VSL NEWS N U M B E R O N E 1 9 9 0 VSL

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Editorial

2

VSL

As we enter the 1990s, it is already clear that the new decade will witness anexhilarating array of new beginnings and new directions. In business, industry,

and society, our world is rapidly changing, creating exciting opportunities for thoseorganizations who are in touch with their customers and prepared for change.

This issue of VSL News is a prime example of the VSL Group’s commitment tomaintaining close lies with our markets through communication and constant impro-vement. The preceding two issues were presented with a new look, but this editionis a further step in the right direction. The old newsletter has evolved into a full-grown periodical, with an improved graphic format and articles which reflect theinnovation and diversity of VSL’S worldwide construction activities.

Our lead story concerns the spectacular underpinning of a huge retail complexin Sao Paulo. Written by Ing. E. Rudloff, the partner of our Brazil affiliate, the storyshows once more that VSL is non only synonymous with quality post-tensioning,but also with new problem-solving ideas to serve our clients. In the next article byDr. H.R. Ganz, we present another innovative idea which has become reality : theVSL Post-Tensioned Masonry System. This system is now marketed in Switzerlandthrough the joint efforts of VSL International Ltd. and brick manufacturer ZürcherZiegeleien.

Next we present the latest developments of our five VSL Operating Units. Ofspecific interest are the various fascinating applications of VSL Post-Tensioning,including projects where VSL specialists have assisted with significant value engi-neering. In the US.A., a breakthrough is reported by the VSL Transit SystemsGroup ; after a reorganization of the Transit Division in 1988, a contract for a newsystem has been signed in Nevada, with many others to follow.

As the new editor of VSL News, we are pleased to introduce Ms. Therese Wen-ger, who also serves as the assistant to VSL Group Management in Berne, Swit-zerland. Therese has been with VSL since 1981, and is well-regarded for her diver-se capabilities and dependability. She has taken over the editorial responsibilitiesfrom Hans Ulrich Aeberhard, who has left our group. Hans was the editor of theVSL Newsletter for many years, and made the publication one of high technicalstandards.

We also welcome Mr. Donald McDaniel, a native of California, who will serveas creative director for our periodical. He is responsible for assuring that our newpublication meets the highest criteria for visual presentation and client commu-nication.

Preparing for a decade of opportunity and change

Reto JenatschChairman of the Board andChief Executive Officer

Contents

3Brazil

4Converting Research

Into Reality

6Australia

8USA West

10USA East

12Europe

14Far East

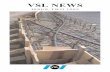

Cover : VSL Monostrand post-tensioningtendons are automatically coated andsheathed by a computerised, high-speedextrusion process. The cover photoshows the payoff baskets of the Mono-strand production line at VSL Corpora-tion’s Washington, D.C. fabrication plant.

Brazil

3

Shopping centre in Sao Paulo expands— downward! A42-year-old shopping centre in

Sao Paulo, Brazil, had to beenlarged and modernized. The sitewould not allow a horizontal additionand current building regulationsrequired such à large setback thatreplacement with a new building wasnot practical. It was decided toextend the building downward threestories and build three additional sto-ries on the existing structure.

In March 1988, RUDLOFF-VSLwere asked to provide a technicalsolution and project design for thedownward expansion. The challengewas to provide temporary supportfor the 76 reinforced concretecolumns while they were extendeddownward. Each column carried anaverage load of 600 tonnes. As àfurther challenge, the shoppingcentre was to remain in use duringthe six-month downward expansion.

The solution proposed by RUD-LOFF-VSL was to transfer column

loads to temporary foundations with asteel strut and lie system, permittingthe columns and permanent founda-tions to be extended downward. Amajor key to the project’s successwas the use of hydraulic jacks toensure proper load transfer to thetemporary foundations and to preventexcessive movements in the super-structure. After removing the oldfoundations, shafts for the columnextensions were excavated. At adepth of approximately 20m, theshafts were belled to accommodatethe new foundation. When all of thecolumns were extended, the under-ground space was excavated.

RUDLOFF-VSL provided the enti-re steel strut system, lifting jacks andpumps, as well as the post-tensioningof the concrete slabs. The slabs werecast in succession from the topdown, that is, the lowest slab wascast last.

The project was completed onschedule, and with the experiencegained, it is expected that with sui-table soil conditions, this method ofunderpinning could be used for buil-dings with loads of 2,000 to 3,000tonnes per column.

Ing. E. RudlofRUDLOFF-VSLSao Paulo, Brazil

VSL

Shopping centre remained in useduring the entire underpinning anddownward expansion.

