Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

BRANDS

ABOUT ROLMAN WORLDROLMAN WORLD AND END USER SERVICES

INDEX

BALL BEARINGSROLLER BEARINGSBEARING UNITSLINEAR MOTION

BEARINGS

LUBRICATION

MAINTENANCE TOOLS

OIL SEALS

BELTS & PULLEYS

BELTS

ROLLER CHAIN & SPROCKETSCONVEYOR CHAINDRAG CHAIN & ENERGY CHAIN

CHAIN

COUPLINGSTORQUE LIMITERSCLAMPING SETS & PRECISION JOINTSTORQUE MEASURING TECHNOLOGYBRAKE SYSTEMSHYDRAULIC COMPONENTSCOOLING SYSTEMS

POWER TRANSMISSION TECHNOLOGY

FILTRATION PRODUCTS FOR INDUSTRIAL APPLICATIONS

CEMENT & QUARRYING INDUSTRYINDUSTRIAL GEARS & ELECTRIC MOTORS FOOD & BEVERAGE INDUSTRYFANS & BLOWERS, PUMPS & COMPRESSORSSTEEL & METALS INDUSTRYOIL, GAS, PETROCHEMICAL INDUSTRY

APPLICATION SOLUTIONS

THE WORLD INMOTION

RO

LM

AN

WO

RL

D ROLMAN WORLD& END USERS

ABOUTROLMAN WORLD

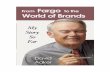

50 Years of Experience with Industry

From a modest start 50 years ago, the Rolman World Group has evolved into the region’s dominant distributor for industrial spare parts & services. From its roots as a bearing distributor, the Group has consistently followed its principles of quality, customer service and technical know-how to become the Middle East & Africa’s foremost replacement parts & technical services provider. We remain our customers’ first choice across the region.

2015 saw the completion of our new Headquarters building in Dubai, and this investment has heralded the beginning of a new phase of growth and change within our Group. With a growing network of branches strategically located across the Middle East & Africa, we have set our sights on strengthening our market-leading position in four key business areas – Power Generation, Automotive, Industrial Wholesale and End User Direct.

TOOLS & MONITORING SERVICES

Timely maintenance and the correct parts will help you get the most from your machinery. However, it is vital to treat the components and your machinery correctly – when mounting and in operation, in order to get the maximum lifetime, and avoid unplanned, expensive downtime.

We supply the tools for heating, handling, fitting and removing the bearings and other components correctly. We can help you align your machinery correctly to avoid unnecessary stresses on components. We can work with you to monitor the condition of your machinery and components to understand how and when mechanical problems may cause or contribute to unplanned downtime.

COMPONENT FAILURE ANALYSIS

Our engineers are trained and experienced in establishing and understanding the root causes of component failure.

We can of course work with you to get the machinery moving again – but it is important to understand why a component has failed, in order to provide a lasting remedy. We work together with our manufacturers to understand the root cause of failure in your application, and provide a solution which drive improved performance, and allow your maintenance team to focus on other issues.

ON-SITE TECHNICAL SUPPORT

Whilst most distributors in the region are content to sell you their products, and leave you with your own problems, Rolman World stand ready to support our End User customers with extended technical services.

We have long experience in working side-by-side with maintenance departments to solve major problems – mounting giant-sized bearings with our specialist equipment; solving issues with gearboxes whose drive belts fail constantly; developing design solutions for screw conveyors and other machines which are a bottleneck for production processes; creating lubrication solutions in hard-to-reach or dangerous parts of your factory; and even working with you on machine overhauls during planned shutdowns. Replacing the part is not always the right solution.

SHARING BEST PRACTICE

Our extensive work with the region’s major End Users, and our engineers’ experience in each industry has given us invaluable insights into the most common maintenance issues, and the solutions which bring the best results.

We will work together with your Maintenance Departments and Production Engineers to identify the areas where our solutions bring added value, and where we believe we can help develop your efficiency and productivity.

TRAINING

We have invested heavily in our capabilities to train your engineers in the correct techniques.

We have the capacity to train up to 60 people at one time, utilising our manufacturers’ skills and experiences to bring the latest products and techniques to your teams. Our hands-on training facility at our Headquarters allows your staff to learn and practice best handling practices, eliminating some of the problems leading to shortened product lifetime, and therefore more downtime.

Partnership with the Region’s Major End Users

Nowadays, simply selling products is not enough. Manufacturers in every industry know that they need to continuously improve their productivity and reduce costs in order to stay ahead of fierce competition. Unplanned plant stoppages are expensive. Inefficient processes cost time and money.

As a serious partner to our End User customers, we have developed our capabilities to be able to discuss the requirements of every application, and to be able to offer the most effective solutions – be it a product, service, training or advice.

Our growing team of dedicated specialist MRO Sales Engineers, who have been brought together from across the region and are selected for their qualifications, skills and experience, are able to confidently work together with Maintenance & Production teams for a common goal – reduced unplanned downtime and increased production. Supported by our suppliers where appropriate, we will help you choose the right solution to suit your application and operational requirements.

STOCK SERVICES

For 50 years, Rolman World Group has been one of the Middle East & Africa region’s largest stockists of industrial spare parts. Our stock is second to none, and our experience has driven us to hold a comprehensive range of replacement bearings for all applications.

We will work with you to ensure availability of your requirements, and can supply it to your machine when you need it. We can put our stocks in your warehouse as part of a service agreement, releasing your resources, and leaving you to focus on your core business.

Our Services

Stock Services ○ Express & Line-Side Delivery Available ○ Customer Stock Audits ○ Compontent Condition Assessment

Tools & Monitoring Services ○ For Mounting & Dismounting ○ For Equipment Alignment ○ Condition Monitoring & Analysis

Component Failure Analysis ○ Failed Component Analysis ○ Root Cause Analysis ○ Lubrication Analysis

On-Site Technical Support ○ Mounting & Dismounting ○ Equipment Alignment Services ○ Equipment Repair & Overhaul Services

Cost Down & Best Practice ○ Application Reviews ○ Bearing Selection Advice ○ Machinery Diagnostics

Product Training ○ Industry & Application Specific Training

○ Bearing Handling & Fitting ○ Best Practice & Case Studies

BE

AR

ING

S

DEEP GROOVE BALL BEARINGS ○ Single Row Deep Groove Ball Bearings ○ Miniature Ball Bearings ○ Maximum Type Ball Bearings ○ Magneto Bearings ○ Double Row Deep Groove Ball Bearings

ANGULAR CONTACT BALL BEARINGS ○ Single Row Angular Contact Ball Bearings ○ Double Row Angular Contact Ball Bearings ○ 4-Point (Duplex) Angular Contact Ball Bearings ○ Super Precision Angular Contact Ball Bearings – Matched Configurations

Single Row Deep Groove Ball Bearings ○ High speed & low power loss ○ High radial force; moderate axial force ○ Cages: steel, brass & polymer ○ All sealing variants ○ All clearance variants ○ Available with snap-ring and groove ○ Thin section series 16*** ○ Electric motor specification ○ Bore dia 10 mm – 800 mm ○ 68**, 69**, 60**, 62**, 63**, 64**, 16***

Single Row Angular Contact Ball Bearings ○ Significant axial load-bearing capabilities in one direction, together with radial loads

○ Sealing available for tough environments ○ Cage: steel, brass & polymer ○ Contact angles 15, 25, 30, 40 degrees ○ Bore dia 10 mm – 200 mm ○ Available for matching - Back-to-back (DB); Face-to-face (DF); Tandem (DT)

○ 79**, 70**, 72**, 73**

Aqua Bearings ○ Arduous environments ○ Corrosive environments ○ Chemical & Pharmaceutical, Food & Beverage ○ Special self-lubricating fluororesin

Pulley Bearings ○ Contaminated environments ○ Sealing – Z & RS variants ○ Cage – Steel & polymer ○ Food & Beverage, Machine Tools

Stainless Steel Bearings ○ Corrosive environments ○ Chemical & Pharmaceutical, Food & Beverage, Utilities

○ Outperforms SUS440C

High Capacity Precision Angular Contact Ball Bearings

○ Contaminated environments ○ High speed, low friction, polymer cage ○ Machine tools ○ Bore sizes 30 mm – 100 mm

Hybrid Bearings ○ Corrosive environments ○ High temperature ○ Food & Beverage ○ Lasts 5 times longer than stainless steel in water-immersed environments

