1000 Technology Drive, Pittsburgh, PA 15219 645 Russell Street, Batesburg, SC 29006 SM 5994 Copyright © 2008 SM 5994, Rev. 2.0 Union Switch & Signal Inc. June 2008 W-400 Transformer Series US&S Part Nos. N451428-0101 to N451428-0114 Installation Operation Troubleshooting

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

1000 Technology Drive, Pittsburgh, PA 15219 645 Russell Street, Batesburg, SC 29006 SM 5994

Copyright © 2008 SM 5994, Rev. 2.0 Union Switch & Signal Inc. June 2008

W-400 Transformer Series

US&S Part Nos. N451428-0101 to N451428-0114

Installation

Operation

Troubleshooting

Notices

SM 5994, Rev. 2.0, June 2008 i

Proprietary Notice This document and its contents are the property of Union Switch & Signal Inc. (hereinafter US&S). This document has been furnished to you on the following conditions: no right or license under any patents or any other proprietary right in respect of this document or its content is given or waived in supplying this document. This document or its content are not to be used or treated in any manner inconsistent with the rights of US&S, or to its detriment, and are not to be copied, reproduced, disclosed to others, or disposed of except with the prior written consent of US&S.

Important Notice US&S constantly strives to improve our products and keep our customers apprised of changes in technology. Following the recommendations contained in the attached service manual will provide our customers with optimum operational reliability. The data contained herein purports solely to describe the product, and does not create any warranties.

Within the scope of the attached manual, it is impossible to take into account every eventuality that may arise with technical equipment in service. Please consult your local US&S sales representative in the event of any irregularities with our product.

We expressly disclaim liability resulting from any improper handling or use of our equipment, even if these instructions contain no specific indication in this respect. We strongly recommend that only approved US&S spare parts are used as replacements.

This Class A digital apparatus complies with Canadian ICES-003.

CET appareil numerique de la classe A est conforme a la norme NMB-003 du Canada.

Revision History

ii SM 5994, Rev. 2.0, June 2008

Revision History

REV. DATE NATURE OF REVISION

0 February 1979 Initial Issue

1 March 2002 Updated to current Service Manual format. Corrected minor errors.

2 June 2008

Updated to current Service Manual format. Evaluated and incorporated ECOs as applicable: EE-1758 (6/03), EE-1804 (11/03 - N/A), EE-1811 (12/03), and K-0265 (9/05 - N/A).

Table of Contents

SM 5994, Rev. 2.0, June 2008 iii

Table of Contents 1. INTRODUCTION................................................................................................................................1-1

1.1 General Description ..................................................................................................................1-1

1.2 Electrical Specifications ............................................................................................................1-1

1.2.1 Dielectric Strength ........................................................................................................1-2

1.2.2 Ratings..........................................................................................................................1-2

1.2.3 Insulation.......................................................................................................................1-2

1.3 Mechanical Specifications ........................................................................................................1-2

1.3.1 Operating Temperature Range.....................................................................................1-2

1.3.2 Weight...........................................................................................................................1-2

1.4 AREMA Compliance .................................................................................................................1-2

2. OPERATION AND INSTALLATION .................................................................................................2-1

2.1 General .....................................................................................................................................2-1

2.2 Ratings......................................................................................................................................2-1

2.3 Winding Arrangements and Adjustments .................................................................................2-1

2.3.1 Winding Arrangements .................................................................................................2-1

2.3.2 Input Terminal Designations .........................................................................................2-1

2.3.3 Output Terminal Designations and Adjustments ..........................................................2-2

2.4 Terminal Board Drawings and Schematic Diagrams................................................................2-4

2.5 Installation Procedure .............................................................................................................2-18

3. MAINTENANCE.................................................................................................................................3-1

3.1 Preventive Maintenance ...........................................................................................................3-1

3.2 Corrective Maintenance............................................................................................................3-1

4. PARTS LIST ......................................................................................................................................4-1

5. RAIL TEAM AND TECHNICAL SUPPORT ......................................................................................5-1