Strut and tie system provided tempo-rary support to column while perma-nent foundations and columns wereextended downward.

Converting Research Into Reality

4

VSL

Masonry is an ancientconstruction material which

combines high durability with excel-lent thermal and acoustic insulationproperties. In addition, the buildingmethods for masonry structures aresimple and very flexible.

Like concrete, masonry has arelatively high compressive strengthbut possesses a low tensile strength.Because of this, it has been used pri-marily as a construction material forvertical members subjected essen-tially to gravity loads. In addition toaxial loads, masonry walls are alsosubject to in-plane shear, ouf-of-plane transverse loads, and imposeddeformations caused by deflectionsand volume changes of floor slabs.Under such conditions, walls with lowaxial force exhibit poor crackingbehaviour and reduced strength.

To overcome the structural andperformance limitations of conventio-nal masonry structures, VSL hasdeveloped a new post-tensioningsystem for the construction ofmasonry watts. Post-tensioning willactively introduce any desired level ofaxial force in a wall to provide therequired strength and crack control.

Post-tensioned masonry is non anew idea. In 1825, a post-tensioningmethod was employed for tunnel lingunder the Thames River in England.The development of reinforcedconcrete in the fate 19th century ledto the significant decline of masonryas a structural material. Only in theearly 1950’s did Europe experience agradual revival of its use. Since the1960’s, a number of prestressedmasonry applications have beenreported, primarily in England. Theapplications include prestressedmasonry water tanks, large walls inbuildings, retaining walls and bridgeabutments.

The new system developed byVSL utilizes high strength steel strandthat is greased and coated with extru-ded plastic for maximum corrosionprotection. A solid and durable ductaround the monostrand tendons pro-vides an additional layer of protection.

Typical tendon arrangement forVSL post-tensioned masonry wall.

New post-tensioning system increases strength andheight potential of masonry structures

5

The monostrand is easy to use in thefield. It eliminates the multiple XXX ofprestressing bars and provides super-ior tension capacity per weight ofprestressing steel.

A typical VSL masonry tendonconsists of a self-activating dead-endanchorage, a stressing anchorageplaced in a prefabricated concrete ele-ment, the 15mm diameter greasedand coated monostrand, and a steelduct. The dead-end anchorage at thelower end of the tendon is cast into theconcrete foundation. During the wallconstruction, short duct segments arethreaded to the anchorage or pre-viously placed duct segments. Thisprocedure allows the bricks to be laideasily because only a small numberneed be threaded over each duct seg-ment. When the final wall height isreached, the last duct segment is cutto the required length and the prefa-bricated concrete element containing

the stressing anchorage is placed.Monostrands are introduced throughthe stressing anchorage and duct intothe self-activating dead-end anchora-ge. After the masonry reaches thespecified strength, the tendons arestressed to a maximum of 75% of theirultimate capacity.

The VSL post-tensioned masonrysystem has been successfullyemployed for two recent applicationsin Switzerland. First, brick walls of aschool in Zurich were post-tensionedto provide the strength required toresist ouf-of-plane transverse loads.The clay brick walls were 140mm thickand up to 4m high with large windowopenings. In the second project, a250mm thick fireproof factory wallnear Zürich was post-tensioned towithstand a wind velocity of 21m/s asa cantilever. Only 17 tendons wererequired for the 36m long wall, whichwas up to 8.8m high.

An increasing number of peopleprefer masonry structures overconcrete due to masonry’s aesthetics,variety and high durability. Masonryconstruction procedures also providean inherent flexibility for the shape ofwalls non easily achievable withconcrete. Thus, post-tensionedmasonry offers new potential for inno-vative and cost-conscious structuralengineers.

The VSL post-tensioned masonrysystem is marketed jointly in Switzer-land by VSL International Ltd. andbrick manufacturer Zürcher Ziege-leien.

Hans-Rudolf Ganz, Ph. D.VSL WesternCampbell, California

VSL

Threading a duct segment Introduction of monostands

Stressing of tendon Post-tensioned fireproof factory wall under construction

Australia

6

VSL

VSL rock anchorsrehabilitate Warra-gamba Dam

VSL has recently completedthe fabrication, installation,

and stressing of 102 permanent rockanchors at Warragamba Dam. Thework was associated with the raisingand strengthening the 30-year-oldstructure.

A total of 420 tonnes of 15mmhigh tensile strand was used for the16,500 kN capacity anchors whichhad a maximum length of 112m,making them the highest capacityand longest anchors ever used inAustralia. Stressing of the anchorswithin galleries with limited workingspace required a specially commis-sioned stressing jack. all of theanchors are fully encapsulated,monitorable and restressable.