High Performance Double Row ACBBs ○ High load, high speed, high temperature ○ High axial load capacity (30 degree contact angle) ○ Fans & Blowers, Paper, Petrochemical, Quarrying & Mining, Utilities

Ceramic Ball Bearings ○ Arduous environments ○ Low noise ○ Fan Motors ○ ALL-CERAMIC ball bearings also available

ACBBs – Outer Ring Guided Brass Cage ○ High accuracy, load, speed, temperature ○ Chemical & Pharmaceutical, Industrial Pumps Compressors, Petrochemical

○ Long-life, high speed, reduced heat generation, vibration & noise

Nickel-Coated Ball Bearings ○ Corrosive environments ○ Contamination ○ High temperature ○ Chemical & Pharmaceutical, Food & Beverage, Material Handling, Printing

Sealed Angular Contact Ball Bearings ○ Contaminated conditions ○ Cement, Ceramic, Chemical & Pharmaceutical, Machine Tools, Rubber & Plastics, Textile & Leather

Deep Groove Ball Bearings with Special Heat Treatment

○ Contamination ○ Lubrication ○ Industrial Pumps & Compressors, Power Transmission

ELCOMP Bearings for Screw Compressors ○ Superior resistance to oil chemicals, gas & heat, giving longer life

○ Contamination, corrosive environments ○ High load, high temperature ○ Industrial Pumps & Compressors, Power Transmis-sion

Extreme Temperature Sealed Deep Groove Ball Bearings

○ Chemical & Pharmaceutical, Electric Motors, Fans & Blowers, Industrial Pumps & Compressors, Petrochemical, Power Transmission

○ Available up to 330°C - 450°C

BMPC Angular Contact Ball Bearings ○ High Load, high speed ○ 40 degree contact angle, brass cage ○ Universal grinding for matching ○ Reduced axial clearance ○ Pumps & Compressors, Petrochemical

High Capacity Deep Groove Ball Bearings for High Loads

○ Chemical & Pharmaceutical, Electric Motors, Food & Beverage, Industrial Pumps & Compressors, Petrochemical, Power Generation, Utilities

LNG Pump Bearings ○ Arduous environments ○ Corrosive environments ○ High speed, high temperature ○ Chemical & Pharmaceutical, Petrochemical

Creep-Free Ball Bearings ○ High Loads ○ Electric Motors, Industrial Pumps & Compressors, Petrochemical, Power Tools

ADDED-VALUE SOLUTIONS - DGBB ADDED-VALUE SOLUTIONS - ACBB

Miniature Ball Bearings ○ Metric & imperial ○ Flanged variants ○ All sealing variants ○ All clearance variants ○ Stainless steel available ○ Available with snap-ring and groove ○ Electric motor specification ○ Bore dia 1 mm – 9 mm ○ 68*, 69*, 60*, 62*, 63*

Double Row Angular Contact Ball Bearings ○ In principle, a back-to-back configuration, but with a single inner and outer ring.

○ Sealing variants – Z and RS available ○ Cage: pressed steel, polymer ○ Bore dia 10 mm – 85 mm ○ 32**, 33**, 52**, 53**

Maximum Type Ball Bearings ○ Filling slots in inner & outer ring allow larger number of balls for higher radial load capacity.

○ Not recommended for high axial loads ○ Open, Z & ZZ sealing variants ○ C3 clearance variant available ○ Bore dia 25 mm – 110 mm ○ BL2**, BL3**

4-Point Angular Contact Ball Bearings (QJ) ○ Inner ring split radially into 2 pieces ○ Significant axial load in either direction ○ 35 degree contact angle ○ Machined brass cage ○ Bore dia 30 mm – 200 mm

Magneto Bearings ○ Outer ring with shoulder on one side only, so the outer is removable

○ Generally used in duplex pairs ○ Pressed brass cage ○ Bore dia 4 mm – 20 mm ○ E*(*), EN*(*), L**

Super Precision Angular Contact Ball Bearings ○ Long-life steel ○ High speed, high precision ○ Significant axial load in either direction ○ Machined brass cage, polymer cage available ○ Bore dia 30 mm – 200 mm ○ Available for matching: ○ Back-to-back (DB); Face-to-face (DF); Tandem (DT)

○ 79**, 70**, 72**, 73**

Double Row Deep Groove Ball Bearings ○ Higher load rating than 2 single bearings ○ High temperature, high speed, low noise ○ Pressed brass cage ○ Bore dia 10 mm – 90 mm ○ Power transmission applications ○ 42**, 43**

Single Direction Thrust Ball Bearings ○ Initial misalignment can be accommodated by spherical aligning seats or aligning seat washers

○ High axial loads in one direction but no radial loads

○ Cages – pressed steel or machined brass

○ Bore dia 10 mm – 360 mm ○ 5**** (flat seat); 5**** (aligning seat); 5****U (aligning seat washer)

Double Direction Thrust Ball Bearings ○ Initial misalignment can be accommodated by spherical aligning seats or aligning seat washers

○ High axial loads in both directions but no radial loads

○ Cages – pressed steel or machined brass

○ Bore dia 10 mm – 190 mm ○ 5**** (flat seat); 5**** (aligning seat); 5****U (aligning seat washer)

THRUST BALL BEARINGS ○ Single Direction Thrust Ball Bearings ○ Double Direction Thrust Ball Bearings

BEARINGS

BE

AR

ING

S

ROLLER BEARINGS ○ Cylindrical Roller Bearings ○ Taper Roller Bearings ○ Spherical Roller Bearings ○ Needle Roller Bearings

CYLINDRICAL ROLLER BEARINGS ○ Single Row Cylindrical Roller Bearings ○ Double Row Cylindrical Roller Bearings

Extra Capacity CRB ○ High load, speed, temp & low noise ○ Steel or machined brass cage ○ Agriculture, Construction, Electric Motors, Fans & Blowers, Pumps & Compressors, Material Handling, Paper, Petrochemical, Power Transmission, Quarrying & Mining

High Performance Cylindrical Roller Bearings ○ Contaminated environment ○ High load, high temperature ○ Electric Motors, Fans & Blowers, Oil & Gas, Paper, Power Transmission

Cylindrical Roller Bearings with Outer Ring Guided Brass Cage

○ High accuracy, load, speed, temperature ○ Chemical & Pharmaceutical, Pumps & Compressors, Petrochemical

NUB Series Cylindrical Roller Bearings ○ Compact environment ○ High load, low friction ○ Extended lifetime – accommodates roll shaft bending & smooth release of roll extension

○ Steel & Metals industries

CRB for Vibrating Screen ○ High load, high vibration ○ Extended lifetime – one piece machined brass cage,

○ Material Handling, Quarrying & Mining, Utilities

ELCOMP Bearings for Screw Compressors ○ Superior resistance to oil chemicals, gas & heat, giving longer life

○ Contamination, corrosive environments ○ High load, high temperature ○ Industrial Pumps & Compressors, Power Transmission

CRBs with Aligning Rings ○ High load and misalignment ○ Prevents wear related to differential slid-ing.

○ Permits unrestricted axial thermal expansion on the roll shaft

○ Oil & Gas, Steel & Metals

Full Complement Cylindrical Roller Bearings ○ No cage, with a full complement of rollers for greater loads

○ For low speed and heavy load applications ○ Often used in industrial applications such as crane sheaves

ADDED-VALUE SOLUTIONS - CYLINDRICAL

Single Row Cylindrical Roller Bearings ○ Cage: pressed steel, machined brass, polyamide, LPPS

○ Special materials available for specific applications

○ Low noise, low heat generation, high speeds

○ All clearances available ○ Extra capacity versions available ○ Metric & imperial sizes available ○ Bore dia 0.5”– 1320 mm

Single Row Taper Roller Bearings ○ High radial & axial loads in a single direction ○ Axial loads in both directions when arranged in pairs

○ Also available in 2 and 4 row versions ○ Advanced materials for arduous conditions ○ Steel cages – segmented plastic cage available for bores greater than 1000mm

○ Metric and imperial dimensions available ○ Bore dia 15 mm – 2500 mm

Spherical Roller Bearings ○ Seizure & wear resistant in demanding conditions

○ Tolerate vibration, misalignment & shock load

○ High radial load, moderate axial load ○ All clearances available ○ Cages – steel, brass and polyamide ○ Bore dia 20 mm – 1400 mm ○ Sealed versions available ○ Special treatments and materials available

Thrust Spherical Roller Bearing ○ Spherical raceway in the housing washer ○ Very high load carrying capacity ○ Machined brass cages ○ Bore dia 60 mm - 500 mm ○ 29***

Large & Giant Spherical Roller Bearings for Special Applications

○ SRBs for Vibrating Screen applications ○ High requirement Steel Mill applications ○ Paper Industry Applications ○ Bearings for Crushers ○ Split Bearings for the Steel Industry

Double Row Taper Roller Bearings ○ High axial loads in both directions ○ Advanced materials for arduous conditions ○ Steel cages – segmented plastic cage available for bores greater than 1000mm

○ Bore dia 40 mm – 260 mm

○ Design dependent on design or absence of side ribs.

