CLASSIFICATION NOTES No. 30.7 DET NORSKE VERITAS Veritasveien 1, NO-1322 Høvik, Norway Tel.: +47 67 57 99 00 Fax: +47 67 57 99 11 FATIGUE ASSESSMENT OF SHIP STRUCTURES JUNE 2010

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

CLASSIFICATION NOTESNo. 30.7

FATIGUE ASSESSMENT OF SHIP STRUCTURESJUNE 2010

DET NORSKE VERITASVeritasveien 1, NO-1322 Hvik, Norway Tel.: +47 67 57 99 00 Fax: +47 67 57 99 11

FOREWORDDET NORSKE VERITAS (DNV) is an autonomous and independent foundation with the objectives of safeguarding life, property and the environment, at sea and onshore. DNV undertakes classification, certification, and other verification and consultancy services relating to quality of ships, offshore units and installations, and onshore industries worldwide, and carries out research in relation to these functions. Classification Notes Classification Notes are publications that give practical information on classification of ships and other objects. Examples of design solutions, calculation methods, specifications of test procedures, as well as acceptable repair methods for some components are given as interpretations of the more general rule requirements. All publications may be downloaded from the Societys Web site http://webshop.dnv.com/global/. The Society reserves the exclusive right to interpret, decide equivalence or make exemptions to this Classification Note.

This edition replaces the October 2008 edition of Classification Note 30.7. Main Changes The following topics have been included or changed: A table of stress reduction factors to be used if principal stress direction is parallel with the weld line, is included. Analysis guidance for bent hopper knuckle type is included. Guidance on post weld treatment for low cycle fatigue is included. The validity of the S-N curve is elaborated. It is states that the curves is also valid for duplex, and austenitic steels.

The electronic pdf version of this document found through http://www.dnv.com is the officially binding version Det Norske Veritas Any comments may be sent by e-mail to [email protected] For subscription orders or information about subscription terms, please use [email protected] Computer Typesetting (Adobe Frame Maker) by Det Norske Veritas

If any person suffers loss or damage which is proved to have been caused by any negligent act or omission of Det Norske Veritas, then Det Norske Veritas shall pay compensation to such person for his proved direct loss or damage. However, the compensation shall not exceed an amount equal to ten times the fee charged for the service in question, provided that the maximum compensation shall never exceed USD 2 million. In this provision "Det Norske Veritas" shall mean the Foundation Det Norske Veritas as well as all its subsidiaries, directors, officers, employees, agents and any other acting on behalf of Det Norske Veritas.

Classification Notes - No. 30.7, June 2010 Page 3

CONTENTS1. 1.1 1.2 1.3 1.4 1.5 1.6 2. 2.1 2.2 2.3 2.4 2.5 2.6 3. 3.1 3.2 3.3 3.4 3.5 3.6 4. 4.1 4.2 4.3 4.4 4.5 4.6 4.7 5. 5.1 5.2 5.3 5.4 5.5 6. 6.1 6.2 6.3 6.4 6.5 7. 7.1 7.2 7.3 7.4 8. 8.1 8.2 8.3 8.4 9. 9.1 9.2 9.3 9.4 9.5 9.6 9.7 GENERAL................................................................. 5 Introduction..................................................................5 Validity of Classification Note ...................................5 Methods for fatigue analysis........................................5 Guidance to when a detailed fatigue analysis can be omitted .........................................................................6 Definitions ...................................................................6 Symbols and abbreviations ..........................................7 ANALYSIS OF FATIGUE CAPACITY ............... 9 Introduction..................................................................9 Fatigue damage accumulation .....................................9 Fatigue analysis methodology and calculation of stresses ......................................................................10 S-N curves .................................................................11 Effect of corrosive environment ................................13 Fatigue damage from multiple loading conditions ....13 FATIGUE ANALYSIS OF SHIPS........................ 14 General.......................................................................14 Oil tankers..................................................................14 Gas carriers ................................................................14 Bulk carriers...............................................................15 Container Ships .........................................................16 Roll on / Roll off- and Car carriers............................17 SIMPLIFIED FATIGUE CALCULATIONS ...... 17 General.......................................................................17 Calculation procedure................................................17 Long term distribution of stresses .............................17 Definition of stress components ................................18 Calculation of stress components ..............................18 Combination of stresses.............................................18 Cumulative damage ...................................................19 SIMPLIFIED STRESS ANALYSIS ..................... 20 General.......................................................................20 Hull girder bending....................................................20 Bending of girder systems .........................................20 Local stiffener bending ..............................................20 Local plate bending....................................................22 SIMPLIFIED WAVE LOAD CALCULATIONS .................................................. 22 General.......................................................................22 Wave induced hull girder bending moments .............23 External pressure loads ..............................................23 Internal pressure loads due to ship motions...............24 Ship accelerations and motions .................................25 SPECTRAL FATIGUE CALCULATIONS......... 26 General.......................................................................26 Cumulative damage ...................................................26 Component stochastic analysis ..................................27 Full stochastic analysis ..............................................28 WAVE LOADING BY DIRECT CALCULATIONS .................................................. 29 General ......................................................................29 Hydrodynamic modelling ..........................................29 Transfer functions......................................................29 The long-term distribution ........................................29 FINITE ELEMENT ANALYSIS .......................... 31 Finite element models................................................31 Load cases..................................................................32 Global hull analysis ...................................................33 Cargo hold analysis....................................................33 Frame and girder models ...........................................35 Local structure models...............................................35 Stress concentration models ......................................36 10. 10.1 10.2 10.3 10.4 10.5 10.6 10.7 10.8 10.9 11. 11.1 11.2 11.3 11.4 12. CALCULATION OF HOT SPOT STRESS BY FINITE ELEMENT ANALYSIS .......................... 36 Stress field at a welded detail .................................... 36 FE modelling ............................................................. 37 Derivation of hot spot stress...................................... 37 Derivation of stress at read out points 0.5t and 1.5t .. 38 Hot spot S-N curve .................................................... 38 Derivation of effective hot spot stress from FE analysis ...................................................................... 42 Procedure for analysis of web stiffened cruciform connections ............................................................... 42 Hot spot stress concept for simple connections ........ 44 Verification of analysis methodology ....................... 44 IMPROVEMENT OF FATIGUE LIFE BY FABRICATION ............................................... 45 General ...................................................................... 45 Weld toe grinding...................................................... 45 TIG dressing .............................................................. 45 Hammer peening ....................................................... 45 REFERENCES ....................................................... 46

APPENDIX A STRESS CONCENTRATION FACTORS ..................... 47 APPENDIX B FATIGUE DESIGN TABLES .......................................... 72 APPENDIX C EXAMPLE OF APPLICATION - SIMPLIFIED CALCULATION METHOD ............................................ 75 APPENDIX D SIMPLIFIED LOADS FOR DIRECT STRENGTH ANALYSIS ......................................................................... 88 APPENDIX E SIMPLIFIED CALCULATION OF THE COMBINED LONGITUDINAL STRESS IN SHIPS WITH LARGE HATCH OPENINGS......................................................... 89 APPENDIX F WORKMANSHIP AND LINK TO ANALYSIS PROCEDURES.................................................................. 92 APPENDIX G S-N CURVE FATIGUE DAMAGE EXPRESSIONS .... 94 APPENDIX H UNCERTAINTIES IN FATIGUE LIFE PREDICTIONS ................................................................. 95 APPENDIX I LOW CYCLE FATIGUE ................................................. 97 APPENDIX J WAVE INDUCED HULL GIRDER VIBRATIONS .. 107 APPENDIX K DERIVATION OF EFFECTIVE HOT SPOT STRESS ........................................................................... 108

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 4

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 5

1. General1.1 Introduction1.1.1 Fatigue cracks and fatigue damages have been known to ship designers for several decades. Initially the obvious remedy was to improve detail design. With the introduction of higher tensile steels (HTS-steels) in hull structures, at first in deck and bottom to increase hull girder strength, and later on in local structures, the fatigue problem became more imminent. 1.1.2 In the DNV Rules for Classification of Ships, the material factor f1, which gives the ratio of increase in allowable stresses as a function of the material yield point was initially introduced in 1966. The factor is varying with the yield point at a lower than linear rate in order to give some (but insufficient) contribution to the general safety against fatigue fracture of higher tensile steels. However, during recent years a growing number of fatigue crack incidents in local tank structures made from HTS steels have demonstrated that a more direct control of fatigue is needed. 1.1.3 This Classification Note is intended to give a general background for the rule requirements for fatigue control of ship structures, and to provide detailed recommendations for such control. The aim of the fatigue control is to ensure that all parts of the hull structure subjected to fatigue (dynamic) loading have adequate fatigue life. Calculated fatigue lives, calibrated with the relevant fatigue damage data, may give the basis for the structural design (steel selection, scantlings and local details). Furthermore, they can form the basis for efficient inspection programs during fabrication and throughout the servicelife of the structure. 1.1.4 To ensure that the structure will fulfil its intended function, fatigue assessment, supported where appropriate by a detailed fatigue analysis, should be carried out for each individual type of structural detail subjected to extensive dynamic loading. It should be noted that every welded joint and attachment or other form of stress concentration is potentially a source of fatigue cracking and should be individually considered.

