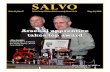

THE SALVO Vol. 14, No. 3 U.S. Army Watervliet Arsenal March 31, 2014 How many companies put their CEO’s initials on their products? We do and it speaks volumes about our confidence in our quality! Quality Control Story on Page 3 Photo by John B. Snyder

Watervliet Arsenal Newsletter: The Salvo 31 March 2014

May 07, 2015

This is the U.S. Army Watervliet Arsenal's monthly newsletter called The Salvo. The Salvo contains the latest stories and information that pertains to the Army's manufacturing center at Watervliet. The Watervliet Arsenal is an Army-owned and operated manufacturing center having established operations in upstate New York in 1813.

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

THE SALVO

Vol. 14, No. 3 U.S. Army Watervliet Arsenal March 31, 2014

How many companies put their CEO’s initials on their products?

We do and it speaks volumes about our confidence in our quality!

Quality Control Story on Page 3

Photo by John B. Snyder

Page 2 Salvo March 31, 2014

The Arsenal Salvo is an authorized monthly publication for members of the Department of Defense. Contents of the Salvo are not necessarily the official views of, or an endorse-ment by the U.S. Government, the Department of Defense, the Department of the Army, or the Watervliet Arsenal. News may be submitted for publication by sending articles to Public Affairs Officer, 1 Buffington Street, Bldg. 10, Watervliet, NY 12189, or stop by office #102, Bldg. 10, Watervliet Arsenal. The editor may also be reached at (518) 266-5055 or by e-mail: [email protected]. The editor reserves the right to edit all information submitted for publication.

Commander, Col. Lee H. Schiller Jr.Public Affairs Officer, John B. SnyderEditor, John B. SnyderPhotographer: John B. Snyder

Arsenal Facebook Page @http://on.fb.me/sq3LEm

Lee H. Schiller Jr.Commanding

Manufacturer 6

Commander’sCorner

During last month’s Diversity Day Luncheon, I was very pleased by the significant number of arsenal employ-ees who not only attended the event, but attended it for the right reason ̶ to celebrate our workforce regardless of its race, creed, or gender. Achieving a diverse workforce, where everyone is treated equally, is not only an arsenal goal, it also is re-quired if we are to stay competitive in the defense market where competition will be extremely tough in the near future. The bottom line is that recruiting from a larger pool of applicants will make us better able to hire the best and brightest who will be critical to ensuring our long-term viability. And as much as we promote diversity, we are not yet where we need to be in regards to our workforce reflecting the demographics of our local community. Nevertheless, we have led the way in the Army promoting diversity since our humble beginnings more than 200 years ago. Something dramatic happened in the military in 1972, all Army military occupational specialties opened to Women’s Army Corps (WAC) officers and enlisted women except those that might require combat training or duty. I suspect that when that news hit the arsenal there were many who thought “What took the Army so long.” After all, women have been a part of our workforce since our products were first manufactured during the War of 1812. There are many women who are part of our workforce who directly or indirectly support each cannon, mortar, and howitzer product that leaves our gate. This is a far cry from the more than 3,000 women who worked here during World War II. Nevertheless, arsenal women’s significance

to the accomplishment of our mission today is no less im-portant than it was 70 years ago or even 200 years ago. And as our nation recently closed out its celebration of Black History Month, I thought about the great African Americans who are part of our workforce. African Ameri-cans have been a significant part of our Army since 1776. And some believe that given Troy, N.Y. was the birthplace of the American Industrial Revolution that African Ameri-cans were not only part of that revolution but also part of the arsenal’s transformation from a maker of saddles to a maker of cannons. Whether you have worked here one year or forty years, our values of acceptance and accommodation cannot be taken for granted. The arsenal was founded on these prin-ciples, which are not only historic, they are also beacons of light that will guide future generations of arsenal workers.

Page 3 Salvo March 31, 2014

Arsenal seeks to raise its quality, confidence of infantrymen

By John B. Snyder

(From left) Fred Campbell, a quality control team leader at the arsenal asks Thomas Larkin, a laboratory manager with Talon Test Laboratories who led the training, a question regarding the transducers that identify potential indicators of a defect. Mike Merrill, a quality control inspec-tor, is listening in. Inset photo: Assembler Anthony Aini stamping the commander’s initials into the end of a 120 mm tube, which signifies the confidence the arsenal has in its quality.

