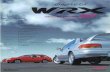

High efficiency deep shoulder milling for steel, stainless steel, cast iron, non-ferrous & exotic material High Performance Milling Systems Exotic Materials Non-ferrous Metal Cast Iron Stainless Steel Steel WRX Endmill

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

High efficiency deep shoulder milling for steel, stainless steel, cast iron, non-ferrous & exotic material

Hig

h Pe

rfor

man

ce M

illin

g Sy

stem

s

ExoticMaterials

Non-ferrousMetal

CastIron

StainlessSteelSteel

WRX Endmill

• Long cutting edges are arranged in multiple stages to enable high efficiency milling

• Optimized cutting positions provide low cutting resistance and low vibration

• Dual level cutting edge design reduces number of passes

• Lead groove and special pocket shape offer smooth chip evacuation and high body rigidity

• Low edge supporting face reduces bottom edge breakage and provides high reliability

Features & Benefits

Cutting Resistance6000

5000

4000

3000

2000

1000

0

-1000WRX type Competitor

Main component force

Feed component force

Back component force (-)

Back component force (+)

Cutting resistancereduced by 30%

Res

ista

nce

(N)

Material: Medium carbon steelTool: WRX2025E2725SFM=330 IPT=0.006 Cutting Width=0.394D.O.C.=1.000 Dry

Vibration Comparison

WRX

Competitor

Vibr

atio

n A

mpl

itude

Vibr

atio

n A

mpl

itude

Time

Time

LowVibration

Material: Medium carbon steelTool: WRX3080RS5332SFM=490 IPT=0.008 Cutting Width=0.197D.O.C.=1.575 Dry

WRX3000 27mmWRX2000 18mm

Short type cutting edge lengthShort type cutting edge length

Standard endmill cutting edge length

Dual Level cuttingedge designreduces numberof passes

Product Range

CuttingEdge Series Code

Cutting EdgeLengthin (mm)

Cutter Dia.in (mm)

Cutter Type

ApplicableInsert

StandardType

WRX2000/20000E 1.063 ~1.417 (27 ~ 36) 0.787 ~ 1.575 (20 ~ 40) ShankAXMT1235

WRX2000/20000R 1.417 (36) 1.575 ~ 1.969 (40 ~ 50) ShellWRX3000/30000E 1.574 ~ 2.087 (40 ~ 53) 1.575 ~ 1.969 (40 ~ 50) Shank

AXMT1705WRX3000/30000R 2.087 (53) 1.969 ~ 3.937 (50 ~ 100) Shell

ShortCuttingEdgeType

WRX2000/20000E0.709 (18)

0.787 ~ 1.575 (20 ~ 40) ShankAXMT1205

WRX2000/20000R 1.575 ~ 1.969 (40 ~ 50) ShellWRX3000/30000E

1.063 (27)1.575 ~ 1.969 (40 ~ 50) Shank

AXMT1705WRX3000/30000R 1.969 ~ 3.937 (50 ~ 100) Shell

Unique Clamping Design

1) Unique claming combines spigot and drive

2) Easy position adjustment minimizes deterioration of run-out precision

3) Available as an integrated unit with an arbor

Special Tooling

Integrated Arbor Indexable Head

Characteristics

Low edge supporting surface

Special pocket shape

Lead groove

Clss

ificati

on

WorkMaterial

Hard

ness

(HB)

Chipb

reak

er

Grades

ACP100 ACP200 ACP300 ACK200 ACK300 DL1000

Feed Rate - IPT (mm/tooth)

.004 .006 .008 .004 .006 .008 .004 .006 .008 .004 .006 .008 .004 .006 .008 .004 .006 .008

Cutting Speed - SFM (m/min)

P

Carbon steel125 G 1049

(320)984

(300)918

(280)984

(300)918

(280)853

(260)918

(280)853

(260)787

(240)

190 G 787(240)

721(220)

656(200)

721(220)

656(200)

590(180)

656(200)

590(180)

