CAPSULES CAPSULES

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

CAPSULES CAPSULES

PlanPlan

1.1. Characteristic of capsules as dosage Characteristic of capsules as dosage forms.forms.

2.2. Manufacturing of Hard Gelatin Shells Manufacturing of Hard Gelatin Shells (capsules).(capsules).

3.3. Hard-Gelatin Capsule filling.Hard-Gelatin Capsule filling.

4.4. Soft-Gelatin Capsules.Soft-Gelatin Capsules.

5.5. Microcapsules.Microcapsules.

Capsules areCapsules are solid dosage forms in which solid dosage forms in which medicinal agents or inert substances are medicinal agents or inert substances are enclosed in small shell of gelatin. enclosed in small shell of gelatin.

They are of various shapes and sizes, and They are of various shapes and sizes, and contain a single dose of one or more active contain a single dose of one or more active ingredients. They are intended for oral ingredients. They are intended for oral administration.administration.

Capsule shells are made of gelatin Capsule shells are made of gelatin or other substances, the consistency or other substances, the consistency of which may be modified by the of which may be modified by the addition of substances such as addition of substances such as glycerol or sorbitol. glycerol or sorbitol.

The shell should disintegrate in the The shell should disintegrate in the presence of digestive fluids so that presence of digestive fluids so that the contents are released. the contents are released.

The contents should not cause The contents should not cause deterioration of the shell.deterioration of the shell.

Advantages of CapsulesAdvantages of CapsulesDrug with unpleasant odor and taste can be Drug with unpleasant odor and taste can be

easily administered.easily administered. Itself has no taste.Itself has no taste.Elegant Physical Appearance.Elegant Physical Appearance.More stable if properly stored.More stable if properly stored.Easily Swallowed.Easily Swallowed.Shells are inert and absorbable in GIT.Shells are inert and absorbable in GIT.For encapsulation less additives are For encapsulation less additives are

required.required.Manufacturing procedure is simple and Manufacturing procedure is simple and

faster.faster.

Cont…..Cont…..

Not many machines and equipment are Not many machines and equipment are required.required.

Shipment is economic (little or no damage Shipment is economic (little or no damage during transportation).during transportation).

Mostly used carrier in clinical trials.Mostly used carrier in clinical trials. In special conditions it can be opened In special conditions it can be opened

either as a whole or in portion can b either as a whole or in portion can b dispensed with food or drink by dispensed with food or drink by Pharmacist.Pharmacist.

Type of capsules depend on Type of capsules depend on plasticizer content plasticizer content

and technological principleand technological principle

1. Hard-Shell Gelatin Capsules;1. Hard-Shell Gelatin Capsules;

2. Soft- Gelatin Capsules 2. Soft- Gelatin Capsules ((softgelssoftgels););

Categories of capsulesCategories of capsules

hard capsules;hard capsules; soft capsules (softgels); soft capsules (softgels); modified-release capsules:modified-release capsules:

1.1. delayed-release capsules delayed-release capsules (gastroresistant / enteric capsules)(gastroresistant / enteric capsules)

2.2. sustained-release capsules sustained-release capsules

(extended-/prolonged release capsules).(extended-/prolonged release capsules).

GelatinGelatin

protein, prepared from hydrolysis of collagen (animal protein, prepared from hydrolysis of collagen (animal bones and skin)bones and skin) type A : pig skintype A : pig skin type B : animal bonestype B : animal bones

possesses following essential propertiespossesses following essential properties• stable when drystable when dry• subject to microbial degradation when moistsubject to microbial degradation when moist• digested and absorbeddigested and absorbed

99

Hard CapsulesHard CapsulesHard capsules have shells consisting of Hard capsules have shells consisting of

two prefabricated cylindrical sections that two prefabricated cylindrical sections that fit together. fit together.

One end of each section is rounded and One end of each section is rounded and closed, and the other is open. The closed, and the other is open. The contents of hard capsules are usually in contents of hard capsules are usually in solid form (powder or granules).solid form (powder or granules).

Hard Gelatin CapsulesHard Gelatin Capsules

AdvantagesAdvantages tasteless and odourlesstasteless and odourlessswallowing is easyswallowing is easy flexibility in formulatingflexibility in formulatinguniquely suitable for blinded clinical trialsuniquely suitable for blinded clinical trialsuseful for extemporaneous compounding by useful for extemporaneous compounding by

pharmacistpharmacist

1111

DisadvantagesDisadvantages tend to be more expensive to produce than tend to be more expensive to produce than

tabletstabletsnot suitable for highly soluble saltsnot suitable for highly soluble salts

