-

Subtitle

W.J. van Zeist1

M. Marinussen1

R. Broekema1

E. Groen1

A. Kool1

M. Dolman2

H. Blonk1

1 Blonk Consultants

2 Wageningen University and Research Centre

November, 2012

LCI data for the calculation

tool Feedprint for greenhouse

gas emissions of feed

production and utilization

Wet Milling Industry

-

Blonk Consultants

Gravin Beatrixstraat 34

2805 PJ Gouda

the Netherlands

Telephone: 0031 (0)182 579970

Email: [email protected]

Internet: www.blonkconsultants.nl

Blonk Consultants helps companies, governments and civil society organisations put sustainability into practice. Our team of dedicated

consultants works closely with our clients to deliver clear and practical advice based on sound, independent research. To ensure optimal

outcomes we take an integrated approach that encompasses the whole production chain.

-

LCI data for the calculation

tool Feedprint for greenhouse

gas emissions of feed

production and utilization

Wet Milling Industry

W.J. van Zeist1

M. Marinussen1

R. Broekema1

E. Groen1

A. Kool1

M. Dolman2

H. Blonk1

1 Blonk Consultants

2 Wageningen University and Research Centre

November, 2012

-

Table of contents

2.1 Introduction 1

2.1.1 Context of this document & reading guide 1

2.1.2 Overview of products and allocation principles 1

2.1.3 Structure of data 1

2.1.4 Glossary of terms 2

2.1.5 References 2

2.2 By-products from the wet milling of maize 3

2.2.1 By-products from wet milling of maize 3

2.2.2 Note on allocation 3

2.2.3 Sourcing 3

2.2.4 Flowcharts 4

2.2.5 Inputs 6

2.2.6 Production of maize germ oil 10

2.2.7 Maize germ oil: Mass balance 11

2.2.8 Maize germ oil: Inputs 12

2.2.9 Maize germ oil: Allocation 12

2.2.10 References 13

2.3 Wet milling of sorghum 14

2.3.1 Introduction 14

2.3.2 References 14

2.4 Wet milling of starch potatoes 15

2.4.1 Note on allocation 15

2.4.2 By-products from potato starch production 15

2.4.3 Sourcing 15

2.4.4 Flowcharts 16

2.4.5 Mass balance 16

2.4.6 Inputs 17

2.4.7 Allocation 17

2.4.8 Energy use and allocation for heat treated and dried products 18

2.4.9 References 18

2.5 Wet milling of wheat 19

2.5.1 By-products from wet milling of wheat 19

2.5.2 Note on allocation 19

2.5.3 Sourcing 19

-

2.5.4 Flowcharts 20

2.5.5 Mass balance 20

2.5.6 Inputs 23

2.5.7 Allocation 23

2.5.8 References 23

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

1

2.1 Introduction

2.1.1 Context of this document & reading guide

This document is part of the background documentation for the FeedPrint program and database.

Background information of this project, underlying methodology and justification thereof, can be found

in the FeedPrint methodology document. These chapters focus only on the processing step of crops into

the feed materials. Information on origin of crops is given, but details on cultivation and transportation

(to and from the processing facility) are described in separate documents: the cultivation of each crop is

described in the cultivation background reports similar to this one (Marinussen et al, 2012), whereas

transportation is described in the Feedprint methodology report (Vellinga et al, 2012).

Each chapter can be read and interpreted as a standalone set of LCI data, which covers the country of

crop cultivation, the country of processing, mass balances, energy inputs (and outputs, if applicable), as

well as data needed for the allocation of the by-products. In some cases, multiple processes can follow

one another with multiple allocation steps. In these cases, the data is entered into the database by

following these specific processing steps consecutively. Usually (but not restrictively) the data entered are

relative to an input of 1000 kg of crop product.

2.1.2 Overview of products and allocation principles

Each chapter in this document describes a different animal feed material production process within the

wet milling industry. Unless noted otherwise, the processes described in this document are treated as a

single unit process with multiple valuable output products, where allocation approach 1 is applied (see

5.3, Vellinga et al, 2012) in which all products are treated as valuable by-products to which upstream

emissions will be allocated according to economic, energy, or mass allocation.

2.1.3 Structure of data

This document contains tables that reflect those data applied in the FeedPrint program. Additionally,

tables with background data are supplied, which are often inventories of encountered literature. Only the

tables that are used as data for the FeedPrint database and calculations are given a table number (see for

an example Table 2.1.1). Other tables that are not used in the FeedPrint database are not numbered and

have a simpler layout, see the example below.

Table 2.1.1 Example default inputs table for FeedPrint database. Output Values Unit

Best estimate Error (g2)

Electricity 88 1.4 MJ/ton

Natural gas 245 1.4 MJ/ton

Example of background data not directly used in FeedPrint database

Source Data found Remarks

Reference 1 80 MJ/ton Older data from 1 processing facility.

Reference 2 90 MJ/ton Newer data from multiple facilities.

There are a number of recurring types of tables, usually in the following order:

1) Definition of feed materials related to the process;

2) Estimation of countries of origin of the crop and countries of processing;

3) Mass balances for the process;

4) Energy or material inputs needed for the process;

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

2

5) Allocation factors for the outputs from the process.

Unless explained otherwise in a specific chapter, these five tables are present for each process. Additional

sections or figures can give information on, for example, the definition of the process represented with a

flowchart. Each section also contains the references for cited sources. The usual structure of a section is

that first the default inputs for the FeedPrint database are presented, with the rest of the section

explaining in detail which data sources were used and why.

There are a number of different types of error ranges that can be given for each data point, and these are

applied for the energy and auxiliary inputs. More background information can be found in the overall

methodology document (Vellinga et al. 2012), which also explains the decision process followed to arrive

at the error ranges.

2.1.4 Glossary of terms

Below is a list of terms with definitions as applied in this document.

DMC Dry matter content in g/kg. GE Gross Energy content in MJ/kg.