Table of Contents

iv SM 5994, Rev. 2.0, June 2008

List of Figures Figure 2-1. N451428-0101 Terminal Faceplate and Schematic Diagram..........................................2-4 Figure 2-2. N451428-0102 Terminal Faceplate and Schematic Diagram..........................................2-5 Figure 2-3. N451428-0103 Terminal Faceplate and Schematic Diagram..........................................2-6 Figure 2-4. N451428-0104 Terminal Faceplate and Schematic Diagram..........................................2-7 Figure 2-5. N451428-0105 Terminal Faceplate and Schematic Diagram..........................................2-8 Figure 2-6. N451428-0106 Terminal Faceplate and Schematic Diagram..........................................2-9 Figure 2-7. N451428-0107 Terminal Faceplate and Schematic Diagram........................................2-10 Figure 2-8. N451428-0108 Terminal Faceplate and Schematic Diagram........................................2-11 Figure 2-9. N451428-0109 Terminal Faceplate and Schematic Diagram........................................2-12 Figure 2-10. N451428-0110 Terminal Faceplate and Schematic Diagram........................................2-13 Figure 2-11. N451428-0111 Terminal Faceplate and Schematic Diagram........................................2-14 Figure 2-12. N451428-0112 Terminal Faceplate and Schematic Diagram........................................2-15 Figure 2-13. N451428-0113 Terminal Faceplate and Schematic Diagram........................................2-16 Figure 2-14. N451428-0114 Terminal Faceplate and Schematic Diagram........................................2-17 Figure 4-1. W-400 Transformer ..........................................................................................................4-2

List of Tables Table 1-1. Electrical Specifications ...................................................................................................1-1 Table 4-1. W-400 Transformer Parts List..........................................................................................4-1 Table 4-2. W-400 Transformer Parts List Tabulation........................................................................4-1

Introduction

SM 5994, Rev. 2.0, June 2008 1-1

1. INTRODUCTION

1.1 General Description

The W-400 transformer series is designed for general voltage adjustment, except for N451428-0110 and -0111, which have special applications. N451428-0110 is a decoding transformer for wayside coded track circuits. N451428-0111 is an indication transformer for coded Centralized Traffic Control (CTC) systems.

W-400 transformers are designed for indoor rack, wall, or shelf mounting. Electrical connections are made to Association of American Railroads (AAR) terminals. Terminal designations and secondary output adjustments are indicated on the terminal faceplates of the units.

1.2 Electrical Specifications

Electrical specifications for the transformers are listed in Table 1-1. This information is also indicated on the terminal faceplates of the units (see Figure 2-1 through Figure 2-14).

Table 1-1. Electrical Specifications Primary (Input) Secondary (Output)

Part No. N451428

Trans. Type Voltage Freq.

(Hz) No. 1 (Vac/A)

2 (Vac/A)

3 (Vac/A)

4 (Vac/A)

TotalPowerRating

(W)

-0101 General 120/114 Vac 60/100 1 18/20 - - - 360 -0102 General 120/114 Vac 60/100 2 18/10 18/10 - - 360 -0103 General 120/114 Vac 60/100 4 6/3 6/3 25/5 16/12 353 -0104 General 120/114 Vac 60/100 3 12/12 12/10 12/10 - 384 -0105 General 120/114 Vac 50/100 2 16/10 16/10 - - 320 -0106 General 240/228 Vac 60/100 2 18/10 18/10 - - 360 -0107 General 120/114 Vac 50/100 2 32/5 32/5 - - 320 -0108 General 120 Vac 60/100 2 18/3.5 18/3.5 - - 126 -0109 General 240/228 Vac 60/100 1 18/20 - - - 360 -0110 Decoding 10 Vdc 1.25/3 - - - - - - -0111 Indication - - - - - - - - -0112 General 120/114 Vac 60/100 2 18/10 36/5 - - 360 -0113 General 120/114 Vac 60/100 1 18/20 - - - 360 -0114 General 120 Vac 60/100 1 11.3/18 - - - 200

Introduction

1-2 SM 5994, Rev. 2.0, June 2008

1.2.1 Dielectric Strength

W-400 Transformers are designed to provide AREMA-specified 3000 Vac isolation between primary and secondary windings and between windings and core.