524(160)

Hardened carbon steel

250 G 656(200)

590(180)

524(160)

590(180)

524(160)

459(140)

524(160)

459(140)

393(120)

270 G 524(160)

459(140)

393(120)

492(150)

426(130)

360(110)

426(130)

360(110)

328(100)

300 G 393(120)

328(100)

262(80)

328(100)

262(80)

196(60)

262(80)

196(60)

164(50)

Low alloy steel 180 G 721(220)

656(200)

590(180)

656(200)

590(180)

557(170)

590(180)

557(170)

492(150)

Hardened alloysteel

275 G 459(140)

393(120)

328(100)

426(130)

360(110)

328(100)

360(110)

328(100)

262(80)

300 G 426(130)

360(110)

295(90)

360(110)

295(90)

262(80)

328(100)

262(80)

196(60)

350 G 341(104)

262(80)

209(64)

288(88)

236(72)

183(56)

236(72)

183(56)

131(40)

High alloy steel 200 G 656(200)

590(180)

524(160)

590(180)

524(160)

459(140)

524(160)

459(140)

393(120)

Hardened high alloy steel 325 G 328(100)

262(80)

196(60)

262(80)

196(60)

164(50)

196(60)

164(50)

98(30)

M StainlessSteel

200 G 557(170)

492(150)

426(130)

459(140)

426(130)

360(110)

426(130)

360(110)

328(100)

240 G 459(140)

393(120)

328(100)

393(120)

328(100)

295(90)

328(100)

295(90)

229(70)

180 G 590(180)

524(160)

459(140)

524(160)

459(140)

426(130)

459(140)

426(130)

360(110)

KCast iron 200 G 787

(240)721

(220)656

(200)721

(220)656

(200)590

(180)

Nodular cast iron 280 G 524(160)

459(140)

393(120)

459(140)

393(120)

328(100)

S Super alloys G 164(50)

98(30)

164(50)

98(30)

N Aluminum alloys 3280(1000)

2624(800)

1968(600)

Recommended Cutting ConditionsTool: WRX3050E5342 Insert: AXMT170508PEER-GD.O.C. = 1.969 in. (50 mm)Cutting Width = 0.3937 in. (10 mm)Dry

Part/Work Material Stainless Steel Part

Tool

Manufacturer Sumitomo CompetitorBody WRX3040E4042 ø40Insert AXMT170508PEERG 0.59 in (15mm)

Grade ACP300 PVDTool Dia. in (mm) 1.57 (40) 40

Total Teeth 9 6Effective Teeth 3 2

Conditions

Cutting Speed 4.92 sfm (125mm/min) 4.92 sfm (125mm/min)

Feed 0.008 ipt (0.2 mm/t) 0.008 ipt (0.2 mm/t)Axial Cutting Depth 1.575 in (40mm) 1.575 in (40mm)Radial Cuting Depth 0.1969 in (5mm) 0.1969 in (5mm)

Dry/Wet Wet WetResults Tool Life/ Corner 20 5 to 10

Evaluation Stable machining with double the competitor’s tool life and no breakage

Application Example

WRX20000 Endmill Cutter Bodies - Weldon Shank - INCH

CatalogNumber St

ock Dimensions (inch)

Steps EffectiveTeeth

Total Teeth

Weightlbs(kg)øDc øDs L l1 l2 ap

WRX21000E100-150 ● 1.000 1.000 4.250 1.950 2.300 1.500 4 2 8 1.10 (0.5)

WRX21250E125-175 ● 1.250 1.250 4.500 2.200 2.300 1.750 5 3 15 1.48 (0.7)

WRX21500E125-200 ● 1.500 1.250 4.800 2.500 2.300 2.126 6 4 24 1.82 (0.8)

ap

øDs

h7

øDc

L

l2l1

WRX2000 Endmill Cutter Bodies - METRIC

CatalogNumber St

ock Dimensions (mm)