Hard Gelatin Capsules Hard Gelatin Capsules SizesSizes

SIZE VOLUME (cm3) 000 1.37 00 0.95 0 0.68 1 0.50 2 0.37 3 0.30 4 0.21 5 0.13

1313

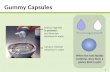

Soft gelatin capsules (softgels) are hermetically sealed one-piece capsules containing a liquid or a semisolid fill.Soft capsules are usually formed, filled, and sealed in

one operation. shells are softened by addition of glycerin or polyhydric alcohol (ex. sorbitol)

Advantages of soft-gelatin capsules1. Improved bioavailability, as the drug is presented in a

solubilized form. 2. Enhanced drug stability. 3. Consumer preference regarding ease of swallowing,

convenience, and taste can improve compliance. 4. Offer opportunities for product differentiation via colour,

shape, and size and product line extension. 5. The softgels can be enteric coated for delayed release.6. may contain liquids, suspensions, pastes7. rapid release of contents8. useful for drugs prone to oxidation

They are popular for pharmaceuticals, cosmetics, andnutritional products.

Soft Capsules

DISADVANTAGES

have a greater tendency to adhere to each other

more expensive increased possibility of interactions between

drug and shell

16

Stage of capsules production:

1. Preparing of gelatin solutions.

2. Preparing of gelatin shells.

3. Hard-gelatin capsule filling.

4. Packing and labeling.

1. Preparing of gelatin solutions.

2. Preparing and filling of soft-gelatin capsules.

3. Packing and labeling.

In the manufacture of capsules, measures are taken to:

ensure that the active ingredient(s) when present in solid state form have appropriate solid-state properties such as particle-size distribution and polymorphic form;

ensure that mixing with excipients is carried out in a manner that ensures homogeneity;

minimize the degradation of the active ingredient(s);

minimize the risk of microbial contamination; minimize the risk of cross contamination.

Excipients for production of the Capsule shells :

solvents, surface-active substances, opaque fillers, antimicrobial agents, sweeteners, colouring matter, flavouring substances, disintegrating agents, substances capable of modifying the behaviour of the active

ingredient(s) in the gastrointestinal tract.

Methods obtaining of gelatin solutions

Obtaining of gelatin solutions

with stage of swelling

Obtaining of gelatin solutions without stage of

swelling

Obtaining of gelatin solutions with stage of swelling

1. Swelling of gelatin in cold water (15 - 18 °C, 1.5 - 2 hours).

2. Dissolving of gelatin.

3. Adding preservatives, plasticizers and others excipients.

4. Remove of air bubbles from the solution of the gelatin by the vacuum.

5. Stabilization of solution of the gelatin (45-60 °C).

Obtaining of gelatin solutions without stage of swelling

1. Heating of purified water (70-75 °C).

2. Dissolution of preservatives, plasticizers and others excipients in the water.

3. Dissolution of the gelatin.

4. Remove of air bubbles from the solution of the gelatin by a vacuum.

5. Stabilization of the solution of the gelatin (45-60 °C).

Hard capsules production To manufacture the shells, pairs of molds, for the

body and the cap, are dipped into an aqueous gelatin solution (25 – 30 % w/w), which is maintained at about 50 °C in a jacketed heating pan.

As the pins are withdrawn, they are rotated to distribute the gelatin evenly and blasted with cool air to set the film.

Drying is carried out by passing dry air over the shell as heating temperatures are limited due to the low melting point of gelatin.

The two parts are removed from the pins, trimmed, and joined using a prelock mechanism.

Preparation of Filled Hard Gelatin Capsules

Following Steps: Developing and Preparing the formulation Selection of Capsule Size Filling Capsule Shells Capsule Sealing Cleaning and polishing filled capsules

Hard - Gelatin Capsule Filling

Powders and granules are the most common filling materials for hard - shell gelatin capsules, although pellets, tablets, pastes, oily liquids, and nonaqueous solutions and suspensions have been used.

Filling machines are differentiated by the way they measure the dose of material and range in capacity from bench - top to high - output, industrial, fully automated machines.

Hard - Gelatin Capsule FillingMost automated machinery is of the

independent type and compresses a controlled amount of powder using a low compression force (typically 50 – 200 N ) to form a plug. Most are piston - tamp fillers and are dosator or dosing disk machines.

The powder is passed over a dosing plate containing cavities slightly smaller than the capsule diameter, and powder that falls into the holes is tamped by a pin to form a plug.

Process flow diagram for automated capsule filling.

NJP-3000,3500 series automatic capsule filling machine

It comply with volume-produce. This machine adopts full sealed filling

and turret parts and easy to clean, upper and lower die assemblies move in

one-way, imported double-lip sealing ring made of polyurethane and have high performance,

die assemble cleaning work station combine blowing and breathing to ensure no powder in die hole during high speed running,

there is no absorb device in locking work station, lubricant be added timing in transmission work station.