1.2.2 Ratings

Output current is limited to maximum current as shown in Table 1-1 for maximum voltage output. The input voltage must be full line voltage (120, 240, etc.) at rated frequency for maximum output rating.

1.2.3 Insulation

Insulation is Class A.

1.3 Mechanical Specifications

1.3.1 Operating Temperature Range

The operating temperature range of the transformer is -40°F to +160°F.

1.3.2 Weight

The weight of a transformer is approximately 18.5 lb.

1.4 AREMA Compliance

The W-400 transformer series complies with all current AREMA specifications.

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-1

2. OPERATION AND INSTALLATION

2.1 General

Terminal identification drawings and schematic diagrams for the W-400 transformers are shown in Figure 2-1 through Figure 2-14. Input/output voltages are listed in Table 1-1. Transformer connection and installation information is provided in this section. Ordering information for replacement parts is provided in Section 4. Product support contact information is in Section 5.

2.2 Ratings

See Section 1.2 for input/output ratings.

2.3 Winding Arrangements and Adjustments

2.3.1 Winding Arrangements

See Figure 2-1 through Figure 2-14 for terminal faceplate drawings and schematic diagrams for each transformer. Internal windings are connected to the terminals as shown on the terminal boards of the transformers.

For the following example, refer to the terminal faceplate drawing for transformer N451428-0101 illustrated in Figure 2-1. A connection for the complete primary winding is shown across terminals +lP and 3P with a tap at 2P. From terminal +A to terminal D is a complete secondary winding with taps at B and C. No internal connections exist between the P terminals and the A to D terminals; thus, no connections are shown on the terminal board.

2.3.2 Input Terminal Designations

2.3.2.1 Transformers N451428-0101 to -0107, -0109, -0112, -0113

Input primary windings: +lP, 2P, 3P

2.3.2.2 Transformers N451428-0108, -0110

Input primary windings: +lP, 2P, 3P, 4P.

2.3.2.3 Transformer N451428-0111

No. 1 input primary windings: +lP, 2P.

No. 2 input primary windings: 3P, 4P.

2.3.2.4 Transformer N451428-0114

Input primary windings: +1P, 3P.

.

Operation and Installation

2-2 SM 5994, Rev. 2.0, June 2008

2.3.3 Output Terminal Designations and Adjustments

Terminals connected to secondary windings are designated +A, B, C, etc. and terminals connected to associated adjustment windings are designated +W, X, Y, etc. The “+” symbol indicates the start, or instantaneous, polarity of the winding.

When there is more than one secondary winding, the first secondary terminals are designated +lA, lB, lC, etc. and the associated adjustment winding terminals are designated +1W, lX, lY, etc. The second secondary terminals are designated +2A, 2B, 2C, etc. and the associated adjustment winding terminals are designated +2W, 2X, 2Y, etc.

Main and associated secondary adjusting windings are to be used together as a group for the purpose of selecting desired secondary output voltages. In order for the adjustment winding to be additive, the negative terminal of the main secondary winding must be jumpered to the positive terminal of its associated adjusting winding. In similar fashion, sections of main or adjusting windings must also be jumpered together with negatives of main windings being connected to positives of the adjusting windings. For example, to obtain an output of 9.03 V from transformer N451428-0101 (see Figure 2-1), a jumper must be connected from C to X and the outputs taken from terminals B and Y (7.9 + 1.13 = 9.03).

2.3.3.1 Output Terminal Designations for Transformers N451428-0101, -0102, -0105, -0106, -0107, -0109, -0112, and -0113

Main secondary windings: +A, B, C, D.

Secondary adjusting windings: +W, X, Y, Z.

2.3.3.2 Output Terminal Designations for Transformer N451428-0103

No. 1 secondary winding: +lS to 4S.

No. 2 secondary winding: +lT to 4T.

No. 3 secondary winding: +lR to 6R.

No. 4 secondary winding: +lL to 6L.

Each winding is separate and can be connected together for higher voltage output, but output current is limited to the lowest current rating of the combined secondaries.

2.3.3.3 Output Terminal Designations for Transformer N451428-0104

No. 1 secondary winding: +lR to 4R.