2.1.5 References

CVB-table: see appendix 1 in Vellinga et al. (2012)

European Commission. (2011). COMMISSION REGULATION ( EU ) No 575 / 2011 of 16 June 2011

on the Catalogue of feed materials. Official Journal of the European Union, (L 159), 2565.

Marinussen et al (2012) Background data documents on cultivation. Blonk Consultants. Gouda, the

Netherlands

Vellinga, T.V., Blonk, H., Marinussen, M., van Zeist, W.J., de Boer, I.J.M. (2012) Methodology used in

feedprint: a tool quantifying greenhouse gas emissions of feed production and utilization

Wageningen UR Livestock Research and Blonk Consultants. Lelystad/Gouda, the Netherlands.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

3

2.2 By-products from the wet milling of maize

2.2.1 By-products from wet milling of maize

Maize, also named corn, is a cereal grain1 and is known for being a high-yielding variety of cereal grains.

There are multiple types of maize which are used for various purposes like grain, cattle, seed, or cobs for

consumption. In this section, only the wet milling of the industrially processed dent corn is described.

Dent corn, getting its name from the dent in the crown of the seed, is grown more than any other type of

corn. Millions of tons of grain are produced from dent corn, and is used for human and industrial use,

and for livestock feed. The starch reaches the summit of the seed, and the sides are also starchy. The

denting is caused by the drying and shrinking of the starch. The dent corn grown in the Corn Belt came

from a mix of New England flints and gourseed (an old variety of corn grown by the Indians in

southeaster North America).

By-products from the wet milling process can come from North America as well as Europe, but since

there is no specific regional data the choice has been made to focus on reporting one general mass

balance. Feed materials derived from wet milling of maize are described below. The products from the oil

production process originate from oil extraction from dried maize germ, a by-product of wet milling.

Table 2.2.1 By-products from maize wet milling in the CVB list are: name CVB Process DMC

(g/kg) Starch (g/kg)

Maize germ meal extruded Oil production 887 299

Maize germ meal feed expeller Oil production 897 336

Maize germ meal feed extruded Oil production 875 326

Maize gluten meal Wet milling 901 177

Maize glutenfeed Crude Protein 200-230 Wet milling 893 127

Maize glutenfeed Crude Protein230 Wet milling 890 102

Maize glutenfeed fresh+sillage Wet milling 418 283

Maize solubles Wet milling 480 7.5

Maize starch Wet milling 876 836

Maize bran Wet milling 873 280

2.2.2 Note on allocation

For the wet milling of maize it was decided to apply detailed sub-process allocation (approach 2 for

allocation, see 5.3, Vellinga et al, 2012). The specific energy use for by-products is fully allocated to those

products (e.g. drying). The prices and composition data of intermediate products are derived form end

products on the basis of a deduced dry matter value of the different end-products

2.2.3 Sourcing

An inventory of the origin of feed materials for the Dutch feed industry indicated that four countries

supply the major part of this material. We assumed a division amongst these countries according to the

shares listed in Table 2.2.2. This means for example that 25% of the maize wet milling feed material is

sourced from Dutch wet milling factories which sources the maize for 34% of the USA, 33% of Germany

and 33% of France. Both the origin of wet milling feed materials form industry and the input of maize in

that industry fluctuates over the years.

1 Maize is known as corn in countries such as the United States, the English-speaking provinces of Canada, Australia and New Zealand.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

4

Table 2.2.2 Estimated countries of origins of the feed materials. Processing in: the Netherlands USA Germany France

percentage 25% 35% 20% 20%

Crop-country

the Netherlands

USA 34% 100% 25%

Germany 33% 50%

France 33% 25% 100%

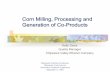

2.2.4 Flowcharts

Corn

1.Receving and

Steeping

2. Degermination

3. Grinding and

Screening

4. Starch-Gluten

Separation

Corn Oil

Production

Drying

Dry germ

Starch

Steepwater/

steep liquor

Corn oil

Fiber/Bran

Gluten meal

Starch

Fiber/Bran

Gluten

Process

Main products

Input product

1 kg

Germ meal

Gluten feed

meal

Dewatering

Dewatering

Drying

5. Mixing

and drying

Figure 2.2.1 Flowchart of wet milling of maize. For each main product, a drying or dewatering step is included.

The main feed products of the wet milling of maize are corn oil, fiber, gluten, and starch. Depending on

the prices of these products though, the manufacturer can decide to alter processing routes, resulting in a

different mix of alternative products such as corn steep liquor, dry germ and ethanol (not shown in the

figure). Yields of the different by-products vary through the years so yields from processing found in

literature should be qualified as typical yields.

Gluten feed is composed by mixing bran/fiber and steep liquor. Depending on many factors steep liquor,

germ and bran/fiber can also be final products, but typically they are processed as described above

Corn oil is often included as a main product in maize wet milling studies. However, it is usually not

processed on the same site, and additional animal feed by-products (maize germ meal and expeller) arise

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

5

from this next step. It is therefore treated here as a separate industry, with the maize germ as described in

the first part as an input2.

Since the data from Galatisky is detailed enough to perform a step-by-step allocation at each sub-process,

it was opted to apply the mass balance from this source. The elaboration of this is found in the next

section, while below a number of the mass balances are presented, in order to show that the mass balance

by Galitsky is reasonable in general3.

Table 2.2.3 Mass balance maize wet milling (excluding corn oil production) Input DMC (g/kg) Mass, as is Mass, dm

Corn 850 1000 1000

output

Maize germ 920 70 75

Maize gluten feed bran/fibre steep liquor

900 950 480

175 105 115

185 120 65

Maize gluten meal 900 55 56

Maize starch 920 630 680

The mass balances are expressed on a dry matter basis, since often an undisclosed amount of water is

used at a number of different points during the process.