Story continues on page 4, Quality

The arsenal recently announced that it was bringing on line more than $26 million of new or enhanced manufacturing capability this fiscal year. Although this is great news to the arsenal workforce, it should be better news to the United States infantry. Some of the new manufacturing machines will allow the arsenal to become more efficient. For example, a new million dollar computer-controlled, dual-spindle machine will be able to perform multiple machining functions, whereas, the machine it will replace could only perform one function. This will save a significant amount of direct labor hours due to a reduction in the number of times a machinist will need to set up an operation. To an infantryman, however, the fact that the arsenal is more efficient probably is no concern of his. He simply wants a weapon system that is reliable, troop friendly, and will maintain a competitive edge over potential adversaries. There is one other consideration, however, that infantrymen demand in their mortar systems ̶ that

they can fire their mortars without concern that their weapon system will cause them harm. After all, every second during a fire mission is critical and the last thing anyone wants is for a Soldier to hesitate, even for a second, due to his concern that his weapon system may not be safe to fire. It is with this last consideration where the arsenal’s behind the scenes efforts to continuously seek ways to improve its quality kick in. Earlier this month, about 200 gallons of water was slowly poured into the first of what seemed to be two holding tanks. Then, another 200 gallons of water was poured into a second tank. In one tank was a 120 mm mortar tube. In the other, a 60 mm mortar tube. As five ultrasound transducers were being put into position over each tube, four arsenal quality assur-ance technicians were gathered around dual-computer screens listening to an instructor walk them through

Photos by John B. Snyder

Page 4 Salvo March 31, 2014

Quality Cont.

the dynamics of immersion ultrasonic test inspections. This type of ultrasonic testing is the first of its kind on Watervliet’s production lines. “With these machines the arsenal will be better able to detect indications of a crack or defect,” said Thomas Larkin, a laboratory manager with Talon Test Laborato-ries who led the training. “This new capability will sig-nificantly add to the arsenal’s quality control program because it will complement the arsenal’s other nonde-structive testing procedures, such as magnetic-particle in-spections.” The arsenal now has two ultrasound systems that can do much more than inspect mor-tar tubes, Larkin said. The ar-senal could use this enhanced capability to support quality assurance inspections for the aerospace, marine, transporta-tion, and medical industries. Inspection capability is only limited to the dimensions of the product that would fit in the tanks of this new technol-ogy. But for now, the arsenal will focus on its mortar pro-gram, from 60 mm mortars to 81 mm to 120 mm mortars. According to Fred Camp-bell, an arsenal quality con-trol team leader, the arsenal currently puts each mortar tube through three magnetic-particle inspections. Mag-netic-particle inspection is a non-destructive test that uses a magnetic field to detect surface and slightly subsurface discontinuities. “With the ultrasonic machines, the arsenal will conduct two magnetic-particle inspections and one ultrasonic inspection,” Campbell said. “Although the mag-particle inspections are a great tool that has served us well, using ultrasound will give us additional visibil-

ity on indicators that may effect the quality of a mortar tube.” Each machine will pulse ultrasound waves through water into a mortar tube. This happens by using five transducers that measure every aspect of a mortar tube, externally and internally, and will detect indications of a defect down to ten-thousandths of an inch in length and five-thousandths of an inch in depth. Sound pulses are then captured and graphed on two computer screens that will be observed by a quality control inspector. Ev-ery inspector must be certified for this procedure. If there is an indication there might be a defect that

may cause the tube not to meet high quality standards, then another higher-level certified quality control inspector will review the results and make a determination on whether to accept or to reject the part. Since its humble begin-nings in 1813, the Watervliet Arsenal has always prided itself on its quality. After all, hundreds of thousands of troops have used the arsenal’s products without incident. Despite that record, quality is not taken for granted at Watervliet. Although these two ultra-sonic machines make up just a small part of the arsenal’s $26 million investment this year, they will be a huge part of the arsenal’s inspection program that will ensure that our na-tion’s infantry have the highest quality mortar systems in the world.

One of two new ultrasonic immersion test machines that will be brought on line within the next 30-60 days.

