Carbohydrate Mediation of Aqueous Polymerizations: Cyclodextrin Mediation of Aqueous Polymerizations of Methacrylates Phillip H. Madison, IV Thesis submitted to the Faculty of the Virginia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of Masters in Chemistry Timothy E. Long James E. McGrath Thomas C. Ward Susan E. Duncan June 2001 Blacksburg, VA Keywords: cyclodextrin mediation, aqueous free radical polymerization, inclusion complexation, carbohydrate/methacrylic blends

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

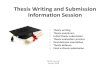

Carbohydrate Mediation of Aqueous Polymerizations:Cyclodextrin Mediation of Aqueous Polymerizations of

Methacrylates

Phillip H. Madison, IV

Thesis submitted to the Faculty of the Virginia PolytechnicInstitute and State University in partial fulfillment of the

requirements for the degree of

Mastersin

Chemistry

Timothy E. LongJames E. McGrathThomas C. WardSusan E. Duncan

June 2001Blacksburg, VA

Keywords: cyclodextrin mediation, aqueous free radical polymerization,inclusion complexation, carbohydrate/methacrylic blends

Phillip H. Madison, IV

II

Dedication

To my wife, Sarah, who has been there through my time here at VPI &SU and who willbe with me no matter where this journey through life takes us. I am blessed to have such

a good woman by my side.

To Mom, Dad, Ma and Papa for gently pushing me along my entire life to pursuesomething greater.

To Joe and Ann for making me proud to be a big brother.

To all my friends both far and near who have made the effort to stay in touch. You makethe hard times a little easier.

To Mrs. Thomas from Powhatan High and Dr. Simeon Pickard from King College forigniting, fanning, and sharing both the fire for chemistry that most people don’tunderstand, and the ability and desire to share it with those who want to learn.

Phillip H. Madison, IV

III

Acknowledgements

I lift up my eyes to the hills-

where does my help com from?

My help comes from the Lord,

the Maker of heaven and earth.

…………………………………Ps 121:1-2

First and foremost I give thanks and praise to God. Through him all things are possible.

I would like to express a wealth of gratitude to my advisor, Dr. Timothy E. Long. Your

imagination is an inspiration, your work ethic and dedication to science are unparalleled,

and the delicate balance that you keep between career and family is most commendable.

Thank you for your patience and guidance throughout my time here.

I would also like to thank my committee members; Dr. James E. McGrath, Dr. Thomas

C. Ward, and Dr. Susan E. Duncan for the knowledge conveyed both in and out of the

classroom environment.

Thanks goes out to the entire Long group as well. Without your companionship and

support this time would have been much more difficult. Special thanks to Jeremy for his

friendship, it is a blessing to have a coworker who shares the same faith: to AJ for the

wealth of knowledge and inherent love of chemistry that you are always willing to share:

and to Dave for fishing and being another example of how chemistry and marriage can be

balanced.

Lastly I would like to thank the other faculty and staff in the chemistry department who

have helped me in the past and who work hard every day to keep this place running

smooth.

Phillip H. Madison, IV

IV

Table of Contents

List of Figures..............................................................................................................VI

List of Tables ...............................................................................................................IX

List of Schemes............................................................................................................XI

Abstract ......................................................................................................................... 1

Chapter I: Literature Review ....................................................................................... 31.1 Introduction........................................................................................................ 31.2 Heterogeneous Free Radical Polymerizations ..................................................... 3

1.2.1 General Concepts of Free Radical Polymerization............................................ 31.2.2 Introduction to Heterogeneous Free Radical Polymerizations ......................... 131.2.3 Emulsion Polymerization ............................................................................... 141.2.4 Suspension Polymerization............................................................................. 171.2.5 Dispersion and Precipitation Polymerization .................................................. 19

1.3 Introduction to Cyclodextrins ........................................................................... 201.4 Industrial Applications of Cyclodextrins........................................................... 261.5 Research Interests Involving Cyclodextrins ...................................................... 301.6 Cyclodextrin Mediation of Polymer Synthesis...................................................... 36

Chapter II: Preparation and Characterization of Cyclodextrin/ MethacrylateComplexes.................................................................................................................... 39

Abstract ..................................................................................................................... 392.1 Introduction.......................................................................................................... 402.2 Experimental........................................................................................................ 422.3 Results and Discussion......................................................................................... 432.4 Conclusions.......................................................................................................... 61

Chapter III: Methylated-ββ-Cyclodextrin Mediated Aqueous Polymerization ofHydrophobic Methacrylic Monomers ........................................................................ 63

Abstract ..................................................................................................................... 633.1 Introduction.......................................................................................................... 643.2 Experimental........................................................................................................ 663.3 Results and Discussion......................................................................................... 673.4 Conclusions.......................................................................................................... 77

CHAPTER IV: Emulsion Polymerizations Using Cyclodextrin and Linear Dextrinas Emulsifiers .............................................................................................................. 79

Abstract ..................................................................................................................... 794.1.1 Introduction....................................................................................................... 804.2 Experimental........................................................................................................ 814.3 Results and Discussion......................................................................................... 824.4 Conclusions.......................................................................................................... 88

Phillip H. Madison, IV

V

Chapter V: The Preparation and Characterization of Carbohydrate/MethacrylicBlends .......................................................................................................................... 89

Abstract ..................................................................................................................... 895.1 Introduction.......................................................................................................... 905.2 Experimental........................................................................................................ 915.3 Results and Discussion......................................................................................... 925.4 Conclusions.......................................................................................................... 96

CHAPTER VI: Cyclodextrin Mediated Polymerizations in Ethylene Glycol.......... 97Abstract ..................................................................................................................... 976.1 Introduction.......................................................................................................... 986.2 Experimental........................................................................................................ 996.3 Results and Discussion....................................................................................... 1016.4 Conclusions........................................................................................................ 109

Chapter VII: Synthesis of a Novel, Side Chain Liquid Crystalline Monomer andSubsequent Cyclodextrin Mediated Aqueous Polymerization ................................ 111

Abstract ................................................................................................................... 1117.1 Introduction........................................................................................................ 1127.2 Experimental...................................................................................................... 1157.3 Results and Discussion....................................................................................... 1177.4 Conclusions........................................................................................................ 131

CHAPTER VIII: Recommendations For Future Directions.................................. 132

Phillip H. Madison, IV

VI

List of FiguresFigure Page

Figure 1.1 General mechanism of free radical polymerization. ........................................ 4

Figure 1.2 Idealized drawing of a typical emulsion polymerization system.................... 15

Figure 1.3 Cyclodextrin size and structure.75 ................................................................. 22

Figure 1.4 Names and structures of typical compounds utilized recently in the formationof host-guest complexes with ββ-CD derivatives.,,,,,,, ................................................. 24

Figure 1.5 Water solubility of ββ-cyclodextrin (ββ-CD), di (DiMe-ββ-CD), and trimethylated(TriMe-ββ-CD) derivatives. ...................................................................................... 31

Figure 2.1 Cyclodextrin size and structure..................................................................... 43

Figure 2.2 CPK models of t-butyl methacrylate and ββ-cyclodextrin in free andcomplexed form...................................................................................................... 45

Figure 2.3. CPK models of cyclohexyl methacrylate and ββ-cyclodextrin in free andcomplexed form...................................................................................................... 45

Figure 2.4 CPK models of 2-ethylhexyl methacrylate and ββ-cyclodextrin in free andcomplexed form...................................................................................................... 45

Figure 2.5 1H NMR of methylated(1.8)-ββ-cyclodextrin in chloroform. ......................... 48

Figure 2.6 1H NMR of 2-ethylhexyl methacrylate in chloroform. .................................. 49

Figure 2.7 1H NMR of 2-ethylhexyl methacrylate (top), MeCD (middle), and thesubsequent complex in chloroform (bottom). .......................................................... 50

Figure 2.8 1H NMR of cyclohexyl methacrylate in chloroform...................................... 51

Figure 2.9 1H NMR of cyclohexyl methacrylate (top), MeCD (middle), and thesubsequent complex in chloroform (bottom). .......................................................... 52

Figure 2.10 1H NMR of n-butyl methacrylate in chloroform.......................................... 53

Figure 2.11 1H NMR of n-butyl methacrylate (top), MeCD (middle), and the subsequentcomplex in chloroform (bottom). ............................................................................ 54

Figure 2.12 1H NMR of t-butyl methacrylate in chloroform. .......................................... 55

Figure 2.13 1H NMR of t-butyl methacrylate (top), MeCD (middle), and the subsequentcomplex in chloroform (bottom). ............................................................................ 56

