensitive axises directed to normal direction are located atpoint A, B, C, D respectively. We call these four sensorsnormal direction sensors.

4086

Authorized licensed use limited to: UNIVERSITY OF ALBERTA. Downloaded on August 16,2010 at 16:43:31 UTC from IEEE Xplore. Restrictions apply.

Table ITHE MAXIMUM MEASUREMENT RELATIVE ERROR OF CURRENT FOR FOUR

SENSOR CONFIGURATION WITH IDENTICAL SENSITIVITY

In order to evaluate the influence of non-identicalsensitivities, we assume that SB=Se=SD=S, SA=l.lS. Themaximum measurement relative error of current is illustratedin Table II. Comparing the data of table II with that of table I,it can be seen that the maximum measurement error for

(lOb)

(lOa)

(IOc)

~ 0.01 0.02 0.03 0.04 0.05

1&lmax (%) 0.02 0.05 0.08 0.10 0.13

7R 0.06 0.07 0.08 0.09 0.10

1&lmax (%) 0.16 0.19 0.22 0.25 0.28

7R 0.11 0.12 0.12 0.14 0.15

1&lmax (%) 0.32 0.35 0.39 0.43 0.48

7R 0.16 0.17 0.18 0.19 0.20

1&lmax (%) 0.53 0.58 0.64 0.70 0.77

7R 0.21 0.22 0.23 0.24 0.25

1&lmax (%) 0.84 0.92 1.00 1.09 1.20

7R 0.26 0.27 0.28 0.29 0.30

18Jlmax (%) 1.30 1.42 1.55 1.69 1.84

7R 0.31 0.32 0.33 0.34 0.35

1&lmax (%) 2.00 2.18 2.37 2.58 2.80

7R 0.36 0.37 0.38 0.39 0.40

1&lmax (%) 3.04 3.30 3.57 3.87 4.19

7R 0.41 0.42 0.43 0.44 0.45

1&lmax (%) 4.53 4.90 5.30 5.72 6.17

7R 0.46 0.47 0.48 0.49 0.50

1&lmax (%) 6.65 7.17 7.72 8.31 8.94

sensors with non-identical sensitivities is greater than that forsensors with identical sensitivities. In order to reduce currentmeasurement error, the sensitivity of magnetic sensor shouldbe calibrated.

Table IITHE MAXIMUM MEASUREMENT RELATIVE ERROR OF

CURRENT FOR SENSORS OF NON-IDENTICAL SENSITIVITIES

(FOUR-SENSOR CONFIGURATION, SB=SC=SD=S, SA=l.l S,)

B Current measurement based on current carrying wireposition estimation

According to the output signals of magnetic sensor, theposition of current carrying wire can be estimated.

The direction of HA, HB, He, HD can be represented bytheir deviation angle

qJA =atan2(HAT , HAN)

qJB = atan2(HBT' H BN)

qJc = atan2(HCT' H CN)

When the current carrying wire is not centered, the sum ofthe outputs of all the sensors is not equal to that for centeredwire carrying the same current. The current measurement erroris produced. The current measurement relative error is

8J =1M - I X 100%I (9)

For four-sensor configuration with identical sensitivity,the maximum measurement relative error of current isillustrated in Table I. As r/R increases, 18/lmax increases

rapidly. In order to reduce the current measurement error, thecurrent carrying wire should be centered.

iR 0.01 0.02 0.03 0.04 0.05

1&lmax (%) 1.0E-6 1.6E-5 8.1E-5 2.6E-4 6.2E-4

7R 0.06 0.07 0.08 0.09 0.10

1&lmax (%) 1.3E-3 2.4E-3 4.1E-3 6.6E-3 0.010

7R 0.11 0.12 0.12 0.14 0.15

1&lmax (%) 0.015 0.021 0.029 0.038 0.051

7R 0.16 0.17 0.18 0.19 0.20

18Jlmax (%) 0.066 0.084 0.11 0.13 0.16

7R 0.21 0.22 0.23 0.24 0.25

18Jlmax (%) 0.19 0.23 0.28 0.33 0.39

7R 0.26 0.27 0.28 0.29 0.30

1&lmax (%) 0.46 0.53 0.62 0.71 0.82

7R 0.31 0.32 0.33 0.34 0.35

1&lmax (%) 0.93 1.06 1.20 1.35 1.52

7R 0.36 0.37 0.38 0.39 0.40

1&lmax (%) 1.71 1.91 2.13 2.37 2.63

7R 0.41 0.42 0.43 0.44 0.45

1&lmax (%) 2.91 3.21 3.54 3.89 4.28

1R 0.46 0.47 0.48 0.49 0.50

1&lmax (%) 4.69 5.13 5.61 6.12 6.67

4087

Authorized licensed use limited to: UNIVERSITY OF ALBERTA. Downloaded on August 16,2010 at 16:43:31 UTC from IEEE Xplore. Restrictions apply.

.(17)

(16c)

(16b)«« =~(O-xY +(R- yY

de =~(-R-X)2 +(0- yY

do =~(0-X)2 +(-R- yY

O.

(16d)The sensitivity variation of magnetic sensor at point A, B,

C and D due to current carrying wire position deviation can becompensated. The sum of output of magnetic sensors shouldbe

«; ~ 2 2 dB ~ 2 2VOSUM = - VOAT + VOAN + - VOBT + VOBNR R

de ~ 2 2 dD ~ 2 2+ - VOCT + VOCN + - VODT + VODNR RThen the current can be calculated using (4).Theoretically.the measurement error can be reduced to

III. EXPERIMENTAL RESULTS

Eight AMR sensors (HMCI02IS) were placed on aprinted circuit board, realizing a circular arrary of 25.4 mmradius around the measurement hole of 10 mm radius. Foursymmetrically distributed sensors on the upside of the boardare of their sensitive axises directed to tangential direction andfour symmetrically distributed sensors on the downside are oftheir sensitive axises directed to normal direction.