Guidance on how to take into account the effect on fatigue strength by low cycle fatigue (repeated yielding), e.g. as occurring during the cargo ballast loading cycles is presented in Appendix I Low cycle fatigue. This Classification Note may be adapted for modification to existing ship structures, subject to the limitations imposed by the original material and fabrication techniques. This Classification Note is valid for C-Mn steels, duplex and super duplex steels and austenitic steels with yield stress less than 500 MPa.

1.3 Methods for fatigue analysis1.3.1 Fatigue design may be carried out by methods based on fatigue tests (S-N data) and estimation of cumulative damage (Palmgren - Miners rule). 1.3.2 The long term stress range distribution is a fundamental requirement for fatigue analysis. This may be determined in various ways. This Classification Note outlines two methods for stress range calculation: 1) A postulated form of the long-term stress range distribution with a stress range based on dynamic loading as specified in the rules. 2) Spectral method for the estimation of long-term stress range. In the first method a Weibull distribution is assumed for the long term stress ranges, leading to a simple formula for calculation of fatigue damage. The load effects can be derived directly from the ship rules. The nominal stresses have to be multiplied by relevant stress concentration factors for calculation of local hotspot stresses before entering the S-N curve. The second method implies that the long-term stress range distribution is calculated from a given (or assumed) wave climate. This can be combined with different levels of refinement of structural analysis. Thus a fatigue analysis can be performed based on simplified analytical expressions for fatigue lives or on a more refined analysis where the loading and the load effects are calculated by numerical analysis. The fatigue analysis may also be performed based on a combination of simplified and refined techniques as indicated by the diagonal arrows in Figure 1-3. 1.3.3 The requirement to analysis refinement should be agreed upon based on experience with similar methods on existing ships and structural details with respect to fatigue consequences of a fatigue damage in terms of service problems and possible repairs. In general, the simplified method for fatigue life calculation is assumed to give a good indication as to whether fatigue is a significant criterion for design or not. The reliability of the calculated fatigue lives is, however, assumed to be improved by refinement in the design analysis. 1.3.4 It should further be kept in mind that real fatigue lives are a function of workmanship related to fabrication and corrosion protection. Therefore, to achieve the necessary link between the calculated and the actual fatigue lives for ships, the fabrication has to be performed according to good shipbuilding practice with acceptance criteria as assumed in the calculation.

1.2 Validity of Classification Note1.2.1 This Classification Note includes procedures for evaluation of fatigue strength, but not limited to, for the following: steel ship structures excluding high speed light crafts foundations welded to hull structures any other areas designated primary structures on the drawings of ship structures attachment by welding to primary ship structures, such as double plates, etc. The procedures do not include provisions for taking directly into account effect on the fatigue strength by wave induced hull vibrations. Guidance on how to take into account the fatigue effect of wave induced vibrations for full body vessels under North Atlantic and world wide wave conditions based on full scale measurements is however presented in Appendix J Wave induced hull girder vibrations. The same fatigue effect by wave induced vibrations is suggested to be considered also for other ships types, in lieu of relevant available data. The additional fatigue effect of wave induced vibrations on specific routes of operation may be predicted based on weather data for the route, as available.

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 6

1.4 Guidance to when a detailed fatigue analysis can be omitted1.4.1 A detailed fatigue analysis can be omitted if the largest hot spot stress range for actual details in air or cathodic protected environment is less than the fatigue limit at 107 cycles. The use of the fatigue limit is illustrated in Figure 1-1. A detailed fatigue assessment can be omitted if the largest stress cycle is below the fatigue limit. However, in the example in Figure 1-2, there is one stress cycle 1 above the fatigue limit. This means that a further fatigue assessment is required. This also means that the fatigue damage from the stress cycle 2 has to be included in the fatigue assessment and the summation of fatigue damage presented in this document should be used.S

1 Fatigue limit

Stress cycling

N

Figure 1-1 Stress cycling where further fatigue assessment can be omitted

S 1 2 Fatigue limit Stress cycling

N

Figure 1-2 Stress cycling where a detailed fatigue assessment is required

1.5 Definitions1.5.1 Classified structural detail: A structural detail containing a structural discontinuity including a weld or welds, for which the nominal stress approach is applicable, and which appear in tables of many fatigue design standards such as CSR for Tanker Structures and DNV-RP-C203, also referred to as a standard structural detail. Each classified detail is defined to belong to one S-N curve. This means that the K-factor for this detail is included in the S-N curve. Constant amplitude loading: A type of loading causing a regular stress fluctuation with constant magnitudes of stress maxima and minima. Crack propagation rate: Amount of crack propagation during one stress cycle. Crack propagation threshold: Limiting value of stress intensity factor range below which the stress cycles are considered to be non-damaging. Eccentricity: Misalignment of plates at welded connections measured transverse to the plates. Effective notch stress: Notch stress calculated for a notch with a certain effective notch radius. Fatigue: Deterioration of a component caused by crack initiation and/or by the growth of cracks.

Fatigue action: Load effect causing fatigue. Fatigue damage ratio: Ratio of fatigue damage at considered number of cycles and the corresponding fatigue life at constant amplitude loading. Fatigue life: Number of stress cycles at a particular stress range magnitude required to cause fatigue failure of the component. Fatigue limit: Fatigue strength under constant amplitude loading corresponding to a high number of cycles large enough to be considered as infinite by a design code. Fatigue resistance: Structural details resistance against fatigue actions in terms of S-N curve or crack propagation properties. Fatigue strength: Magnitude of stress range leading to particular fatigue life. Fracture mechanics: A branch of mechanics dealing with the behaviour and strength of components containing cracks. Geometric stress: See hot spot stress. Hot spot: A point in structure where a fatigue crack may initiate due to the combined effect of structural stress fluctuation and the weld geometry or a similar notch. Hot spot stress: The value of structural stress on the surface at the hot spot (also known as geometric stress or structural stress). Local nominal stress: Nominal stress including macro-geometric effects, concentrated load effects and misalignments, disregarding the stress raising effects of the welded joint itself. Local notch: A notch such as the local geometry of the weld toe, including the toe radius and the angle between the base plate surface and weld reinforcement. The local notch does not alter the structural stress but generates non-linear stress peaks. Macro-geometric discontinuity: A global discontinuity, the effect of which is usually not taken into account in the collection of standard structural details, such as large opening, a curved part in a beam, a bend in flange not supported by diaphragms or stiffeners, discontinuities in pressure containing shells, eccentricity in lap joints. Macro-geometric effect: A stress raising effect due to macrogeometry in the vicinity of the welded joint, but not due to the welded joint itself. Membrane stress: Average normal stress across the thickness of a plate or shell. Miner sum: Summation of individual fatigue damage ratios caused by each stress cycle or stress range block according to Palmgren-Miner rule. Misalignment: Axial and angular misalignments caused either by detail design or by fabrication. Nominal stress: A stress in a component, resolved, using general theories such as beam theory. Nonlinear stress peak: The stress component of a notch stress which exceeds the linearly distributed structural stress at a local notch. Notch stress: Total stress at the root of a notch taking into account the stress concentration caused by the local notch. Thus the notch stress consists of the sum of structural stress and nonlinear stress peak. Notch stress concentration factor: The ratio of notch stress to structural stress. Paris law: An experimentally determined relation between crack growth rate and stress intensity factor range (Fracture mechanics). Palmgren-Miner rule: Fatigue failure is expected when the Miner sum reaches unity. Rainflow counting: A standardised procedure for stress range counting.