Phillip H. Madison, IV

VII

Figure 2.14 Thermogravimetric analysis comparing a CMA/MeCD complex (0.70mol/1.00 mol) and uncomplexed MeCD. Heating procedure was as follows: (1).Heat from 25 °°C to 120 °°C at 10 °°C/min (2). Hold from 15 min (3). Heat form 120°°C to 250 °°C at 10 °°C/min (4). Hold for 15 min (5). Heat from 250 °°C to 800 °°C at 10/min. ....................................................................................................................... 58

Figure 2.15 TGA of CMA from 25-150 °°C, under N2, at a heating rate of 10 °°C/min..... 58

Figure 2.16 TGA of MeCD from 25-500 °°C, under N2, at a heating rate of 10 °°C/min... 59

Figure 2.17 TGA of CMA/MeCD complex from 25-500 °°C, under N2, at a heating rate of10 °°C/min. .............................................................................................................. 59

Figure 3.1 Thermogravimetric analysis comparing a CMA/ MeCD complex (0.70mol/1.00 mol) and uncomplexed MeCD. Heating procedure was as follows: (1).Heat from 25 °°C to 120 °°C at 10 °°C/min (2). Hold from 15 min (3). Heat form 120°°C to 250 °°C at 10 °°C/min (4). Hold for 15 min (5). Heat from 250 °°C to 800 °°C at 10/min. ....................................................................................................................... 70

Figure 3.2. 1H NMR spectra of CMA, MeCD, CMA/MeCD complex, and poly(CMA)from aqueous polymerization of CMA/MeCD complex. ......................................... 71

Figure 3.3 TEM analysis of precipitate formed from the aqueous polymerization of atBuMA/MeCD complex; performed on precipitated product cast from reactionsolution onto a carbon grid...................................................................................... 76

Figure 3.4 CPK molecular model of a possible tBuMA/ββ-CD complex. ....................... 76

Figure 4.1 Chemical structures of several of the more common ionic emulsifiers, and thestructures of MeCD and linear dextrin..................................................................... 83

Figure 6.1 GPC chromatographs of poly(CMA) that was prepared using the complexbefore (green) and after (red) repricipitaion from THF into 10x vol of water......... 105

Figure 6.2 1H NMR spectrum of poly(CMA) that was prepared using the complex before(top) and after (bottom) reprecipitation from THF into 10x vol of water. .............. 106

Figure 7.1 Names and structures of typical compounds utilized recently in the formationof host-guest complexes with ββ-CD derivatives.,,,,,,, ............................................... 113

Figure 7.1 Chemical structure of methacrylic acid 6-(4’-hexyloxy-biphenyl-4-yloxy)-hexyl ester. ........................................................................................................... 117

Figure 7.2 1H NMR spectrum of the 4’-hexoxy-biphenyl-4-yloxy hexane byproduct fromthe first step in the liquid crystalline monomer synthesis scheme. ......................... 120

Figure 7.3 1H NMR spectrum of the desired product, 4-hexoxy-4’-biphenol from the firststep in the liquid crystalline monomer synthesis scheme. ...................................... 121

Phillip H. Madison, IV

VIII

Figure 7.4 1H NMR spectrum of the desired product, 6-(4’-hexoxy-biphenyl-4-yloxy)-hexanol from the second step in the liquid crystalline monomer synthesis scheme.122

Figure 7.5 1H NMR spectrum of the desired product, 6-(4’-hexyloxy-biphenyl-4-yloxy)-hexyl methacrylate from the final step in the liquid crystalline monomer synthesisscheme.................................................................................................................. 125

Figure 7.6 13C NMR spectra of the precursor, 6-(4’-hexoxy-biphenyl-4-yloxy)-hexanol(top) and the desired product, 6-(4’-hexyloxy-biphenyl-4-yloxy)-hexyl methacrylate(bottom)................................................................................................................ 126

Figure 7.7 Electron ionized mass spectrum of 6-(4’-hexyloxy-biphenyl-4-yloxy)-hexylmethacrylate. ........................................................................................................ 128

Figure 7.8 CPK molecular models of 6-(4’-hexyloxy-biphenyl-4-yloxy)-hexylmethacrylate and ββ-cyclodextrin. .......................................................................... 131

Figure 8.1 Example of a cinnimate substituted methacrylic monomer for possiblecyclodextrin mediated aqueous polymerization. .................................................... 134

Phillip H. Madison, IV

IX

List of TablesTable Page

Table 1.1 Half-lives (t1/2 = 0.693/kd) of several common free radical thermal initiators atdifferent temperatures in either benzene or toluene. .................................................. 6

Table 1.2 Physical properties of methylated (1.8)-αα, ββ, and γγ-cyclodextrins as reported byWacker Biochem Corporation................................................................................. 25

Table 2.1 Comparison of results from complexation procedures that involved stirring foreither one or six days in chloroform. ....................................................................... 47

Table 3.1 Comparison of results from complexation procedures that involved stirring foreither one or six days in chloroform. ....................................................................... 72

Table 3.2 Polymerizations of t-butyl methacrylate under specified conditions. .............. 74

Table 3.3 Polymerizations of cyclohexyl methacrylate under specified conditions......... 74

Table 3.4 Polymerizations of 2-ethylhexyl methacrylate under specified conditions. ..... 74

Tables 3.5-6 Dependence of Tg on weight % MeCD present in film. Approximately 1mm thick films were optically clear as cast from CHCl3 with up to 20 weight %MeCD..................................................................................................................... 75

Table 4.1 Recipe for emulsion polymerizations using methylated-ββ-cyclodextrin or lineardextrin as surfactants. ............................................................................................. 84

Table 4.2 Results from emulsion type polymerizations incorporating MeCD and lineardextrin in emulsifier concentrations. ....................................................................... 86

Tables 5.3-4 Dependence of Tg on weight % MeCD present in film. Approximately 1mm thick films were optically clear as cast from CHCl3 with up to 20 weight %MeCD..................................................................................................................... 94

Table 6.1 Polymerizations of t-butyl methacrylate under specified conditions. ............ 104

Table 6.2 Polymerizations of n-butyl methacrylate under specified conditions. ........... 104

Table 6.3 Polymerizations of cyclohexyl methacrylate under specified conditions....... 104

Table 6.4 Polymerizations of 2-ethylhexyl methacrylate under specified conditions. ... 104

Table 6.5 Comparison of the results from the polymerizations of the CMA/MeCDcomplex in water and ethylene glycol. .................................................................. 107

Table 6.6 Comparison of the results from the polymerizations of the tBuMA/MeCDcomplex in water and ethylene glycol. .................................................................. 107

Phillip H. Madison, IV

X

Table 6.7 Chain transfer constants for methyl methacrylate to various organic solvents.25

............................................................................................................................. 108

Phillip H. Madison, IV

XI

List of SchemesScheme Page

Scheme 1.1 Decomposition reaction of persulfate ion in water. ....................................... 7

Scheme 2.1 Preparation of monomer/methylated(1.8)-ββ-cyclodextrin complexes .......... 46

Scheme 4.1 Preparation of the monomer/MeCD complex (Step 1), and subsequentaqueous polymerization (Step 2). ............................................................................ 70

Scheme 5.1 Bulk polymerizations of tBuMA, CMA, and 2EHMA. ............................... 94

Scheme 6.1 Preparation of the monomer/MeCD complex (Step 1), and subsequentpolymerization in ethylene glycol (Step 2). ........................................................... 102

Scheme 7.1 Three step synthesis procedure for the liquid crystalline monomer, 6-(4’-hexyloxy-biphenyl-4-yloxy)-hexyl methacrylate................................................... 118

Scheme 7.2 Synthesis scheme for the formation of the side-chain liquid crystallinemethacrylic monomer/cyclodextrin complex, and subsequent aqueouspolymerization...................................................................................................... 129

Phillip H. Madison, IV Abstract 1

Carbohydrate Mediation of Aqueous Polymerizations:Cyclodextrin Mediation of Aqueous Polymerizations of

Methacrylates

Phillip H. Madison, IV

Abstract

Cyclodextrin mediation offers a unique mechanism with the potential forinteresting control of reaction parameters. Cyclodextrin mediation of hydrophobicmonomers may offer desirable kinetics over conventional free radical polymerizations,and it has been shown in this work that cyclodextrin mediation facilitates polymerizationof hydrophobic monomers in aqueous solution and in ethylene glycol. It also may be afacile method for controlling relative reactivity of comonomer mixtures.1 In addition,complexation of cyclodextrin with guest molecules has been utilized in selectivesynthesis where the host cyclodextrin has been utilized to sterically hinder the attack ofcertain reactive sites contained within the host cavity. This aspect of inclusioncomplexation could also be utilized in free radical polymerizations of monomers withmultiple reactive double bonds to preferentially reduce the reactivity of the hinderedreactive sites.

