S ALVO Watervliet Arsenal ... 1813-2013 Vol. 13, No. 9 U.S. Army Watervliet Arsenal Sept. 30, 2013 SecArmy’s first visit to the Army’s manufacturing center at Watervliet Story on page 3 Photo by John B. Snyder

Watervliet Arsenal Newsletter : Salvo - 30 September 2013

May 07, 2015

This is the U.S. Army Watervliet Arsenal's monthly newsletter called the Salvo. The Salvo contains the latest stories and information that pertains to the Army's manufacturing center at Watervliet.

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

SALVOWatervliet Arsenal ... 1813-2013

Vol. 13, No. 9 U.S. Army Watervliet Arsenal Sept. 30, 2013

SecArmy’s first visit to the Army’s manufacturing center

at WatervlietStory on page 3

Photo by John B. Snyder

Page 2 Salvo Sept. 30, 2013

The Arsenal Salvo is an authorized monthly publication for members of the Department of Defense. Contents of the Salvo are not necessarily the official views of, or an endorse-ment by the U.S. Government, the Department of Defense, the Department of the Army, or the Watervliet Arsenal. News may be submitted for publication by sending articles to Public Affairs Officer, 1 Buffington Street, Bldg. 10, Watervliet, NY 12189, or stop by office #102, Bldg. 10, Watervliet Arsenal. The editor may also be reached at (518) 266-5055 or by e-mail: [email protected]. The editor reserves the right to edit all information submitted for publication.

Commander, Col. Lee H. Schiller Jr.Public Affairs Officer, John B. SnyderEditor, John B. SnyderPhotographer: John B. Snyder

Lee H. Schiller Jr.Commanding

Manufacturer 6

Commander’sCorner

As we enter this time of year, change is all around us. Trees change colors, plants stop flowering and last year’s gas is being drained from snow blowers in anticipation that winter is coming. Change is abundant too at the arsenal. Fiscal year 2013 was not only challenging, it was also frustrating to many of you. Many things that were out of our control, such as a declining defense budget and seques-tration, affected every corner of the arsenal. Most of you lost pay due to furloughs and some of you lost great work-force companions as many retired in the last few months. But through it all, we passed 200 years of continuous operation last July with our reputation and history beyond reproach. With the 200th anniversary behind us, your leadership is working hard to maintain a sufficient level of workload for 2014 and 2015 to ensure that we retain a core capability that can respond to any urgent needs of our troops. What will be key as we go forward does not have so much to do with our history, but has everything to do with our reputation. When we can machine a great product that gets into the hands of our military or an allied military on time, that is our reputation. When we can respond to an urgent order for 60 mm mortar systems for the Afghanistan National Army, an order that will help to create an environment that will allow our troops to withdraw from that country, that is our reputation. When we can do all that and do so safely, that is our reputation. Everything that we do must be done with a strong sense of appreciation for and understanding of that our reputation rides on your actions. At the end of the day, our reputation is our blood and soul. This is a great command that truly has significance to our national security and Secretary of the Army John McHugh said so last week.

This was a great visit for us because this was the secre-tary’s first visit to the arsenal, even though he was a U.S. congressman from New York. Nevertheless, we filled his visit with our history, capacity, and a sense for our crtical capabilities that we can respond to any manufacturing re-quirement thrown our way. I have no doubt that he left us with a better understanding and appreciation of who we are. Once again, your reputation showed as every area the secretary visited and person he talked to was well prepared. I can’t thank you enough for your support. As we get into the winter months, please plan now for adverse weather and don’t wait until you get 12-inches of snow before you check out your snow blower or get your car tires replaced. And, please be extremely careful as you remove fallen leaves from your yard. I have read too many stories of people falling off of ladders trying to clean out their gutters on their roofs. I only want to read about you as part of a positive story.

Page 3 Salvo Sept. 30, 2013

Secretary of the Army visits,touts, challenges Watervliet

John B. SnyderMaj. Christopher Kasker

George Flanders grinding burs while the Secretary of the Army passes by. This was the secre-tary’s first trip to the arsenal.