The mass balance described by Kim and Dale (2002) (see table A) was difficult to interpret. Adding up

and comparing the dry matter going in and dry matter coming out of the process described by Kim and

Dale leads to the observation that the mass balance is not complete, because more dry matter goes into

the process than seems to come out.Ethanol is produced by fermentation of starch. The chemical

equation of this fermentation process is:

2 C6H10O5 + 2 H2O 4 C2H5OH + 4 CO2

Table 2.2.4 :Mass balance according to Kim and Dale (2002) (A = original, B = deduced to input of starch used for ethanol) A B

The amount of dry matter of starch corresponding with 0,295 kg of ethanol is 0,508 kg (see equation of

fermentation process). Replacing ethanol by starch in the mass balance of table B above almost completes

the dry matter coming out of the process. The minor difference might be explained by rounding errors.

2 Other sources (e.g, http://www.ag.ndsu.edu/pubs/ansci/dairy/as1127.pdf) also describe germ meal as a separate

product from the feed by-products directly from wet milling. 3 Galitsky (2003) presents typical yields of corn components. The mass balance is on a dry matter basis, but no

information is given on exact dry matter contents and these have been deduced from other sources.

IN kg dry matter

corn 0,85

OUT

ethanol 0,295

corn oil 0,038

corn gluten meal 0,047

corn gluten feed 0,201

IN kg dry matter

corn 0,794

OUT

starch 0,508

corn oil 0,038

corn gluten meal 0,047

corn gluten feed 0,201

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

6

Ramirez (2009) has also published a mass balance for the wet milling of maize. The two values are derived

from conventional and enzymatic wet milling. Ramirez has quite detailed information on the processes

involved and the evolution of dry matter contents of the intermediate products. Although unfortunately

no direct information on energy usage during the process steps is presented. The data were used in

constructing the intermediate mass balances (especially dry matter contents) for the process allocation

steps.

Mass balance according to Ramirez (2009), from 1 tonne corn, dry matter basis Product DM% Value (mass, dm) Unit

Min Max

Maize germ 92 77 80 Kg

Maize gluten feed 90 194 185 Kg

Maize gluten meal 90 62 64 Kg

Maize starch 92 667 671 Kg

Balance arises after taking into account loses of 2.4% in the prehandling of corn.

2.2.5 Inputs

Galitsky (2003) reports a rather detailed table on energy consumption of the wet milling of maize. Here,

we will follow the allocation of subprocess and intermediate product prices. The energy data by Galtisky

gives us enough information to do this. What follows will be a step-by-step breakdown of the production,

including allocation steps. Additional energy usage such as drying steps will be included as well, but not

treated as an allocation step. In this final breakdown, the mass balance from Galitsky is used, which seems

prudent as energy usage originates from the same source. The dry mater contents of (intermediate)

products have been taken from Galitsky, Ramirez and the CVB list. According to Ramirez, corn enters at

85% dry matter. Protein contents and GE (all on dry matter basis) have been calculated from the CVB

list.

Prices for allocation are derived from Faostat and Eurostat prices on bran/fiber, germ, starch and gluten

feed/meal. These were recalculated based on dry matter content and applied in the intermediate process

steps. Often the intermediate product can be directly related to a final product (such as wet germ resulting

in the final dried germ) and the price of the final product is applied (on a dry matter basis). Some

intermediate corn products arise and the price components are derived from the final product. For

example, in processing step 4, the intermediate corn product from step 3 named intermediate wet corn

(step 3) enters and the process produces starch and gluten. From the mass balance we know that 680 kg

starch (at 0.39/kg) and 56 kg gluten (at 0.18/kg) is produced from this intermediate product. From

these proportions the price of the intermediate product is calculated at 0.37/kg (resulting from

56*0.18+680*0.39)/740). The prices (and composition data) are all derived in this way.

Table 2.2.5 Product category Price (euro/kg) DMC (g/kg) Price on DM basis

Bran or fiber 0.181 875 0.21

Germ 0.570 900 0.63

Starch 0.345 875 0.39

Gluten feed/meal 0.162 900 0.18

The tables below show all the steps involved in corn wet milling, including energy usage. As the moisture

content of intermediate products vary significantly during processing and is highly uncertain, the mass

balance is based on the dry matter content.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

7

Step 1: Corn receiving, steeping and steepwater evaporation

Step 1a: Corn receiving and steeping

Parameter Value Unit

Inputs Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Corn 1000 850 17.7

Energy inputs Error (g2)

natural gas 192 1.3 MJ/tonne corn

electricity from the grid 31 1.3 Mj/tonne corn

Outputs Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Steepwater (wet) 65 10% 100 0.18 14.1

Intermediate wet corn (step 1) 935 10% 450 0.37 17.9

Step 1b: Steepwater dewatering

Parameter Value Unit

Inputs Mass (dm) DMC (g/kg)

Steepwater (wet) 65 100

Energy inputs Error (g2)

natural gas 1192 1.3 MJ/tonne corn

electricity from the grid 25.5 1.3 MJ/tonne corn

Outputs (CVB Name) Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Maize Solubles 65 10% 480 0.18* 14.1

* [Editors note: This price should be double-checked; specific price for maize solubles).]

Step 2: Degermination (Germ recovery) and germ drying

Step 2a: Degermination

Step 2b: Germ drying

Parameter Value Unit

Inputs Mass (dm) DMC (g/kg)

Germ (wet) 75 500

Energy inputs Error

(g2)

natural gas 167 1.3 MJ/tonne corn

Diesel 164 1.3 MJ/tonne corn

electricity from the grid 22 1.3 MJ/tonne corn

Parameter Value Unit

Inputs Mass (dm) DM (g/kg) Price (/kg) GE (MJ/kg)

Intermediate wet corn (step 1)

935 450 0.37 17.9

Energy inputs Error (g2)

electricity from the grid 51 1.3 MJ/tonne corn

Outputs Mass (dm) DMC (g/kg)

Price (/kg) GE (MJ/kg)

Germ (wet) 75 10% 500 0.63 20

Intermediate wet corn (step 2)

860 10% 240 0.35 17.7

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

8

Outputs Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Germ (dried)* 75 920 0.63 20

* Dried germ are used as input for the oil crushing process described later in this document.