No. 2 secondary winding: +lS to 4S.

No. 3 secondary winding: +lT to 4T.

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-3

2.3.3.4 Output Terminal Designations for Transformer N451428-0108

No. 1 adjusting winding: +1W to lZ.

No. 2 adjusting winding: +2W to 2Z.

The line input is connected to +lP and 4P, and outputs are taken across +lP, 2P, or 3P. For adjusting output voltage, jumper 2P or 3P to the appropriate +1W to lZ or +2W to 2Z sections. For example, to obtain 49.0 V output, jumper from 2P to lX and then connect the output to +lP and lY (40 + 9.0 = 49.0).

2.3.3.5 Output Terminal Designations for Transformer N451428-0110

No. 1 secondary winding: +lH to 3H.

No. 2 secondary winding: +11 to 41.

2.3.3.6 Output Terminal Designations for Transformer N451428-0111

Secondary winding: +SO to S2000.

2.3.3.7 Output Terminal Designations for Transformer N451428-0114

Secondary winding: B to Z.

Operation and Installation

2-4 SM 5994, Rev. 2.0, June 2008

2.4 Terminal Board Drawings and Schematic Diagrams

Figure 2-1 through Figure 2-13 illustrate the terminal faceplates and schematic diagrams for the W-400 transformer series.

STYLE W-400 TRANSFORMER

SECONDARY IS ADJUSTABLEADDITIVELY IN 0.37 V. STEPS

UN451428-0101+ 1P

120/114V. 60/100 Hz.2P

VA3603P

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

1P

2P

3P

+

+

+

_

_

_

A

B

C

DW

X

Y

Z

SCHEMATICN451428-0101

Figure 2-1. N451428-0101 Terminal Faceplate and Schematic Diagram

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-5

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

STYLE W-400 TRANSFORMERUN451428-0102

+ 1P120/114V. 60/100 Hz.

2PVA360

3P

SECONDARY IS ADJUSTABLEADDITIVELY IN 0.37 V. STEPS

1P

2P

3P

+

+

+

_

_

_

1A

1B

1C

1D1W

1X

1Y

1Z+

+

_

_

2A

2B

2C

2D2W

2X

2Y

2Z

SCHEMATICN451428-0102

Figure 2-2. N451428-0102 Terminal Faceplate and Schematic Diagram

Operation and Installation

2-6 SM 5994, Rev. 2.0, June 2008

STYLE W-400 TRANSFORMER

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

1P

2P

3P

+

+

+

+

+

_

_

_

_

_

SCHEMATICN451428-0103

1L

2L

3L

4L

5L

6L

1R

2R

3R

4R

5R

6R

1S

2S

3S

4S

1T

2T3T

4T

Figure 2-3. N451428-0103 Terminal Faceplate and Schematic Diagram

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-7

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

STYLE W-400 TRANSFORMER

1P

2P

3P

+

+

+

+

_

__

_

1R

2R

3R

4R

1S

1T

2S

2T

3S

3T

4S

4T

SCHEMATICN451428-0104

Figure 2-4. N451428-0104 Terminal Faceplate and Schematic Diagram

Operation and Installation

2-8 SM 5994, Rev. 2.0, June 2008

1P

2P

3P

+

+

+

+

+

_

_

_

_

_

1A

2A

1B

2B

1C

2C

1D

2D

1W

2W

1X

2X

1Y

2Y

1Z

2Z

SCHEMATICN451428-0105

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

STYLE W-400 TRANSFORMER

Figure 2-5. N451428-0105 Terminal Faceplate and Schematic Diagram

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-9

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

1P

2P

3P

+

+

+

+

+

_

_

_

_

_

1A

2A

1B

2B

1C

2C

1D

2D

1W

2W

1X

2X

1Y

2Y

1Z

2Z

SCHEMATICN451428-0106

Figure 2-6. N451428-0106 Terminal Faceplate and Schematic Diagram

Operation and Installation

2-10 SM 5994, Rev. 2.0, June 2008

STYLE W-400 TRANSFORMER

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

UN451428-0107

+ 1P

120/114V. 50/100 Hz.