Gareth Pickering VSL Prestressing (Aust.) PtY. Ltd.Thornleigh, New South Wales

Post-tensionedflooring systemchosen for 56 level Mel-bourne building

The Bourke Place project is a212m rail concrete building

situated in Melbourne’s City Centre.Currently under construction, theproject is due for completion in mid-1990.

A VSL post-tensioned bandbeam flooring system was chosenas the most suitable for the59,000m2 of office space, due tofavourable economics and speed ofconstruction. The system consistsof a 125mm thick floor slab and400mm deep x 1000mm wide bandbeams at 4.7m centres. The beamstypically span 10.8m from the per-imeter to the core. The beams arehaunched at the ends to allow air-conditioning and other services topass without increasing the floor tofloor height.

P. Tilley VSL Prestressing (Aust.) Pty. Ltd.Noble Park, Victoria

The raised and strengthened Warragamba Dam.

Bourke Place climbform at level 18 with post-tensioned floors at level 13.

7

The World Square developmentin Sydney’s central business

district will be one of the largest pres-tressed concrete structures in theworld. Begun in 1986, it will take over7 years to complete and cost nearlyone billion dollars.

VSL Prestressing (Aust.) Pty. Ltd.has been awarded the climbing form-work contract for the first tower buil-ding, and the post-tensioningcontracts for this tower and the totalpodium. VSL will install nearly 150,

000m2 of post-tensioned slabs in theproject and will use over 700 tonnes ofprestressing strand.

The completed project will be adominant feature of the city, with fourtowers of up to 60 storeys su rmoun-ting a twelve storey podium. The totalfloor area on completion will exceed350,000m2.

David J. Standley VSL Prestressing (Aust.) Pty. Ltd.Thornleioh, New South Wales

VSL

Climbform in place and post-tensioned deck under construction for World Square project, Sydney

VSL climbforming :The sky is the limitin Sydney

USA West

8

VSL

The Astronauts Memorial is amajor U.S. monument dedica-

ted to the memory of the fourteenAmerican Astronauts who lost theirlives in the space effort. The nationalcompetition-winning design, by archi-tects Holt Hinshaw Pfau Jones, SanFrancisco, consists of an exposedsteelspace frame structure that sup-ports a 40ft x 50ft (12m x 15m) planeof highly polished granite. The entire

structure rotates and tilts to track thesun so that the tablet always facesaway from the sun to reflect the skywithout glare. The names of the astro-nauts are etched completely throughthe granite slabs. A serres of adjus-table mirrors are hung from the backof the support structure to reflect andfocus the sunlight through the cutoutnames, making the names glowagainst the reflected sky.

VSL Western was chosen as themechanized structure’s principal engi-neering group by NASA’S AstronautsMemorial Foundation and the archi-tect in June 1988. VSL’S EngineeringStructures Group is responsible forthe structural, mechanical, ‘Î and elec-trical engineering of the memorial,and has completed the design engi-neering and specifications for all com-ponents, fabrication, installation, andconstruction. The memorial is schedu-led for completion in mid-1990.

The VSL Transit System Group iscurrently building an 1,800 foot-

long (550m) passenger transportationsystem for the new Primadonna Hotel &Casino at Stateline, Nevada, near LasVegas. The fully automated, cable-pro-pelled VSL METRO-SHUTTLE willconnect an existing hotel/casino loca-ted on the west side of Interstate 15with a new development on the eastside of the highway. The shuttle will tra-vel above, four lanes of traffic, making itthe first privately-owned transit systemto cross a U.S. interstate highway.

Operation of the system is com-pletely automated, requiring no on-board drivers or attendants.

The Primadonna shuttle is thesixth cable propelled METROSHUTT-LE system to be built by VSL Corpo-ration. Previously-built VSL systemsare performing reliably in Memphis,Las Vegas (two systems) and Reno(two systems).

NASA’s Astronauts Memorial readv for construction

VSL Western has completed thestructural, mechanical and electricalengineering of the Astronaut’sMemorial, soon to be built by VSL atKennedy Space Center.

VSL peoplemover to cross interstate highway in Nevada

Carlos Banchik Don McDanie/ David SwansonMan/y Jackson VSL Western Campbell, California

Model of VSL’S newly-designed transitvehicle and guideway structure, currentlyunder construction in Nevada.