Step 3: Grinding and screening (Fibre recovery) and fibre dewatering

Step 3a: Grinding and screening

Parameter Value Unit

Inputs Mass (dm)

DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Intermediate wet corn (step 2) 860 240 0.35 17.7

Energy inputs Error (g2)

electricity from the grid 105 1.3 Mj/tonne corn

Outputs Mass (dm)

DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Fibre/Bran (wet) 120 250 0.21 16.7

Intermediate wet corn (step 3) 740 270 0.37 17.8

Step 3b: Fibre dewatering

Parameter Value Unit

Inputs Mass (dm) DM (g/kg)

Fibre/Bran (wet) 120 250

Energy inputs Error (g2)

electricity from the grid 18 1.3 MJ/tonne corn

Outputs Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Fibre/Bran (dewatered) 120 400 0.21 16.7

Step 4: Starch gluten separation (Gluten recovery), gluten drying and starch drying

Step 4a: Gluten recovery

Parameter Value Unit

Inputs Mass (dm) DM (g/kg)

Price (/kg)

GE (MJ/kg)

Intermediate wet corn (step 3) 740 270 0.37 17.8

Energy inputs Error (g2)

electricity from the grid 49 1.3 MJ/tonne corn

Outputs Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Gluten (wet) 56 340 0.18 17.9

Starch (wet) 680 250 0.39 17.1

Loss 4 Loss in overall process.

Step 4b: Gluten drying

Parameter Value Unit

Inputs Mass (dm) DM (g/kg)

Gluten (wet) 56 340

Energy inputs Error (g2)

Diesel 174 1.3 MJ/tonne corn

electricity from the grid 25 1.3 MJ/tonne corn

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

9

Outputs (CVB Name) Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Maize gluten meal 56 900 0.18 17.9

Step 4c: Starch drying

Parameter Value Unit

Inputs Mass (dm) DM (g/kg)

Starch (wet) 680 250

Energy inputs Error (g2)

Diesel 1319 1.3 MJ/tonne corn

electricity from the grid 154 1.3 MJ/tonne corn

Outputs (CVB Name) Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Maize Starch 680 920 0.39 17.1

Step 5. Mixing fiber with steep liquor for gluten feed.

Step 5a: Maize glutenfeed production (no drying)

Parameter Value Unit

Inputs Mass (dm)

DMC (g/kg)

Fibre/bran (dewatered) 120 400

Steep liquor (concentrated, Maize Solubles) 65 480

Output (CVB Names) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Maize glutenfeed fresh+sillage 185 420 0.18 16.2

Step 5b: Maize glutenfeed production (with drying)

Parameter Value Unit

Inputs Mass (dm) DMC (g/kg)

Fibre/bran (dewatered) 120 400

Steep liquor (concentrated, Maize Solubles) 65 480

Energy inputs for drying step Error (g2)

Diesel 1096 1.3 MJ/tonne corn

electricity from the grid 47.5 1.3 MJ/tonne corn

Outputs (CVB Names) Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Maize glutenfeed crude protein 230

185 185 185

900 0.18 16

Step 5c: Maize dried bran production (with drying)

Parameter Value Unit

Inputs Mass (dm) DMC (g/kg)

Fibre/bran (dewatered) 120 400

Energy inputs for drying step Energy input

Error (g2)

Diesel 711 1.3 MJ/tonne corn

electricity from the grid 31 1.3 MJ/tonne corn

Outputs (CVB Names) Mass (dm) DMC (g/kg)

Price (/kg)

GE (MJ/kg)

Maize bran 120 900 0.21 16.8

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

10

Maize bran is the dried gluten feed without steep liquor (maize solubles) added. It is listed here as

comparable as maize glutenfeed as the same drying step applies, but with reduced energy usage as the

total amount dried has changed.

Detailed input and output data for end products.

Data below on composition is used in the detailed breakdown of the process in the section above. Also

included are the overall energy usage without the process breakdown. The European Commission (EC)

has published a reference document on best available techniques in the Food, Drink and Milk Industries

(2006) which indicates an energy use for the wet milling of maize comparable to the energy use reported

by Galitsky. The EC reports a variation in energy use between a minimum and a maximum. These values

have also been used to get an insight on the error margin of the values by Galitsky, which we have chosen

to be 30%.

Table 2.2.6 Input data inventory Product Parameter Value Unit Data quality Ref

Mean Min Max Rel Com TRC GSp TeC

Energy use: fuels diesel 33,2 kg/kg 1 1 3 3 2 a

natural gas 1360 950 2215 MJ/kg 1 4

1 5

3 3

3 2

2 2

a (mean) b (min-max)

Energy use: electricity electricity from the grid 113,8 100 200 kWh/kg 1 4

1 5

3 3

3 2

2 2

a (mean) b (min-max)

a) Galistky C., Worrel E., Ruth M., 2003, Energy Efficiency Improvement and Cost Saving Opportunities for the Corn

Wet Milling Industry, University of California, USA.

b) European Commission, 2006, Reference document on best available techniques in the food, drink and milk industries.

2.2.6 Production of maize germ oil

The germ that originates (in dried form) from the wet milling process, is further processed to extract the

oil content, which is particularly high in this part of maize. This produces, as a by-product, germ meal or

expeller.