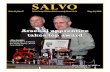

Secretary of the Army John McHugh was at the Watervliet Arsenal September 26 to assess the effect of sequestration on the arsenal’s ability to conduct research and design efforts, and manufactur-ing, in support of howitzers, can-nons, and mortars for U.S. Armed Forces and allies. During the visit, McHugh, a former U.S. Congressman from up-state New York, met with Arsenal leaders and the civilian workforce, where he provided insight into the Army’s current fiscal challenges and received updates about arsenal manufacturing. “Let me be clear, the Army is undergoing a significant cut to its budget that has caused us to look at reductions in organizations, pro-grams, and activities,” McHugh said. “No staff or command will be untouched during this fiscal uncertainty.” He stated what the work force needs to do. “Throughout its 200-year history, the arsenal’s workforce has a track record of bold and innovative strategies that better supported the needs of our sol-diers,” McHugh said. “That kind of leadership and innovation will be critical for our future.” Despite the challenges McHugh noted the impor-tance of the arsenal to the United States Army. “The Watervliet Arsenal provides critical support to our national security, which is why, earlier this year, I designated it as a Center of Industrial and Technical Excellence (CITE) for cannons and mortars,” he said. “This designation means the Arsenal’s core compe-

tency to manufacture cannons and mortars cannot be found anywhere else in the Defense Department.” A significant effect of the CITE designation is that the Arsenal may now more freely enter into public-private partnerships to perform work that will enhance its manufacturing core competencies. “Such private-partnership may not only keep the Arsenal’s skills sharper, but may also reduce the Ar-senal’s cost of operation,” said Joe Turcotte the Arse-nal’s director of Installation Management. The CITE recognition by the Army secretary is some-thing the arsenal commander knows the workforce will maintain. “The arsenal’s ability to adapt goes beyond the lever-

Story continues on page 4, See SecArmy

Photo by John B. Snyder

Page 4 Salvo Sept. 30, 2013

Clockwise from Top Right: Secretary of the Army John McHugh taking a moment from his busy trip to thank the workforce for all that they do everyday to support our troops and especially for their great effort in providing 902 60mm mortar systems to the Afghan National Army. Remy A. Polacinski taking a measurement for quality control while the Secretary of the Army approaches. Secretary of the Army John McHugh, pointing, is asking Benet Laboratories’ Deputy Director John Askew, left, a question about the mortar systems on display.

Photos by John B. Snyder

aging of skilled artisans who work in tens of thousandths of an inch tolerances as they machine today’s products that support artillery, tank, and mortar system in the U.S. military,” said Arsenal commander Col. Lee H. Schiller Jr. “There is also a strong sense of duty that each worker has that drives their ability to leverage unique capabili-ties and capacity to meet the critical, urgent needs of their Army.” McHugh also acknowledged the strong support of the area’s Congressional delegation, and state and local government. “This facility and its mission have benefitted from our longstanding partnership with Senators Schumer and Gillibrand and Representative Tonko, as well as the state

and local community,” he said. “We’re grateful for their continued leadership and support.” The Watervliet Arsenal is an Army owned-and-operat-ed manufacturing facility and is the oldest, continuously active arsenal in the United States. It began operations during the War of 1812, and celebrated its 200th year of continuous service to the nation on July 14, 2013. Today’s Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar sys-tems. This National Historic Registered Landmark has an annual economic benefit to the local community in excess of $90 million. As Secretary of the Army, McHugh has statutory re-sponsibility for all matters relating to the United States Army: manpower, personnel, reserve affairs, installations, environmental issues, weapons systems and equipment acquisition, communications, and financial management.

SecArmy Cont.

Page 5 Salvo Sept. 30, 2013

Where Army manufacturing supports U.S. troop withdrawal

A final shipment of 60mm mortars left the Watervliet Arsenal, N.Y., this month en route to the Afghanistan National Army and with each crate was a tremendous sense of pride that the arsenal is helping the president to achieve his goal of bringing 34,000 troops home from Afghanistan by the end of 2014. The Arsenal announced last February that it received a $5.9 million contract to provide the Afghanistan National Army with approximately 900, 60mm mortar systems. The former arsenal commander, Col. Mark F. Migaleddi, said in February that this was a very aggressive fielding with up to 150 systems to be sent out in the first 30 days upon receipt of the order. “This order not only reflects the high confidence the Department of Defense has on the arsenal’s ability to rapidly support the warfighter, but also speaks volumes to the importance of DOD maintaining an Army-owned and -operated manufacturing center,” Migaleddi said in regards to the rapid fielding schedule that the arsenal promised and has now delivered. To put this fielding challenge into perspective, Lt. Col. William McDonough, the Army’s Program Manager for the 60mm order, said this type of order would typically take the Army about two to three years to achieve. The Arsenal completed the order in less than eight months. “This was a great team effort and the fact that we could complete the order in about seven months says a lot about the strong relationship we (Army program managers) have with the Watervliet Arsenal,” McDonough said. McDonough validated that the rush to get this order

into the hands of the Afghanistan army was to support the President’s goal to get 34,000 U.S. troops home by the end of 2014. In essence, the sooner the Afghanistan army is equipped and trained, the sooner U.S. troops may come home.. This week’s shipment of 92 mortar systems to the