9

One of the many ways inwhich VSL has expanded its

scope of services for U.S. bridgeprojects is through the design andsupply of travelling formwork sys-tems. When combined with VSL Mul-tistrand post-tensioning, VSL form-work provides bridge contractorswith an efficient, single-source struc-tural package.

The steel travellers are essentiallytruss structures which support form-work for the cast-in-place method offree cantilevering. The componentsare pin-connected for fast assemblyand dismantling, and are safe andeasy to use. Currently, VSL maintainsa fleet of nine travellers, all of whichare in use across the United States.The projects include the Illinois River

Bridge near Jacksonville, Illinois,Jamestown Bridge in Rhode Island,the West Seattle Bridge in Washing-ton State, Bennett Bay Bridge inIdaho, Westmoreland Bridge in Dal-las, Texas, and the Hoover Dam Visi-tors Center Bridge outside Las Vegas,Nevada.

Travellers at four western U.S.airports now undergoing

major expansions will soon be par-king their cars in VSL post-tensionedparking structures. VSL Western’sCommercial Structures Group haswon contracts for Sky Harbor Interna-tional Airport in Phoenix, AZ, JohnWayne Orange County Airport in Sou-thern California, San Jose Internatio-nal Airport in Northern California, andSalt Lake City International Airport inUtah. The contracts include the desi-gn, fabrication, delivery and technicalassistance for the post-tensioning ofover two million square feet Il90,000m2) of parking structure deck.

VSL’S presence in the busyArizona building market

expanded dramatically in 1989. InPhoenix, the company has completedthe following recent projects : Citi-bank Tower, 2800 N. Central officebuilding and parking structure, CrystalPoint Condominiums, Esplanade Offi-ce Towers and Merabank Centre.

In Tucson, VSL post-tensioningwas utilized in both horizontal and ver-tical directions to construct the newscholarship suites addition for the Uni-versity of Arizona’s sports stadium.The suites hang above the stadiumfrom cantilevered beams on 185ft(56m) cast-in-place columns.

VSL

VSL travelling formwork now at work on six major U.S. bridge projects

Westmoreland Bridge under construction in Dallas, Texas.

VSL Commercial Structures Group strengthens leadership positionin western post-tensioning marketMajor airport expansions utilizeVSL post-tensioned concrete

Horizontal and vertical post-tensioningprovided the required resistance tobending and overturning forces on thefreestanding cantilevered suites.

Increased activity in Arizonabuilding market

USA West

10

VSL

Georgia damstrengthened withVSL rock anchors

Yonah Dam, owned and opera-ted by the Georgia Power

Company is located along the Tuga-loo River approximately 85 miles nor-theast of Atlanta. The dam length atthe crest is approximately 975ft.(300m), with a 450ft ( 140m) central-ly located overflow spillway. It has amaximum height of 90ft. (27m). Builtbetween 1923 and 1925, the damrequired strengthening to meet cur-rent design standards.

The dam strengthening involvedthe installation of 52 VSL rockanchors through the crest of the dam.Design bond lengths range from 39ftto 55ft (12 to 17m) with overall anchorlengths of up to 178ft. (54m). The ins-talled anchor capacity totalled 91,416kips (407,000 kN). VSL designed andsupplied all of the rock anchor mate-rials for the project.

John Crigler VSL Eastern Springfield Virginia

Parking expansion forAmerican Airlinescontinues

VSL’s Dallas, TX office is cur-rently involved in the second

phase of construction for the Ameri-can Airlines parking complex thatincludes approximately 1, 650,000square feet (153, 000m2) of elevatedconcrete deck. The initial phase ofconstruction was completed by VSLin 1986 and included 700,000 squarefeet (65,000m2). Construction of thesecond phase began in April 1989.The structural frame was completedin December 1989. The structural fra-ming system consists of post-tensio-ned beams spanning 60ft (18.3m)and 7in. (180 mm) post-tensionedslabs spanning 27 ft (8.2m). Post-ten-sioning is also used for slab tempera-ture reinforcing.

Mountainous terrain required that all of the work be done from barges tied tothe upstream face of the dam.

American Airlines parking expansion utilizes more than 460 tons of prestressingstrand.

Larry Krauser VSL Eastern Grand Prairie, Texas

11

The Adolph Coors Companyrequired a 1.5 million gallon

(5,500,000l) tank for an expansion oftheir waste water treatment facility inGolden, Colorado. The process usedto treat brewery waste uses gaseous

oxygen and requires a gas tight struc-ture. Since existing non-prestressedtanks of similar size and shape hadnot performed as desired, a fully post-tensioned tank was considered to bethe most functional alternative. Post-

tensioned tanks are inherently morecrack-free than non-prestressedconcrete tanks.