The processing of germ to germ (corn) oil and germ meal is a fairly straightforward process where the oil

is extracted via a solvent extraction process with hexane (usually preceded by a light mechanical pressing

step), or via a mechanical pressing method.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

11

Figure 2.2.2 Flowchart of germ processing

2.2.7 Maize germ oil: Mass balance

Typical oil contents for maize germ (dried) is up to 50% (http://www.westfalia-

separator.com/applications/renewable-resources/maize-germ-oil.html) while typical values lie around

45% (http://www.aaccnet.org/cerealchemistry/backissues/1989/66_273.pdf)

If the dry matter and oil contents of the oilseed are known, the mass balances can be deduced for both

the mechanical cold pressing (which leaves more oil in the residue, typically 75% of the oil is extracted)

and oil extraction with an organic solvent (which leaves very little oil, typically 98% of the oil is extracted).

The numbers in Table 2.2.7 and Table 2.2.8 are based on these extraction rates (while also taking into

account de deshelling), while allowing for a loss of around 1.5% (see Schmidt (2007)). Oil content data is

found in a range from around 40 (Johston, 2005) to 48 (Ramirez, 2009) procent. A 44% oil content is

used as a basis for the mass balance below.

The dry matter contents of dried germ are calculated backwards based on the germ meal and expeller

production and moister content from the CVB. The moisture content is within the expected range for

dried germ (see for example http://www.satake.co.uk/cereal_milling/maize_products.htm)

Table 2.2.7 Default mass balance of germ processing (cold pressing, from 1 tonne of germ).

Input DMC (g/kg) Mass (kg)

Germ (dried) 920 1000

Output

Germ expeller 900 655

Germ oil 1000 330

Loss (mostly water) 0 15

*Germ originating from corn wet milling process as described in 6.2.5.

Table 2.2.8 Default mass balance of germ processing (solvent extraction, from 1 tonne of germ).

Input DMC (g/kg) Mass (kg)

Germ 920 1000

Dried maize germ

Solvent extraction

Crude oil Meal

Mechanical pressing

Crude oil Expeller

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

12

Output

Germ meal 880 555

Germ oil 1000 430

Loss (mostly water) 0 15

*Error margin determined by pedigree matrix, see generic oilseed processing.

2.2.8 Maize germ oil: Inputs

Rapeseed processing is used as a basis of comparison to obtain general oilseed figures on energy

requirements for processing of germ. Thus, values obtained for the CFPAN project for rape seeds are

used (see chapter Generic oilseed production in the background data report on the crushing industry

(Part 1/7). These can then be recalculated based on the energy required for the extraction of a unit of oil.

Table 2.2.9 and Table 2.2.10 show the inputs needed for processing 1 tonne of germ, calculated in this

manner.

Table 2.2.9 Default inputs for oilseed processing (pressing, for 1 tonne of germ, based on rapeseed) for the production germ expeller.

Input Values Unit

Best estimate Error (g2)

Electricity (pressing) 212 1.3 MJ/ton

Based on values from Croezen (2005) and Hamelinck (2008), recalculated relative to oil production.

* Error margin to be calculated based on pedigree matrix.

Table 2.2.10 Default inputs for oilseed processing (solvent extraction, for 1 tonne of germ, based on rapeseed) for the production germ meal.

Input Values Unit Ref

Best estimate Error (g2)

Electricity (extraction) 148 1.3 MJ/ton b

Natural gas (extraction) 760 1.3 MJ/ton b

Hexane 1.0 1.3 kg/ton c

b: Based on values from Croezen (2005), Schmidt (2007), and Hamelinck (2008), recalculated relative to oil production.; c:

Schmidt (2007)

2.2.9 Maize germ oil: Allocation

All items on the CVB list, except for the unprocessed germ, are represented in the mass balances and

allocation data tables below. Maize germ meal prices derived from Faostat (Cake of Maize) average prices

from 2005 2009 (prices not available for 2007 and 2008). Germ oil prices are from Eurostat (Corn oil).

Table 2.2.11

Pressing Name CVB Mass DMC (g/kg) Price

(euro/ton) GE (MJ/kg)

Germ expeller Maize germ meal feed expeller (13600) 655 900 0.11 15.1

Germ oil NA 330 1000 0.91 37.0

Extraction

Germ meal Maize germ meal extruded (13500) Maize germ meal feed extruded (13700)

555 880

0.11 14.1

Germ oil NA 430 1000 0.91 37.0

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

13

2.2.10 References

Croezen, H. en B. Kampman 2005. Op (de) weg met pure plantenolie? De technische, milieuhyginische en

kostengerelateerde aspecten van plantenolie als voertuigbrandstof. Report 2GAVE-05.05. CE Delft.

CVB-table: see appendix 1 in Vellinga et al. (2012)

European Commission, 2006, Reference document on best available techniques in the food, drink and

milk industries.

Galistky C., Worrel E., Ruth M., 2003, Energy Efficiency Improvement and Cost Saving Opportunities

for the Corn Wet Milling Industry, University of California, USA.

Hamelinck, C., K. Koop, H. Croezen, M. Koper, B. Kampman, G. Bergsma 2008. Technical specification:

Greenhouse gas calculator for biofuels. Version 2.1b. Ecofys CE Delft.

Johnston, David B, Mcaloon, Andrew J, Moreau, Robert A, Hicks, Kevin B. Composition and Economic

Comparison of Germ Fractions from Modified Corn Processing Technologies. JAOCS, Vol. 82, no. 8

(2005).

Kim S., Dale B.E., 2002, Allocation Procedure in Ethanol Production System from Corn Grain, Michigan

State University, USA.

National Academy of Sciences,1971, Atlas of nutritional data of United States and Canadian feeds

Ramirez (2009), Enzymatic corn wet milling: engineering process and cost model, Biotechnology for

biofuels, january 2009.

Singh, VijaySchmidt, J. H. 2007. Life cycle assessment of rapeseed oil and Ph.D. thesis, Part 3: Life cycle inventory

of rapeseed oil and palm oil. Department of Development and Planning, Aalborg University, Aalborg.