Photo by John B. Snyder

Special Recognition... This story had tremendous success in its placement with higher commands and staffs. The story was: -One of the Top 10 Stories in the entire Army as it was highlighted on the Army’s homepage -One of the Top 10 Stories for the Assistant Secretary of the Army for Acquisition, Logistics, and Technology -#1 Story for the Army G-4, Deputy Chief of Staff for Army Logistics

Page 5 Salvo March 31, 2014

By John B. Snyder

The United States infantry has some of the finest mor-tar systems in the world. They are lightweight, have great range, and provide a significant amount of lethal and de-structive fire to close-range combat. And so, why would anyone think about tweaking something that has already been proven very capable in training and in combat? “It is all about our troops maintaining the competitive edge over potential adversaries,” said Wayland Barber, chief of the Mortars and Recoilless Rifle Branch at Benét Laboratories. “Even without funding for new weapons research, Army scientists and engineers are always seek-ing opportunities to improve weapons systems that are in the field.” “No sooner than we field a new mortar system, our customers demand that we make it better in regards to extended range, increased lethality or capability, and reduced weight,” Barber said. “This triggers the entire Army research community, from those who improve the lethality of ammunition to those who design the delivery

system, to work on parallel and converging fields of sci-ence to achieve a common goal.” Barber supervises a team of 14 Department of the Army civilian engineers and technicians who not only de-sign and build prototypes of future mortar and recoilless systems, they also design product improvements of what has already been fielded. Given today’s fiscal challenges due to sequestration, and the lack of any major orders for new weapon systems, improving what the U.S. military currently has fielded drives Barber and his team’s near-term focus. Some of the latest work at Benét Labs transcends all fielded mortar systems in the U.S. inventory, from 60 mm to 81 mm to 120 mm mortars. “The current 120 mm mortar system has good range, is reliable, and the troops like it,” said Bob Cooley, a Benét Labs Integrated Process Team leader. “But as good as

Benét Labs' mortar redesign to help infantrymen become more lethal, more safe

By John B. Snyder

Story continues on page 6, Mortar

KHOST PROVINCE, Afghanistan - U.S. Army mortar men from Company B, 2nd Battalion, 151st Infantry Regiment, Indiana National Guard, provide 120 mm mortar fire support to Soldiers from Company D, 3rd Battalion, 509th Parachute Infantry Regiment, 4th Brigade Combat Team, 25th Infantry Division, out of Fort Richardson, Ala, at Afghan Combat Outpost Chergotah located in the Terezayi district of Khost province, Afghanistan, Dec. 4. (Photo by U.S. Air Force Staff Sgt. Stephen J. Otero, Khost Provincial Reconstruction Team Public Affairs Office)

Page 6 Salvo March 31, 2014

Bob Cooley, a Benét Labs Integrated Process Team leader, adjusting the newly redesigned 120 mm mortar bipod in the product development labora-tory at Watervliet Arsenal, N.Y.

Photo by John B. Snyder

that system is, we have several product improvements that we are currently working that may improve Soldiers’ safety, increase range by up to 25 percent, and reduce the system’s weight by nearly 16 percent.” “One of the major upgrades to the 120 mm system is with its bipod,” Cooley said. “Our bipod redesign will improve the accuracy of the system because it moves the fire control system from the tube to the bipod.” According to Cooley, the fire control system or FCS is currently at-tached to the tube, which in turn places a signifi-cant amount of stress and movement on the FCS during a fire mission. By moving the FCS to the bipod, there will be less force exerted on the sys-tem, which in turn will improve accuracy. Another design im-provement for the 120 mm mortar system in-cludes a new baseplate that will not only provide more stability for extend-ed-range munitions, it will save U.S. taxpayers money. If and when the redesigned baseplate goes into full production, the cost of the baseplate will be reduced by nearly 50 percent from the current legacy system’s cost. The qualifica-tion test was recently completed with the firing of 3,000 rounds without incident. The final major piece to the redesigned 120 mm mortar system is an improved cannon tube. When extended- range ammunition is developed, the tube must also be modified to withstand higher tube pressure, heat, and

muzzle velocity. Benét Labs plans to conduct a full-quality testing of the redesigned 120 mm mortar system in fiscal year 2015, and Barber’s team is also doing research and design work on the 60 mm and the 81 mm mortar systems. News of those potential product improvements will be released in a future story. Some at Benét pride themselves in that they made it (weapon system), just before they made it better. In es-

sence, this team is never satisfied having met the prescribed technical data standards for product development because they know that there is an American service man or woman whose life will depend on their product. If there is any chance to make our troops more lethal or more safe, Benét research will discover it. Benét Labs has a rich history of designing and fielding new weapon sys-tems. Although Benét of-ficially opened its doors as the Army’s large caliber research and design facil-ity in 1962, its weapons research at the Watervliet Arsenal dates back to the 1840s. Therefore, seek-ing to improve previously tested and fielded weapon systems is not just a task that the Benét’s workforce does when work for new weapon systems dries up, doing continuous product improvement is in their DNA.

Mortar Cont.