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 7

Shell bending stress: Bending stress in a shell or plate like part of a component, linearly distributed across the thickness as assumed in the theory of shells. S-N curve: Graphical presentation of the dependence of fatigue life (N) on fatigue strength (S). Stress cycle: A part of a stress history containing a stress maximum and a stress minimum. Stress intensity factor: Factor used in fracture mechanics to characterise the stress at the vicinity of a crack tip. Stress range: The difference between stress maximum and stress minimum in a stress cycle. Stress range block: A part of a total spectrum of stress ranges which is discreet in a certain number of blocks. Stress range exceedance: A tabular or graphical presentation of the cumulative frequency of stress range exceedance, i.e. the number of ranges exceeding a particular magnitude of stress range in stress history. Here frequency is the number of occurrences. Stress ratio: Ratio of minimum to maximum value of the stress in a cycle. Structural discontinuity: A geometric discontinuity due to the type of welded joint, usually found in tables of classified structural details. The effects of a structural discontinuity are (i) concentration of the membrane stress and (ii) formation of secondary bending stress. Structural stress: A stress in a component, resolved taking into account the effects of a structural discontinuity, and consisting of membrane and shell bending stress components. Also referred to as geometric stress or hot spot stress. Structural stress concentration factor: The ratio of hot spot (structural) stress to local nominal stress. In this classification note the shorter notation: Stress concentration factor due to geometry (Kg) is used. Variable amplitude loading: A type of loading causing irregular stress fluctuation with stress ranges (and amplitudes) of variable magnitude.

L Lpp M Mwo MH Q ()

S ( )S ( )Td Tact T Tz Z

Rule length of ship in m, confer DNV Rules for Ships Pt.3 Ch.1 Sec.1. Length between perpendiculars Moment Wave induced vertical moment Wave induced horizontal moment Probability level for exceedance of stress range Wave spectrum Stress response spectrum Design life Draught actual vessel mean moulded summer draught Zero crossing period Section modulus S-N fatigue parameter Local / global load combination factor Local / global load combination factor Flange width Acceleration in direction I Material factor as specified in the Rules Pt.3 Ch.1 Sec.1 Environmental reduction factor Mean stress reduction factor Factor for calculation of load effects at 10-4 probability level Acceleration of gravity (=9.81 m/s2) Weibull shape parameter Basic Weibull shape parameter Web height Stiffener length 10th logarithm Natural logarithm S-N fatigue parameter Spectral moment of order n Lateral pressure Occurrence probability of sea condition i and heading j Sailing rate = fraction of design life at sea Weibull scale parameter Stiffener spacing Plate thickness Plate thickness Flange thickness Web thickness Net plate thickness Deformation Zero crossing frequency in short-term condition i, j Wave frequency Long-term average zero up-crossing frequency Correlation coefficient Stress amplitude Secondary stress amplitude Tertiary stress amplitude produced by bending of plate elements between longitudinal and transverse frames/ stiffeners Nominal stress amplitude, e.g. stress derived from beam element or finite element analysis Fatigue usage factor Moulded displacement in tonnes in salt water (density 1.025 [t/m3] on draught T Stress range

aa b bf ai f1 fe fm fr g h ho hw l log( ) ln( ) m mn p pij ps q s t tp tf tw tn d vij

1.6 Symbols and abbreviations1.6.1 The following general symbols are used in this Classification Note:A B CB Cw D D F() H() Hs I K Kg Kn Kte Kt Kw Cross sectional area Greatest moulded breadth of ship measured at the summer waterline Block coefficient = 1.025LBTRULE Wave coefficient as given in DNV Rules for Ships Pt.3 Ch.1. Moulded depth of ship, confer DNV Rules for Ships Pt.3 Ch.1 Sec.1 Fatigue damage Weibull distribution Transfer function Significant wave height Moment of inertia Stress concentration factor Geometric stress concentration factor Un-symmetrical stiffeners with lateral loading stress concentration factor Eccentric tolerance stress concentration factor (normally plate connections) Angular mismatch stress concentration factor (normally plate connections) Weld geometry stress concentration factor

vo

2 3 nominal

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 8

( )

g l h v

Global stress range Local stress range Nominal stress range due to horizontal bending Nominal stress range due to vertical bending Gamma function [-]

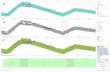

Simplified AnalysisRule Loads Ch. 6 Long Term Load Distribution

Direct AnalysisLoad Transfer Functions Sec. 8.3

Stress Components

Ch. 5

Interchangeable Results

FE Model of Ship Sec. 9.3-9.4

SCF: K-factors App. A

Interchangeable Results

FE Model of detail Sec. 9.5-9.6

Combination of Stresses Sec. 4.6

Local Stress TransferFunctions for stress components Sec. 7.3

Long Term Stress Distribution Sec. 4.3

Stress Component based Stochastic Fatigue Analysis

Full Stochastic Fatigue Analysis Sec. 7.4

Sec. 7.3

Equivalent Long Term Stress Distribution (Weibull param.) Sec. 5.2

Calculation of hotspot stress Ch. 10

Fatigue Damage Calculation Sec. 4.7

Fatigue Damage Calculation App. G

Figure 1-3 Flow diagram over possible fatigue analysis procedures

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 9

2. Analysis of Fatigue Capacity2.1 Introduction2.1.1 The main principles for fatigue analysis based on fatigue tests are described in this section. The fatigue analysis may be based on hot spot stress S-N curves for welded plated structures. The hot spot stress at a weld toe is defined as the geometric stress that includes stress rising effects due to structural discontinuities and presence of attachments, but excluding the localised stress due to the presence of the weld itself. Guidance on finite element modelling and hot spot stress derivation is presented in Section 6. The calculated hot spot stress is then entered a hot spot stress S-N curve for derivation of cycles to failure. Additional stresses resulting from fabrication tolerances for butt welds and cruciform joints should be considered when the fabrication tolerances exceed that inherent the S-N data. Reference is made to section for stress concentration factors in Appendix A. Results from performed fatigue analyses are presented in Appendix B in terms of allowable stress ranges as function of the Weibull shape parameter. The basis for the allowable stress ranges is that long term stress ranges can be described by a two parameter Weibull distribution. The following fatigue cracking failure modes are considered in this document (see also Figure 2-1): Fatigue crack growth from the weld toe into the base material In welded structures fatigue cracking from weld toes into the base material is a frequent failure mode. The fatigue crack is initiated at small defects or undercuts at the weld toe where the stress is highest due to the weld notch geometry. A large amount of the content in this classification note is made with the purpose of achieving a reliable design with respect to this failure mode. Fatigue crack growth from the weld root through the fillet weld Fatigue cracking from root of fillet welds with crack growth through the weld is a failure mode that can lead to significant consequences. Use of fillet welds should be avoided in connections where the failure consequences are large due to less reliable NDE of this type of connection compared with a full penetration weld. However, in many welded connections use of fillet welds can hardly be avoided and it is also efficient for fabrication. The specified design procedure in this document is considered to provide reliable connections also for fillet welds. Fatigue crack growth from the weld root into the section under the weld Fatigue crack growth from the weld root into the section under the weld is observed during service life of structures and is also observed in laboratory fatigue testing. The number of cycles until failure for this failure mode is of similar magnitude as fatigue cracking from the weld toe. There is no methodology recommended used to avoid this failure mode except from using alternative types of welds locally. This means that if fatigue life improvement of the weld toe is required the connection will become more highly utilised and it is also required to make improvement for the root. This can be performed using full penetration weld along some distance of the stiffener nose. Fatigue crack growth from a surface irregularity or notch into the base material Fatigue cracking in the base material is a failure mode that is of concern in components with high stress cycles. Then the fatigue cracks often initiate from notches or grooves in the components or from small surface defects/irregulari-

ties. The specified design procedure in this document is considered to provide reliable connections also with respect to this failure mode.

a)

Fatigue crack growth from the weld toe into the base material

b)