This thesis involves the use of methylated (1.8)-β-cyclodextrin (MeCD) as amediator for polymerizations in solvents that would not facilitate polymerization of thepure monomer in the absence of cyclodextrin. This study focuses on the carbohydratemediation of a series of methacrylic monomers. t-Butyl methacrylate, n-butylmethacrylate, cyclohexyl methacrylate, and 2-ethylhexyl methacrylate were complexedwith methylated (1.8)-β-cyclodextrin and subsequently dissolved in either water orethylene glycol. The complexes were studied by 1H and 13C NMR spectroscopy, thinlayer chromatography, CPK modeling, and thermogravimetric analysis, and were foundto have molar ratios of cyclodextrin to monomer as high as 1.0 to 0.72. These complexeswere then free radically polymerized in either water or ethylene glycol and resulted inhigh molecular weight polymers that precipitated out of solution, allowing for facilepolymer isolation through filtration. Isolated yields were found to be as high as 86 %.The majority of the cyclodextrin remained in solution after polymerization. It was alsorecovered and found to be recyclable.

Heterogeneous polymerizations were also performed with 2-ethylhexylmethacrylate in which linear dextrin and methylated (1.8)-β-cyclodextrin were used inemulsifier quantities. It was found that linear dextrin, at concentrations of 3.0 wt%produced a stable latex product with high molecular weight and an isolated yield of 1 Casper, P.; Glockner, P.; Ritter, H. Macromolecules 2000, 33(12), 4361.

Phillip H. Madison, IV Abstract 2

>90%. MeCD on the other hand failed to produce a stable emulsion at concentrationsbetween 0.9-3.0 wt%, but remarkably MeCD at 3.0 wt% gave high molecular weightcoagulated polymer with a yield of >90%. It is proposed that a heterogeneousmechanism inconsistent with the four major types discussed by Arshady2 is taking place.Unlike typical suspension or emulsion polymerizations, the cyclodextrin mediatedpolymerizations are completely homogeneous at the onset, making them more like adispersion or precipitation polymerization. However, in dispersion and precipitationpolymerizations the pure monomer is soluble in the reaction media. In the absence ofcyclodextrin, the monomers utilized in this study possessed no appreciable solubility inthe reaction media. Therefore, it is proposed that cyclodextrin acts as a phase transferagent, effectively solublizing the hydrophobic monomer and allowing for the aqueousdispersion or precipitation type polymerization to occur, depending on the relativesolubility of the components.

Bulk polymerizations of t-butyl methacrylate, cyclohexyl methacrylate, and 2-ethylhexyl methacrylate and their subsequent use in the preparation ofcarbohydrate/poly(alkyl methacrylate) blends was also performed in this project. Bulkpolymers were utilized as references for physical properties for the polymers producedthrough polymerization of the MeCD/monomer complexes in either aqueous solution orin ethylene glycol. 1H NMR analysis of the polymers from both the cyclodextrinmediation and bulk polymerizations indicated that the tacticity of the polymers producedin both cases were identical. The bulk polymers were also used in the preparation ofcarbohydrate/methacrylic blends with potential applications in the areas of selectivebarriers, biodegradable films. Inclusion of drug molecules or antioxidants into thesecyclodextrin containing films also may have potential in drug delivery, or food packagingapplications.

In addition, the side chain liquid crystalline monomer, 6-(4’-hexyloxy-biphenyl-4-yloxy)hexyl methacrylate was synthesized in high purity via a three-step procedure andconfirmed by a combination of mass spectrometry, thin layer chromatography, and 1Hand 13C NMR. This hydrophobic liquid crystalline monomer was subsequentlycomplexed with 1.0-3.0 equivalents of methylated(1.8)-β-cyclodextrin in an attempt toalter the water solubility of the monomer. Complexes of this side-chain liquid crystallinemonomer have not been studied previously and it is proposed that complexation withcyclodextrin will lead not only to novel polymerizations routes for this monomer, but alsoto novel smectic phases for this thermotropic liquid crystalline polymer.

2 Arshady, R. Colloid Polym. Sci. 1992 270(8) 717.

Phillip H. Madison, IV Chapter I: Literature Review 3

Chapter I: Literature Review

1.1 Introduction

This chapter will offer an overview of the literature relevant to this research

project. First it will include a discussion of heterogeneous polymerizations. General

concepts of free radical polymerization will be introduced and some of the more

applicable concepts will be discussed including basic mechanism and rate equations, and

parameters such as kinetic chain length, number-average degree of polymerization and

number average molecular weight. Also, a brief discussion of thermodynamic and

kinetic factors affecting polymerization is included and the roles of sterics, polar forces,

stereoelectronic, bond strengths, and reaction conditions are discussed.

Heterogeneous polymerizations are then discussed. The differences between the

four major types of heterogeneous polymerizations (emulsion, suspension, dispersion,

and precipitation polymerizations) are outlined. Finally, the review will introduce the

structures and chemistry of cyclodextrins. The physical and chemical nature, more recent

industrial applications, and major areas of research are included. In conclusion, the role

of cyclodextrin in polymer synthesis is discussed.

1.2 Heterogeneous Free Radical Polymerizations

1.2.1 General Concepts of Free Radical Polymerization

The concept of free radical chain polymerization was first conceived in the early

1920’s by Staudinger,1 and an accepted mechanism had been established by the 1950’s.2

Presently the mechanism of free radical polymerization is understood to proceed through

three stages; initiation, propagation, and termination.3,4 Figure 1.1 outlines the chemistry

involved in each of these three stages.

1 Staudinger, H. Chem. Ber. 1920, 53, 1073.2 Flory, P. Principles of Polymer Chemistry Cornell University Press, NY 1953.3 Moad, G.; Solomon, D. H. The Chemistry of Free Radical Polymerization Pergamon Press, ElsevierScience, Inc. Tarrytown, NY 1995.

Phillip H. Madison, IV Chapter I: Literature Review 4

Initiation:

Propagation:

Termination:

combination disproportionation

I2 2 I

I

CH2 C

Y

X

I CH2 C

X

Y

I CH2 C

X

Y

CH2 C

Y

X

n

I CH2 C

X

Y

CH2 C

X

Yn

n

I CH2 C

X

Y

CH2 C

X

Y

+ ICH2C

X

Y

CH2C

X

Ym

I CH2 C

X

Y

CH2 C

X

Y

ICH2C

X

Y

CH2C

X

Yn m

ICH2C

X

Y

CH2HC

X

Ymn

I CH2 C

X

Y

CH C

X

Y

Figure 1.1 General mechanism of free radical polymerization.3

4 Odian, G. Principles of Polymerization John Wiley & Sons, Inc. New York, NY 1991.

Phillip H. Madison, IV Chapter I: Literature Review 5

Initiation is the first stage and is considered to proceed through two steps. The

first step involves the dissociation of a radical generating species to form an active

radical. This step is considered rate determining for initiation and is dependent on the

rate of dissociation of the initiator, designated by the rate constant kd and the particular

initiator’s efficiency.4 The decomposition of an initiator to form a polymerization

initiating species is generally not a completely efficient process. The radicals produced

are extremely reactive and there are a number of side reactions that can occur, which will

consume some of the radicals produced.5,6,7 For example benzoyl peroxide has been

shown to have an efficiency lower than one due to side reactions such as decarboxylation

of an initiator radical.4 The phenyl radical produced has been shown to either react with

another phenyl radical to yield biphenyl or react with an initiator radical to form a

relatively stable ester product. Therefore, the number of radicals produced by the

decomposition of initiator that actually initiate polymerization is noticeably below the

expected amount if the reaction were to proceed with 100% efficiency. Typically, the

initiating efficiency of most radical generating species is somewhere in the range of 30-

80 %.4

The second step involved in initiation is the reaction of an active radical with

monomer. This reaction is given the rate constant ki. Typical means by which initiating

radicals are formed include thermal, photochemical and redox methods. Among these the

most commonly used initiators are those that are produced by thermal degradation. 2,2’-

Azobisisobutyronitrile (AIBN), benzoyl peroxide, acetyl peroxide, dicumyl peroxide and

dit-butyl peroxide are a few of the more common thermal initiators. In order for an

initiator to be useful its decomposition rate constant (kd) should be in the range of 10-4-

10-6 s-1 under the reaction conditions used.4 The overall rate of initiation is defined based

on the rate determining step involving initiator decomposition and is represented by

equation 1.