Steps EffectiveTeeth

Total Teeth

Weightlbs(kg)øDc øDs L l1 l2 ap

WRX2020E1820* 20 20 120 40 80 18 2 2 4 0.66 (.03)

WRX2020E3620 20 20 130 45 85 36 4 1 4 0.66 (.03)

WRX2025E1825* 25 25 130 45 85 18 2 3 6 0.88 (.04)

WRX2025E2725 25 25 130 45 85 27 3 2 6 0.88 (.04)

WRX2032E1832* 32 32 140 50 90 18 2 4 8 1.76 (.08)

WRX2032E2732 32 32 130 45 85 27 3 3 9 1.54 (.07)

WRX2040E1832* 40 32 160 40 120 18 2 5 10 2.43 (1.1)

WRX2040E3642 40 42 130 45 85 36 4 4 16 2.65 (1.2)

ap

Lf

a

bl

l1

ød H

7

øDc

ød2

WRX2000 Shell Mill Cutter Bodies - METRIC

CatalogNumber St

ock Dimensions (mm)

Steps EffectiveTeeth

Total Teeth

Weightlbs(kg)øDc ød ød2 Lf l1 l2 a b ap

WRX2040RS1816* 40 16 9 50 28 18 8.4 5.6 18 2 5 10 0.66 (0.3)

WRX2040RS3616 40 16 9 55 28 18 8.4 5.6 36 4 4 16 1.10 (0.5)

WRX2050RS1822* 50 22 11 50 26 20 10.4 6.3 18 2 5 10 0.88 (0.4)

WRX2050RS3622 50 22 11 55 26 20 10.4 6.3 36 4 4 16 1.10 (0.5)

Inserts for WRX20000/2000 Series

CatalogNumber

Coated Carbide Carbide DLC rEin

(mm)ACP100

ACP200

ACP300

ACK200

ACK300 H1 DL

1000AXMT123504PEERG ● ● ● ● ● .016

(0.4)AXMT123504PEERH ● ● ● ● ●AXMT123508PEERG ● ● ● ● ● .031

(0.8)AXMT123508PEERH ● ● ● ● ●AXMT123512PEERG ● ● ● ● ● .047

(1.2)AXMT123512PEERH ● ● ● ● ●AXET123502PEFRS ● ● .008

(0.2)

AXET123504PEFRS ● ● .016(0.4)

AXET123508PEFRS ● ● .031(0.8)

.260 in(7.0 mm)

.472 in(12.0 mm)

RE

.138 in(.358 mm)

Hardware

Wrench ScrewTRDR08IP BFTX0306IP

● = USA Stocked Item = Worldwide Warehouse Item

*Short Cutting Edge Type

WRX30000 Endmill Cutter Bodies - Weldon Shank - INCH

CatalogNumber St

ock Dimensions (inch)

Steps EffectiveTeeth

Total Teeth

Weightlbs(kg)øDc øDs L l1 l2 ap

WRX32000E125-250 ● 2.000 1.250 5.000 2.700 2.300 2.500 5 3 15 2.56 (1.2)

WRX30000 Shell Mill Cutter Bodies - INCH

CatalogNumber St

ock Dimensions (inch)

Steps EffectiveTeeth

Total Teeth

Weightlbs(kg)øDc øDs L l b ap a

WRX32500R100-250 ● 2.500 1.000 2.750 1.023 0.236 2.500 0.375 5 4 20 3.42 (1.6)

WRX33000R125-300 ● 3.000 1.250 3.375 1.260 0.315 3.000 0.500 6 5 30 6.24 (2.8)

ap

L

l2l1

øDs

h7

øDc

aøDc

ød H

7

ap

L

t

1

WRX3000 Endmill Cutter Bodies - METRIC

CatalogNumber St

ock Dimensions (mm)

Steps EffectiveTeeth

Total Teeth

Weightlbs(kg)øDc øDs L l1 l2 ap

WRX3040E2732* 40 32 180 60 120 27 2 3 6 2.65 (1.2)