Fatigue crack growth from the weld root through the fillet weld

c)

Fatigue crack growth from the weld root into the section under the weld

d)

Figure 2-1 Explanation of different fatigue failure modes

Fatigue crack growth from a surface irregularity or notch into the base material

2.2 Fatigue damage accumulation2.2.1 The fatigue life under varying loading is calculated based on the S-N fatigue approach under the assumption of linear cumulative damage (Palmgren-Miners rule). The total damage the structure is experiencing may be expressed as the accumulated damage from each load cycle at different stress levels, independent of the sequence in which the stress cycles occur. The design life assumed in the fatigue assessment of ships is normally not to be taken less than 20 years. The accumulated fatigue damage is not to exceed a usage factor of 1.0. The acceptance criterion is related to design S-N curves based on mean- minus-two-standard-deviations curves for relevant experimental data. 2.2.2 When the long-term stress range distribution is expressed by a stress histogram, consisting of a convenient number of constant amplitude stress range blocks i each with a number of

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 10

stress repetitions ni the fatigue criterion reads

D=whereD k ni Ni

i =1

k

ni 1 = Ni a

ni =1

k

i

( i )m

the hole. The maximum principal stress range within 45 of the normal to the weld toe should be used for the analysis.

a ,m

= = = = = =

accumulated fatigue damage S-N fatigue parameters number of stress blocks number of stress cycles in stress block i number of cycles to failure at constant stress range i usage factor. Accepted usage factor is defined as = 1.0

Applying a histogram to express the stress distribution, the number of stress blocks, k, is to be large enough to ensure reasonable numerical accuracy, and should not be less than 20. Due consideration should be given to selection of integration method as the position of the integration points may have a significant influence on the calculated fatigue life dependent on integration method.

Figure 2-2 Explanation of local hot spot stresses

2.2.3 Expressions for fatigue damage based on long term stress distributions defined through Weibull distributions and short term Rayleigh distribution within each sea state are given in Appendix C.

2.3 Fatigue analysis methodology and calculation of stresses2.3.1 The procedure for fatigue analysis is based on the assumption that it is only necessary to consider the ranges of cyclic stresses in determining the fatigue endurance. However, some reduction in the fatigue damage accumulation can be credited when parts of the stress cycle range are in compression. It should be noted that in welded joints, there may be several locations at which fatigue cracks can develop, e.g. at the weld toe in each of the two parts joined, at the weld ends, and in the weld itself. Each potential location should be considered separately. 2.3.2 When the potential fatigue crack is located in the parent material at the weld toe, the relevant local hot spot stress is the range of maximum principal stress adjacent to the potential crack location with stress concentrations being taken into account. This stress concentration is due to the gross shape of the structure. As an example, for the welded connection shown in Figure 2-2a), the relevant local hot spot stress for fatigue design would be the tensile stress, . For the weld shown in Figure 22b), the stress concentration factor for the local geometry must in addition be accounted for, giving the relevant hot spot stress equal to Kg, where Kg is the stress concentration factor due to

2.3.3 The maximum principal stress is considered a significant parameter for analysis of fatigue crack growth. When the principal stress direction is different from that of the normal to the weld toe, it becomes conservative to use the principle stress range together with a classification of the connection for stress range normal to the weld toe as shown in Figure 2-3. As the angle between the principal stress direction and the normal to the weld, , is increased further, fatigue cracking may no longer initiate along the weld toe, but may initiate in the weld and grow normal to the principal stress direction as shown in Figure 2-4. This means that the notch at the weld toe does no longer significantly influence the fatigue capacity and a higher allowable hot spot stress applies for this stress direction. More guidance on this effect of stress direction relative to the weld toe as shown in Figures 2-3 and 2-4 when using finite element analysis and hot spot stress S-N curves is presented in Appendix K. // //

Principal stress direction Weld toe

Fatigue crack

Section

Figure 2-3 Fatigue cracking along weld toe

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 11

//

//

Principal stress direction

Weld toe

stress range for fatigue analysis can therefore be reduced due to the mean stress effect also for regions affected by residual stresses from welding. The following reduction factor on the derived stress range may be applied for welded joints:

fm =Fatigue crack

t + 0.7 c t + c

2.4 S-N curvesSection

Figure 2-4 Fatigue cracking when principal stress direction more parallel with weld toe

2.4.1 The fatigue design is based on use of S-N curves which are obtained from fatigue tests. The design S-N curves which follow are based on the mean-minus-two-standard-deviation curves for relevant experimental data. The S-N curves are thus associated with a 97.6% probability of survival. 2.4.2 The S-N curves are applicable for normal and high strength steels used in construction of hull structures.

2.3.4 For fatigue analysis of regions in the base material not significantly affected by residual stress due to welding, the stress range may be reduced dependent on whether the cycling stress is tension or compression. Mean stress means the static hot spot stress including relevant stress concentration factors. The calculated stress range may be multiplied with the reduction factor fm before entering the S-N curve, see also Figure 2-5:

The S-N curves for welded joints include the effect of the local weld notch. They are also defined as hot spot S-N curves. Thus these S-N curves are compatible with calculated stress that does not include the notch stress due to the weld. This also means that if a butt weld is machined or grind flush without weld overfill a better S-N curve can be used. Reference is e. g. made to DNV-RP-C203.2.4.3 The basic design S-N curve is given as

fm =wheret= tension stress

t + 0.6 c t + c

log N = log a m log + max static 2 0 with S-N curve parameters given in Table 2-1 and Table 2.2.N = predicted number of cycles to failure for stress range

=

c

=

compression stress

m

= stress range = negative inverse slope of S-N curve = intercept of log N-axis by S-N curve

=

min static 2 0

log a

log a = log a 2swherea s = = = is constant relating to mean S-N curve standard deviation of log N; 0.20

For variable amplitude stresses can be taken as the stress range at 10-4 probability level of exceedance.Reduction factor fm 1.0 0.6 Compression - m = /2 m = 0 m = /2 Tension

Table 2-1 S-N parameters for air or with cathodic protection

S-N Curve

Material

N 107 m log a3.0 4.0

N > 107 m log a15.606 5.0 17.146 5.0

Figure 2-5 Stress range reduction factor that may be used with S-N curve for base material

I III

Welded joint 12.164 Base Material 15.117

For unprotected joints in sea water the S-N curve I presented in Table 2-1 shall be reduced by a factor of 2 on fatigue life.Table 2-2 S-N parameters base material for corrosive environment

2.3.5 Residual stresses due to welding and construction are reduced over time as the ship is subjected to external loading. If it is likely that a hot spot region is subjected to a tension force implying local yielding at the considered region, the effective

S-N CurveIV

MaterialBase material

log a12.436

m3.0

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 12

2.4.4 Most of the S-N data are derived by fatigue testing of small specimens in test laboratories. For simple test specimens the testing is performed until the specimens have failed. In these specimens there is no possibility for redistribution of stresses during crack growth. This means that most of the fatigue life is associated with growth of a small crack that grows faster as the crack size increases until fracture.