RI = fkd[I] (1)

5 Sato, T.; Sato, M.; Seno, M. J. Appl. Polym. Sci. 2000, 75(2), 218.6 Charpentier, P.; DeSimone, J.; Roberts, G. Chem. Eng. Sci. 2000, 55(22), 5341.7 Mahling, F.; Daiss, A.; Kolhapure, N.; Fox, R. Comput.-Aided Chem. Eng. 2000, 8, 427.

Phillip H. Madison, IV Chapter I: Literature Review 6

where f is the initiator efficiency constant, kd is the rate constant for decomposition of

initiator, and [I] is the concentration of initiator. Typical overall rates for initiation are

approximately 10-6-10-10 mol/L· s.

Table 1.1 Half-lives (t1/2 = 0.693/kd) of several common free radical thermal initiators atdifferent temperatures in either benzene or toluene.4

Half Life atInitiator

50 °C 60 °C 70 °C 85 °C 100 °C 115 °C 130 °C 145 °C

Azobisisobutyronitrile 74 h 4.8 h 7.2 min

Benzoyl peroxide 7.3 h 1.4 h 19.8 min

Acetyl peroxide 158 h 8.1 h 1.1 h

Lauryl peroxide 47.7 h 12.8 h 3.5 h 31 min

t-Butyl peracetate 88 h 12.5 h 1.9 h 18 min

Cumyl peroxide 13 h 1.7 h 16.8 min

t-Butyl peroxide 218 h 34 h 6.4 h 1.38 h

Rate constants are dependent on the temperature at which the reaction is

performed. Table 1.1 shows the temperature ranges in which the rate constants fall

within the acceptable use range for the thermal initiators listed above.4 Aqueous

reactions, however, such as emulsion polymerizations typically utilize water soluble,

redox initiators.8,9,10,11,12,13 Redox initiation involves either the direct electron transfer

between reductant and oxidant or the formation of reductant-oxidant complexed

intermediates known as charge transfer complexes. Scheme 1.1 shows the decomposition

reaction of a typical redox initiation system, the persulfate ion in water. Some redox

initiators can also be useful at lower temperature with the addition of a

coinitiator.12,13,14,15

8 VanderHoff, J. J. Polym. Sci.: Polym. Symp. 1985, 72, 161.9 Cortizo, M.; Scaffardi, L.; Tocho, J; Figini, R. Angew. Makromol. Chem. 1999, 271, 1.10 McCarthy, T.; Williams, R.; Bitay, J.; Zero, K.; Yang, M.; Mares, F. J. Appl. Polym. Sci. 1998, 70(11),2211.11 Shaffie, K.; Moustafa, A.; Mohamed, E.; Badran, A. J. Polym. Sci., Part A: Polym. Chem. 1997, 35(15),3141.12 Shaffei, K.; Ayoub, M.; Ismail, M.; Badran, A. Eur. Polym. J. 1998, 34(3-4), 553.13 Sarac, A.; Prog. Polym. Sci. 24(8) 1999 1149.14 Huang, J.; Zhang, H.; Li, J.; Cheng, S.; Hu, F.; Tan, B. J. Appl. Polym. Sci. 1998, 68(12), 2029.

Phillip H. Madison, IV Chapter I: Literature Review 7

Scheme 1.1 Decomposition reaction of persulfate ion in water.3

During propagation, the initiated species react with a large number of monomer

molecules to form a long chain species in which one end of the chain is still an active

radical. Typical rate constant values for propagation (kp) are on the order of 102-104

L/mol·s with the overall rate governed by equation 2.

Rp = kp[M· ][M] (2)

where kp is the rate constant of propagation, [M] is the molar concentration of monomer,

and [M· ] is the steady state concentration of active radicals. Typical Rp values are in the

range of 10-5-10-6 mol/L· s.

Polymerization through a double bond involves two possible sites of attack for a

radical species. If the double bond is substituted, or in other words if it is not ethylene,

the carbon that is most highly substituted is referred to as the head position. The least

substituted carbon is known as the tail position. In most cases, the majority of repeat

units (>98-99%) are isoregic or all head-to-tail linkages.4,16 However, under some

circumstances it is possible to increase the number of head to head and tail-to-tail

linkages and make the polymer more aregic. For example, increases in temperature have

been shown to increase the amount of head-to-head placement by a few percent.3,16

Termination occurs when two active radicals come into close enough proximity

that they both react in a way that eliminates the active radicals on both chains. In the

15 Huang, H.; Zhang, H.; Hu, F.; Al, Z.; Tan, B.; Cheng, S.; Li, J. J. Appl. Polym. Sci. 1999, 73(3), 315.

O S O

O

O

O S

O

O

O

H2O O S

O

O

O

O S

O

OH

O

HO

Phillip H. Madison, IV Chapter I: Literature Review 8

absence of chain transfer, termination is believed to occur by two competing

mechanisms: combination and disproportionation (Figure 1.1). Combination (coupling)

involves the direct reaction of two radical species to form a new C-C single bond

between the two polymeric species. Disproportionation occurs when the radical species

from one chain abstracts a hydrogen atom from the chain end of the second radical

species, resulting in two separate molecules. However, regardless of the type of

termination that occurs the rate of termination is defined by equation 3.

Rt = kt[M· ]2 (3)

where kt is the rate constant for termination and [M· ] is the steady state radical

concentration. Typical rates of termination are of the order of 10-8-10-10, which is close

to rates of initiation (10-6-10-8), but several orders of magnitude lower than the rates of

propagation (10-5-10-6).

In determining the overall rate of polymerization, it is assumed that the

concentration of radicals is constant. This means that the rate of termination is equal to

the rate of initiation. The steady state approximation can then be applied and substitution

can then be made for [M·] to give the overall rate defined by equation 4.

From these rate expressions one can derive the kinetic chain length of a polymer. The

kinetic chain length is defined by the following equation:

ν = (5)

16 Vogl. O.; Qin, M.; Zilkha, A. Prog. Polym. Sci. 2000, 24(10), 1481.

Rp = kp [M]f kd [I]

kt

1/2

(4)

Rp

Rt

Phillip H. Madison, IV Chapter I: Literature Review 9

Ri

Rp

However, assuming steady state concentration of radicals, kinetic chain length can be

expressed as:

ν = (6)

or in other terms:

ν = (7)

Another important term is the number-average degree of polymerization (Xn). This is

defined as the average number of monomer molecules contained in a polymer molecule.

Xn is dependent on the mode of termination and is given by the expressions:

Xn = ν , for disproportionation (8)

Xn = 2ν , for coupling (9)

Xn is then directly related to the number average molecular weight (Mn) by:

Mn = Xn Mo (10)

where Mo is the molecular weight of the monomer.

Another important factor to consider in free radical polymerization is chain

transfer. In many systems the expected molecular weight, given the extent of termination

expected by either coupling of disproportionation is found to be higher than the observed

molecular weight.4 This phenomenon occurs when the propagating radical reacts with a

compound within the system such as initiator, monomer, solvent, polymer, or additive so

that the radical is transferred and the macromolecule is effectively terminated

prematurely.17,18,19,20 It is therefore obvious that there should be subsequent decrease in

17 Barson, C. in Comprehensive Polymer Science, Vol. 3, Eds. Eastmond, G.; Ledwith, A.; Russo, S.;Sigwalt, P. Pergamon; London, 1989 171.18 Palit, S.; Chatterjee, S.; Mukherjee, A. in Encyclopaedia of Polymer Science and Technology, Vol. 3,Eds. Mark, H.; Gaylord, N.; Boutevin, B. Wiley; New York 1966 575.19 Farina, M. Makromol. Chem., Macromol. Symp. 10/11 1987 255.20 Eastmond, G. in Comprehensive Chemical Kinetics, Vol 14A, Eds. Bamford, C.; Tipper, C. Elsevier;Amsterdam 1976 153.

kp [M]

f kd kt [I] 1/2

Phillip H. Madison, IV Chapter I: Literature Review 10

the degree of polymerization in the presence of chain transfer of any kind. The actual

effect on Xn is defined by the Mayo equation (11):3

where Xno is the expected number average degree of polymerization in the absence of

chain transfer, CM, CI, CP, and CS are the constants for chain transfer to monomer,

initiator, polymer, and transfer agent respectively and [M], [I], [P], and [T] are the

concentrations of monomer, initiator, polymer, and transfer agent respectively.