WRX3040E4042 40 42 150 65 85 40 3 3 9 2.87 (1.3)

WRX3050E2732* 50 32 180 60 120 32 2 4 8 3.09 (1.4)

WRX3050E5342 50 42 165 75 90 53 4 3 12 3.97 (1.8)

WRX3000 Shell Mill Cutter Bodies - METRIC

CatalogNumber St

ock Dimensions (mm)

Steps EffectiveTeeth

Total Teeth

Weightlbs(kg)øDc ød ød2 Lf l1 l a b ap

WRX3050RS2722* 50 22 11 50 26 20 10.4 6.3 27 2 4 8 0.88 (.04)

WRX3050RS5322 50 22 11 70 26 20 10.4 6.3 53 4 3 12 1.32 (.06)

WRX3063RS2722* 63 22 11 50 26 20 10.4 6.3 27 2 5 10 1.54 (.07)

WRX3063RS5327 63 27 13.5 70 30 23 12.4 7 53 4 4 16 2.20 (1.0)

WRX3080R27254* 80 25.4 13 50 31 25 9.5 6 27 2 6 12 2.43 (1.1)

WRX3080RS5332 80 32 17 85 36 26 14.4 8 53 4 5 20 4.85 (2.2)

WRX3100R27317* 100 31.75 17 63 39.5 32.5 12.7 8 27 2 7 14 4.41 (2.0)

WRX3100RS5340 100 40 21 85 36 30 16.4 9.5 53 4 6 24 7.72 (3.5)Inserts for WRX0000/3000 Series

CatalogNumber

Coated Carbide Carbide DLC rEin

(mm)ACP100

ACP200

ACP300

ACK200

ACK300 H1 DL

1000

AXMT170504PEERG ● ● ● ● ● .016(0.4)

AXMT170508PEERG ● ● ● ● ●.031(0.8)AXMT170508PEERH ● ● ● ● ●

AXMT170508PEERL ● ● ● ●AXMT170512PEERG ● ● ● ● ● .047

(1.2)AXMT170512PEERH ● ● ●

AXMT170516PEERG ● ● ● ● ● .063(1.6)

AXMT170520PEERG ● ● ● ● ● .079(2.0)

AXMT170530PEERG ● ● ● ● ● .118(3.0)

AXMT170532PEERG ● .126(3.2)

AXET170502PEFRS ● ● .008(0.2)

AXET170504PEFRS ● ● .016(0.4)

AXET170508PEFRS ● ● .031(0.8)

.402 in(10.2 mm)

.689 in(17.54 mm)

RE

.219 in(5.59 mm)

Hardware

Wrench ScrewTRDR15IP BFTX0409IP

● = USA Stocked Item = Worldwide Warehouse Item

*Short Cutting Edge Type

CAT.WRX.03/10

Huntsville Branch5650 Sanderson Street NWSuite JHuntsville, AL 35805Phone: (256) 895-2845Fax: (256) 895-3150

Torrance Branch21221 South Western AvenueSuite 200Torrance, CA 90501Phone: (800) 950-5202Fax: (310) 782-0211

Headquarters1001 Business Center DriveMount Prospect, IL 60056-2181P.O. Box 545, Mt. Prospect, IL 60056-0545Phone: (800) 950-5202Phone: (847) 635-0044Fax: (847) 635-7866http://www.sumicarbide.com

Detroit Branch14496 Sheldon Road #230Plymouth, MI 48170Phone: (800) 239-5177Phone: (734) 451-0200Fax: (734) 451-5338

Cincinnati Branch4450 Carver Woods DriveCincinnati, OH 45242-5545Phone: (800) 879-1887Phone: (513) 891-4000Fax: (513) 794-2911

Sumitomo Hardmetal Mexico (SHMM)

Avenida Universidad #1703-AFracc. Lomas del CampestreAguascalientes, AGS MexicoPhone: 011-52-449-993-2740 Fax: 011-52-449-993-2753

Related Documents