Table 2-3 Stress reduction factor KP Stress reduction factor KP 0.72 Figure Description Requirement

The initiation of a fatigue crack takes longer time for a notch in base material than at a weld toe or weld root. This also means that with a higher fatigue resistance of the base material as compared with welded details, the crack growth will be faster in base material when fatigue cracks are growing. For practical purpose one defines the failures in test data as being crack growth though the thickness. When this failure criterion is transferred into a crack size in a real structure where some redistribution of stress is more likely, this means that this failure criterion corresponds to a crack size that is somewhat less than the plate thickness.2.4.5 The fatigue strength of welded joints is to some extent dependent on plate thickness and on the stress gradient over the thickness. Thus for a thickness larger than 25 mm, the S-N curve in air reads0.80

1. Automatic welds carried out from both sides.

1. No startstop position is permitted except when the repair is performed by a specialist and inspection carried out to verify the proper execution of the repair.

log N = log a

m t log m log 4 25

2. Automatic fillet or butt welds carried out from both sides but containing stopstart positions. 3. Automatic butt welds made from one side only, with a backing bar, but without start-stop positions. 3. When the detail contains start-stop positions use Kp = 0.90

where t is thickness (mm) through which the potential fatigue crack will grow. This S-N curve in general applies to all types of welds except butt-welds with the weld surface dressed flush and small local bending stress across the plate thickness. The thickness effect is less for butt welds that are dressed flush by grinding or machining. Also a less severe S-N curve can be used if the weld notch is removed by machining. Reference is made to DNV-RP-C203 if needed.2.4.6 The S-N curves given in Table 2.1-2 are developed for principal stresses acting normal to the weld and should be used together with the maximum stress range within 45 of the normal to the weld as explained in 2.3.2.0.90

4. Manual fillet or butt welds. 5. Manual or automatic butt welds carried out from one side only, particularly for box girders

If the governing stress direction is parallel with the weld direction a stress reduction factor KP should be used on the principal stress range before entering stress into the SN curve. The stress reduction factor will depend on the quality of the weld, Table 2-3. Alternatively the procedure of effective hot spot stress described in 2.3.3 and Appendix K may be used.1000 I III IV Stress range (MPa)

100

5. A very good fit between the flange and web plates is essential. Prepare the 6. Repaired au- web edge such that the tomatic or manual fillet or root face is adequate for butt welds the achievement of regular root penetration with out brake-out. 6. Improvement methods that are adequately verified may restore the original category.

10 10000

100000

1000000

10000000

100000000

1000000000

Number of cycles

Figure 2-6 S-N curves

2.4.7 For Duplex and Super Suplex steel one may use the same S-N curve as for C-Mn steels. Also for austenitic steel one may use the same S-N curve as for C-MN steels.

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 13

2.5 Effect of corrosive environment2.5.1 It is recognised that the fatigue life of steel structures is considerably shorter in freely corroding condition submerged in sea water than in air, i.e. in dry indoor atmosphere such as common laboratory air. For steel submerged in sea water and fully cathodically protected, approximately the same fatigue life as in dry air is obtained. An intact coating system will also protect the steel surface from the corrosive environment, so that the steel can be considered to be as in dry air condition. The basic S-N curve for welded regions in air is only to be applied for joints situated in dry spaces, for joints in cargo oil tanks or joints in ballast tanks effectively protected against corrosion. For joints efficiently protected only a part of the design life and exposed to corrosive environment the remaining part, the fatigue damage may be calculated as a sum of partial damages according to 2.5.2. For joints in freely corroding conditions submerged in sea water the basic S-N curve for welded joints in air are to be reduced by a factor 2 on fatigue life. 2.5.2 For coated ballast tanks the fatigue strength may be assessed with the S-N curve in air for the effective corrosion protection period. The effective corrosion protection period is taken to be the specified design life of the vessel minus five years (TD-5). Corrosive environment is to be used for the remaining five years of the specified design life. For uncoated cargo oil tanks and coated cargo oil tanks, S-N curves in air may be used for the specified design life. For dry cargo holds, fuel oil tanks, void spaces, cofferdam, and hull external surfaces, the S-N curve in air may normally be used for the specified design life. 2.5.3 Global stress components may be calculated based on gross scantlings. Local stress components should be calculated based on reduced scantlings, i.e. gross scantlings minus corrosion addition tk as given in Table 2-3. (The corrosion addition specified below is similar to that specified in the Rules [1]).Table 2-4 Corrosion addition tk in mm Location Within 1.5 m Elsewhere below weather deck tank or hold top Ballast tank1) 3.0 1.5 Cargo oil tank only 2.0 1.0 (0)2) Hold of dry bulk cargo carriers 4) 1.0 1.0 (3)5) Plate boundary between given Within 1.5 m Elsewhere space categories below weather deck tank or hold top Ballast tank 1) / Cargo oil tank only 2.5 1.5 (1.0) 2) Ballast tank 1) / Hold of dry bulk 2.0 1.5 cargo carrier 4) Tank/hold region Internal members and plate boundary between spaces of the given category

Ballast tank 1) / Other category 2.0 1.0 space 3) Cargo oil tank only / Other catego1.0 0.5 (0) 2) ry space 3) Hold of dry bulk carrier 4) / Other 0.5 0.5 category space 3) 1) The term ballast tank includes also combined ballast and cargo oil tanks, but not cargo oil tanks which may carry water ballast according to Regulation 13 (3), of MARPOL 73/78, see Rules 2) The figure in bracket refers to non-horizontal surfaces. 3) Other category space denotes the hull exterior and all spaces other than water ballast and cargo oil tanks and holds of dry bulk cargo carriers. 4) Hold of dry bulk cargo carriers refers to the cargo holds of vessels with class notations Bulk Carrier and Ore Carrier 5) The figure in bracket refers to lower part of main frames in bulk carrier holds.

2.6 Fatigue damage from multiple loading conditions2.6.1 Depending on the required accuracy of the fatigue evaluation it may be necessary to divide the design life into a number of time intervals due to different loading conditions and limitations of the corrosion protection. For example, the design life may be divided into one interval with good corrosion protection and one interval where the corrosion protection is more questionable for which different S-N data should be used. Each of these intervals should be divided into that of loaded and ballast conditions. 2.6.2 The combined fatigue damage, D, and the corresponding fatigue life, T, in multiple loading conditions and non-corrosive and corrosive environment can be calculated as follows:

1) Calculate the fatigue damage for non-corrosive environment equal to the design life, Tdesign, of the vessel, DInAir:

D InAir = p i D InAir,ii =1

n

where i = loading condition no. i = 1 to n pi = fraction of the lifetime operating under loading condition i 2) Calculate the fatigue damage for corrosive environment equal to the design life, Tdesign, of the vessel, DCorrosive:

DCorrosive = pi DCorrosive,i = 2 pi DAir , ii =1 i =1

n

n

3) The combined fatigue damage for the design life of the vessel is calculated as:

D = DInAir

Tdesign 5 Tdesign

+ DCorrosive

5 Tdesign

The corresponding fatigue life is calculated as:Tdesign DInAir

T=

if DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 14

tions, pn, may be taken from Table 3-2.

Tdesign DInAirelse

(Tdesign 5)

T D T = Tdesign 5 + design Tdesign + 5 InAir D D InAir Corrosive

where Tdesign-5 is the effective corrosion protection period.

3. Fatigue Analysis of Ships3.1 General3.1.1 Fatigue damages are known to occur more frequently for some ship types and categories of hull structure elements. The fatigue life is in particular related to the magnitude of the dynamic stress level, the corrosiveness of the environment and the magnitude of notch- and stress concentration factors of the structural details, which all vary depending on ship type and structure considered. The importance of possible fatigue damage is related to the number of potential damage points of the considered type for the ship or structure in question and to its consequences. 3.1.2 A major fraction of the total number of fatigue damages on ship structures occurs in panel stiffeners on the ship side and bottom and on the tank boundaries of ballast- and cargo tanks. However, the calculated fatigue life depends on the type of stiffeners used, and the detail design of the connection to supporting girder webs and bulkheads. In general un-symmetrical profiles will have a reduced fatigue life compared to symmetrical profiles unless the reduced effectiveness of the un-symmetrical profile is compensated by an improved design for the attachment to transverse girder webs and bulkhead structures. 3.1.3 The dynamic wave loading on the hull varies with the draught and load distribution and it is therefore necessary to consider more than one loading condition in the fatigue evaluation. Depending on the ship type 2-3 loading conditions representing the most frequently used loaded and ballast conditions are normally sufficient. The fraction of the lifetime operating under each loading conditions should reflect the operational trading pattern of the ship.