University of Missouri Exntention, april 2011, Feed prices of by-products sorted by product:

http://agebb.missouri.edu/dairy/byprod/AllProducts.asp

USDA: http://www.nal.usda.gov/fnic/foodcomp/search/

Vellinga, T.V., Blonk, H., Marinussen, M., van Zeist, W.J., de Boer, I.J.M. (2012) Methodology used in

feedprint: a tool quantifying greenhouse gas emissions of feed production and utilization

Wageningen UR Livestock Research and Blonk Consultants. Lelystad/Gouda, the Netherlands.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

14

2.3 Wet milling of sorghum

2.3.1 Introduction

Sorghum gluten meal is included as a number of sources indicate that the wet milling of sorghum is quite

comparable to that of maize. This is valid for the processes involved as well as the resulting products.

Since only one, relatively unimportant, feed ingredient is derived from sorghum, it is included here as a

similar product to those arising from corn wet milling. See:

- C. Wayne Smith,Richard A. Frederiksen. 2001. Sorghum: origin, history, technology, and

production.

- Ping Yang and Paula Seib. 1995, Low-Input Wet-Milling of Grain Sorghum for Readily

Accessible Starch and Animal Feed. Cereal Chem. 72(5):498-503

Therefore, sorghum gluten meal can be considered a substitute of maize gluten meal, which is discussed

in the chapter on maize wet milling. Obviously upstream emissions from sorghum cultivation can be

applied instead of maize cultivation.

Table 2.3.1 By-products from sorghum wet milling in the CVB list are: name CVB Process DMC (g/kg) Starch (g/kg)

Sorghum gluten meal Wet milling 900 245

Thus, for the process description, inputs and outputs, and allocation, the chapter on maize wet milling

applies, specifically the by-product Maize gluten meal which is the maize version of Sorghum gluten

meal.

2.3.2 References

C. Wayne Smith,Richard A. Frederiksen. 2001. Sorghum: origin, history, technology, and production.

Ping Yang and Paula Seib. 1995, Low-Input Wet-Milling of Grain Sorghum for Readily Accessible Starch

and Animal Feed. Cereal Chem. 72(5):498-503

Vellinga, T.V., Blonk, H., Marinussen, M., van Zeist, W.J., de Boer, I.J.M. (2012) Methodology used in

feedprint: a tool quantifying greenhouse gas emissions of feed production and utilization

Wageningen UR Livestock Research and Blonk Consultants. Lelystad/Gouda, the Netherlands.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

15

2.4 Wet milling of starch potatoes

2.4.1 Note on allocation

Unlike for the wet milling of maize, not enough detailed information was uncovered to allocate according

to subprocesses in the wet milling of potatoes.4 Thus, the wet milling is described as a single unit process.

It should be noted that the European starch industry has informed us that, in the beginning of 2012, a

detailed report on energy usage in the industry will be publicly released. It is our intention to update the

default values in this document when this report becomes available.

2.4.2 By-products from potato starch production

Feed materials derived from the potato starch production are:

name CVB DMC (g/kg)

Starch (g/kg)

Potato protein Crude ASH 10 905 54

Potato starch dried 800 800

Potato pulp pressed 165 165

Potato juice concentrated 577 697

Potato pulp Crude Protein95 881 246

Potato starch heat treated and dried 875 745

According to Roelof de Weerd potato pulp crude protein, which is mentioned in the CVB-table, is hardly produced

any more by this industry. Roquette in France is to his knowledge the only producer of potato pulp crude protein

in Europe. Potato starch heat treated is produced in another process than is being done in this industry. For sake of

completeness, however, these products will be included, with an estimate on the amount of energy needed for drying

the products to the listed moisture content.

2.4.3 Sourcing

It is assumed that the Dutch feed industry sources the feed materials in the countries that are listed in

Table 2.4.1.

Table 2.4.1 Estimated countries of origins of the feed materials

Processing in: the Netherlands

percentage 100%

Crop-country

Germany 30%

the Netherlands 70%

4 Although and older source (Blonk, 1997), does mention an estimation of energy use in a number of processes. However, as the source is somewhat outdated, it was decided not to incorporate these data

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

16

2.4.4 Flowcharts

Figure 2.4.1 Flowchart of potato starch production (as is).

The first stage in potato processing is a cleaning stage in which the tare is removed from the potatoes.

Then the potatoes are grinded and the fibers are extracted. From the remaining substance the starch and

fruit juice are separated. The fruit juice can be a final product from processing but can also be further

processed producing a protein meal and protamylase (also called concentrated fruit juice). Protamylase is a

thick fluid substance, which can be used as a fertilizer.

2.4.5 Mass balance

Various mass balances have been found in literature, providing information on varying output products

(Blonk 1997, Rosenau 1979, Karup Kartoffelmehl Fabrik (2002-2003)). However, most literature was

found to be outdated, and superior information was retrieved from an industry expert of AVEBE, which

represents a large part of the feed rawe materials being consumed in the Dutch sector. The figures

endorsed by the industry expert are generally in agreement with average figures from the older sources

and are considered broadly applicable. They are presented below in the default mass balance. This mass

balance will be applied to the Netherlands with an error of 10%, and for Germany and Belgium with an

error of 20%.

Table 2.4.2 Default mass balance per tonne of potatoes. Input DMC (g/kg) (kg/tonne)

Potatoes 260 1000

Output DMC (g/kg) Best estimate (kg/tonne)

Starch potatoes

Cleaning of

potatoes

Grinding of

potatoes

Tare

Extraction of fibers

Fibers

Starch

Fruit juice

Separation

process

Starch refinery

Protein

Protamylase

Starch

Additional products

Process

Input product

Main products

1 kg

0,238 kg

0,140 kg

0,016 kg

0,054 kg

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

17

Potato Starch 800 238

Potato fibers/ pulp 165 140

Potato protein 900 16

Protamylasse/ concentrated fruit juice 560 54

2.4.6 Inputs

Table 2.4.3 gives the default values for energy usage in potato starch processing. These values will be

underpinned in the remainder of the text.