2P

VA320

3P

1P

2P

3P

+

+

+

+

+

_

_

_

_

_

1A

2A

1B

2B

1C

2C

1D

2D

1W

2W

1X

2X

1Y

2Y

1Z

2Z

SCHEMATICN451428-0107

Figure 2-7. N451428-0107 Terminal Faceplate and Schematic Diagram

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-11

STYLE W-400 TRANSFORMERUN451428-010 8 120V. 60/100 Hz. VA700

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

1P

2P

3P

4P

+

+

+

_

_

_

1W

1X

1Y

1Z2W

2X2Y

2Z

SCHEMATICN451428-0108

Figure 2-8. N451428-0108 Terminal Faceplate and Schematic Diagram

Operation and Installation

2-12 SM 5994, Rev. 2.0, June 2008

STYLE W-400 TRANSFORMER

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

1P

2P

3P

+

+

+

_

_

_

A

B

C

DW

X

Y

Z

SCHEMATICN451428-0109

Figure 2-9. N451428-0109 Terminal Faceplate and Schematic Diagram

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-13

DECODING TRANSFORMER

STYLE W-400 TRANSFORMER1.25/3 Hz.

+ 1H

2P

N451428-0110

3P

4P

3I 4I2I+ 1I

3H2H

4P

10 VDC

+ 1P

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

1P

2P

3P

4P

+

+

+

_

_

_

1I

2I

3I

4I

1H

2H

3H

SCHEMATICN451428-0110

Figure 2-10. N451428-0110 Terminal Faceplate and Schematic Diagram

Operation and Installation

2-14 SM 5994, Rev. 2.0, June 2008

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

INDICATION TRANSFORMERUN451428-0111STYLE W-400 TRANSFORMER

1P

2P3P

++

+

_ _

_

SCHEMATICN451428-0111

4P

S0

S300

S1700

S1900

S2000

Figure 2-11. N451428-0111 Terminal Faceplate and Schematic Diagram

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-15

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

STYLE W-400 TRANSFORMERUN451428-0102

+ 1P120/114V. 60/100 Hz.

2PVA360

3P

SECONDARY IS ADJUSTABLEADDITIVELY IN 0.37 V. STEPS

1P

2P

3P

+

+

+

_

_

_

1A

1B

1C

1D1W

1X

1Y

1Z+

+

_

_

2A

2B

2C

2D2W

2X

2Y

2Z

SCHEMATICN451428-0102

Figure 2-12. N451428-0112 Terminal Faceplate and Schematic Diagram

Operation and Installation

2-16 SM 5994, Rev. 2.0, June 2008

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

STYLE W-400 TRANSFORMER

1P

2P

3P

+

+

+

_

_

_

A

B

C

DW

XY

Z

SCHEMATICN451428-0113

Figure 2-13. N451428-0113 Terminal Faceplate and Schematic Diagram

Operation and Installation

SM 5994, Rev. 2.0, June 2008 2-17

1P

SCHEMATICN451428-0114

3P

B

ZSECONDARY

STYLE W-400 TRANSFORMERN451428-0114

+ 1P60/100Hz

3P

UNION SWITCH & SIGNAL645 RUSSELL ST.BATESBURG, SC 29006

B

11.3 V.

Z

PRIMARY

120 V.

3E1.

0001

.00

Figure 2-14. N451428-0114 Terminal Faceplate and Schematic Diagram

Operation and Installation

2-18 SM 5994, Rev. 2.0, June 2008

2.5 Installation Procedure

WARNING

Disable all power before installing the unit. Failure to do so could result in serious personal injury or loss of life.

WARNING

Install insulating sleeves and insulating nuts as described in Step 3 of the following procedure. Failure to do so could result in serious personal injury or loss of life.

CAUTION

Observe voltage and current limits printed on the terminal board of the transformer. Do not exceed maximum voltages. If these restrictions are not followed, damage to equipment could result.

1. Observe all warning and caution statements listed throughout this manual. Follow the safety policies established for your work site regarding the installation of electronic equipment.

2. Place the transformer in position and secure to equipment rack or mounting surface. Attach wire leads to the AAR terminals.