Table 3-1 Tankers Structure Structural detail member Side-, bot- Butt joints, deck opentom- and ings and attachment to deck plating transverse webs, transand verse bulkheads, hopper longitudiknuckles and intermedinals ate longitudinal girders Transverse Bracket toes, girder girder and flange butt joints, stringer curved girder flanges, structures knuckle of inner bottom and sloped hopper side and other panel knuckles including intersection with transverse girder webs. Single lug slots for panel stiffeners, access and lightening holes Longitudi- Bracket termination's of nal girders abutting transverse of deck and members (girders, stiffbottom eners) structure

Load type Hull girder bending, stiffener lateral pressure load and support deformation

Sea pressure load combined with cargo or ballast pressure load

Hull girder bending, and bending / deformation of longitudinal girder and considered abutting member

Table 3-2 Fraction of time at sea in loaded and in ballast condition Vessel type Tankers Loaded condition 0.425 Ballast condition 0.425

3.3 Gas carriers3.3.1 Structural elements being of possible interest for fatigue evaluation of gas carriers are listed in Table 3.3. For vessels intended for normal, world wide trading the fraction of design life in the fully loaded cargo and ballast conditions, pn, may be taken from Table 3.4.Table 3-3 Gas carriers Structure member Structural detail Side-, bottomButt joints, deck openand deck plating ings and attachment to and longitudinals transverse webs, transverse bulkheads, hopper knuckles and intermediate longitudinal girders Transverse girder Inner hull knuckles inand stringer cluding intersection structures with transverse girder webs. Single lug slots for panel stiffeners, access and lightening holes Longitudinal Inner hull knuckles at girders of deck, intersection with transside and bottom verse BHDs. structure Tank supports Tank supporting structure in general Load type Hull girder bending, stiffener lateral pressure load and support deformation Sea pressure load combined with cargo or ballast pressure load

3.2 Oil tankers3.2.1 Structural elements in oil tankers being of possible interest for fatigue evaluation are listed in Table 3-1. For vessels intended for normal, world wide trading the fraction of design life in the fully loaded cargo and ballast condi-

Hull girder bending, and bending / deformation of longitudinal girder and considered abutting member Hull girder bending, cargo and sea pressure loads

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 15

Table 3-4 Fraction of time at sea in loaded and in ballast condition Vessel type Gas carriers (*) Loaded condition 0.45 Ballast condition 0.40

be taken from Table 3-5.Table 3-5 Fraction of time in different conditions Vessel type Bulk carri- Panamax Vessels in- Ore carrier ers larger bulk carri- tend to than Paners and carry ore amax (*) smaller cargoes (*) mostly Alternate 0.25 0 0.5 0 condition Homogenous 0.25 0.5 0 0.5 condition Ballast 0.35 0.35 0.35 0.35 condition

(*) Fraction of time values should be according to latest version of DNV Ship Rules. Current values for gas carriers refers to DNV Ship Rules, July 2008 issue.

3.4 Bulk carriers3.4.1 Structural elements in the bulk carriers being of possible interest for fatigue evaluation are listed in Table 3-6 and Table 3-7 For vessels intended for normal trading the fraction of the fraction of the design life in loaded and ballast conditions, pn, may

(*) Panamax vessel as defined in Classification Note 31.1 Sec.1.2.1.

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 16

Table 3-6 Bulk Carriers Structure member Structural detail Hatch corners Hatch corner Hatch side coaming Main frames Termination of end bracket End bracket terminations, weld of main frame web to shell for un-symmetrical main frame profiles Connection to transverse webs and bulkheads Connection to transverse webs and bulkheads

Load type Hull girder bending, hull girder torsional deformation Hull girder bending External pressure load, ballast pressure load as applicable

erations need to be considered, see 6.4.1. The appropriate density and pressure height for bulk cargoes should specially be considered to give a hold mass according to Table 3-8. If masses specified in the submitted loading conditions are greater than those in Table 3-8, the maximum masses shall be used for fatigue strength calculations.Table 3-8 Hold mass Ore holds Alternate MHD or MFull accordcondition ing to Pt.5 Ch.2 Sec.5 Homogenous MH according to Rules condition Pt.5 Ch.2 Sec.5 Empty holds Zero MH according to Rules Pt.5 Ch.2 Sec.5

Hull girder bending, sea- and ballast pressure load Hull girder bending stress, double bottom bending stress and sea, cargo- and ballast pressure load Transverse webs Slots for panel stiff- Girder shear force, and of double bottom, ener including stiff- bending moment, suphopper and top ener connection port force from panel wing tank members, knuckle of stiffener due to seainner bottom and ,cargo- and ballast sloped hopper side pressure load including intersection with girder webs (floors). Single lug slots for panel stiffeners, access and lightening holes 1) The fatigue life of bottom and inner bottom longitudinals of bulk carriers is related to the combined effect of axial stress due to hull girder- and double bottom bending, and due to lateral pressure load from sea or cargo. Table 3-7 Ore Carriers Structure member Structural detail Upper deck plating Hatch corners and side coaming terminations Side-, bottom- and Butt joints and attachdeck longitudinals ment to transverse webs, transverse bulkheads, hatch opening corners and intermediate longitudinal girders Transverse girder Bracket toes, girder and stringer struc- flange butt joints, curved tures girder flanges, panel knuckles at intersection with transverse girder webs etc. Single lug slots for panel stiffeners, access and lightening holes Transverse girders Single lug slots for panel of wing tank1) stiffeners 1) Load type Hull girder bending Hull girder bending, stiffener lateral pressure load and support deformation Sea pressure load combined with cargo or ballast pressure load

Longitudinals of hopper tank and top wing tank Double bottom longitudinals1)

3.4.3 The draught for the loaded conditions shall be taken as the scantling draught. The draught for the ballast condition shall be taken as the ballast draught given in the loading manual, or 0.35T if the loading manual is not available (where T is scantling draught). 3.4.4 For bottom and inner bottom longitudinals the effect of relative deflections and double hull bending shall be taken into account at locations where this effect is significant. The relative deformations are to be obtained by a direct strength analysis.

3.5 Container Ships3.5.1 Structural elements in the cargo area being of possible interest for fatigue evaluation of container ships are listed in Table 3-9.Table 3-9 Container carriers Hull Structural detail member Side-and Butt joints and attachment to bottom transverse webs, transverse longitudibulkheads and intermediate nals longitudinal girders Load type

Sea pressure load (in particular in ore loading condition) The transverse deck-, side- and bottom girders of the wing tanks in the ore loading condition are generally subjected to considerable dynamic shear force- and bending moment loads due to large dynamic sea pressure (in rolling) and an increased vertical racking deflection of the transverse bulkheads of the wing tank. The rolling induced sea pressure loads in the ore loading condition will normally exceed the level in the ballast (and a possible oil cargo) condition due to the combined effect of a large GM-value and a small rolling period. The fatigue life evaluation must be considered with respect to the category of the wing tank considered (cargo oil tank, ballast tank or void). For ore-oil carriers, the cargo oil loading condition should be considered as for tankers.

Hull girder bending, torsion1), stiffener lateral pressure load and support deformation Upper deck Plate and stiffener butt joints, Hull girder bendinghatch corner curvatures and and torsional warpsupport details welded on up- ing stress2). per deck for container pedestals etc. 1) Torsion induced warping stresses in the bilge region may be of significance from the forward machinery bulkhead to the forward quarter length. 2) The fatigue assessment of upper deck structures must include the combined effect of vertical and horizontal hull girder bending and the torsional warping response. For hatch corners, additional stresses introduced by the bending of transverse (and longitudinal) deck structures induced by the torsional hull girder deformation must be included in the fatigue assessment. Table 3-10 Fraction of time at sea in loaded and in ballast condition Vessel type Container vessels Loaded conditions 0.65 Ballast conditions 0.20

3.4.2 For bulk and ore cargoes only pressures due to vertical accel-

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 17

3.6 Roll on / Roll off- and Car carriers3.6.1 Structural elements in the cargo area being of possible interest for fatigue evaluation of Roll on/ Roll off- and Car carriers are listed in Table 3-11.Table 3-11 Roll on / Roll off- and Car carriers Structure member Structural detail Load type Side- and bottom Butt joints and atHull girder bending, longitudinals tachment to transstiffener lateral presverse webs, sure load and support transverse bulkheads deformation and intermediate longitudinal girders Racking Stress concentration Transverse acceleraconstraining points at girder sup- tion load1) girders, bulkheads ports and at bulkhead etc. openings 1) It should be noted that the racking constraining girders and bulkheads are in many cases largely unstressed when the ship is in the upright condition. Thus the racking induced stresses may be entirely dynamic, which implies that fatigue is likely to be the primary design criterion. For designs which incorporate racking bulkheads, the racking deformations are normally reduced such that the fatigue assessment may be limited to stress concentration areas at openings of the racking bulkheads only. If sufficient racking bulkheads are not fitted, racking deformations will be greatly increased, and the fatigue assessment of racking induced stresses should be carried out for primary racking constraining members and vertical girder structures over the ship length as applicable.Hydrodynamic loads Simplified calculations Ch. 8