The sensors are flipped periodically at 400 Hz. The outputof magnetic sensor is a square wave signal with amplitudeproportional to the magnetic field intensity. The output signalof each sensor is amplified by precise instrumentationamplifier AD623 and then demodulated [5]. The demodulatedsignals are led through two multicore cables to the signalprocessing board, where they are converted into digitalquantities. On the signal processing board, microcontrollerC805lF061 which has 16-bit 1 Msps ADC is used. The signalprocessing board is connected to computer through RS-232.

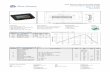

The influence of the wire position is illustrated in Fig. 2.The measurement was performed with a constant DC currentof 3A and the current carrying wire moved around the edge ofthe measurement hole. In order to eliminate the influence ofgeomagnetic field, geomagnetic field intensity is measuredwhen current being measured is zero. From Fig.2, it can beseen that the maximum relative error of wire positionestimation method due to non-concentric wire is about 0.2%(absolute value), which is better than that of direct summationmethod (2.6%). The residual error is caused mainly by crossaxis effect of AMR sensors and asymmetries in the probelayout.

(14a)

(16a)

(13a)

(lla)

(12a)

({JD = atan2(HDT' H DN)

(14b)The position of current carrying wire can be estimated

using (x(A, B), y(A, B)), (x(B, C), y(B, C)), (x(C, D), y(C, D))and (x(D, A), y(D, A)).

1x=-(x(A, B)+x(B, C)+x(C, D)+x(D, A))

4 .(15a)1

y = -(yeA, B)+ y(B, C)+ y(C, D)+ y(D, A))4 .(15b)

The distance between current carrying wire and point A,B, C, D can be calculated.

«, =~(R-xY+(0- y)2

(12b)From the direction of Heand HD , we can calculate the

position of current carrying wire (x(C, D), y(C, D)).

~cos ( 9'c +~) .x(C, D) = -R ( ) sInqJD

cos qJc - ({JD

~COS(9'D -~) .y(C, D) = R ( ) sln({Jc

cos ({Jc - ({JD

(lIb)From the direction of HB and He, we can calculate the

position of current carrying wire (x(B, C), y(B, C)).

~cos (9'c - ~) .x(B, C) = -R ( ) SIn qJB

COS ({JB - ({Jc

hCOs(9'B +~) .y(B,C)=-R ( ) slnqJc

COS qJB - qJc

(13b)From the direction of HD and HA , we can calculate the

position of current carrying wire (x(D, A), y(D, A)).

~cos ( 9'A - ~) •

xeD, A) = R ( ) sm e.,cos ({JD - ({JA

~COS(9'D +~) .y(D,A)=-R ( ) Sln({JA

COS ({JD - ({JA

(IOd)From the direction of HA and HB , we can calculate the

position of current carrying wire (x(A, B), y(A, B)).

~COs(9'A +~J .x(A, B) = -R ( ) sInqJB

cos qJA - qJB

~COS(9'B -~) .yeA, B) = R ( ) sIn({JA

cos qJA - ({JB

4088

Authorized licensed use limited to: UNIVERSITY OF ALBERTA. Downloaded on August 16,2010 at 16:43:31 UTC from IEEE Xplore. Restrictions apply.

0.2 ,------------------------,

O. 1 f-----~ 1!-----~-----__:_:-----I~

~

e~

'"'">~ -0 .1

'"'"- 0. 2 f--- - - - - - - - - - - - - - - - -----'- --j

- 0.3 L- -----'

Angl e [deg]

Fig. 2. Relativ e error of current measurement,when the wire rotates around the measurement hole . Radius of the

measurement hole 10 mm, radius of the sensor circle 25.4 mm.

IV. CONCLUSIONS

An innovative contactless current measurement method

4089

has been presented. It is based on current carrying wireposition estimation. Experimental results show that themaximum relative error of wire position estimation methoddue to non-concentric wire is much lower than that of directsummation method.

R EFERENCES

[I] ] 1. 1. Yao, J. Wang , 1. H. Wang , Y. S. Geng , " Investigation on the theoryof interference rejection for current measurement with magnetic sensorarrays" , Proceedings ofthe CSEE, vol. 24, no. 12, pp. 160-164 ,2004.

[2] 1. Wang , Y. S. Geng, 1. 1. Yao, 1. H. Wang , " Investigation on the signalprocessing algorithms applied in the multi-sensor system measuringelectric current", Proceedings of the CSEE, vol. 25, no. 22, pp. 130-135,2005.

f3] P. Mlejnek, M. Vopalensky, P. Ripka, "AMR current measurementdevice", Sensors and Actuators A, vo1.141, pp. 649-653, 2008.

f4] P. Ripka, P. Kaspar, K. Draxler, "Precise DC current sensors " , IEEEInstrumentation and Measurement Corfe rrence, Brussles , Belgium, June4-6 ,1996, pp. 1479-1483.

[5] X. S. Li, J. X. Wang, C. Tang, L. J. Wang , S. C. Wang , "Development ofhigh accuracy magnetic electronic compass", Chinese journal of sensorsand actuators, vol. 19, no. 6, pp. 2441-2444, 2006.

Authorized licensed use limited to: UNIVERSITY OF ALBERTA. Downloaded on August 16,2010 at 16:43:31 UTC from IEEE Xplore. Restrictions apply.

Related Documents