○ Pressed steel or machined brass cages

○ NU, N, NNU & NN – suitable as free-end bearings

○ NJ & NF accept axial loads in one direction

○ NH & NUP suitable as fixed-end bearings

Self-Aligning Ball Bearings ○ Compensates for misalignment in shaft and housing

○ 4-7 degrees of misalignment allowed under normal loads. Spherical raceway in outer ring

○ Pressed steel cage ○ Straight or tapered bore ○ Low axial load carrying capacity ○ Bore dia 5 mm – 110 mm ○ 12**, 13**, 22**, 23**, 1**

Double Row Cylindrical Roller Bearings

○ NN & NNU designs ○ Straight or tapered bore ○ Steel or machined brass cage ○ Bore dia 25 mm – 360 mm

SPHERICAL ROLLER BEARINGS ○ Spherical Roller Bearings ○ Thrust Spherical Roller Bearings

High Performance SRBs ○ High load, speed, temperature ○ Extended lifetime ○ Fans & Blowers, Food & Beverage, Pumps & Compressors, Material Handling, Paper, Quarrying & Mining, Rubber & Plastics, Steel & Metals, Utilities

SRB with Detachable Seal ○ High load, contamination ○ Bolt-fastened seal holder ○ 4-times longer life ○ Cement, Quarrying & Mining

Molded Oil Bearings ○ Contaminated & corrosive environments ○ Agriculture, Chemical & Pharmaceutical, Food & Beverage, Material Handling, Oil & Gas, Packaging, Paper, Quarrying & Mining, Steel & Metals, Utilities

SRB with Special Brass (CAM) Cage ○ High loads & misalignment ○ Fans & Blowers, Pumps & Compressors, Material Handling, Paper, Power Generation, Power Transmission, Quarrying & Mining, Steel & Metals

Long-Life Vibrating Screen SRB ○ High loads, vibration & misalignment ○ Better roller guidance ○ Load rating increased 1.25 times ○ Material Handling, Oil & Gas, Paper, Quarrying & Mining, Utilities

SRB for Papermaking ○ Contamination & high temperatures ○ Special steel composition ○ Lifetime increased 2 times ○ Paper, Power Transmission

Sealed Spherical Roller Bearings ○ Contamination, high load & high temperatures ○ Special lip seal ○ Reduction in grease consumption ○ Food & Beverage, Material Handling, Paper, Power Transmission, Steel & Metals

Quiet & Low Vibration Series SRB ○ Low noise, low vibration ○ Reduced bearing clearance ○ Proven reduced rotational noise ○ Material Handling

ADDED-VALUE SOLUTIONS - SRB SELF-ALIGNING BALL BEARINGS TAPER ROLLER BEARINGS ○ Single Direction Taper Roller Bearings ○ Double Direction Taper Roller Bearings

BEARINGS

BE

AR

ING

S

NEEDLE ROLLER BEARINGS

New Stainless Steel ○ Food & Beverage, Pharma-ceutical, Fertiliser industries

○ Redesigned for wash down ○ Plastic or stainless steel covers available (including drainage hole)

○ Engineered surface for water to run off, preventing bacteria growth

○ Housings made of SUS316 grade stainless steel for additional rust-proofing

○ Packed with H1 food-grade grease

○ Floback sealing for bearing protection during wash down

○ Laser marking, including QR code

New Z-LOCK Locking System ○ Patented, revolutionary lock-ing system

○ Utilises a taper bore UK insert with a Z-LOCK sleeve

○ Factory pre-assembled, and ready to use straight from the box.

○ Z-LOCK uses one key to tight-en just 2 set screws, requiring no torque charts and leaving bearing clearance unaffected

VALUE-ADDED SOLUTIONS – BEARING UNITS PRODUCT RANGE – BALL BEARING UNITS

UCP – Set Screw

UCIP – Thick Series UCPA(N) – Tapped Base UCPH – High Base BLP – Light Series

UP – Compact Series UCSP – Stainless Steel

SBPP – Pressed Steel

NCFS – Pilot Flange

NANFL – Locking Collar

UCSFL – Stainless Steel

UCFB(U) – 3-Bolt Flange

SBPF – Pressed Steel

UCTH – Sectioned Steel

UCF – 4-Bolt Flange

UCSF – Stainless Steel

NCFL – Concentric Collar

SBPFL – Pressed Steel

UCFC – 4-Bolt Cartridge

UCT – Take-Up Unit

UCTL – Channeled Steel

NANF – Locking Collar

UCVF – Thermoplastic

BLF – Light Series

UCVFL – Thermoplastic

NCFC – Concentric Collar

NAT – Locking Collar

UCC – Cartridge Unit

NCF – Concentric Collar

UCFL – 2-Bolt Flange

UFL – Clean Series (Zinc)

UCFA – Adjustable 2-Bolt

SATFD – Light Series

UCST – Stainless Steel

UCHA – Hanger Unit

NAP – Locking Collar NCP – Concentric Collar

UCSPA – S.S. Tapped Base

UCVP – Thermoplastic

UKP – Taper Bore

Needle Roller Bearings ○ Low cross-section height ○ High load carrying capacity ○ Small envelope size, reducing overall machine size

○ Frequently used in automobiles, motorcycles, printing presses, industrial robots and construction equipment

Radial-Type Needle Roller Bearings ○ Shell-type needle roller bearings ○ Needle Roller Bearing cages for general use

○ Needle Roller Bearing cages for engine connecting rods

○ Machined type needle roller bearings

Combined-Type Needle Roller Bearings

○ Combined with thrust ball bearings ○ Combined with thrust roller bearings

○ Combined with angular contact ball bearings

○ Combined with three-point-contact ball bearings

Cam & Roller Followers ○ Standard type cam followers ○ Solid eccentric stud type cam followers

○ Eccentric type cam followers ○ Thrust disc type cam followers ○ Cam followers for centralised piping ○ Easy mounting type cam followers ○ C-Lube type cam followers, miniature type cam followers

○ Miniature cam followers with thrust washer

○ Heavy duty type cam follower ○ C-Lube unit for Cam & Roller followers

Crossed Roller Bearings ○ Mounted hole type high rigidity crossed roller bearing

○ High rigidity type crossed roller bearing

○ Standard type crossed roller bearings

○ Super slim type crossed roller bearings

○ Slim type crossed roller bearings

Slewing Bearings ○ Ball & Roller bearing types ○ Single row, double row, three row and combination bearings

○ Sizes up to 18 metres

Rod Ends ○ Lubrication type Spherical Bushings insert type

○ Lubrication type Rod Ends insert type ○ Lubrication type Rod Ends die-cast type

○ Maintenance-free Rod Ends

Spherical Bushings ○ Steel-on-steel Spherical bushings ○ Maintenance-free Spherical bushings

Link BallA spherical slide bearing with a ball stud that provides smooth operation with a minimal clearance.

PLAIN BEARINGS ○ Rod Ends (Pilloballs) ○ Spherical Plain Bearings

Our Ball Bearing Units are manufactured by the industry’s leading producers with severe operating conditions in mind where high speed rotation and heavy loads are regularly encountered. Almost 700 kinds of bearings and 300 types of housings are available in our product line – giving several thousand combinations possible..