Special Recognition... This story had tremendous success in its placement with higher commands and staffs. The story was: -One of the Top 10 Stories in the entire Army as it was highlighted on the Army’s homepage -One of the Top 10 Stories for the Assistant Secretary of the Army for Acquisition, Logistics, and Technology -One of the Top 10 Stories in the Army Materiel Com-mand

Page 7 Salvo March 31, 2014

Every year, there is an outflow of arsenal talent by the way of retirement. Ed McCarthy, the arsenal’s former deputy commander, recently said in a briefing that in this month alone the arsenal will lose about 1,000 years of experience. If you think about what is captured in those 1,000 years, from apprentice training to machining 155 mm howitzer barrels to learning how to implement the new Logistics Modernization Program, it is simply amazing that the arsenal will be able to continue its mission without any loss to productivity. But what if they didn’t retire? Could they stay on and continue to be productive for other 10, 20, or even 30 years? Today, we have a few folks who are still working here after having more than 40 and even 50 years of service to the Army. I always thought those individuals were unique given their tenure. That is, until now. Given my travels these last five-plus years as the arsenal’s public affairs officer, I thought that I had seen it all in regards to long-term tenure. But this month I discovered a worker whose active-service dates back to 1933. Oh, 1933 was a notable year. The original King Kong movie premiered, President Franklin D. Roosevelt closed all United States banks and froze

all financial transactions for about two weeks due to the Great Depression, and the 21st Amendment to the United States Constitution was passed that repealed Prohibition. I got thirsty just writing that last bullet. At the arsenal in 1933, V. Press began working in Building 135 and has never left. Think about how many tubes that may have passed though the confines of Press’ work area. For example, just in the period of time from the attack on Pearl Harbor to the landing on Normandy during World War II, the arsenal produced more than 23,000 barrels with an on-time delivery rate that exceeded 99 percent. Press probably touched many of those barrels. Think about the different types of tubes that have traveled through Press’ work area to outfit Soldiers for the Korean War, Vietnam War, and the Gulf War. Pretty significant, right? I tried to gain more information from Press, but was met with cold-steel silence. And so, Press’ secret regarding how to survive 81 years of service will remain a mystery. As you say goodbye to those who will leave this month, don’t forget about the 81-year service of V. Press. You will find Press at the bottom of the autofrettage pit in building 135. This “V”ertical “Press” machine, with five million pounds of pressure, has ensured the durability of our tubes for generations.

Oh, 1933... -The Great Depression -25 percent unemployed -Dust Bowl in S. Dakota -All U.S. banks closed -Gold standard ends -Pres. Coolidge dies

But, amid all the bad news was some good news... a career begins for arsenal worker who is still on the job today

Photo of V. Press is on page 11

By John B. Snyder

Page 8 Salvo March 31, 2014

Watervliet receives Army contracts worth more than

$6.7M, bringing total to more than $18M in last 60

days

The Watervliet Arsenal announced this month that it received two contracts worth more than $6.7 million to provide the U.S. Army with 39 120 mm tank barrels and inspection services for 500 120 mm Stryker mortar barrels. With this month’s announcement, the arsenal has in the last 60 days received more than $18 million in new orders. “These multimillion dollar orders will add to our current workload more than 11,900 hours of direct labor,” said Ray Gaston, the arsenal’s former chief of production planning and control. “What makes these orders so important is that they highlight the arsenal’s critical skills in regards to machining and quality control.” The Abrams tank barrels require hundreds of individual machining operations that often have tolerances in the tens of thousandths of an inch, Gaston said. Just about every critical machining operation, from the rotary forge to computerized lathes to specialized painting, will be challenged to produce the finest tank cannon in the world. According to Tom Buckton, the arsenal’s program manager for the $4.6 million tank barrel order, the barrels are for the U.S. Army’s TACOM Life Cycle

Management Command and will eventually be fielded on Abrams tanks in the U.S. and in foreign militaries. Work will begin immediately using pre-positioned barrel forgings and initial delivery is set for August 2014. The order should be complete by March 2015. Bruce Pienkoski, the project manager for the $2.1 million Stryker barrel inspection order, said the 120 mm barrels, which had been fielded by a different manufacture, will undergo multiple quality control inspections that can only be found at the Watervliet Arsenal. “Every mortar tube we inspect typically goes through three magnetic-particle inspections to ensure serviceability,” Pienkoski said. “What will be different with this service is that in April we will bring on line a unique quality control capability called ultrasonic immersion testing.” Ultrasonic machines pulse ultrasound waves through water into a mortar tube and will detect indications of a defect down to ten-thousandths of an inch in length and five-thousandths of an inch in depth. The fact that the arsenal is inspecting weapon systems that have been previously fielded is not new,

By John B. Snyder

Story continues on page 9, Order

Photo by 1st Lt. Cory Titus

Page 9 Salvo March 31, 2014

Pienkoski said. The Army has traditionally called on the arsenal’s unique quality control capability to verify the serviceability of weapon systems that have been in use by Soldiers. Sometimes, Army program managers are simply trying to make a determination as to when barrels may need to be replaced. The inspection process provides the program manager a current status of the tube’s serviceability life. Pienkoski said the inspection of the 500 barrels should be complete in 2016.