VSL provided complete design,supply and installation for the coveredtank which measured 200ft. x 50ft. x21ft. high (61m x 15m x 6.4m). Suc-cess was ensured through the carefulselection of structural details andconstruction procedures aimed atreducing shrinkage and restraint crac-king. These included designing allmembers for 200 psi (1,4 MPa) resi-dual compression after all fosses; addi-tion of 1% horizontal non- prestressedreinforcement in lower portion of watts;stressing a portion of the base slabtendons at the same time as those inthe watts; early stressing of the baseslab; vertical closure strips at corners;and a shear friction joint between thewall and the roof which while initiallyallowing the roof slab to shorten wasfinally “locked” by post-tensioning.

VSL’s well established ability to pro-vide a complete design and constructpackage proved to be the key to ano-ther successful project.

Continued growthwith Retained Earth

Since its introduction in 1981, VSLhas supplied approximately five

million square feet (500,000m2) ofRetained Earth walls on 180 projectsin the U-S.

Contracts have been as large as220,000 square feet (20,500m2),with wall heights up to 70ft. (21.3m).The job shown here includes170,000 square feet (15,800m2) of“raised relief” facing panels, 600,000pounds (272 tonnes) of galvanizedreinforcing mesh, and 88,000 cubicyards (67,000m3) of select granularbackfill.

VSL

Vertical closure strips at corners allow unrestrained orthogonal movement ofwalls and base slab eliminating the accumulation of tensile stresses at thesecritical locations.

Retained Earth walls provide visually interesting access ramps to 1 - 275south of Tampa, Florida.

Problem tanks no problem for VSL

Robert Allen VSL Eastern Lakewood, Colorado

Roger Bloomfield VSL Eastern,Springfield Virginia

Europe

12

VSL

VSL stay cables carrymain span of bridge in Finland

VSL International has recentlycompleted the design, fabrica-

tion, testing, and installation of the staycable system which carries the 324mmain span of the Kemijoki River bridgein northern Finland.

The 28 VSL stay cables consist ofbetween 32 and 55 15.7mm steelstrands which are individually greasedand sheathed with high density poly-ethylene pipe and covered with “TED-LAR” tape. VSL anchorages are loca-ted at each end of the stay cables.Additional corrosion protection is pro-vided by filling the anchorages with acorrosion preventative grease and bycement grouting the main length of thestay cables.

The various stay cable compo-nents were assembled on site by VSLand subsequently installed and stres-sed, using equipment specially desi-gned for the project. After all the cableswere stressed and the fuit dead load ofthe deck was carried by the stay cable

Post-tensioning of AareRiver bridge now under-way in Switzerland

A direct highway connection bet-ween the two largest Swiss cities, Züri-ch and Basel, is now under construc-tion.

The crossing of the Aare valley atSchinznach consists of a twin box gir-der bridge with 23 spans and a totallength of over 1200m. Twenty-onespans of approximately 50m are beingconstructed on conventional formwork,while the free cantilevering construc-tion method will be used for the two90m spans.

VSL was the successful bidder forthe post-tensioning subcontract. The19-strand longitudinal tendons arebeing installed by VSL’S push-throughmethod. The transverse tendons with3 strands are prefabricated and placeddirectly into the deck.

system, the grease and grout injec-tions were performed, followed by thetapewrapping - again using equipmentspecially designed by VSL.

Ferdinand Graber/Thomas SchneiterVSL International Ltd.Lyssach, Switzerland

Kemijoki River Bridge nearing completion.

Construction of the twin box girders of the Aare River bridge is well underway.

Construction of the superstructurebegan in mid-1989. The completion ofthe bridge structure is scheduled for1992.

Dario Cilloni VSL International Ltd.Lyssach, Switzerland

13

In November of 1988, VSLwas awarded a contract for

the slipforming of two caissonsneeded to carry the main piers ofthe new Dartford cable stayedbridge across the Thames Rivereast of London.

Originally the caissons were to bemade in sections in a drydock close tothe site, but Dutch contractor BallastNedam’s solution was to constructcomplete caissons in a drydock inRotterdam’s Europort.

Each caisson measured 59m by28m in plan and was divided into 40cells. The slipformed height was 21m.VSL supplied equipment for one com-plete caisson which consisted of

1100m of steel formwork and 360 lif-ting jacks. The equipment transportedto Rotterdam totalled 240 tonnes; anew record for VSL’s slipform activities.