Ball Bearing Units ○ Radial ball bearing ○ Spherical OD to accommodate misalignment ○ Cast iron, pressed steel, stainless steel, zinc-alloy, thermoplastic housings

○ Inch & metric sizes available ○ Locking – set screw, eccentric collar, concentric collar, and new Z-Lock technology

BEARING UNITS ○ Ball Bearing Units (Pillow Blocks) ○ Roller Bearing Units (Plummer Blocks) ○ Split Bearing Housings

BALL BEARING UNITS

SLEWING BEARINGS

BEARINGS

BE

AR

ING

S

High & Low Temperature Units ○ For extra high & low temperature applications ○ Standard -20 to +100 degC ○ Cold resistant (D2K2) -50 to +120 deg C ○ Heat resistant (D1K2) -40 to +180 degC ○ Heat resistant (D9K2) -20 to +230 degC ○ Supplied with the appropriate grease

Ceramic Ball Units ○ For special operating environments ○ Reduced maintenance costs ○ Relubrication interval extended or eliminated ○ Eliminates the need for other external devices ○ Low friction & high stress resistance ○ Electric arcing is eliminated

Corrosion Resistant Units ○ Solutions to resist and eliminate rust ○ Thermoplastic Polyester housings ○ Stainless Steel or Nickel-plated housings ○ Stainless Steel inserts SUS440C ○ Zinc plated inserts ○ Solid base prevents debris build-up ○ Corrosion resistant backside guard available, made from nitrile rubber

Bearing Units for Air Handling Units ○ Air handling series used for HVAC and air handling applications

○ S3 & S5 standards available ○ 100% noise checked ○ C2 bearing clearance ○ Tighter tolerances, reducing noise & vibration ○ Non-contact lip seals for lighter torque

Dust Resistant Units ○ Sealing options to extend bearing life and reduce maintenance costs

○ Triple lip seals (L3) ○ Tight triple lip seals (LT3) ○ Pressed steel open covers ○ Cast iron open covers ○ Nitrile rubber backside guards

○ Adapter sleeves

○ Withdrawal sleeves

○ Lock nuts

○ Lock washers

SNT Plummer Blocks ○ Durable cast iron housings ○ Robust sealing options ○ 2 or 4 bolt mounting ○ Housing series available – 200, 300, 500, 600, and 3000 & 3100 for larger sizes

○ Shaft size – 20mm to 380mm Linear Motion Guides

Ball Spline

Linear Bushing

Cross Roller Table

Lead Screw Nut

Linear Actuators

LM Stroke

Linear Ball Slide

Ball Screws

Change Nut

○ Industries – Power Generation, Quarrying & Mining, Cement, Steel & Metals, Water Treatment, Food Processing, Movable Bridges, Industrial Fans & Blowers

SN Plummer Blocks ○ SN5 & SN6 types ○ SN30 & SN31 for larger sizes ○ Larger sizes available with dual-struc-ture oil seals, and the bearing is mounted with the use of an adapter sleeve

A new range Ball Screw Angular Contact Thrust Ball Bearings. These bearings have been improved by focusing on material cleanliness - which has a big impact on the bearings life. Universal arrangement bearings for interchangeable matching.

Angular Contact Thrust Ball Bearings for Ball Screws

High rigidity thrust bearings designed specifically for ball screw support applications in machine tools.

Sealed Angular Contact Thrust Ball Bearings for Ball Screw Support

Sealed Angular Contact Thrust Ball Bearings for Ball Screw Support provide excellent resistance to ingress of coolant and metal chippings, while providing highly rigid and accurate ball screw support.

Sealed Angular Contact Ball Bearings

Sealed Angular Contact Ball Bearings ensure that the bearings are in the best possible condition, free of contamination, before and during operation while providing high level machining performance.

Ultra High Precision Angular Contact Ball Bearings

High rigidity thrust bearings designed specifically for ball screw support applications in machine tools.

High Precision Deep Groove Ball Bearings

Quiet operation with low vibration, these bearings are suitable for high-speed and high precision motors.

Dust proof Type Plummer Blocks ○ Combination of oil seals, labyrinth seals, and oil groove seals

○ Bearing is mounted with the use of an adapter sleeve

Stepped Shaft Type Plummer Blocks ○ SN2C & SN3C ○ Bore diameter on one side is smaller ○ Bearing is mounted using a nut & washer.

Long-Life Split CRB Units ○ Contaminated environments ○ High load and misalignment ○ Special seal configuration ○ Improved load rating capacity ○ For segmented drive rolls in continuous casting machines

SNN Plummer Blocks ○ Contaminated environments ○ High load and misalignment ○ Cement, Fans & Blowers, Power Trans-mission, Steel & Metals

Plummer Block Accessories ○ Felt seals ○ Locating Rings ○ ZF Seals (NBR) ○ U-Lok Seals )NBR & Steel) ○ Labyrinth Seals ○ V-Ring Seals ○ Spacer Rings ○ End Covers

BEARING UNIT ACCESSORIES

LINEAR MOTION – LINEAR GUIDES & BALLSCREWS PLUMMER BLOCKS BEARINGS FOR SUPER PRECISION APPLICATIONS

Did you know ....?

Rolman World can cut your Linear Guide Rail to your selected length, using our high precision cutting machine.

BEARINGS

Proven Quality, Perfect PriceFor over a decade Rolman World has been developing a range of products tailored for your purpose and your budget. Based on the BW bearings® credo of Quality & Value, we guarantee you the reassurance of the highest global standards, but at a price which suits your pocket.Designed and manufactured to DIN and JIS international standards, our BW products have been overcoming the most challenging conditions in our customers' applications in automotive and industrial for more than a decade. Our products are engineered to perform flawlessly in the world's harshest environments, delivering reliability and performance across the Middle East, Africa, Russia, Asia and European markets.Every year we are developing new products based on customers' and markets' requirements. Our BW product range is now in excess of 4,000 products, and growing fast.

Spherical ▪ Cylindrical ▪ Taper ▪ Giant Size ▪ Needle

Roller Bearings

Radial Ball Bearings ▪ Self Aligning ▪ Angular Contact ▪ Thrust

Ball Bearings

Pillow Block ▪ Plummer Block ▪ Accessories

Bearings Units

Bearings for Excavators & Forklifts ▪ Slewing Bearings ▪ Spherical Bushings

Special Bearings

• Wheel Bearings & Hubs• Clutch Release Bearings• Timing Belt Tensioners

• Universal Joints• Fuel Filters• In-Tank Fuel Filters

Automotive Bearings & Components

Industrial Bearings

Roller Chain

LU

BR

ICA

TIO

N

BEARING GREASES FOR SPECIFIC APPLICATIONS

SINGLE POINT AUTOMATIC LUBRICATORS

LGMT3 – General Purpose ○ Used in a wide range of automotive and industrial applications

○ Operating temperature -30°C to 130°C ○ Mineral Oil / Lithium Complex ○ NLGI Grade 3 ○ 200g, 400g, 500g, 1kg, 5kg, 18kg, 180kg

LGEP2 – High Load, Extreme Pressure ○ Used in heavily loaded industrial applications – jaw crushers, mining, steel mills, paper making, construction machinery, salt water applications

○ Operating temperature -30°C to 120°C ○ Mineral Oil / Lithium Complex ○ NLGI Grade 2 ○ 400g, 500g, 1kg, 5kg, 18kg

LGHP2 – High Performance, High Temperature ○ Used in industrial applications under extreme pressure – industrial machinery, mining, pumps & marine applications, electric motors, agricultural machinery

○ Operating temperature -40°C to 150°C ○ Mineral Oil / Di-Urea ○ NLGI Grade 2 ○ 1kg, 5kg, 18kg

LGFP2 – Food Compatible Bearing Grease ○ Used as a premium multipurpose food grade grease – H1 approved and Halal registered.

○ Operating temperature -30°C to 150°C ○ Medical White Oil / Aluminium Complex ○ NLGI Grade 2 ○ 1kg

Accessories

A comprehensive and practical accessory programme enables a smooth application of simalube lubricators. The accessory programme is arranged in a unit assembly system, ie. the different

parts are compatible and can be combined so that every lubricating problem can be solved.

○ Product Automatic grease and oil lubricator ○ Power generation Hydrogen gas producing dry cells ○ Working pressure Max. 5 bar ○ Adjustment Stepless 1–12 months ○ Dispensing quantity 0.04–8.3 ml/day ○ Operating temp –20°C to +55°C ○ Usage The lubricator can be installed in any position, even underwater.