Stress response Simplified calculations: Ch. 5 Finite element analysis Ch. 9

Combination of stress components Sec. 4.6

Long term stress distribution Sec. 4.3

For vessels intended for normal, world wide trading, the fraction of design life in the homogeneous design load and ballast conditions, pn , may be taken from Table 3-12.Table 3-12 Fraction of time at sea in loaded and in ballast condition Vessel type Car carriers Loaded conditions 0.65 Ballast conditions 0.20

Fatigue damage calculation Sec. 4.7

Figure 4-1 Flow diagram for simplified fatigue calculations

4.3 Long term distribution of stresses4.3.1 The long term distribution of stress ranges at local details may be described by the Weibull distribution h Q( ) = exp q

4. Simplified Fatigue Calculations4.1 General4.1.1 This section outlines a simplified approach to determine the distributions of long-term stress ranges expressed as Weibull distributions. Simple formats for combination of global and local stress components are given to calculate the total stress response.

where:Q h q = = = probability of exceedance of the stress range Weibull shape parameter Weibull scale parameter, defined as

4.2 Calculation procedure4.2.1 A flow chart of the calculation procedure is given in Figure 41.

q=

(ln n 0 )1 h

0

The stress range distribution may also be expressed as ln n = 0 ln n 0 1h

whereo = reference stress range value at the local detail exceededonce out of no cycles

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 18 no = total number of cycles associated with the stress range level

o

The Weibull shape parameter may be established from longterm wave load analysis. In lieu of more accurate calculations, the shape parameter may be taken as h = h0 h = h 0 + h a (D z ) / (D Tact ) h = h0 + ha h = h 0 + h a z Tact 0.005(Tact z ) h = h 0 0.005Tact h = h0 + ha where:ho ha = basic shape parameter = 2.21 0.54 log (L ) 10 = additional factor depending on motion response period = 0.05 in general = 0.00 for plating where roll motion related forces are governing and vessel roll period TR > 14 sec. = vertical distance from baseline to considered longitudinal (m) For deck longitudinals For ship side above the waterline Tact 1.5

= 3C B +

at A.P. and aft

fr

= moment distribution factor 1.0 between 0.40L and 0.65L from = A.P., for ships with low/moderate speed F.P. = 0.0 at A.P. and these(linear interpolation between values) factor to transform the load from = 10-8 to 10-4 probability level =

= 3C B between 0.2L and 0.7L from A.P = 3C B +

4.0 at F.P. and forward CB

Between specified areas ks is to be varied linearly.Zw y = vertical distance from the baseline to the load point = maximum Tact (m) = horizontal distance from the centre line to the load point (m) = y, but minimum B/4 (m) = the smallest of Tact and f = vertical distance from the waterline to the top of the ships side at transverse section considered (m) = maximum 0.8Cw (m) = maximum roll angle, simple amplitude (rad) as defined in 6.5.1 = vessel design speed in knots = reduction of pressure amplitude in the surface zone = 1.0 for z < Tact - zwl =Tact + z wl z 2z wl

0.5

1/ ho

ho

= long-term Weibull shape parameter = 2.21 0.54 log(L) = Rule length of ship (m) Greatest moulded breath of ship = measured at the summer waterline (m) coefficient (actual = Block data may be used) load condition

ykf f

L B CB

V rp

6.2.2 The horizontal wave bending moment amplitude at 10-4 probability level may be taken as follows (ref. Rules Pt.3, Ch.1 /1/):

M H = 0.22f r L9 4 (Tact + 0.30B)C B (1 cos(2x / L )) (kNm)Tact x L, B, CB, fr = = = actual draught in considered load conditions distance from A.P. to section considered as defined in 6.2.1

for Tact - zwl < z < Tact + zwl

where= 0.0 for z > Tact + zwl distance measured from actual water line (m). In the area of side above z zwl it is assumed that = the externalshellpressure = Tact + contribute to fatigue sea will not damage =

zwl

6.2.3 Wave torsional loads and moments which may be required for analyses of open type vessels ( e.g. container vessels) are defined in Appendix E.

3 p dT 4 g

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 24

pdT

= pd at z = Tact = density of sea water = 1.025 (t/m3)

The accelerations av, at and al are given in 6.5. For the upper part of bulkheads the pressure range due to horizontal acceleration may be reduced by a factor rull within a distance zul below the tank top due to the effect of ullage as follows: p1 = a v hs pi = f a max p 2 = rull at y s (kN/m2 ) p3 = rull al xs rull = h s + z ull , max 1.0 for cargo oil tanks 2z ull

Figure 6-1 Reduced pressure range in the surface region

= 1.0 for ballast tanks

where

6.4 Internal pressure loads due to ship motions6.4.1 The dynamic pressure from liquid cargo or ballast water should be calculated based on the combined accelerations related to a fixed co-ordinate system. The gravity components due to the motions of the vessel should be included. The dynamic internal pressure amplitude, pi in kN/m2, may be taken as the maximum pressure due to acceleration of the internal mass: p 1 = a v h s p i = f a max p 2 = a t y s (kN/m 2 ) p = a x l s 3 wherep1 = pressure due to vertical acceleration (largest pressure in lower tank region) p2 = pressure due to transverse acceleration p3 = pressure due to longitudinal acceleration ballast, bunkers = density of than 1.025 (t/m3or liquid cargo, normally not to be ) taken less longitudinal distance from centre of free surface of liquid in xs = tank to pressure point considered (m) surface of ys = transverse distance from centre of freesee Figure liquid in tank to the pressure point considered (m), 6-5 vertical distance from point considered to surface inside the hs = tank (m), see Figure 6-5 av = combined vertical acceleration (m/s2) at = combined transverse acceleration (m/s2) al = combined longitudinal acceleration (m/s2) factor to transform the load effect to probability level 10-4 , fa = when the accelerations are specified at the 10-8 probability level. = 0.5l/h h = h0 + 0.05 = 2.26 - 0.54log10(L)Note:

z ull =

3 p3 4 g

for longitudinal acceleration

zull =

3 p2 4 g

for transverse acceleration

Note: The above scaling of pressures, by use of the factor fa, is only valid for fatigue assessment and may be justified as the dominating fatigue damage is caused mainly by moderate wave heights.---e-n-d---of---N-o-t-e---

For bulk and ore cargoes, only p1 need to be considered. The appropriate density and pressure height should be specially considered.

Figure 6-2 Distribution of pressure amplitudes for tankers in the fully loaded condition.

The factor fa is estimated for ships with a roll period TR < 14 sec., and may otherwise be less for roll induced pressures and forces, see also 4.3.---e-n-d---of---N-o-t-e---

Figure 6-3 Distribution of pressure amplitudes for tankers in ballast condition

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 25

The distance is related to the roll axis of rotation that may be taken at zr (m) above the baseline, where zr is the smaller of [ D / 4 + T / 2 ] and [ D / 2 ]. RRZ = vertical distance from axis of rotation to centre of tank/mass (m) RRY = transverse distance from axis of rotation to centre of tank/ mass (m) TR = period of roll = 2k r

GM , maximum 30 (s)

Figure 6-4 Distribution of pressure amplitudes for a bulk carrier in the ore loading condition.