The slipforming of each caissonwas a day and night operation, avera-ging 3.5m per day. The total wlipfor-med area was 45,000m2. Upon com-pletion, the dock was flooded and thecaissons were towed to the bridge sitein Great Britain.

VSL

Slipforming of the first Dartford Bridge caisson.

VSL slipforms two giant caissons

Completed caisson being towed acrossthe North Sea.

René Ruprecht VSL International Ltd.Lyssach, Switzerland

Far East

14

VSL

Decking over roadwayprovides recreationspace in Hong Kong

Arecreational area was createdby decking over an eight lane

roadway near Hong Kong’s Lam TinStation. The project covers an area of261m x 46.5m and was performedwithout disrupting traffic.

The engineer’s design used 3mdeep precast prestressed U-beamsspanning 46.5m. A 200 mm thick insitu slab was cast over the top to com-plete the deck. Each of the 87 precastUbeams weighed 300 tonnes.

VSL was responsible for develo-ping the construction methodologyand for carrying out all of the precas-ting, post-tensioning 1510 tonnes),erection work and bearing supply forthe beams.

VSL accomplished this assign-ment by developing a precasting yardat finished deck level. The beamswere lifted from their beds by an ove-rhead rail system. They were then slidhorizontally to the end of the castingyard, lowered onto the support struc-ture, and slid horizontally to their finalposition. All of the lifting and sliding ofbeams was done with the VSL heavylifting system.

To accommodate simultaneousconstruction of the support structureand other constraints, a temporarycasting deck was used to build suffi-cient beams to construct the perma-nent casting deck. The permanentcasting deck being part of the perma-nent work was reinstated upon com-pletion of the precasting.

Formwork for the beams was desi-gned to be moved with the sameequipment as used for the beams. Theformwork could be moved from bed tobed, lowered onto a completed rein-forcement cage and aligned in oneday. An extremely fast turn aroundtime for the formwork was achieved.

Developer: Godfrey Ltd.Co-ordinating Architects : Ng Chun Man andAs-

sociatesConsulting Engineert: Freeman Fox

(Far East).Project Managers : EHC Project Management

Co.Main Contractor : Kumagai Gumi Co. Ltd.Post-Tensioning and other services : VSL Engi-

neers (HK) Ltd.

Permanent precasting yard in foreground with beams placed in background.

General view of beams which have been moved into position at the end of the structure.

Andrew PayneVSL Engineers (HK) Ltd.Hong Kong

15

VSL

Another major bridgeproject for Malaysia

The town of Kuala Terengganu,on the eastern coast of the

Malayan peninsula is divided by thelarge Sungai Terengganu River. Thetransportation link across the riverinvolved the construction of four bridgestructures: the 1195m South ChannelApproach; the 240m Noah Bridge 1;the 320m Noah Bridge 2; and the 40mPulau Duyong Interchange. Theapproach spans of the South ApproachBridge and the three other bridgesconsist of standardized 40m prestres-sed beams while the main 65m spansof the South Approach consist of aprestressed concrete box order desi-gned to be constructed segmentally bythe cantilever method.

The original design for the approa-ch spans was based on precast 1-beams with diaphragms at 10mcentres. VSL provided an alternativedesign using wide top flange T-beamsthus eliminating the need for bottomformwork for the deck slab (except for asmall gap of 30mm between the topflanges). The diaphragms were alsoreduced and located at the ends of thebeams only. The alternative reducedconstruction time and produced appre-ciable material cost savings for theclient and main contractor.

VSL involvement included: fabrica-tion and erection of 520-40m T-beams;design and supply of travellers andtemporary props; reinforcement place-ment and concreting of main span can-tilever box sections; supply of bearings;supply of all prestressing work; andconsultancy services for deflectioncontrol of the cantilever construction.

This is the second longest bridgeproject in Malaysia. It is only exceededby the Penang Bridge, another notableVSL achievement.

Owner: State Government of Terengganu

Consulting Engineers : Wan Mohamedand Khoo Sdn. Bhd.

Contractor: SPDPK-Shapadu-Shimizu-Marubeni Joint Venture

Post-Tensioning and other services VSL Engineers (M) Sdn. Bhd.

Cantilever segmental construction of the main spans.

Modified T-beams replace the originally designed I-beams.

Steven Pong VSL Engineers (M) Sdn. Bhd.Kuala Lunopuc Malaysia.

VSL

VSL

VSL NEWSN U M B E R O N E 1 9 9 0

Published byVSL International Ltd.