The occurrence of chain transfer effectively lowers the molecular weight of a

polymer obtained compared to what would be expected in its absence. This aspect has

been utilized in areas where extremely high molecular weights can be achieved and/or

where high molecular weight polymer is not desirable. For example, chain transfer

agents are added to many industrial emulsion polymerizations in order to obtain

molecular weights low enough that the resulting latex can be directly applied and easily

form a film upon solvent evaporation.21,22,23 The most common chain transfer agents

used historically are the thiols and disulfides,3,24,25,26 and there has been little resent

research dealing with alternative transfer agents.

Free radical chain polymerization is dependent on both thermodynamic and

kinetic factors. A negative change in free energy (∆G) must be observed between

monomer and polymer in order for a polymerization to be thermodynamically feasible.4,27

This applies to a large number of monomeric species, however, thermodynamic

feasibility does not ensure that a polymerization is kinetically feasible under all

21 Plessis, C.; Arzamendi, G.; Leiza, J. R.; Alberdi, J. M.; Schoonbrood, H. A.; Charmot, D.; Asua, J. M. J.Polym. Sci., Part A: Polym. Chem. 2001, 39(7), 1106.22 Puzin, Y.; Egorov, A.E.; Kraikin, V.A. Eur. Polym. J. 2001, 37(6), 1165.23 De la Fuente, J. L.; Lopez, M. E. Macromol. Chem. Phys. 2001, 202(3), 375.24 Plessis, C.; Arzamendi, G.; Leiza, J. R.; Alberdi, J. M.; Schoonbrood, H. A. S.; Charmot, D.; Asua, J. M.J. Polym. Sci., Part A: Polym. Chem. 2001, 39(7), 1106.25 De la Fuente, J. L.; Lopez, M. E. Macromol. Chem. Phys. 2001, 202(3), 375.26 Matsumoto, A.; Tanno, R.; Aota, H.; Ikeda, J. Eur. Polym. J. 2001, 37(5), 1071.27 Billmeyer, F. W. Textbook of Polymer Science John Wiley & Sons, Inc., NY 1984.

Xn o

= 1

Xn

CM CI CP CS[I] [P] [T]

[M][M] [M]+ + ++

1(11)

Phillip H. Madison, IV Chapter I: Literature Review 11

conditions. The kinetics of a free radical polymerization is of utmost importance.

Though the thermodynamics may be ideal for a multitude of monomers, at times

extremely specific reaction conditions are required to satisfy strict kinetic requirements in

order to obtain high molecular weight polymer. Moad and Solomon3 outline the major

factors to consider when predicting the kinetic feasibility of a polymerization. These

include steric and polar factors, stereoelectronics, relative bond strengths, and reaction

conditions.

Steric influence on kinetics manifests itself in three ways. The first is the amount

of steric hindrance located around the point of attack of the incoming radical to the

monomer. This effect is seen only when there are bulky groups present around the

incoming radical or around the point of attack on the monomer.3,28,29,30,31,32,33,34,35 The

second place where sterics play a role is when there is β-strain induced as the incoming

radical forces a change in hybridization from sp2 to sp3 and forces substituents that were

once planar into a more crowded tetrahedral position.3,36,37 The third steric effect is

found when there is hindrance to adoption of transition state geometry. This strain

usually manifests itself when an intramolecular addition occurs.3

The second major influence on kinetics lies with consideration of polar forces

imposed through substituents. Polar forces are largely responsible for the overall

reactivity and degree of regiospecificity. The electron donating/withdrawing character of

substituents on vinyl monomers will influence both the relative electron density of the

head and tail positions and also the overall electron density of the unsaturation.3 This in

turn affects the overall rate of addition of the attacking radical to monomer as well as the

28 Okamoto, Y.; Yamada, K.; Nakano, T. ACS Symp. Ser. 2000, 768, 57.29 Yin, M.; Baker, G. Macromolecules 1999, 32(23), 7711.30 Somvarsky, J.; Dusek, K.; Smrckova, M. Comput. Theor. Polym. Sci. 1998, 8(1/2), 201.31 Grenier-Loustalot, M.; Da Cunha, L. Eur. Polym. J. 1998, 34(1), 95.32 Kobatake, S.; Yamada, B. Polym. J. 1996, 28(6), 535.33 Penelle, J.; Verraver, S.; Raucq, P.; Marchand-Brynaert, J. Macromol. Chem. Phys. 1995, 196(3), 857.34 Vrhovac, L.; Djurasovic, N.; Velickovic, J. J. Polym. Sci., Part A: Polym. Chem. 1993, 31(1), 45.35 Matsumoto, A.; Oki, Y.; Otsu, T. Macromolecules 1992, 25(12), 3323.36 Matsumoto, A.; Hirai, F.; Sumiyama, Y.; Aota, H.; Takayama, Y.; Kameyama, A.; Nakanishi, T. Eur.Polym. J. 1999, 35(2), 195.37 Azuma, H.; Katagiri, Y.; Yamabe, S. J. Polym. Sci., Part A: Polym. Chem. 1996, 34(8), 1407.

Phillip H. Madison, IV Chapter I: Literature Review 12

relative reactivity of the head and tail of the monomer with respect to the incoming

radical. Thus, this will in turn influence the point of attack for the incoming radical. For

example vinyl fluorine monomers have been reported to result in approximately 12 %

head-head linkage3,16 where as typical percentages of head-head linkages for most

polymers is only approximately 2-3 %.4 A fluorine substituent is electron withdrawing

and will pull electron density away from the double bond. This will make the double

bond more reactive to electrophilic radicals such as halogenated methyl radicals (i.e.

Cl3C· , or F3C· ), but will also change the relative electron density of the head and tail

positions. A halogen substituent will pull electron density from both the head and tail

positions, but not to the same extent. The head position will feel the effect more than the

tail position. This will cause the head position to have less electron density than the tail

when the substituent is electron withdrawing. If the substituent is electron donating, then

the opposite effect is observed. The double bond will have increased overall reactivity

toward nucleophilic radicals (i.e. Me· ) and the head position will have more electron

density than the tail.

Moad and Solomon3 also discussed the stereo electronic requirements and the

effect of reaction conditions on radical reactions. Stereoelectronics come into play when

considering that the incoming radical must attack perpendicular to the plane of the

unsaturated portion of the molecule. Intramolecular interactions have been found to

inhibit such alignment in cases, giving a product that is less thermodynamically stable.

Reaction conditions such as temperature and solvent have also been found to greatly

impact regiospecificity and rates of polymerization. These factors discussed collectively

determine the regioselectivity, or the relative head vs. tail addition of a radical to

monomer.

One of the major disadvantages of free radical polymerization when compared to

other chain polymerizations such as the anionic or cationic types is that there is certain

level of control that cannot be achieved, which leads to a broader distribution of

molecular weights. In recent years there have been advances in the area of free radical

polymerization that allow for a more controllable polymerization. One method,

Phillip H. Madison, IV Chapter I: Literature Review 13

discovered by Georges and coworkers38 in 1993 involves the addition of a stable free

radical species. The presence of these stable free radical compounds have been found to

allow for greater control of polymerization leading to molecular weight distributions

approaching values obtainable through anionic polymerizations.39,40,41 This is believed

to be the result of the stable nitroxide radical species reacting with the propagating

radical to form a chemical bond that essentially caps the polymeric radical. However,

this chemical bond is labile at high temperature (> 100 °C) and equilibrium is established

between the free and capped forms of the polymeric radical. This equilibrium leads to

product with a narrower molecular weight distribution.

The presence of a stable nitroxide capped radical at low temperatures also allows

for the formation of block polymers. The nitroxide containing polymer products can be

isolated and then subsequently raised to an appropriate reaction temperature where chain

addition of a second monomer could occur. In this way multilblock42,43 and star44

copolymers have been synthesized via free radical chain polymerization.

1.2.2 Introduction to Heterogeneous Free Radical Polymerizations

A heterogeneous polymerization is a polymerization in which there are at least

two distinct phases at some point during the reaction.4 In aqueous heterogeneous

polymerizations, water is the continuous phase and the monomer and/or the final polymer

is the dispersed phase. The initiator used can be soluble in either of the two phases, and

additives can be used in order to stabilize different size particles. The particles formed

can be nearly anything from regularly dispersed spheres on the order of 50 nm to an

irregularly shaped precipitant on the order of a few mm. The following sections will

attempt to define each of the four types of heterogeneous polymerizations of concern

including emulsion, suspension, dispersion and precipitation. Each of the techniques will

38 Georges, M.; Veregin, R.; Peter, M.; Hamer, G. Macromolecules 1993, 26(11), 2987.39 Kazmaier, P.; Moffat, K.; Georges, M.; Veregin, R.; Hamer, G. Macromolecules 1995, 28(6), 1841.40 Hawker, C. Acc. Chem. Res 1997, 30, 373.41 Malmstrom, E.; Hawker, C. Macromol. Chem. Phys.1998, 199, 923.42 Zou, Y.; Jian, L.; Zhuang, R.; Ye, J.; Dai, L.; Zheng, L. Macromolecules 2000, 33(13), 4745.43 Hawker, C. J.; Hendrick, J. L.; Malmstrom, E.; Trollsas, M.; Stehling, U. M.; Waymouth, R. M. ACSSymp. Ser. 1998, 713, 127.