In case the values of roll radius, kr, and metacentric height, GM, have not been calculated for the relevant loading conditions, the following approximate values may be used:kr = = = = GM = = = = = = = = roll radius of gyration (m), kr in the main rules Pt.3 ch.1 sec.17 shall be used unless the calculated value of kr is available 0.39 B for ships with even distribution of mass and double hull tankers in ballast. 0.35 B for single skin tankers in ballast. 0.25 B for ships loaded with ore between longitudinal bulkheads. metacentric height (m) 0.07 B in general 0.12 B for single skin tankers, bulk carriers and fully loaded double hull tankers. 0.17 B for bulk and ore carriers in the ore loading condition. 0.33 B for double hull tankers in the ballast loading condition. 0.25 B for bulk carriers in the ballast condition 0.05 B for container ships with B40.0m With interpolation for B in between maximum roll angle, single amplitude (rad)

6.5 Ship accelerations and motions6.5.1 The formula for ship accelerations and motions given below are derived from the Rules, Ch.1. Pt.3, Sec.4, [1]. The acceleration and motions are extreme values corresponding to a probability of occurrence of 10-8. Combined accelerations:at = = al = = av = = combined transverse acceleration (m/s2)

a y 2 + g 0 sin + a rya x 2 + g 0 sin + a px a 2 +a 2 z rz max 2 a pz + a z 2

(

)2)2c k

combined longitudinal acceleration (m/s2)

(

combined vertical acceleration (m/s2)

= = = = = =

50c (B + 75)

(1.25 0.025TR )k1.2 for ships without bilge keel 1.0 for ships with bilge keel 0.8 for ships with active roll damping facilities

Acceleration components:ax = = ay az ao = = = = = = CV V = = surge acceleration (m/s2)0.2ga 0 C B

Pitch motions:(m/s2) ap apx = = = = apz RP = = = tangential pitch acceleration (m/s2)

acceleration due to sway and yaw heave acceleration (m/s2) 0.7g a o C B acceleration constant0.3g a o

(2 TP )2 R Plongitudinal component of pitch acceleration (m/s2)

3C W L + C V VL 50 max. 0.2

L

(2 TP )2 R PZvertical component of pitch acceleration (m/s2)

(2 TP )2 R PXdistance from the axis of rotation to the tank centre (m) The distance is related to the pitch axis of rotation that may be taken as 0.45L from A.P. at centreline, zr above baseline, where zr is the smaller of [D / 4 + T / 2] and [D / 2]. vertical distance from axis of rotation to centre of tank/ mass (m) longitudinal distance from axis of rotation to centre of tank/mass (m) period of pitch (s)

ship design speed (knots).

Roll motions:ary arz = horizontal component of roll acceleration (m/s2) = (2 T )2 R R RZ = vertical component of roll acceleration (m/s2) = (2 TR ) R RY2

RPZ

=

RPX = TP = =

RR

= distance from the axis of rotation to centre of mass (m).

1.80

L g

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 26

= =

maximum pitch angle (rad)

0.25 a o C B

sure range may be taken as the sum of the pressure amplitudes in the two tanks. Otherwise the range may be taken equal to the amplitude. Unless otherwise specified, it may be assumed that tanks ( in tankers ) are partly filled 10% of the vessels design life.

7. Spectral Fatigue Calculations7.1 General7.1.1 Spectral fatigue calculations are based on complex stress transfer functions established through direct wave load analysis combined with stress response analyses. The stress transfer functions express the relation between the wave heading and frequency and the stress response at a specific location and may be determined by eitherFigure 6-5 Illustration of acceleration components

component stochastic analysis full stochastic analysis. Component stochastic calculations may in general be employed for stiffeners and plating and other details with a well defined principal stress direction mainly subjected to axial loading due to hull girder bending and local bending due to lateral pressures. Full stochastic calculations can be applied to any kind of structure. 7.1.2 Spectral fatigue calculations imply that the simultaneous occurrence of the different load effect is preserved through the calculations and the uncertainties are significantly reduced compared to simplified calculations. The calculation procedure includes the following assumptions for calculation of fatigue damage: wave climate is represented by scatter diagram Rayleigh distribution applies for stresses within each short term condition (sea state) cycle count is according to zero crossing period of short term stress response linear cumulative summation of damage contributions from each sea state in the wave scatter diagram. 7.1.3 The spectral method assumes linear load effects and responses. The hydrodynamic loads should be calculated using 3D potential theory as described in Section 8. Non-linear effects due to large amplitude motions and large waves can be neglected in the fatigue analysis since the stress ranges at lower load levels (intermediate wave amplitudes) contribute relatively more to the cumulative fatigue damage. In cases where linearization is required, e.g. in order to determine the roll damping or intermittent wet and dry surfaces in the splash zone, the linearization should be performed at a load level representative to stress ranges giving the largest contribution to the fatigue damage. In general a reference load or stress range at 10-4 probability of exceedance should be used.

Figure 6-6 Illustration of acceleration components and centre of mass for double hull tankers or bulk carriers with connected top wing- and hopper/bottom ballast tanks

For similar tank filling conditions on both sides of a bulkhead, e.g. for a bulkhead between two cargo tanks, the following apply; a) the effect of vertical acceleration is cancelled and may be set to zero b) the pressures due to motion are added for bulkheads normal to the direction (plane) of the motions. The combined pressure on a bulkhead between two tanks, i and ii, may be calculated by adding the pressure calculated independently for each tank:pi pi = = p2, tank i + p2, tank ii for longitudinal bulkheads between cargo tanks and, p3, tank i + p3, tank ii for transverse bulkheads between cargo tanks,

7.2 Cumulative damage7.2.1 When the long term stress range distribution is defined through a short term Rayleigh distribution within each short term sea state the fatigue damage for one-slope S-N curves is given by

6.5.2 As a simplification, sloshing pressures may normally be neglected in fatigue computations. However, if sloshing is to be considered, the sloshing pressures in partly filled tanks may be taken as given in the Rules [1], Pt.3 Ch.1 Sec. 4, C306. The pressure amplitude is defined at the probability level of 10-4. In case of partly filled tanks on both sides of a bulkhead, the pres-

D=

0 Td

all headings m N load (1 + ) pn rijn (2 2m0ijn ) m a 2 n =1 i =1, j =1

all seastates

DET NORSKE VERITAS

Classification Notes - No. 30.7, June 2010 Page 27

where= the relative number of stress cycles in short-term condition i, j vo = long-term average response zero-crossing-frequency moij = zero spectral moment of stress response process rij

surface to the load point in x-, y- and z-direction defined by the coordinate of the free surface centre minus the coordinate of the load point. The acceleration transfer functions are to be determined in the tank centre of gravity and include the gravity component due to pitch and roll motions. 7.3.2 For each load transfer function the corresponding stress transfer function is determined as H ,k ( ) = A k H k ( ) whereAk = = Stress/load ratio for load component k Load transfer function for load component k

Expressions for fatigue damage applying bi-linear S-N curves are given in Appendix D

7.3 Component stochastic analysisThe component stochastic fatigue calculation procedure is based on combination of load transfer functions calculated by the wave load analysis program and stress response factors representing the stress per load ratio. A flow diagram of the calculation procedure is given in Figure 7-1.Hydrodynamic load calculations Direct calculations Ch. 8 Stress response per unit load calculations Simplified calculations: Ch. 5 Finite element analysis Ch. 9

H k ( )

The combined stress response is determined by a linear complex summation of stress transfer functions

Load transfer functions

Stress/ load ratios

H ( ) =

H ( ), kk =1

n

Hot spot stress transfer functions per load component Sec. 7.3

7.3.3 The following stress component factors may be relevant to determine the combined stress in stiffeners and plating:A1 A2 A3 A4 A5 A6 A7 = = = = = = = = = Axial stress per unit vertical hull girder bending moment Axial stress per unit horizontal hull girder bending moment Axial stress per unit global axial force Bending stress per unit local external pressure Bending stress per unit local internal pressure (to be combined with accelerations in x-, y- and z-direction) Axial stress due to double hull bending per unit external pressure Axial stress due to double hull bending per unit internal pressure (to be combined with accelerations in x-, y- and zdirection) Bending stress due to relative deflection of stiffeners between web frames per unit external pressure Bending stress due to relative deflection of stiffeners between web frames per unit internal pressure (to be combined with accelerations in x-, y- and z-direction)

Combined stress transfer function Sec. 7.3

Wave data S-N data

Fatigue damage calculation Sec. 7.2

A8 A9

Figure 7-1 Flow diagram for component stochastic fatigue calculations

7.3.1 The load transfer functions to be considered normally include: vertical hull girder bending moment horizontal hull girder bending moment hull girder axial force vessel motions in six degrees of freedom external (panel) pressures.

Load transfer functions for internal cargo and ballast pressures due to accelerations in x-, y- and z-direction are derived from the vessel motions: H p _ ax ( ) = x s H ax ( ) H p _ ay ( ) = y s H ay ( ) H p _ az ( ) = z s H az ( ) where xs, ys and zs is the distance from the centre of free liquid