Afghanistan National Army completed the arsenal’s role in the U.S. State Department’s Foreign Military Sales program, or FMS, to equip the Afghanistan Army with 60mm mortar systems. FMS is a program that provides sales of U.S. arms, defense equipment, defense services, and military training to foreign governments. “There is a tremendous sense of pride and professionalism for us to be at the tip of the sphere of the national security strategy by supporting the Afghans in their own mission in taking over the fight, thus allowing our servicemen and women to come home,” said Col. Lee H. Schiller Jr., the current arsenal commander, as the final crates were being sealed. According to Ray Gaston, the Arsenal’s chief of the Production Planning and Control Division, the main

part of the contract required the Arsenal to act as a staging area for the various parts of the 60mm mortar system that are being collected from other Army installations. Upon the receipt of the parts, which consisted of such things as barrels and base plates, the Arsenal packaged them into complete mortar systems and then shipped to Afghanistan. The contract also required traditional manufacturing of select parts for the mortar system. The 60mm mortar system is used primarily by the infantry as an indirect fire weapon when a high angle trajectory is required to hit enemy troops, materiel, and positions. It has a maximum range of about 3,500 meters.

Final crates loaded on a truck signify great success to Army Program Manager Lt. Col. William McDonough, left, and Arsenal Commander Col. Lee H. Schiller Jr.

By John B. Snyder

Photo by John B. Snyder

Page 6 Salvo Sept. 30, 2013

Watervliet, with $10M in new contracts, is still Army

Strong after 200 yearsBy John B. Snyder

Photo by John B. Snyder

Some may think that at the grand old age of 200 that things ought to be slowing down for the Watervliet Arsenal, but that does not seem the case as the arsenal announced last week more than $10 million in new contracts for two different types of 155mm howitzer tubes for the U.S. Army. These new contracts will add to the $4.3 million contract an-nounced last month for experimen-tal mortar work and to the more than $27 million in new work announced last spring, said Ray Gaston, the arsenal’s chief of Pro-duction Planning and Control. “This is great news in that these orders were not part of our planned workload for fiscal years 2014 or 2015,” said Gaston. “Given an era of fiscal uncertainty in the U.S. defense budget, just trying to maintain production on planned work can be very challenging and so, when new work comes in each order is critical to sustaining the critical skill base that resides at the arsenal.” The two contracts require the arsenal to manufacture: 60 M284 155mm cannon tubes with a con-tract value of approximately $8 million; and 10 M776 155mm cannon tubes valued at nearly $2 million. “The M284 contract will add to our current workload more than

13,000 hours of direct labor,” said Diane Nelson, the arsenal’s program manager for the order. “And I am very hopeful the Army will provide us a follow-on or-der sometime next year for more tubes.” The arsenal has not manufac-tured the M284 barrel since 2007 and the barrel goes on the Army’s M109 155mm self-propelled how-itzer, Nelson said. “We will ship our first barrel

in August 2014 and complete the contract in July 2015,” Nelson said. The M776 tube is for the M777 155mm lightweight howitzer, said George Roach, the arsenal’s pro-gram manager for this order. “Although this is not a new type of barrel for us to manufac-ture, we will try a new plating process in anticipation the new process will extend the life of the tube,” Roach said. “If testing of the new plating process goes well, this could open the door for a sig-nificant amount of work for the arsenal.” Roach said that more than 2,200 direct labors hours will be added to the manufacturing sched-ule and that shipment of the barrels will begin in April 2014 and the last shipment is planned for June 2014. The Watervliet Arsenal is an Army-owned-and-operated manu-facturing facility and is the oldest, continuously active arsenal in the United States having begun opera-tions during the War of 1812. It celebrated its 200th anniversary on July 14, 2013. Today’s Arsenal is relied upon by U.S. and foreign militaries to produce the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar sys-tems. This National Historic Reg-istered Landmark has an annual economic benefit to the local com-munity in excess of $90 million.

Arsenal machinist Ryan Putnam is preparing a 155mm barrel for pressing. Putnam has learned through his 20,000 hours of machin-ing experience that listening to how tubes "groan" when he presses them with up to 900 tons of pressure assists his ability to straighten the tubes.

Page 7 Salvo Sept. 30, 2013

Congrats to Arsenal Softball ChampionsOur Watervliet Arsenal Howitzers Softball team won the 2nd Annual Northeast Military Softball Tournament at the Picatinny Arse-nal this month. They beat teams from the Picatinny Arsenal, Tobyhanna, Fort Hamil-ton, Aberdeen and the Boys of Summer team which included Larry Berra (Yogi Berra’s son) and Gil Hodges Jr.