Phillip H. Madison, IV Chapter I: Literature Review 14

be defined according to the four criteria outlined by Arshady45 and others4,27,46 with

explanations as to where common overlap may take place. The four criteria include

initial state of the polymerization mixture, the kinetics of polymerization, the prevalent

particle forming mechanism, and the state, shape and size of the resulting polymer

particles.

Specifically defining a heterogeneous polymerization is not an easy task. Over

the years there have been distinctions that are proposed to differentiate them in terms of

initial and final states of reactants, kinetics, and sizes of particles formed. However, at

times there is no clear line defining each type since a simple modification of one may

cause it to slip into the realm that defines another. The following sections represent the

most recent compilation of defining attributes for each of the heterogeneous aqueous

polymerizations with distinctions being made primarily based on those established by

Arshady45 and a number of general texts2,3,4,27,46 outlining the different techniques.

1.2.3 Emulsion Polymerization

The initial state of an emulsion polymerization consists of an insoluble monomer

dispersed in water by aid of a surfactant, or surface-active agent, and the initiator solvated

by the continuous phase. This discussion will deal with an aqueous, continuous phase.

Above a certain concentration some of the surfactant molecules are able to aggregate

together to form small micelles on the order of 2-10 nm. The concentration above which

micelles are formed is known as the critical micelle concentration (CMC).45 At the onset

of polymerization, monomer is present mostly (>95%) in the form of monomer droplets

whose size is generally dependent on the rate of stirring. However, a small amount is

dissolved in the water and can be absorbed by the surfactant micelles.

Figure 1.2 depicts a typical emulsion polymerizations system. Since the initiator

is water-soluble, a monomer is initiated in the aqueous, continuous phase and either

quickly absorbed into a monomer-swollen micelle where propagation occurs or

44 Pasquale, A. J.; Long, T. E. J. Polym. Sci., Part A.: Polym. Chem. 2000, 39(1), 216.45 Arshady, R. Colloid Polym. Sci. 1992, 270(8), 717.46 Painter, P.; Coleman, M. Fundamentals of Polymer Science Technomic Publishing Co., Inc. Lancaster,PN 1997.

Phillip H. Madison, IV Chapter I: Literature Review 15

undergoes a higher degree of solution type polymerization. In the second case, the

oligomeric radicals become insoluble and precipitate through homogeneous coagulation

onto themselves where they are then stabilized by absorbing surfactant and monomer

from solution. These two particle-forming mechanisms are known as heterogeneous

(micellar) and homogeneous nucleation respectively and are thought to be competing

mechanisms.

Figure 1.2 Idealized drawing of a typical emulsion polymerization system.4

Phillip H. Madison, IV Chapter I: Literature Review 16

Polymerization continues in the monomer-swollen micelles. Monomer supplied

from the monomer droplets in the aqueous phase is continuously absorbed by the

micelles to feed the propagating chain. The dissolved monomer is subsequently

replenished in the aqueous phase from the monomer droplets. In this way, the micelles

grow while the monomer droplet size decreases. One should note that there are several

orders of magnitude difference between the diameters of the monomer droplets (1-10

µm) and the micelles (2-10 nm). In addition, the total number of monomer droplets and

micelles are typically 1010-1011 mL-1 and 1017-1018 mL-1 respectively. This indicates that

the total surface area of the micelles is several orders of magnitude higher than that of the

droplets. This aspect is of importance because it explains why polymerization takes place

exclusively in the micelles and virtually no polymerization (<1 %) takes place in the

monomer droplets. This substantially larger surface area translates into radical

absorption and polymerization occurring exclusively in the surfactant micelles.

The rate of polymerization is a complicated expression that varies with a number

of different parameters including initiator concentration, temperature, surfactant

concentration, monomer concentration, and extent of reaction.45,47,48,49,50,51 In general,

emulsion polymerizations are known to simultaneously achieve high degrees of

polymerization and high rates. This is one of the major advantages of this type of

polymerization. Each micelle is considered to contain either one or zero active radicals at

any given time. The rate of radical absorption is considered to be fairly small and the

rates of propagation are high given that monomer concentrations in the micelles can be as

high as 5 M. The rate of termination is also small because it is limited by the rate at

which another radical is absorbed by an active micelle. When a radical enters an active

micelle, termination takes place instantaneously for all practical purposes and the micelle

is dormant until another radical enters.

47 Gilbert, R. Emulsion Polymerization: A Mechanistic Approach Academic Press, 1995.48 Feeney, P.; Napper, D.; Gilbert, R. Macromolecules 1984, 17(12), 2520.49 Vanderhoff, J. J. Polym. Sci.: Polym. Symp. 1985, 72, 161.50 Gol’dfein, M.; Kozhevnikov, N.; Trubnikov, A. Polym. Yearb. 1985, 12, 89.51 Poehlein, G. ACS Symp. Ser. 1985, 285, 131.

Phillip H. Madison, IV Chapter I: Literature Review 17

Emulsion polymerizations are thought to occur in three distinct stages, and the

rates of polymerization depend on the stage.4,47,48,49,50,51 In stage one, the overall rate is

increasing as micelles are gradually absorbing active radicals, which begin chain

propagation. Stage two begins when the concentration of active micelles reaches

equilibrium. During this stage the micelles are growing as more monomer is absorbed

from the aqueous phase to replace that consumed by propagation radical chains, and the

size of the monomer droplets are decreasing as monomer is extracted from them to

replace that absorbed from the aqueous phase. The rate of polymerization is usually

constant during stage two. When all the monomer is depleted from the monomer

droplets, a steady decline in rate is observed due to a steady decrease in monomer

concentration within the micelles. This is referred to as stage three. The final product of

an emulsion polymerization is a latex. The resulting polymer is stabilized in the form of

evenly dispersed spheres (50-300 nm) by adsorption of surfactant.45

1.2.4 Suspension Polymerization

The major difference between an emulsion and suspension technique is that in a

suspension polymerization both the monomer and initiators are insoluble in the

dispersant.45 Also, a stabilizer is utilized rather than an emulsifier. The locus of

polymerization in a suspension takes place within the stabilized monomer droplets since

the initiator is monomer soluble. Given that a stabilizer is used rather than an emulsifier

continuous stirring is required to maintain a stable suspension.4,52,53,54,55,56 In emulsion

polymerizations, it is typical for the emulsifier and other additives to constitute up to 5 %

of the final polymeric product. These absorbed impurities can be extremely difficult to

remove and in most cases are left in the product. For many applications, the presence of

such impurities is undesirable. For applications where polymer in the form of solid beads

is applicable, suspension polymerization may be an attractive alternative method.

52 Yuan, H.; Kalfas, G.; Ray, W. J. Matr. Sci., Rev. Macromol. Chem. Phys. 1991, C31(2-3), 215.53 Warson, H. Polym., Paint, Colour J. 1983, 173(4101), 541.54 Warson, H. Polym., Paint, Colour J. 1988, 178(4226), 865.55 Warson, H. Polym., Paint, Colour J. 1988, 178(4220), 625.56 Brooks, B. Makromol. Chem., Macromol. Symp. 1990, 35-36, 121.

Phillip H. Madison, IV Chapter I: Literature Review 18

One of the advantages of suspension polymerization over typical bulk

polymerizations are that it offers the kinetics of a bulk polymerization, but the

temperature is easily controlled through manipulation of the dispersant, which is water in

most cases. Also, it has a lower viscosity when compared to bulk polymerization so

stirring is easier, and the product is in the form of spherical beads. Solution

polymerization has the advantages of allowing for facile control of temperature and low

viscosity also, however the kinetics and yields obtained in solution vary depending on

solvent and concentration, and in many cases are lower than those obtained through

typical heterogeneous polymerizations. In addition, the introduction of a solvent may

also require considerations of other factors such as chain transfer to solvent.

A suspension polymerization can be considered to be many small water-cooled

bulk reactions, and kinetics are consistent with this model. Ray and coworkers52 outline

two distinct types of suspension polymerizations. The first of these is termed the “bead

suspension polymerization” and the second is known as a “powder suspension

polymerization”. These two types of suspensions vary in terms of solubility of resulting

polymer in its monomer. Styrene and vinyl chloride are typical examples of monomers

that undergo bead and powder suspensions respectively. In a bead suspension, the

polymer is soluble in the monomer making the dispersed droplets homogeneous

throughout the process. However in the case of a powder suspension the polymer is

insoluble in its monomer and thus precipitates to give a heterogeneous droplet system.