○ Ingress protection IP68 (dustproof and waterproof) ○ Usage period Within 2 years of filling date ○ Sizes 15 ml, 30 ml, 60 ml, 125 ml, 250 ml

The simalube lubricator is available in 15, 30, 60, 125 and 250 ml sizes. The compact design of all of the simalube lubricators makes it possible to apply in tight spaces, as well as with numerous lubricants.

○ Adapters and connectors ○ Fitting & reducing nipples ○ Extensions ○ Mounting supports ○ Protective covers

○ Lubricant application brushes ○ Hoses ○ Clamps, fixtures & brackets ○ Greases & Oils

LGFR2 – Fire Resistant Bearing Grease ○ Used in special applications and industries which are prone to fire – steel mills, blast fur-naces, coke making, casters, mining

○ Complex thickener ○ NLGI Grade 2 ○ 1kg, 5kg, 18kg, 180kg

LCAG3 - Automotive ○ High & Low Temperature Automotive Bearing Grease

○ Recommended for automotive applications – wheel hubs and hub units

○ Runs to 75,000 km ○ Mineral Oil / Lithium Complex ○ NLGI Grade 3 ○ 400g, 500g, 1kg, 5kg, 18kg

LGHB 2 - High Load, High Viscosity Bearing Grease ○ Excellent performance in a wide temperature range -40°C up to 150°C

○ Mineral Oil/ Calcium-Sulphonate Complex ○ Extreme load ratings ○ Excellent water and corrosion resistance ○ Excellent mechanical stability ○ Outstanding long life

Sealed dust proof & waterproof systemNo more manual lubricationNo over- or under-lubricationCost savings up to 30%

LUBRICATION

MAINTENANCE TOOLS

Mounting Tools

Dismantling Tools

Checking & Alignment Tools

Shaft Repair Sleeves

Hydraulic Tools

Mechanical or Hydraulic Bearing Pullers

Shims Shaft Alignment Computer Pulley Alignment Computer Temperature Meters Tachometers Decibel meters Vib Checker

Mobile Hydraulic Bearing Pullers Internal Expander Pullers Bearing Splitters Chain Cutting Tools

WearPro Shaft Repair Sleeves (Sleeve4) ○ Used for repairing the worn out shaft in different applications on various industries. ○ Stainless material with thin-wall design, and high quality surface roughness. ○ Sleeve 4 contains the sleeve and assembly tool, simply and fast assembly installation.

Portable Induction Heaters Large Size Heaters MF Cable Heater Cone Heater Bearing Fitting Toolset Chain Connecting Tools

Hydraulic Cylinders Hand/Foot Pumps, Air/Electric PumpsPump Sets Presses Jacks

Nutsplitters Spreading & Lifting Tools Adjustable Workbench

MA

INT

EN

AN

CE

TO

OL

S MAINTENANCE TOOLS

SE

AL

S

SEALS

Pump Seals (Type N) ○ Special design of the shorter flex section to provide better pressure resistance.

○ Special materials and structural designs for different levels of high-pressure applications.

○ Dust lip design protects the seal from external contamination.

V-Rings ○ V-Rings are mounted on the shaft, rotate with the shaft, and seal against a perpendicular counter surface.

○ They protect bearings and radial seals in dirty and demanding applications.

Gearbox / Reducer Seals (Type C) ○ Rubber covered OD to increase the OD sealing capability.

○ Suitable for soft alloy, plastic, steel or cast iron housing materials.

○ Dust lip design protects the seal from external contamination.

Axial Face Seals ○ Axial Face Seals are mounted on the shaft, rotate with the shaft, and seal against a perpendicular counter face.

○ Metal case added on a rubber V-ring to increase rigidity and enhance protection against dust.

Piston Seals ○ For hydraulic piston applications ○ Types – UOP, HPO, HPS, HOD ○ Asymmetric & symmetric designs. ○ PTFE is used for sliding material. Low frictional resistance, eliminating stick slip and assuring high wear resistance.

Bonded Seals ○ The bonded seal is a static seal used as a sealing ring fitted under the bolt head and nut.

○ The rubber part provides good sealing capabilities and the metal part limits the compression.

Rod Seals ○ For hydraulic cylinder applications ○ Types – HRO, UIB, UIP ○ Asymmetric & symmetric designs. ○ Inhibits transmission of oil temperature to rod packing

○ PTFE is used for sliding material. Low frictional resistance, eliminating stick slip and assuring high wear resistance.

Rubber Molded Parts ○ Made of high-performance rubber compounds with excellent capabilities.

○ Molded specifically as per customer requirements or application criteria.

Wiper Seals ○ Types – VA, WP, WPK ○ Effective barrier against dirt intrusion. ○ Excellent sealing performance with lubricant retention.

○ Designed for oscillating, swivel motion. ○ Easy press-fit installation.

Rings ○ O-ring, X-ring, Square ring, D-ring, H-ring, V-ring, Backup Ring with custom shapes and sizes.

○ Complete AS568, JIS B2401 P/G/S O-rings. ○ Made of high-performance rubber compounds with excellent capabilities.

Motor Seals (Type C & G) ○ Rubber covered OD to increase the OD sealing capability.

○ Suitable for soft alloy, plastic, steel or cast iron housing materials.

○ Dust lip design protects the seal from external contamination.

○ Type G/G1 - Special design of a corrugated OD. Particularly suitable for applications where the housing material is subject to thermal expansion.

O-Ring Kit & Cord ○ AS568, JIS, Metric as well as Inch kits available.

○ Standard 70 Shore A hardness as well as customer specified durometer O-rings available.

SEALS

POWER TRANSMISSION BELTS & PULLEYS

INDUSTRIAL TIMING BELTS RAW EDGE V-BELTS & V-RIBBED BELTS

BELTS SOLUTIONS FOR OFF-ROAD VEHICLES

For Low & Medium Power RangeFor Demanding Drives

Multi-Ribbed Belts for Engines

Heavy Duty for High Acceleration

V-Ribbed for Heavy Duty Applications

Open-Ended Belts

Self-Tracking for Horizontal Drives

Open-Ended Timing Belts

For General Applications

Industrial Timing Pulleys

Heavy Duty for High Power RangeFor Heavy Duty Applications

Timing Belts

PU for Low & Medium Power Range

Double-Sided Multi-V Belts

V and V-Ribbed Belts

Combined Belts

Open-Ended Flat Belts for Lift Systems

For Heavy Duty Applications

V-Belt Pulleys Bushings

INDUSTRIAL PULLEYS & BUSHINGS

WRAPPED V-BELTS & V-RIBBED BELTS

BELTS

BE

LTS

CHAINS

CH

AIN

S

ROLLER CHAIN, CONVEYOR CHAIN & CHAIN SOLUTIONS

Pin Gear Attachment Chain

General Use Drive Chain Gen Use Small Conveyor Chain

Indexing Conveyor Chain

Gen Use Heavy Conveyor Chain

Special Large Size C. Chain

Deep Link Conveyor Chain

Waste Treatment Conveyor Chain

Sprockets for Drive Chains

Heavy-Duty Drive Chain

Surface Treated Roller Chain

Cold Resistant Roller Chain

Poly Steel Chain

Curved Chain

Chain Tensioner

Lube-Free Drive Chain Lube Free Small Conveyor Chain

Free Flow Chains

Large Size C.C. for Heavy Loads

Free Flow Large Size C. Chain

Flow Conveyor Chain

Water Treatment Conveyor Chain

Sprockets for Small C. Chains

Corrosion Resistant Small C.C.

Special Small Size C.C.

Corrosion Resistant C.Chain

Bearing Bush Conveyor Chain

Bucket Elevator Chain

Tough Roller

Sprockets for Large C. Chains

Stainless Steel Roller Chain

Titanium Roller Chain

Low Noise Roller Chain

Curved St. Steel Roller Chain

Leaf Chain

DRAG CHAINS & ENERGY CHAIN SYSTEMS

SLE Steel Strap Energy ChainAvailable in steel, stainless steel and in hardened version. It can be supplied with hole stays (SLE and SLA), foam stays (SLS) and plastic dividers (SLP) and tube stays (SLR).

Steel Tube SFKOffers cables and hoses good protection against hot chips, welding spatter and sparks. Proven in short travel distances and at low stroke rates.

Kolibri Standard ChainIs the inexpensive energy chain for light weight applications. Due to the integrated plastic connector additional mounting parts are not needed.