Top Row from left to right: Zach Kirsch, Greg Delgado, Kyle Morcotte, Matthew Marsh, Matthew Church, Rob Cavanaugh, and Chad Peters. Bottom Row from left to right: Jordan Selin, Kyle Buono, Andrew Gorman, and Tom Pond Jr.

Photo by John B. Snyder

Photo provided by Kyle Buono

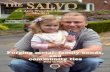

First Town Hall for SchillerThis September marked the first opportunity for Col. Lee H. Schiller Jr. to address the workforce since his change of command on July 18, 2013. Unlike town halls from recent commanders, Schiller took on the entire program briefing and discussing such topics as workload, safety, and his priorities.

One of the main promises Schiller had for the workforce was that his command would be one of complete trans-parency and that he will share a vast amount of informa-tion, as he gets it, with the workforce and its leaders.

Photo by John B. Snyder

Retreat and 9/11Ceremony

The arsenal workforce assembled this month underneath the garrison’s flagpole to not only recall the events of 9/11 —a day that is strongly sewn into our nation’s fabric — but also to renew our faith in tradition and history. In a simple ceremony that brought together Department of the Army Civilians and troops from the New York National Guard the arsenal commemorated those who died and those who became heroes as a result of those tragic events. Retreat is a ceremony in which the unit honors the U.S. flag when it is lowered in the evening. This ceremony is conducted at the direction of the commander.

Page 8 Salvo Sept. 30, 2013

Watervliet: Where family tradition helps the war effort

This 1893 photo shows 24-year-old Robert Cockburn in the first row, first from the left. Carl Christiansen, the Master Engineer of the 16-inch gun project, is seen in the back row, six men from the left.

Next year marks the beginning of the centennial obser-vations for the events leading up to World War I. While the war began in August 1914, the United States did not enter the fighting until 1917. Once war was declared by Congress, the Watervliet Arsenal began a “crash course” of internal improvements, expansion to its existing physi-cal structures, and the hiring of thousands of additional skilled workers. Brothers Robert, Alexander, and Andrew Cockburn were part of this skilled workforce and as many other workers of the day, they had followed their father’s footsteps into arsenal employment. William Cockburn (1840-1918) was born in Edinburgh, Scotland, and immigrated to Canada as a young man. At 51, he moved his family to Watervliet in search of a better life. He worked at the arsenal as a machinist from 1891 until his retirement in 1908. Three of William’s seven sons also worked at the Arsenal: Robert worked 37 years (1891-1928) as a machinist, foreman and Master Mechanic in the Heavy Field Cannon department; younger brother Alexander worked at the arsenal from Oct. 12, 1917 until June 6, 1918; and older brother Andrew worked 29 years at the Arsenal (1895-1924) as a machinist and was a charter member of the 20-Year Club. Production and hiring of new employees increased at

a steady rate in 1917 as many arsenal men enlisted in the Army. Robert was commissioned an officer on Sept. 7, 1917 and as a major, reported to active duty at the arsenal on Oct. 3, 1917. He shipped out to France to serve for 18 months, from Feb. 18, 1918 to May 27, 1919, serving in the Ordnance Shop, 8th Battalion. Alexander, a former professor of Mechanical Engineering at RPI, was com-missioned a captain in the Ordnance Department, and was employed at the Arsenal prior to him shipping out for over-seas. He was stationed in France, also with the 8th Battal-ion. Andrew remained at the arsenal during World War I. After the war, both Robert and Alexander were hon-orably discharged and resumed their pre-war lives and careers. Robert returned to work at the arsenal as Super-intendent of Heavy Field Cannon Department, retiring in 1928. Alexander was assigned to duties at the Aberdeen Proving Grounds, Maryland for three years but ill health forced him to resign from the military and he returned to Watervliet. Andrew worked at the arsenal from 1895 until his retirement in 1924 after 29 years of employment. The Cockburn family is just one of many who have not only become part of the arsenal tradition, but also have made working at the arsenal part of a proud, family tradi-tion.

Photo provided by arsenal museum

By Mark Koziol

Page 9 Salvo Sept. 30, 2013

Albany County’s Veterans’ Day Parade11 November

11 a.m.You will have a chance to join us this November as we honor our Nation’s Vet-erans. As you read this, the Arsenal parade committee is beginning to prepare the Arsenal for the Albany County’s Veterans’ Day Parade down Central Av-enue. In addition to two Arsenal/Benét Labs floats, we plan to have continued support from our emergency services, and from the Hudson-Mohawk Military Vehicle Association.