The stabilizer is a crucial component of the suspension mixture.4,45,52,53,54,55,56

There are generally two types of suspending agents used today. The first type consists of

water-soluble organic polymers. This type of stabilizer acts in two ways. It promotes

dispersion by decreasing the interfacial tension between monomer and dispersed phase

and also creates a thin layer surrounding the droplet, which prevents coalescence during

droplet collisions. The second type of stabilizers is composed of inorganic powders. The

mechanism of adsorption of these compounds is not all together understood, however,

compounds such as NiO, CaCO3, CaO, Al2O3, and Al(OH)3 are common inorganic

powders that are utilized as stabilizers in industrial scale suspension polymerizations.

Phillip H. Madison, IV Chapter I: Literature Review 19

Inorganic powders are generally chosen as stabilizers over organic polymer systems

because they are easily removed, generally cheaper, able to reduce the deposit of particles

on reactor walls, and generally more environmentally benign.

The particles formed from suspension polymerization are on the order of 20 µm–

20 mm. Arshady45 reports that attempts to achieve particle sizes smaller than this by

suspension polymerization techniques results in competing emulsion polymerization,

which is undesirable. The resulting size of the polymer particle has been found to

roughly equal the size of the initial dispersed monomer droplets. Many factors influence

the size of the particles including concentration of stabilizer, relative ratios of dispersant

and dispersed phase, viscosities of the two phases, and stirring speed. Warson53,54,55 has

also reported that alterations in the stirring mechanism (i.e. blade type and width, and

reactor volume) can also have a dramatic effect on both the particle size and temperature

control.

1.2.5 Dispersion and Precipitation Polymerization

The major difference between dispersion and precipitation polymerizations and

emulsion or suspension techniques is that dispersion and precipitation polymerizations

are homogeneous at the onset of reaction.45 Both the monomer and initiator are soluble

in the reaction media while the resulting polymer is insoluble. The major difference

between dispersion polymerization and precipitation polymerization is the degree of

solubility of the polymer in the reaction media. In the dispersion mechanism, the

growing polymer is swelled by the media,57,58,59,60,61 while in a precipitation

polymerization the polymer truly precipitates and is not swollen by the solvent.62,63,64,65,66

57 Saenz, J.; Asua, J. J. Polym. Sci., Part A: Polym. Chem. 1995, 33, 1511.58 Shen, S.; Sudol, E.; El-Aasser, M. J. Polym. Sci., Part A: Polym. Chem. 1994, 32, 1087.59 Barrett, K. (ed) Dispersion Polymerization in Organic Media John Wiley & Sons; London; 1975.60 Kumar, D.; Butler, G. J. Mater. Sci., Rev. Macromol. Chem. Phys. 1997, C37(2), 303.61 Slomkowski, S.; Gadzinowski, M.; Sosnowski, S. Macromol. Symp. 1998, 132, 451.62 Li, W.; Stover, H. J. Polym. Sci., Part A: Polym. Chem. 1999, 37, 2899.63 Li, W.; Stover, H. J. Polym. Sci., Part A: Polym. Chem. 1999, 37, 2295.

Phillip H. Madison, IV Chapter I: Literature Review 20

In dispersion polymerization the components start out homogeneous. Initiation

occurs in the media and polymer chains begin to grow. Depending on the solvency of the

media, the polymer particles then phase separate forming primary particles. These

particles are then swollen with monomer and solvent and thus the polymerization then

proceeds mainly within these particles. As a result the particles take on a spherical shape

and result in a particle size on the order of 0.1-10 µm.45 The particles can be made more

uniform by the addition of a steric stabilizer.

Precipitation polymerization initially proceeds in a similar manor as dispersion

polymerization. As with dispersion polymerization, the components start out

homogeneous and initiation occurs in the media. Polymerization also takes place largely

in the media, however, this leads to continuous nucleation and coagulation of the polymer

into irregularly shaped particles as they precipitate. Further polymerization does not take

place in the precipitated particle and though addition of stabilizers may result in more

uniform particles they are still irregularly shaped due to the method of formation.45

1.3 Introduction to Cyclodextrins

Cyclodextrins (CD) have been described as “seductive molecules, appealing to

investigators in both pure research and applied technologies”.67 Judging by the

logarithmic growth in publications and patents68 dealing with these compounds since

their discovery this description is not undeserved. CDs are cyclic molecules composed of

glucopyranose ring units to form truncated cone type, doughnut structures.69 The most

common are the α, β, and γ-cyclodextrins which are composed of six, seven, and eight

sugar units respectively. The exterior of the CDs are hydrophilic while the interior is

hydrophobic, and the different CDs possess different cavity sizes according to the

number of glucopyranose rings present (Figure 1.3).

64 Downey, J.; Frank, R.; Li, W.; Stover, H. Macromolecules 1999, 32(9), 2838.65 Bunyakan, C.; Hunkeler, D. Polymer 1999, 40, 6213.66 Bunyakan, C.; Hunkeler, D. Polymer 1999, 40, 6225.67 D’Souza, V.; Lipkowitz, K. Chem. Rev. 1998, 95(5), 1741.68 Szejtli, J. Chem Rev. 1998, 98(5), 1743.

Phillip H. Madison, IV Chapter I: Literature Review 21

CDs were first noted in an 1891 publication as simply a crystalline substance

obtained from digestion of starch. Villiers70 referred to the substance as cellulosine.

Twelve years later, Schardinger71 observed the same substance and was able to isolate

and examine it. Schardinger was the first to extensively examine CDs in the late 1800s

and for this reason CDs are often referred to as Schardinger dextrins. It wasn’t, however,

until the 1930s that Freudenberg established the true structure of CDs, with assistance

from the observations made by Karrer and Miekeley.68 In the 1950s, the chemical

process for the production of CDs was thoroughly examined by French and coworkers,72

and the existence of even larger CDs was confirmed. Also, during this time Cramer and

coworkers first began to uncover CDs potential as complexation agents.68 They

examined the ability of CDs to complex with a variety of drug molecules, and noted the

stabilization, volatility reduction, and solubility changes that occurred as a result of

complexation. They subsequently obtained a patent73 in 1953 that encompassed the

potential drug related applications foreseen as a result of their studies.

69 Bender, M.; Komiyama, M. Cyclodextrin Chemistry Springer Verlag,, NY 1978.70 Villiers, A. Compt. Rend. 1981, 112, 536.71 Schardinger, F. Unters Nahr u. Genussm 1903, 6, 865.72 French, D. Adv. Carbohydr. Chem. 1957, 12, 189.73 Freudenberg, K.; Cramer, F.; Plieninger H. Ger. Patent 895-769, 1953.

Phillip H. Madison, IV Chapter I: Literature Review 22

Figure 1.3 Cyclodextrin size and structure.75

Since that time the number of patents and papers have increased exponentially.68

In 1981 the first international symposium74 was organized where lecturers would have the

opportunity to summarize their most recent results. Since then,

symposia74,75,76,77,78,79,80,81,82 have been held every second year and presentations have

increased in both quantity and quality. Today, CD is a relatively inexpensive material

and an important industrial commodity in many ways.

74 Szejtli, J., Ed.; Proc.1st Int. Symp. on Cyclodextrins, Budapest, 1981; D. Reidel Publ.: Dordrecht, 1982.75 Atwood, J. L., Davies, J. E. D., Osa, T., Eds. Clathrate Compounds, Molecular Inclusion Phenomena andCyclodextrins; Proc. of Third Int. Symp. on Clathrate Compounds and Molecular Inclusion and the SecondInt. Symp. on Cyclodextrins; Tokyo, 1981, D. Reidel Publ. Co.: Dordrecht, 1985.76 Atwood, J. L., Davies, E. D., Eds. Inclusion Phenomena in Inorganic, Organic and Organometallic Hosts,Proc. Third Int. Symp. on Inclusion Phenomena and the Third Int. Sympt. on Cyclodextrins; Lancaster,1986; D. Reidel Publ: Dordrecht, 1987; p 455.77 Huber, O., Szejtli, J., Eds. Proc. Fourth Int. Symp. on Cyclodextrins, Munich, 1988; Kluwer AcademicPubl.: Dordrecht, 1988.78 Duchene, D., Ed. Minutes of the Fifth Int. Symp. on Cyclodextrins, Paris, 1990; Editions de Santé: Paris,1990.79 Hedges, A. R., Ed. Minutes of the Sixth Int. Symp. on Cyclodextrins, Chicago, 1992; Editions de Santé:Paris, 1992.80 Osa, T., Ed. Proceedings of the Seventh International Cyclodextrin Symposium, Tokyo, 1994; Publ.Office of Business Center for Academic Societies of Japan, 1994.81 Szejtli, J., Szente, L., Eds. Proceedings of the Eighth International Cyclodextrin Symposium, Budapest,1996; Kluwer Acad. Publ.: Dordrecht, 1996.