MARATHON SYSTEMIs a solution with energy chains with rollers for long travel. The upper part is guided by roller sets on continuous flat treads, whereby the sliding friction between the upper and lower chain part is completely avoided. Particularly suitable for Ports applications and Steel Mills.

Drag Chain ServiceIn addition to the production and delivery of ready for use energy chains and energy chain systems, we also provide - according to customer requirements - a complete service for installation and maintenance on site.

Large Chain GKAUsed for large quantities of cables and hoses with large external diameters, as well as self-supporting lengths up to 18m. Also available in stainless steel quality V4A as well as in special versions.

Plastic Tube PFRSuitable for short travel. Due to the closed design, a good optical effect is achieved. The tube is easy to shorten and lengthen. The metal coated tube is optimally for use in the field of hot chips, weld spatter or sparks.

Plastic Link Chain PLEWith aluminium stays is cheaper and lighter than the steel chain. In sliding applications the chain can be successively used in strokes up to 100 m.

Applications: machine tools, handling equipment, handling and lifting, etc.

Plastic Combi Chain PKKCombines all the advantages of energy chains to one system. The PKK can be shortened and lengthened without tools, opened, extended and closed.

CO

UP

LIN

GS

& P

OW

ER

TR

AN

SM

ISS

ION

TE

CH

NO

LO

GY

COUPLINGS & POWER TRANSMISSION TECHNOLOGY

A CouplingsB Torque LimitersC Clamping Sets & Precision JointsD Torque Measuring Technology

E Brake SystemsF Hydraulic ComponentsG Cooling SystemsH KTR in Industry

A. COUPLINGS

A1. Elastic Jaw & Pin-&-Bush Couplings

○ A1. Elastic Jaw & Pin & Bush Couplings ○ A2. Gear Couplings ○ A3. Backlash-Free Servo Couplings ○ A4. Steel Lamina Couplings ○ A5. Flange Couplings ○ A6. Magnetic Couplings ○ A7. Fluid Couplings

ROTEX® Flexible Jaw CouplingsFlexible, vibration-reducing - Axial plug-in, easy assembly – Failsafe - Torques up to 35,000 Nm - Maintenance-free, easy to inspect visually - Standard material for spiders: T-PUR®

POLY-NORM TORSIONALLY-FLEXIBLE, SHEAR-TYPE SHAFT COUPLINGS

○ Axial plug-in - Maintenance-free – Failsafe - Short design; small shaft distance dimension - NBR spider: Operative range from -30° C to +80° C, peak temperature up to +120° C - Torques up to 67,000 Nm

POLY TORSIONALLY-FLEXIBLE, SHEAR SHAFT COUPLINGSFor vibration-reducing power transmission - Axial plug-in - Maintenance-free - Not fail safe, torsionally-flexible, soft in bending - Elastomer: Operative range -30° C to +80° C, short-term up to +120° C

REVOLEX PIN & BUSH COUPLINGFailsafe - Vibration-damping - Axial plug-in - Maintenance-free - Short design; small shaft distance dimension - Torques from 3,800 to 1,220,000 Nm - Elastomers from chloroprene caoutchouc - Elastomer: Operating range from -30° C to +80° C and short-term max. +120° C

Spiders: T-PUR® ○ Temperature-resistant polyurethane ○ longer service life than polyurethane material ○ Orange (92 Shore A), Purple (98 Shore A) and Green (64 Shore D).

○ Polyurethane spiders in yellow, red and white /green will still be available.

ROTEX Standard

ROTEX Standard with KTL coat

ROTEX Taper Clamping Bush

ROTEX Clamping Ring Hubs

ROTEX Clamping Hubs

ROTEX AFN

ROTEX BFN

ROTEX A-H

ROTEX S-H

ROTEX SP ZS-DKM-C

ROTEX ZS-DKM-H

ROTEX DKM

ROTEX CFN

ROTEX DF

ROTEX DFN

ROTEX ZR

ROTEX BTAN

ROTEX SBAN

ROTEX Flexible Jaw Couplings - Variants

A2. Gear Couplings

A3. Backlash-Free Servo Couplings

A4. Backlash-Free Servo Couplings

BOWEX Gear CouplingsMaterial combination: nylon / steel - Compensation for shaft misalignment: axial, radial, angular - Axial plug-in, simplified assembly - Operative range -25° C to +100° C - Torque from 5 to 2,500 Nm

ROTEX GS Backlash-free Servo CouplingsBacklash-free, vibration-reducing jaw-type coupling - Axial plug-in - Maintenance-free - Electrically isolating – Failsafe - Torques from 0.2 to 5,850 Nm - Ambient temperatures from -50° C to +150° C possible (dependent on spider) -

RADEX-N Steel Lamina CouplingsBacklash-free, torsionally stiff and maintenance-free steel lamina coupling - Wear-free - High displacement figures - Nominal torque up to 280,000 Nm - Operating range up to 280° C - Single- and double-cardanic designs - Standard range up to shaft diameter 330 mm

GEAREX All-Steel Gear CouplingsFlexible, vibration-reducing - Axial plug-in, easy assembly – Failsafe - Torques up to 35,000 Nm - Maintenance-free, easy to inspect visually - Standard material for spiders: T-PUR®

TOOLFLEX Metal Bellow-Type CouplingMaintenance-free - Ambient temperatures from up to +200° C possible - Torques from 0.1 up to 600 Nm - Couplings for power transmission, automation, medical technology, packaging technology, machine tools

RADEX NC Servo Lamina CouplingsBacklash-free, torsionally stiff servo lamina coupling - Maintenance-free - Ambient temperatures up to +200° C possible - Torques from 2.5 to 300 Nm - Couplings for automation engineering, power transmission, medical technology

COUNTEX Shaft-Encoder CouplingsBacklash-free, torsionally stiff shaft encoder coupling - Maintenance-free - Axial plug-in - Electrically insulating - Shaft diameter up to Ø 14 mm possible - Ambient temperatures from -40° C to +160° C possible

RIGIFLEX High-Perf Steel Lamina CouplingsBacklash-free, torsionally stiff and maintenance-free steel lamina coupling - Wear-freeHigh displacement figures - Nominal torque up to 280,000 Nm - Operating range up to 280° C - Double-cardanic design - Standard range up to shaft diameter 400 mm

BOWEX Junior

BOWEX Junior M

BOWEX M

BOWEX M-C

BOWEX Corrosion Proof

BOWEX I

BOWEX AS

GEAREX FA, FB, FAB

GEAREX DA, DB, DAB

Monolastic

BOWEX Spec-I

BOWEX SD

BOWEX SD1

BOWEX SG

BOWEX SSR

BOWEX GT

BOWEX HEW Compact

GEAREX FH, DH

ROTEX SBAN

Pump Mounting Flanges

ROTEX Flexible Jaw Couplings - Variants

COUPLINGS & POWERTRANSMISSION TECHNOLOGY

CO

UP

LIN

GS

& P

OW

ER

TR

AN

SM

ISS

ION

TE

CH

NO

LO

GY

A5. FLANGE COUPLINGS

A7. FLUID COUPLINGS

A6. MAGNETIC COUPLINGS

B. TORQUE LIMITERS

BOWEX FLE-PA Torsionally Rigid Flange CouplingsFor I.C.-engines - up to an engine power of 2,500 kW - Axial plug-in, simplified assembly - Compact measurement - Torsionally-stiff

Outer Wheel DriveSmooth start-up of machines (e. g. conveyors) - Avoids over exertion of engines during the acceleration of large masses - Reduced power consumption with eased and shortened engine start-up - Protection of machines (input and output) in case of overload or blockades - Maintenance-free torque transmission since there is no mechanical transmission

- Vibration-reducing features due to oil as operating medium - Easy torque regulation via oil filling level

MONOLASTIC Flange CouplingsSingle-piece, flexible flange coupling - For the drive of diesel engine/hydraulic pump up to 250 kW - different shore hardnesses - Axial plug-in in connection with SAE and DIN pump spline shaft - Available with 3-hole and SAE mounting

RUFLEX Torque LimiterTorque limiter with high power density - Overload protection up to 12,000 Nm - High density linings for long life - Zinc-coated and yellow passivate - Easy setting of slipping torque with usual tools

KTR SI Overload SystemWith positive operation up to 8,200 Nm - Ratchet, synchronous, fail-safe and idle rotation design - High repeating accuracy - Disengagement in case of overload by limit switch - Maintenance-free - Easy assembly and torque setting