P.O. Box 7124, 3001 Berne/Switzerland, Tel 41-31-66 42 22, Telex 911755 vsl ch. Fax 41-31-66 42 50Printed in Singapore by Saik Wah Press Pte. Ltd., MCI (P) 164/1/90

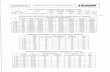

Europe — Middle East — Africa — South AmericaVSL OPERATING UNITS, SUBSIDIARIES AND LICENSEES

Australia —New ZealandAustraliaVSL Prestressing (Aust.)Pty. Ltd.P.O. Box 102Pennant Hills, NSW 21206 Pioneer AvenueThornleigh, NSW 2120Tel 61-2-484-5944Tlx AA 25891Fax 61-2-875-3894

VSL Prestressing (Aust.)Pty. Ltd.P.O. Box 171Albion, Qld. 4010Tel 61-7-265-6400Telex AA 44703Fax 61-7-265-7534

VSL Prestressing (Aust.)Pty. Ltd.P.O. Box 3981 Summit RoadNoble Park, Vic. 3174Tel 61-3-795-0366Tlx AA 34028Fax 61-3-795-0547

New ZealandPrecision Precasting(Wgtn.) Ltd.Main Road SouthPrivate Bag, OtakiTel 64-694-8126 OtakiTlx aalensn nz 32069Fax 64-694-8344

USA West —CanadaUSAVSL Corporation1671 Dell AvenueCampbell, CA 95008Tel 1-408-866-6777Tlx 821 059Fax 1-408-374-4113

VSL Western1077 Dell AvenueCampbell, CA 95008Tel 1-408-866-5000Fax 1-408-379-6205

VSL Corporation10810 TalbertFountain Valley,CA 92708Tel 1-714-964-6330

VSL Corporation91-313 Kauhi StreetEwa Beach, HI 96707Tel 1-808-682-2811

VSL Corporation4208 198th Street, S.W.Lynnwood, WA 98036Tel 1-206-771-3088Fax 1-206-672-3020

CanadaCanadian BBR (1980) Inc.P.O. Box 37Agincourt, OntarioM1S 3B4Tel 1-416-291-1618

Tlx 065-25190 bbr cda

USA EastVSL EasternP.O. Box 8668006 Haute CourtSpringfieldVA 22150-0886Tel 1-703-451-4300Fax 1-703-451-0862

VSL Corporation5555 Oakbrook ParkwaySuite 530Norcross, GA 30093Tel 1-404-446-3000Fax 1-404-242-7493

VSL Corporation7223 N.W. 46th StreetMiami, FL 33166-6490Tel 1-305-592-5075Fax 1-305-592-5629

VSL Corporation11925 12th Avenue SouthP.O. Box 1228BurnsvilleMN 55337-0228Tel 1-612-894-6350Fax 1-612-894-5708

VSL Corporation1414 Post and PaddockGrand Prairie, TX 75050Tel 1-214-647-0200Fax 1-214-641-1192

VSL Corporation608 Garrison StreetUnit V, LakewoodCO 80125Tel 1-303-239-6655Fax 1-303-239-6623

Far EastVSL Far East Pte. Ltd.60B Martin Road, #12-04Singapore WarehouseBuildingSingapore 0923Tel 65-235-7548Fax 65-733-8642

BruneiVSL Systems (B)Sdn. Bhd.P.O. Box 33Bandar Seri Begawan2600Tel 673-2-29153/21827Fax 673-2-21954

Hong KongVSL Engineers (HK) Ltd.20/F., East Town Bldg.41 Lockhart RoadP.O. Box 20056Wanchai/Hong KongTel 852-5-201-600Tlx 83031 vslhk hxFax 852-5-865-6290

SwitzerlandVSL International AGKönizstrasse 74Postfach 71243001 BernTel 41-31-66 42 22Tlx 911 755 vsl chFax 41-31-66 42 50

VSL International AGBernstrasse 93421 LyssachTel 41-34-47 99 11Tlx 914 131 vsl chFax 41-34-45 43 22

AustriaSonderbau GesmbHSechshauser Strasse 831150 ViennaTel 43-1-812-0280Tlx 134 027 sobau aFax 43-1-812-0280/33

BrazilRudloff-VSL Industrial Ltda.Rua Dr. E. Th. Santana, 158Barra FundaSao Paulo / CEP 01140Tel 55-11-826 0455Tlx 113 1121 rudf brFax 55-11-826 62 66

ChileSistemas Especiales deConstruccion SAJosue Smith Solar 434Santiago 9Tel 56-2-231-1205/232-2608Fax 56-2-231-1205