Phillip H. Madison, IV Chapter I: Literature Review 23

The most notable feature of CDs is their ability to accommodate compounds

within their cavities. CDs have different cavity sizes depending on whether they are α, β,

or γ. Figure 1.483,84,85,86,87,88,89,90 shows the structures of some compounds that have been

utilized recently for the formation of complexes involving β-CD derivatives. α-CD,

which is composed of six glucopyranose units has the smallest cavity measuring 4.9Å in

diameter (Figure1.3). β and γ-CDs are made up of seven and eight sugar rings and have

cavity diameters of 6.2 and 7.9Å respectively. The interior of the molecule is

hydrophobic and the exterior is hydrophilic. Each individual glucose ring has one

primary and two secondary hydroxyl groups, which allows for facile derivatization.69 The

hydrophilic nature of the exterior of the CD makes it water soluble, however, through

substitution of the hydroxyl groups this degree of solubility can be altered. The

hydrophobic nature of the interior typically leads to accommodation of relatively

hydrophobic guests within the cavity.91 This accommodation of a molecule within

another molecule is known as complexation and the resulting product is referred to as an

inclusion complex. The surrounding compound is referred to as the host and the

compound that is included in known as the guest. For this reason, inclusion complexes

are often termed host/guest complexes.

82 Torres Labandeira, J.; Villa-Jato, J.; Ed. Proc. of the Ninth Int. Symp. on Cyclodextrins, Santiago dCompostela, Spain, 1998.83 Yu, L.; You, C. J. Phys. Org. Chem. 2001, 14(1), 11.84 Kim, I.; Park, S.; Kim, H. J. Chromatogr., 2000, A 877(1&2), 217.85 Bergamini, J. Belabbas, M.; Jouini, M.; Aeiyach, S.; Lacroix, J.; Chane-Ching, K.; Lacaze, P. J.Electroanal. Chem. 2000, 482(2), 156.86 Shiraishi, Y.; Toshima, N.; Kawamura, T.; Mihori, H.; Shirai, H.; Hirai, H. J. Mol. Catal. A: Chem.1999, 139(2-3), 149.87 Maafi, M.; Aaron, J.; Lion, C. Proc.-Indian Acad. Sci., Chem. Sci. 1998, 110(3), 319.88 Herrmann, W.; Wehrle, S.; Wenz, G. Chem. Commun. 1997, 18, 1709.89 Aithal, K.; Udupa, N. Pharm. Sci. 1996, 2(10), 451.90 Mielcarek, J. Acta Pol. Pharm. 1996, 53(6), 411.91 Szejtli, J.; Osu, T. ed. Comprehensive Supramolecular Chemistry Elsevier Science Ltd; Tarrytown, NY;1996.

Phillip H. Madison, IV Chapter I: Literature Review 24

Figure 1.4 Names and structures of typical compounds utilized recently in the formationof host-guest complexes with β-CD derivatives.83,84,85,86,87,88,89,90

ONH NH

O

CO2H

(Et)2N N(Et)2

SO3H HN HO3S

NH

N

O

N

F

SH2N

O

O

HS

NH2

O

OH

NO2

OH

OH

HO

O

O

(Me)2N N(Me)2

HN N

N

CO2H

OF

N

O

O

N

O

O

NO2NicardipineCiprofloxacin

(Z)-4,4'-bis(dimethylammoniummethyl)stilbene

2,5 norbornadiene

2,6 naphthalenedicarboxylic acid

4-nitrophenol

homocysteine

4-aminosulfonyl-7-flouro-2,1,3-benzoxadiazole

2-(p-toluidino)naphthalene-6-sulfonic acid

8-anilino-1-naphthalenesulfonic acid

Acridine Red

Rhodamine B

Phillip H. Madison, IV Chapter I: Literature Review 25

Among the different compounds that can act as host molecules (i.e. urea, thiourea,

and crown ethers to name a few) CDs are preferred for a number of different reasons.92

The first advantage of CD is its relatively nonreactive nature. CD is stable in alkaline

solution, has fairly good resistance to UV and IR light, is thermally stable at up to 270 oC,

and acid hydrolysis only results in nontoxic glucose products. CDs are also nonreducing

and periodate oxidation does not produce formic acid or formaldehyde, which is a

concern for food and drug applications. CDs are also readily available, thoroughly

studied, natural products that have been found to form stoichiometric complexes with a

wide range of molecules. The cavity size is variable depending on whether you use α, β,

or γ-CD, and through modification of the hydroxyl groups the melting and reactive

characteristics can be altered, which make CDs preferable alternatives to other common

host compounds. Table 1.2 gives some of the physical properties of the methylated (1.8)-

α, β, and γ-cyclodextrins.

Table 1.2 Physical properties of methylated (1.8)-α, β, and γ-cyclodextrins as reportedby Wacker Biochem Corporation.93

Methylated(1.8) CyclodextrinProperty

αα ββ γγ

# of glucose rings 6 7 8

Appearance white powder yellowish powder white powder

H2O solubility > 3 g/mL >1.5 g/mL >3 g/mL

Averagemolecular weight

1120 1310 1500

Bulk density 0.2-0.3 g/mL 0.2-0.3 g/mL 0.2-0.3 g/mL

Melting range NA 160-190 °C NA

92 Huang, L.; Tonelli, A. J. M. S.-Rev. Macromol. Chem. Phys. 1998, C38(4), 781.93 www.wacker.com

Phillip H. Madison, IV Chapter I: Literature Review 26

1.4 Industrial Applications of Cyclodextrins

Today in industry cyclodextrins are incorporated into a variety of items from

chewing gum94 to detergents.91 Cyclodextrin’s ability to incorporate a guest within its

cavity has found usefulness in a multitude of areas.95 Negligible toxicity allows for its

application in everyday products such as shampoo and toothpaste.91,96 CDs have even

been found to be safe enough to be used in food and drug systems. This section will

include a broad but brief introduction into the different ways cyclodextrins and their

ability to accommodate guest molecules are being used today in industry.

Cyclodextrins and their derivatives have found a place in a number of consumer

products and in many industrial processes. They are used to control solubility, mask

agents, and provide stabilization.91,95,96,97 They have also been utilized as general

processing aids and are used to direct chemical reactions, compatibilize materials, and

control volatility. 91,95,96,97

CDs have been found to alter the solubility properties of complexed guests, and

have been utilized to solubilize hydrophobic compounds in aqueous media. Hespiridin is

a compound discovered to be responsible for both a visible cloudiness and bitter taste in

canned oranges.98 Yasumatsuk and coworkers discovered that the addition of CD

noticeably reduced both the cloudiness and bitter taste of the hespiridin.

Increased solubility has also been found to result in increased bioavailability in

drug systems. When administered orally, itraconizole is ineffective due to its insolubility

in the stomach. The insoluble anti-fungal agent is therefore unavailable for absorption

into the body. However, the complex of itraconizole and hydroxypropyl-β-CD shows

increased bioavailability due to its increased solubility.97

94 Sato, Y.; Suzuki, Y.; Ito, K.; Shingawa, T. US Patent 5156866 1992.95 Szetli, J. Inclusion Compounds, vol 3, chapt 11 Academic Press, Orlando, FL; 1984.96 Szetli J. Cyclodextrin Technology Kluwer Academic Pubs, Dordrecht, the Netherlands; 1988.97 Hedges, A. Chem Rev 1998, 98(5), 2035.

Phillip H. Madison, IV Chapter I: Literature Review 27

Many times when a guest is present in a CD cavity some of the original

compound’s activity is “masked”. 91,95,96,97,99 For example, unwanted flavors in foods can

be masked through complexation with CD as in the previous example with the bitter taste

in oranges. When the compound is complexed, it is isolated and thus prevented from

coming into contact with receptive surfaces. So, in the case of a taste compound, when

the substance is complexed it is unable to interact with the taste buds to relay its bitter

nature. This masking technique has also been used in the case of skin irritants.99

Lotions have been developed in which a fragrant, but irritation-causing component is

complexed with CD in order to limit its direct physical contact with the skin but still