KTR SI FRE Overload SystemIdle-rotation overload system (load-separating) - High repeating accuracy - Flange design for the mounting of pulleys or sprockets - Combination with ROTEX®, GEARex® or RADEX®-N for shaft-to-shaft connections - Setting range to 60,000 Nm (higher torques on request)

MINEX-S Magnetic CouplingsContactless torque transmission with permanent magnets - Hermetic separation of the driving and driven side - Resistant to aggressive media - Torque from 0.15 to 1,000 Nm - Optionally API 685 - Frequently used in vacuum and fluid pumps

Inner Wheel DriveSmooth start-up of machines (e. g. conveyors) - Avoids over exertion of engines during the acceleration of large masses - Reduced power consumption with eased and shortened engine start-up - Protection of machines (input and output) in case of overload or blockades - Maintenance-free torque transmission - Vibration-reducing features due to oil as operating medium - Easy torque regulation via oil filling level

Pump Mounting FlangesConnecting hydraulic pumps to diesel engine - Mounting flanges SAE6 to SAE1 - Flanges are made of steel and EN-GJL-250 (GG25) for hydraulic pumps with flange connection acc. to SAE-A, -B, -C, -D and -E as types with 2 and 4 holes - Pump connection housings made of

EN-GJL- 250 (GG25) to be mounted directly to the back plate of the engine.

BOWEX ELASTIC Flange CouplingsFor I.C.-engines - up to an engine power of 5,000 kW - Axial plug-in, simplified assembly - Compact measurement - Torsionally-stiff, flexible or highly flexible

SYNTEX Backlash-Free Overload System - Overload system with positive operation up to 400 Nm - Backlash-free, torsionally-stiff - High repeating accuracy - Available with same dimensions as a ratchet and synchronous design - Safeguarding of high-quality drive units

SYNTEX with integrated sprocket

SYNTEX with pulley SYNTEX with shaft coupling ROTEX GS

C. CLAMPING SETS & PRECISION JOINTS

D. TORQUE MEASURING TECHNOLOGY

E. BRAKE SYSTEMS

CLAMPEX External Clamping SetsBacklash-free shaft-hollow shaft-connection - Simultaneous transmission of torque and axial force - Applications: hollow shafts, slip-on gears - Transmissible torques from 28 Nm to 7,000,000 Nm

CLAMPEX Internal Clamping Sets – Self-CenteringBacklash-free shaft-hub connection - Centering of shaft and hub by the clamping set - No additional hub centering required - Simultaneous transmission of torque and axial force - Transmissible torques from 6 Nm to 1,640,000 Nm

CLAMPEX Internal Clamping Sets – Not Self-CenteringBacklash-free shaft-hub connection - No additional centering between shaft and hub required - Simultaneous transmission of torque and axial force - Transmissible torques from 2 Nm to 3,000,000 Nm

CLAMPEX Rigid Shaft CouplingsBacklash-free, bending and torsionally stiff shaft-to-shaft connection - No compensation for radial and axial shaft displacements - Simultaneous transmission of torque and axial force - Transmissible torques from 62 Nm to 8,000 Nm

Clamping NutsUse of common dynamometric screwdrivers (up to approx. 100 Nm) clamping nuts - Even with big screws, e. g. M42 thread - Benefits with costs, no need for special tools for the assembly - Optimum load of screws - Ideal for narrow assemblies - For screw property classes 8.8 and 10.9.

Precision JointsSuitable for applications in engineering - Precision single joints acc. to DIN 808 - Precision double joints acc. to DIN 808 - Designed with plain bearing or needle bearing

Active Fixed Caliper Brakes

Active Floating Caliper Brakes

Passive Floating Caliper Brakes

Thruster Brakes

Yaw Brakes

Rotor Lock

COUPLINGS & POWERTRANSMISSION TECHNOLOGY

CO

UP

LIN

GS

& P

OW

ER

TR

AN

SM

ISS

ION

TE

CH

NO

LO

GY

F. HYDRAULIC COMPONENTS

Bellhousings - AluminiumBy the use of bellhousings the engine and pump shaft are optimally aligned to each other - Material aluminium: low weight with sufficient strength - Horizontal assembly in connection with KTR foot flanges possible - Bellhousings available with ventilation bore and oil bleed on request - Available from stock for the current engine-pump combinations

Bellhousings - AluminiumBy the use of bellhousings the engine and pump shaft are optimally aligned to each other - Material aluminium: low weight with sufficient strength - Horizontal assembly in connection with KTR foot flanges possible - Bellhousings available with ventilation bore and oil bleed on request - Available from stock for the current engine-pump combinations

Bellhousing PSG for servo-hydraulicBellhousing particularly suitable for servo-hydraulic drives - Flange dimensions suitable for square connection diagrams of servo motors - Suitable for highly dynamic drives

Damping Rings & AccessoriesExtremely failsafe - Use between bellhousing and pump - For the separation of structure-borne noise from pump to drive unit - Noise reduction by reflection of the structure-borne noise vibrations

Aluminium TanksNo additional painting required - With oil collecting groove moulded on periphery for collection of leakage oil - Produced for no-pressure operation - Good heat loss capacity due to high caloric conductibility - All tanks are 100% tight and may be stacked without jamming - Sealing for all tank sizes available

Steel TanksWith bore for oil-level indicator on the side - Without opening for cleaning cover - Cover machining possible according to customer´s request – Full range of accessories available

G. COOLING SYSTEMS

Oil/Air Cooler OAC

Oil/Air Cooler OAC ECO

Oil/Air Cooler OPC

Oil/Air Cooler PIK

Combined Cooler MMC Oil/Water Cooler

COUPLINGS & POWERTRANSMISSION TECHNOLOGY

FILTRATION PRODUCTS FOR OFF-ROAD EQUIPMENT & INDUSTRIAL ENGINES

LUBE, FUEL & COOLANT FILTRATION

HYDRAULIC FILTRATION

FILTRATION PRODUCT RANGE

AIR FILTRATION

Fuel Filtershelp prevent premature pump wear & injector damage by delivering clean fuel to your engine.

Coolant Filtersremove contaminants and maintain cooling system balance.

Lube Filterskeep oil clean by capturing contaminants that can cause engine damage

Hydraulic FiltrationPerformance under any pressure. Protect expensive hydraulic components with Donaldson’s complete line of spin-on, cartridge-style and in-tank hydraulic filters.

Low Pressure - rated for working pressures up to 350 psi, in-tank and in-line configurations are available.

Medium Pressure - Duramax® filters have become the industry standard for operating pressures up to 2000 psi

High Pressure - heavy-duty filters rated for pressures up to 6500 psi for critical applications

Cartridge Style - Using SynteqTM media technology, help extend the life of heavy duty equipment.

Off-Line Filtration - polishes new lubricating oils and achieves baseline ISO cleanliness levels – prior to dispensing into equipment, gearboxes and reservoirs

Air CleanersAre packed with media specially formulated to better trap dust and soot

Pre-CleanersExtend air cleaner life by preventing larger particles from reaching the filter.

Replacement Filtersdeliver superior protection for heavy-duty off-road equipment

Air Dryers

Fuel Filters

Air Filters

Hydraulic Filters

Air Cleaners

Lube Filters

Coolant Filters

Transmission FiltersCabin Air Filters

FILTRATION PRODUCTS

FIL

TR

AT

ION

PR

OD

UC

TS

AP

PL

ICA

TIO

N S

OL

UT

ION

S INDUSTRIAL GEARS &ELECTRIC MOTORS

QUARRYING & CEMENTINDUSTRY

KEY PRODUCTS FOR THE QUARRYING & CEMENT INDUSTRY

Plant Reliability is Key to Achieving Production Targets ○ Cement plants, like other mineral processing plants, face the tough conditions that come with crushing, conveying, vibrating and grinding applications. Cement plants must also contend with the extreme heat of rotary kilns and coolers. Maintaining a range of auxiliary fans, compressors and pumps is also key. High energy costs and increased environmental regulations present further challenges to productivity.