FranceVSL France s.à r.l.154, rue du Vieux-Pont-du-Sèvres92100 Boulogne-BillancourtTel 33-1-4621-4942Tlx 200 687 vslpari fFax 33-1-4761-0558

IndonesiaPT VSL IndonesiaJalan Bendungan Hilir RayaKav. 36A Blok B No. 3Tromol Pos 3609/JKTJakarta 10210Tel 62-21-586 190Tlx 45396 vslind iaFax 62-21-581-217

JapanVSL Japan CorporationTachibana Shinjuku Bldg. 4F2-26, 3-chome, Nishi-Shinjuku, Shinjuku-kuTokyo 160Tel 81-3-346-8913Fax 81-3-345-9153

Taisei CorporationEngineering & ConstructionP.O. Box 4001Shinjuku Center BuildingTokyo 163Tel 81-3-348-1111Tlx 232-2424 taisei jFax 81-3-343-4046

GermanySUSPA SpannbetonGmbHMax-Planck-Ring 1P.O. Box 30334018 Langenfeld/RhldTel 49-2173-79020Tlx 172173412 suspalfFax 49-2173-790-220GreeceEKGE S/A75, El. Venizelou(Ex. Vas. Sophias) Avenue11521 AthensTel 30-1-724-8312Tlx 216-064 tev grFax 30-1-724-1746

ItalyPRECO S.r.l.Via Olona 1220123 MilanTel 39-2-4818 031Tlx 335-392 prebetiFax 39-2-284 4137

NetherlandsCivielco B.V.P.O. Box 751Rhijnhofweg 92300 AT LeidenTel 31-71-768-900Fax 31-71-720-886

NorwayVSL Norge A/SP.O. Box 1734001 StavangeTel 47-4-563-701Tlx 33054Fax 47-4-570-052

PeruPretensado VSL delPeru SAAvenida Principal 190Santa Catalina, Lima 13Tel 51-14-718-347Tlx 20 198 pe incaFax 51-14-717-400

JapanTaiyo Kogyo Co., Ltd.8-4, 4-chome, Kigawa-higashi, Yodogawa-kuOsaka 532Tel 81-6-306-3055Tlx 523-3818 taiyo jFax 81-6-306-1755

KoreaVSL Korea Co., Ltd.5/F, Yang Jae Building261 Yangjae-DongSeocho-GuSeoulTel 82-2-574-8200Tlx vslkor k 28786Fax 82-2-577-0098

MalaysiaVSL Engineers (M) Sdn.Bhd.39 B Jalan Alor50200 Kuala LumpurTel 60-3-2424711Fax 60-3-242-9397

PortugalPrequipe Pre-EsforoçoEquipamento e Montagens, SAAv. da Republica, 471000 LisboaTel 351-1-770-730Tlx 63708 elfp pFax 351-1-771-791

Saudi ArabiaVSL International LtdNada VillageP.O. Box 3886Jeddah 21481Tel 966-2-691-8810 ext. 146Tlx 602 432 siemdv sjFax 966-2-691-8810 ext. 167

South AfricaSteeledale Systems (Pty.) Ltd.P.O. Box 1210Johannesburg 2000Tel 27-11-613-7741/9Tlx 426 847 saFax 27-11-613-7404

SwedenInternordisk Spännarmering ABVendevägen 8918225 DanderydTel 46-8-753 02 50Tlx 11524 skanska sFax 46-8-7557126

TurkeyYapi Sistemleri Insaat veSanayii A.S.Balmumcu, Arzu SokakNo. 5 Daire 380700 Besiktas – IstanbulTel 90-1-174-09 54Tlx 39552 ypss trFax 90-1-174-23 08

United KingdomBalvac Whitley Moran Ltd.P.O. Box 4,Ashcroft Road, KirkbyLiverpool L33 7ZSTel 44-51-549 2121Fax 44-51-549 1436

SingaporeVSL Systems Pte. Ltd.60B Martin Road, #12-04Singapore WarehouseBuildingSingapore 0923Tel 65-235-7077/9Fax 65-733-8642

TaiwanVSL System (Taiwan) Ltd.803 Tun Hwa SouthRoad, 2/F.Taipei 10673 R.O.C.Tel 886-2-738-8837Fax 886-2-736-2595

ThailandVSL (Thailand) Co., Ltd.138/1 PhanSak Bldg.Suite 201Petchburi Road, PhayathaiBangkok 10400Tel 66-2-215-9498Tlx 81055 cnc corp thFax 66-2-215-9490

Related Documents