Table 2.4.3 Default values for energy inputs unit process I Product Parameter Value Unit

Best estimate

Min Max

Energy use: fuels natural gas 0.79* 0.32 1.27 MJ/kg

Energy use: electricity electricity from the grid

0.00* 0.04 0.08 kWh/kg

* Best estimate energy usage is Dutch industry data based on a facility with a CHP, hence no electricity is

listed as input. This input translates to 0.08 kWh and 0.51 MJ natural gas per kg.

The tables below give background information on composition and references for the energy usage

included. For potato starch wet milling, reference values are found in the EC (2006) BREF document,

which give a range of values for energy inputs. The best estimate is information for the Dutch industry

obtained from AVEBE.

Table 2.4.4 Inventory data potato starch processeing Energy use: fuels diesel 0,0016 kg/kg 2 1 3 1 2 a

natural gas 0,079 0,32 1,27 MJ/kg 2 4

1 1

3 5

1 5

2 2

c (mean) b (min-max)

Energy use: electricity electricity 0,00 0,04 0,08 kWh/kg 2 4

1 1

3 5

1 5

2 2

c (mean) b (min-max)

C-contents are based on reference h.

a) Blonk et al.., 1997.

b) European Commission (2006)

c) AVEBE (2011)

2.4.7 Allocation

Table 2.4.5 Data for allocation By-product Name CVB Mass DMC

(g/kg) Economic Fraction*

GE (MJ/kg)

Potato protein Potato protein Ruw ASH 10 (34920)

16 900 2 20,930

Potato starch Potato starch dried (34700) 238 800 1 13,592 Potato fibers/ pulp Potato pulp pressed (53600) 140 165 0.035 2,917 Protamylasse/ concentrated fruit juice

Potato juice concentrated (35000) 54 560 0.05 7,989

* Economic fraction are relative prices provided by AVEBE.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

18

2.4.8 Energy use and allocation for heat treated and dried products

The input table below concerns the potato starch production by-products that are not specifically listed

but are dried varieties of potato pulp (potato pulp crude protein and Potato starch heat treated). There

is no specific information available on how much of this is produced. It is, however, possible to estimate

the energy needed to dry these products from approximately 20% dry matter content in the pulp or wet

starch, which can be subsequently added separately as an input for this specific category. Based on (Roe,

2003) the energy use for drying ranges from 3 6 MJ per kg water evaporated. For drying potatoes from

the 60% dry matter to 88% (up until 60% usually happens via significantly more efficient mechanical

process), this amounts to 920 to 1920 MJ of heat (assumed to be produced with natural gas) per tonne

potatoes.

Table 2.4.6 Default input/output of for drying by-product. Product Parameter Value Unit

Input: Wet potato by-product Amount 1000 kg

DMC 165 g/kg

Natural gas for heat 0.92 (min) 1.92 (max) MJ/kg

Output: DMC (g/kg) Amount (kg)

Potato pulp Crude Protein95 (34820) Potato starch heat treated and dried (79800)

880 186

A: (Nemecek & Kgi, 2007),

As these products likely arise form wet low value by-products, we treat these within the scope of

allocation approach 3 (see 5.3, Vellinga et al, 2012) and no upstream allocation takes place towards these

residual by-products prior to drying. Thus, only the energy use for drying and subsequent transportation

will be taken to be taken into account. No further information on allocation is therefore required.

2.4.9 References

AVEBE (2011), personal communication with Roelof de Weerd.

Blonk H., Lafleur M., van Zuijts H., 1997, Screening LCA on potato starch, IVAM Environmental

Research, Amsterdam.

CVB-table: see appendix 1 in Vellinga et al. (2012)

European Commission, 2006, Reference document on best available techniques in the food, drink and

milk industries.

Eurostat: http://epp.eurostat.ec.europa.eu/newxtweb/submitdimselect.do

Karup Kartoffelmehl Fabrik (2002-2003):

http://www.lcafood.dk/processes/industry/potatoflourproduction.htm

Rosenau J.R., Whitney F., 1979, Low wastewater potato starch/protein production process, Industrial

Environmental Research Laboratory, Cincinnati, Ohio.

USDA: http://www.nal.usda.gov/fnic/foodcomp/search/

Vellinga, T.V., Blonk, H., Marinussen, M., van Zeist, W.J., de Boer, I.J.M. (2012) Methodology used in

feedprint: a tool quantifying greenhouse gas emissions of feed production and utilization

Wageningen UR Livestock Research and Blonk Consultants. Lelystad/Gouda, the Netherlands.

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

19

2.5 Wet milling of wheat

2.5.1 By-products from wet milling of wheat

Feed materials derived from wet milling of wheat are:

name CVB DMC (g/kg)

Starch (g/kg)

Wheat gluten meal 930 63

Wheat gluten feed 906 205

Wheat bran 883 146

Wheat starch tot 300 275 301

Wheat starch tot 400 256 262

Wheat starch tot 600 224 49

2.5.2 Note on allocation

Unlike for the wet milling of maize, not enough detailed information was uncovered to allocate according

to subprocesses in the wet milling of wheat. The manner of allocation is thus chosen to be approach 1 as

described in the methodology document (see 5.3, Vellinga et al, 2012). Thus, only input/output data

covering the overall process is included.

It should be noted that the European starch industry has informed us that, in the beginning of 2012, a

detailed report on energy usage in the industry will be publicly released. It is our intention to update the

default values in this document when this report becomes available.

2.5.3 Sourcing

The Dutch feed industry source the feed materials in the countries that are listed in Table 2.5.1.

Table 2.5.1 Estimated countries of origins of the feed materials.

Processing in: the Netherlands Belgium Germany

percentage 80% 10% 10%

Crop-country

France 25%

Germany 35% 100%

Denmark 10%

UK 25%

Belgium 100%

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

20

2.5.4 Flowcharts

Figure 2.5.1 Flowchart of wet milling of wheat

The main products of the wet milling of wheat are bran, vital gluten, wheat gluten feed and starch slurry.