Order Cont.

Women’s History Month

Celebrating women in our work-

force

CAMP TAJI, Iraq: An M1 Abrams Tank of C Company, 1st Battalion, 13th Ar-mored Regiment engages a target with its 120 mm main gun in 2010. (U.S. Army photo by Sgt. Kevin Bromley)

Page 10 Salvo March 31, 2014

From Vietnam to the Persian Gulf, Sandra

Dessinger has seen it all

It has been nearly 70 years since the peak of the ar-senal’s version of Rosie the Riveter graced our machine shops. During World War II, more than 3,000 women worked on our production floors, planning shops, qual-ity control inspection stations, and in administrative areas. But those were different times and as much as women have dem-onstrated that they can run our ma-chines, very few do so today. Nevertheless, the arsenal does have a handful of women who have machin-ing skills and one of the longest ten-ured production floor workers is a women. Sandra “Sandy” Dessinger, a ma-chine tool opera-tor, began her employment at the Watervliet Arsenal in July 1967. She recalls back to the Vietnam War era as a pleasant time when the work force had a very strong work ethic. The arsenal was an environment of high morale and peers looked out for each other and helped train each other, Sandy said. Since 1967, Sandy said she has performed just about every production floor operation from machining breech rings to howitzer tubes. She has even worked in the warehouse. Sandy said her mechanical and machining inter-est started at a young age. She grew up without her father but was fortunate to have an uncle who took time

to show her how to turn a wrench and to do other me-chanical tasks. The most important advice Sandy could offer anyone is that when you are working on a machine, respect it. Don’t be afraid of it. Just pay attention to what you are doing and you will be fine.

Machining has always made Sandy proud and she hopes that ma-chine tool operator positions will al-ways be available for women. Ma-chine tool operator positions provide women the op-portunity to enter into the world of machining without the extensive train-ing required of apprentices, Sandy

said. Since 1967, Sandy has been a part of the arsenal’s operations during every major armed conflict, from the Vietnam War to Grenada to Panama to the Gulf War. She is not only well-respected, she is also a great exam-ple of arsenal women who have made a significant im-pact on the arsenal since its humble beginnings in 1813. During her tenure, she was able to raise a family of three children and provide a good life for them. Sandy left the Arsenal in 1992 as a result of a reduction in force but returned in March 2004. For her proud and long-tenured service to the Army, Sandra Dessinger well deserves to be this month’s arse-nal Face of Strength.

By Deborah Moody and Jessica Wasko

Photo by Faith Cuilla

Page 11 Salvo March 31, 2014

Arsenal History Trivia

VerticalPress

In 1933, this vertical press was installed and for 81 years it has been an active part of our workforce.

American Legion

In March, Col. Lee H. Schiller Jr. made a visit to the Rensselaer County American Legion to pro-vide an update on the arsenal’s operations.

On June 6, 1905, four young men reported to the Watervliet Arsenal to begin training as machinist apprentic-es. Their names were Frank Roberts, John Strohecker, Edward Larkin, and Raymond Sturges. Before the end of the year, they were joined by Henry Wheeler, James Prairie, John Kilmer, William Muddle, George Theroux, and Charlie Waters. By the time of World War I, 34 apprentices had graduated and four classes were in training.

Photo by John B. Snyder

Photo by John B. Snyder

Page 12 Salvo March 31, 2014

City of WatervlietMemorial Day Parade

Monday, May 26thSave The Date:

The Arsenal is participating in the City of Watervliet Memorial Day Parade on Monday, May 26, at 10 a.m.

We need volunteers to march with the commander in the parade.

We will also support the Village of Green Island’s Memorial Day Parade with a smaller parade contingent on Thursday, May 22nd.

Albany Devils Military Appreciation GameSaturday, April 12th, at 5 p.m.

Save the Date

Former Arsenal Commander Col. Mark F. Migaleddi dropping the puck at last year’s game.

Photo by John B. Snyder

Related Documents