We need folks to march with us on Veterans’ Day, 11 November. What a great way to pay proper recognition to our Veterans’ as well as to showcase the Ar-senal to the community. More info to follow in the near future.

SAVE THE DATE

Nov. 11, 2013

Veterans Day Parade

Page 10 Salvo Sept. 30, 2013

Face of Strength: Bob Rawls

To some people who worked with Bob Rawls during his 38 years as an arsenal machinist, they may have thought that when Bob retired in 2004 that he simply faded away to some sandy beach where sunshine is abun-dant and machinery is absent. But for those who tru-ly know Bob, they must have known that when Bob drove out the gate one last time as a Depart-ment of the Army Civil-ian that he couldn’t stay gone very long. And he didn’t. After all, Bob had in-vested more than 76,000 hours at the arsenal turn-ing and machining barrels for every major artillery and tank system since the Vietnam War. Machining was in his blood. Unlike most retirees, Bob didn’t fade away. In fact, he has quietly become a very valued and productive worker at the arsenal, albeit one without pay. Immediately after Bob retired, he came right back to work in an ar-senal machine shop. Although the machine shop, which consisted at the time of a few broken machines from the late 1800s era, wasn’t meant to produce weapons for our troops, it nonetheless had a very important mission … to tell the arsenal story

of machining. Tucked away in the arsenal mu-seum is a late 1800s-era machine shop with working lathes and drills. Bob built this display from scratch using his personal funds, as well as thousands of hours of his personal time repairing the ma-chines. Although his hands now move a little slower than when he was a machinist at the arsenal, Bob’s mind is just as sharp, if not more so. The repair of each machine

often meant that Bob would spend countless hours researching how the old machines used to work and then fabri-cating parts in a small machine shop he has set up in his garage to bring the machines up to working order. Why does he do it? Bob said he loves working with his hands. But just as important, Bob loves working at the arsenal and helping to tell the arsenal story. Watching Bob en-gage visitors, who have ranged from cadets from the U.S. military academy at West Point to local high school stu-dents, is amazing. His technical expertise, his love of the machines, and his historical knowledge of machine operations is always a visitor highlight.

The museum will temporary close on September 30 due to a reorganization being conducted by the Center of Military History, but Bob’s machine shop will stay and will be a large part of our museum activity when it reopens in 2015 or 2016. For his countless hours of dedi-cation toward helping the arsenal tell its story, Bob Rawls truly de-serves to be this month’s arsenal Face of Strength.

Photos by John B. SnyderTop: Bob Rawls, with hat, explaining the machining shop operations to Sullivan County high school students. Below: Bob Rawls, right, talking to high school students about the machining techniques and procedures used during the late 1800s.

By John B. Snyder

Page 11 Salvo Sept. 30, 2013

CPAC - Civilian Personnel Advisory Center

Military Service Deposit Receipts and Crediting your Military Buyback

In order to be credited for your military service deposit, your eOPF (electronic Official Personnel Folder) must contain proof of payment from your military service deposit. DFAS does NOT automatically send this document to you and ABC-C will not accept Leave and Earning Statements, payment statements or any other documentation as acceptable proof of payment. In order to receive credit, follow the procedures outlined below.

1. Request Proof of Payment:

For military deposits paid back to the government AFTER 2004:

Contact a payroll representative and ask that he/she send a remedy ticket to DFAS requesting a “PIF” letter (Paid In Full letter). The letter will be mailed to your home address so make sure it is correct in the payroll system. This can take up to six weeks.

For military deposits paid back to the government BEFORE 2004:

You will need to compose a letter containing your name, mailing address and social security number. In the body of the letter, state that you are requesting a Service Credit Receipt from your military deposit. This request should be faxed to OPM at (724)-794-4668 or (724)-794-6633. This can take up to six weeks.

2. Provide Proof of Payment to CPAC to be uploaded into your eOPF.

If proof of payment has not been received by your date of retirement, you should compose a memo stating that you are in the process of obtaining your proof of payment letter. Submit this memo to CPAC to be placed in your eOPF until your letter is received. Be sure to supply CPAC with a copy of your proof of payment once it is received.

Please note that your Service Comp Date (SCD) on your SF-50s will not change based on this process. The SCD on your SF-50 is your SCD for Leave purposes. Any creditable military service you have should already be reflected in this date regardless of whether you pay back your military deposit or not.

For questions regarding military deposits, please call 266-5400 or 266-4058.

Page 12 Salvo Sept. 30, 2013

Related Documents