Depending on the current prices of these products though, de manufacturer can make the decision to

alter processing resulting in another variety of products. Altering processing can lead to other products

like pure starch or to alterations in for instance protein, starch and dry matter contents of products.

2.5.5 Mass balance

Below, the default mass balance for wet milling of wheat is shown. As explained below, it is difficult to

construct one accurate mass balance due to large varieties of components and process outputs. The upper

and lower boundaries are therefore quite uncertain.

Table 2.5.2 Default mass balance (in kg, from 1 tonne of wheat). Output DMC (g/kg) Mass

Wheat bran 900 176

Bra

n

Wheat

Dry milling Bran

Dough Making

Vital Gluten

Separation

Dewatering and

DryingVital Gluten

Starch Separation

Evaporation

Stripping

DryingWheat Gluten

Feed

Starch slurry

Main products

Process

Input product

1 kg

0,18 kg

0,10 kg

0,08 kg

0,54 kg

Additional products

Starch

Slurry 0,10 kg

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

21

Wheat protein/ gluten 950 93

Wheat gluten feed 900 78

Wheat starch 880 540

Wheat slurry 210 419

Various mass balances have been found in literature, providing information on varying output products.

One overall mass balance is elaborated for the five main products from the wet milling of wheat. Due to

incomplete data or variations in processing and for instance dry matter content of process outputs it is

unclear what the most likely mass balance is. By combining all mass balances, including protein and starch

contents a mass balance has been constructed.

Table 2.5.3 Mass balance constructed based on Westfalia Seperator Industry and industry experts and based on protein and starch content.

The following mass balance has been found in a presentation given by dr. W. Witt, M. Seiler and B.

Schiemann by Westfalia Separator Industry.

Table 2.5.4 Mass balance according to Westfalia Separator Industry

In the process described by Westfalia Separator Industry the first step is the dry milling of wheat in order

to produce wheat flour. This step is not described in this presentation. A more detailed mass balance is

given below. First the dough is prepared using wheat flower and water. The dough enters a 3 phase

decanter/ 2 gear drive adding more water and separating b-starch, gluten, pentosanes and a rest product

which is added to the starch slurry. The pentosanes are also added to the starch slurry. The b-starch and

gluten are treated in the gluten screen system separating the gluten from the starch. The b-starch is

combined with the rest of the starch slurry. The gluten is treated in a gluten finisher. A rest product from

the gluten finisher is transported back to the gluten screen system.

Table 2.5.5 Detailed mass balance according to Westfalia Separator Industry

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

22

Personal communication with an industry expert in 2009 resulted in the following mass balance:

Table 2.5.6 Mass balance according to industry experts (2009)

This process includes dry milling of wheat in which the bran is separated from the wheat flower (82%).

The wheat flower enters the next process which results in a protein rich gluten fraction, a starch fraction

and starch slurry.

According to another industry expert (2004) the mass balance of the wet milling of wheat looks like this:

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

23

Table 2.5.7 Mass balance according to industry experts

2.5.6 Inputs

Below the default energy inputs for the wet milling wheat are listed. The energy values are from European

Commission (2006), which should give a reliable range of energy uses for the European industry.

Table 2.5.8 Eergy inputs for wet milling of wheat. Product Parameter Value

Mean Min Max

Energy use: fuels natural gas 3,78 2,88 4,68 MJ/kg

Energy use: electricity electricity from the grid 1,26 0,72 1,80 MJ/kg

2.5.7 Allocation

It is likely that the in order to process various types of starch the process and the mass balance will also

slightly vary. We expect that the allocation factor might be different for the three types of wheat starch.

The price per type of wheat starch will probably also be different per type. For now there is not enough

data available to make a well based differentiation between these products.

Table 2.5.9 Allocation data By-product CVB Name Mass (kg) DMC (g/kg) Price

(euro/kg)a GE (MJ/kg)

Wheat bran Wheat bran (20700) 176 900 0.116 9.04

Wheat protein/gluten Wheat gluten meal (21100) 93 950 0.775 15.48

Wheat gluten feed Wheat gluten feed (21200) 78 900 0.85 17.6

Wheat starch NA 540 880 0.25 16.9

Wheat starch slurry Wheat starch tot 300 (80210) Wheat starch tot 400 (80010) Wheat starch tot 600 (59500)

419 210 0.02 2

a. Industry experts, 2004, personal communication, Blonk Milieu Advies database.

2.5.8 References

CVB-table: see appendix 1 in Vellinga et al. (2012)

European Commission, 2006, Reference document on best available techniques in the food, drink and

milk industries.

Industry experts, 2004, personal communication, Blonk Milieu Advies database.

Industry experts, 2009 personal communication, Blonk Milieu Advies database.

National Academy of Sciences,1971, Atlas of nutritional data of United States and Canadian feeds

-

FeedPrint background data report on processing, version 2012, part 3/7: Wet milling

24

Ponsioen T., van der Flier S., Blonk H., 2009, Broeikasgasemissies voedergrondstoffen Nutreco, Blonk

Milieu Advies, Gouda.

Punter G., et. al., 2004, Well to Wheel evaluation for production of ethanol from wheat, Low carbon

vehicle partnership

University of Missouri Exntention, april 2011, Feed prices of by-products sorted by product:

http://agebb.missouri.edu/dairy/byprod/AllProducts.asp

USDA: http://www.nal.usda.gov/fnic/foodcomp/search/

Vellinga, T.V., Blonk, H., Marinussen, M., van Zeist, W.J., de Boer, I.J.M. (2012) Methodology used in

feedprint: a tool quantifying greenhouse gas emissions of feed production and utilization

Wageningen UR Livestock Research and Blonk Consultants. Lelystad/Gouda, the Netherlands.

Westfalia Separator Industry, Presentation: Comparison of wet milling and dry milling by Dr. E. Witt, M.

Seiler and B. Schiemann.