Storage Optimum moisture content 12-16% At very low Humidity, Loses moisture and

becomes brittle. At high humidity, becomes flaccid and

loses shape High temp. also affect adversly.

The best Storage conditions are at temp. 20C to 25C and with humidity 35 to 40%

Methods of softgels production

Droplet method Pressing method

Droplet method1. Container with

medicines substance 2. Hoper with

medicines substance 3. Container with

gelatin solution4. Conical nozzle 5. Pulsater6. Cooler 7. Container with

Vaseline oil

Characteristic of Droplet method

It is based on formation of spherical gelatinous drop filled with a solution or suspension of medicinal substance at simultaneous drop dosage of medicinal substance solution followed by subsequent cooling of heated gelatinous mass in cool liquid petrolatum. As the result joinless spherical gelatious capsule with elastic shell is formed.

RG2-200 250 300 Series Soft RG2-200 250 300 Series Soft Gelatin Encapsulation MachineGelatin Encapsulation Machine

• For volume-production, increase the utilization ration of gelatin skin;

• convey gelatin skin with a plane surface more steady running condition;

• oil saving; • suitable for volume-

production, continually for 24 hour.

(Huizhou Pingfang pharmaceutical machinery co. ltd.)

Pressing method (Plate method)

Preparing of an initial gelatinous tape, placing it into metal plates and rolls having deepening holes resembling half of the capsules.While heating gelatin fills this mould. Drug is fed into a hollow in a gelatinous tape, then this half of a capsule is joined with another one formed and filled in the same way. Obtained capsules have a horizontal weld.

Pressing (rotary or reciprocating die) method

The glycerol – gelatin solution is heated and pumped onto two chilled drums-1 to form two separate ribbons-2, which form each half of the softgel.

The ribbons are lubricated and fed into the filling machine, forcing the gelatin to adopt the contours of the die.

The fill-4 is manufactured in a separate process and pumped in, and the softgels are sealed by the application of heat and pressure.

Once cut from the ribbon (5), they are tumble - dried and conditioned at

20 % relative humidity.

Uses of Soft Gelatin Capsules Water immiscible volatile and non-volatile

liquids (vegetable, aromatic oils chlorinated hydrocarbons, ethers, esters and alcohol)

Water miscible nonvolatile liquids (polyethylene glycols ,nonionic surfactant polysorbate 80)

Water miscible and relativly nonvolatile compounds (propylene glycol, IPA)

Compendial Requirements

Added Substances Should harmless in the quantities used. Do not exceed the minimum amounts

required. Do not impair the products bioavailability,

therapeutic efficacy, and safety. Do not interfere with requisite compendial

assays and tests.

Compendial Requirements

Containers for Dispensing CapsulesShould be according to USP or BP

SpecificationsTight, well-closed, light resistant container

Cont……. Disintegration test Dissolution test Weight Varioation Content uniformity Content Labeling requirement Stability Test Moisture Permeation Test

Oral administration Place the dose upon tongue Swallow with glass of water or beverage Dry intake causes ulcers Oral dosage forms with special coating

must not be chewed, broken or crushed. If patient cannot swallow, suggest

chewable or liquid form of drug.

Modif ied-release capsules They are hard or soft capsules in which

the contents or the shell or both contain excipients or are prepared by special procedures such as microencapsulation which, separately or together, are designed to modify the rate, place or time of release of the active ingredient(s) in the gastrointestinal tract.

Sustained-release capsules

(Extended- or Prolonged-release capsules) are designed to slow the rate of release of the active ingredient(s) in the gastrointestinal tract.

Delayed-release capsules

(gastro-resistant/enteric capsules) are hard or soft capsules prepared in such a manner that either the shell or the contents resist the action of gastric fluid but release the active ingredient(s) in the presence of intestinal fluid.

Microcapsule is a small sphere with a uniform wall around it.

Micro-encapsulation is a process in which tiny particles or droplets are surrounded by a coating to give small capsules many useful properties.

The material inside the microcapsule is referred to as the core, internal phase, or fill, whereas the wall is sometimes called a shell, coating, or membrane.

Most microcapsules have diameters between a few micrometers and a few millimeters.

The reasons for microencapsulation

In some cases, the core must be isolated from its surroundings, as in isolating vitamins from the deteriorating effects of oxygen,

retarding evaporation of a volatile core, improving the handling properties of a sticky material,

or isolating a reactive core from chemical attack. In other cases, the objective is not to isolate the core

completely but to control the rate at which it leaves the microcapsule, as in the controlled release of drugs or pesticides.

The problem may be as simple as masking the taste or odor of the core, or as complex as increasing the selectivity of an adsorption or extraction process.

The end

Related Documents