○ Kilns, Grinding Mills, Ball Mills, Pump & Gearboxes, Hydraulic Roll Press, Fans & Air Handling Units, Motors & Conveyors, Off-Road Equipment

SRBs for Vibrating Screens

TF - Wear, Seizure & Heat Resistant

Slewing Bearings Sealed Deep GrooveBall Bearings

Double Row ACBBs

Needle Roller Bearings Linear ActuatorsLong-Life Thrust Ball Bearings

4-Point (Duplex) ACBBs

High Performance SRBs

Thin Section ACBB &TRB High Performance ACBBfor Pumps

Contamination-resistantMolded Oil

Mounted Units

Extra Capacity CRBs Double Row TRBs

Plummer Blocks

Filtration Products

Drag ConveyorChain

Couplings Flange Couplings Oil/Air Cooler OAC

Reclaimer Chain Bucket ElevatorChain

Heavy-DutyChain

Corrosion-FreeChain

Large ConveyorChain

Backstop CamClutch

Taper Roller Bearings

Application-specificBearing Grease Lubrication Systems Application-specific

Bearing Grease Lubrication Systems Application-specificBearing Grease Lubrication SystemsMaintenance Tools Shaft Repair Sleeve

Maintenance Tools Shaft Repair Sleeve Maintenance Tools Shaft Repair Sleeve

Sealing Solutions Sealing Solutions Sealing Solutions

Segmented prockets

KEY PRODUCTS FOR INDUSTRIAL GEARS KEY PRODUCTS FOR ELECTRIC MOTORS

Industrial gears are used in many different sectors and often face dynamic operating conditions twinned with high shock loads in some cases. They are usually located between the drive on one side and the process technology on the other. In this case, industrial gears primarily serve to reduce input speeds and increase torques for the processes in question.

Electric motors and generators place completely different demands on bearings compared to gears. Knocks and fluctuating torques rarely occur. Different speeds are usually the key consideration when it comes to selecting bearings.

CRBs for Large Gearboxes

Electrically InsulatedCeramic Brgs Creep-Free DGBBs

Electrically InsulatedCeramic Brgs

High Capacity SeriesDGBBs

High Capacity Series DGBBs

Hybrid Bearings withCeramic Balls DGBBs with CM

Hybrid Bearings withCeramic Balls

High Capacity CRBs

High Capacity CRBs

Single Row DGBBs

Taper Roller Bearings

Spherical Roller Thrust

Backstop Clutch Brake Systems

Couplings Couplings

High PerformanceSRBs High Performance SRBs

TF - Wear, Seizure &Heat Resistant

V-Belts & V-Ribbed Belts Timing Belts

AP

PL

ICA

TIO

N S

OL

UT

ION

S FANS & BLOWERSPUMPS & COMPRESSORS

FOOD & BEVERAGEINDUSTRY

KEY PRODUCTS FOR THE FOOD & BEVERAGE INDUSTRY

Plant Reliability is Key to Achieving Production Targets ○ With the continuous pressure to optimize production, reduce costs and comply with strict health, safety and environmental regulations, food and beverage processors and OEMs are turning to manufacturers and suppliers to find out about new technologies that can address these business challenges.

○ Food Preparation, Processing by Applying Heat, Processing by Removing Heat, Post Processing & Packaging

Stainless Steel Bearings

Sealed SRBs

Low NoiseBallscrews

Thermoplastic PolyHousings

Zinc or Nickel PlatedHousings

Food Grade Units with Molded Oil

Zinc or Nickel PlatedHousings

Lubrication Units Linear Guides

Anti-CorrosiveFluororesin Bearings

Dust-resistant Linear Linear Actuators

Nickel-Coated Bearings

Bearing Units

High Temperature Sealed DGBBs

Single Row ACBBs

Ultra High Temp Brgs

Small Conveyor Chain

Couplings Brake Systems

Corrosion ResistantC.C.

Self Lubricating Chain Corrosion-Free ChainHeavy-Duty Chain Segmented Sprockets Energy Chain

Contamination-resistantMolded Oil

Single Row DGBBs

KEY PRODUCTS FOR FANS & BLOWERS KEY PRODUCTS FOR PUMPS & COMPRESSORS

Fans and blowers are strategically relevant plant components for a number of industry segments, such as the cement, steel and petrochemical sectors, mining and quarrying, waste removal, and the food industry. A distinction is made between two different types of fans – centrifugal and axial – depending on the direction in which the air or gas flows.

A wide variety of industries depends on their Pumps & Compressors for the reliability & productivity of their production

○ Pumps – Chemicals, Papermaking, Irrigation, Food & Beverage ○ Compressors – Factory Equipment, Air Supply Equipment, Air

Conditioning, Refrigerators & Cold Storage Warehouses

High Load Capacity CRBs

ELCOMP for ScrewCompressors

Needle Roller Bearings Electrically InsulatedCeramic Brgs

Hi-Speed, Lo-Noise ACBBs Double Row ACBBS forPumps

4-Point (Duplex) ACBBs

Ball Scews

Extra Capacity CRBs

Couplings

Couplings

Hybrid Bearings

Plummer Blocks

Hybrid Bearings

Ceramic Ball Bearingsfor Fans

Brg Units for Air Handling

High Performance Roller Bearings

Deep Groove Ball Brgs

Deep Groove Ball Brgs

Mounted Units

High TemperatureSealed DGBBs

Double Row ACBBs

Filtration ProductsApplication-specificBearing Grease Lubrication Systems Maintenance Tools Shaft Repair Sleeve Sealing Solutions Application-specific

Bearing Grease Lubrication Systems

Application-specificBearing Grease Lubrication Systems

Sealing Solutions

Sealing SolutionsMaintenance Tools Shaft Repair Sleeve

Maintenance Tools Shaft Repair SleeveV-Belts & V-Ribbed Belts Timing Belts

AP

PL

ICA

TIO

N S

OL

UT

ION

S

Heavy-Duty Chain Self Lubricating Chain Corrosion-Free Chain Sprockets Stainless Steel Roller Chain

Attachment Chain

OIL, GAS & PETROCHEMICALINDUSTRY

STEEL & METALSINDUSTRY

KEY PRODUCTS FOR THE STEEL & METALS INDUSTRY KEY PRODUCTS FOR THE OIL & GAS AND PETROCHEMICAL INDUSTRY

The operational environment for our components is unique to steel making, comprising particle contamination, water and heat. In addition, components may have to cope with heavy or shock loads and vibration, operational speeds ranging from extremely slow to extremely high, coupled with rapid acceleration and deceleration. This makes for a demanding operational environment that is not found in other applications.

Minimising production stoppages and maximising productivity are crucial in the petrochemical industry. The machine components used in this sector – such as pumps, compressors, electric motors, blowers and ventilators – are particularly susceptible to change. These components contain bearings which have to work reliably and precisely, even in challenging conditions.

Water-Tough RollneckBearings

Sealed Clean SRBs

High Performance Roll Neck Bearings

Ultra-Large Split Bearings

CRBs with Aligning Rings

4-Row CRBs with Stud-Type Cage

Sealed Clean CRBs forSintering Pallets

Full Complement CRBs forCrane Sheaves

TRBs with Aligning Rings

Sealed Clean 4-Row TRBs

SRBs for Continuous Caster Guide Rolls

Couplings Explosion Proof (ATEX)Couplings

Contamination-resistantMolded Oil

V-Belts & V-Ribbed Belts V-Belts & V-Ribbed BeltsTiming Belts Timing BeltsOpen-Ended Timing Belts Open-Ended Timing Belts

Plummer Blocks Split Bearing Units forSegmented Rolls

Extra Capacity CRBs

Couplings Brake Systems

Filtration Products Filtration ProductsApplication-specificBearing Grease Lubrication Systems

Application-specificBearing Grease Lubrication SystemsMaintenance Tools Shaft Repair Sleeve Maintenance Tools Shaft Repair SleeveSealing Solutions Sealing Solutions

High Performance ACBBs High C apacity DGBBs Extra Capacity CRBs

Full Complement CRBs for Crane Sheaves

BMPC ACBBs for Pumps

Plummer Blocks Slewing Bearings

Creep-Free DGBBs

Duplex Ball Brgs withBrass Cage

Single Row DGBBs

High Performance SRBs

Taper Roller Bearings

High Temperature Sealed DGBBs

Double Row ACBBs

High Load Capacity CRBsLNG Pump Bearings ELCOMP for ScrewCompressors

ACBBs with Brass Cage

Large Conveyor Chain Heavy-Duty Chain Self Lubricating Chain SprocketsCorrosion-Free Chain Energy ChainBackstop Cam Clutch

Related Documents