3. Install insulating sleeves and insulating caps on all AAR terminals. See Figure 4-1.

Maintenance

SM 5994, Rev. 2.0, June 2008 3-1

3. MAINTENANCE

3.1 Preventive Maintenance

WARNING

Before beginning this maintenance procedure, disable all power from the unit and from any nearby circuits. Failure to do so could result in serious personal injury or loss of life.

The transformer should be visually inspected periodically. Examine the condition of the terminal board. Check for loose connections or terminals. Check that the transformer is securely mounted. If excessive dirt is noted on terminals, use a soft, lint-free cloth to remove any accumulated dust or dirt.

3.2 Corrective Maintenance

Maintenance consists of testing for correct output voltages under normal load conditions. If output voltages are incorrect, be sure to test for overloads or incorrect input voltage to the transformer. Information concerning correct input/output voltages for the transformers is located in Table 1-1.

Maintenance

3-2 SM 5994, Rev. 2.0, June 2008

Parts List

SM 5994, Rev. 2.0, June 2008 4-1

4. PARTS LIST

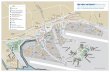

Refer to Figure 4-1 for parts illustration and correlation to Table 4-1 and Table 4-2.

Table 4-1. W-400 Transformer Parts List Item Description Part No.

- W-400 transformer See Table 4-2 10 Terminal board See Table 4-2 15 Side cover See Table 4-2 20 Nuts and washers for electrical connections to external post

(AAR) terminals (supplied in plastic bag; contains insulating caps, sleeves, terminal connectors where applicable)

See Table 4-2

30 Wire terminal M223832 35 Post terminal, no. 14-24 (AAR terminal) See Table 4-2 40 Washer, flat, copper, nickel pl, 17/64 x 9/16 in. J047818 45 Nut, hex head, brass, nickel pl, no. 14-24 J480300 50 Lockwasher, steel, tin pl, 1/4 in. J047775 55 End plate for -0101 through -0112 M376622 55 End plate for -0113 only M296141001 65 Reinforcing bracket for -0113 only M323518 150 Coil See Table 4-2 *1 Insulating cap (install on AAR terminals, supplied with item 20) J078169 *2 Insulating sleeve (install on AAR terminals, supplied with item 20) M195032

Table 4-2. W-400 Transformer Parts List Tabulation

Transformer N451428-

Item 10

Item 15

Item 20

Item 35

Item 150

-0101 M4514290101 M240123 N337810 M160475 N4514300101 -0102 M4514290102 M240123 N337804 M160475 N4514300201 -0103 M4514290201 M240123 N337812 M160475 N4514300301 -0104 M4514290202 M240123 N337803 M160475 N4514300401 -0105 M4514290301 M240123 N337804 M160475 N4514300501 -0106 M4514290302 M240123 N437004 M122489 N4514300601 -0107 M4514290401 M240123 N337804 M160475 N4514300701 -0108 M4514290402 M240123 N337810 M160475 N4514300801 -0109 M4514290501 M240123 N337810 M160475 N4514300901 -0110 M4514290502 M240123 N437005 M160475 N4514301001 -0111 M4514290601 M240123 N337809 M160475 N4514301101 -0112 M4514290602 M240123 N337804 M160475 N4514301301 -0113 M4514290701 M438255 N337810 M160475 N4514300101 -0114 M4514290704 M240123 N337817 M160475 N36700901

Parts List

4-2 SM 5994, Rev. 2.0, June 2008

55

1565

150

*1

*240

35

2045

50

10

30

Figure 4-1. W-400 Transformer

RAIL Team and Technical Support

SM 5994, Rev. 2.0, June 2008 5-1

5. RAIL TEAM AND TECHNICAL SUPPORT

The Rapid Action Information Link Team (RAIL Team) is a group of experienced product and application engineers ready to assist you to resolve any technical issues concerning this product. Contact the RAIL Team in the United States at 1-800-652-7276 or by e-mail at [email protected].

RAIL Team and Technical Support

5-2 SM 5994, Rev. 2.0, June 2008

End of Manual

Related Documents