Seeing is believing buying Imagine showing a prospective customer a picture of their dream deck—and not just a drawing or sketch, but a full-color, 3D image they can look at from any angle. DeckTools Software ® , a sales, design and estimating software program for decks, makes it easy for deck builders and suppliers to create one-of-kind deck designs right from their laptops. Customize nearly every detail, from the deck shape and railings to materials, connectors and fasteners, while quickly generating plans, proposals and material lists. Learn to turn your proposals into sales with Simpson Strong-Tie ® DeckTools Software ® . Visit www.strongtie.com/decktools or call (800)999-5099. DeckTools version 3.0 is available now. See website or call for details. ©2009 Simpson Strong-Tie Company Inc. DT09 Come see us at IBS booths C755 and C955 FOCUS ON WESTERN WOODS VIRTUAL MEETINGS LUMBERYARD AUCTIONS JANUARY 2010 The MERCHANT Magazine THE VOICE OF THE WEST’S LBM DEALERS & DISTRIBUTORS – SINCE 1922

The Merchant Magazine - January 2010

Mar 06, 2016

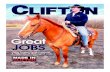

January 2010 issue of The Merchant Magazine, the leading monthly magazine for lumber and building material dealers and distributors in the Western U.S.

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Seeing is believing buying

Imagine showing a prospective customer a picture of their dream deck—and not just a drawing or sketch, but a full-color, 3D image they can look at from any angle. DeckTools Software®, a sales,design and estimating software program for decks, makes it easy for deck builders and suppliers to create one-of-kind deck designs right from their laptops. Customize nearly every detail, from the deck shape and railings to materials, connectors and fasteners, while quickly generating plans, proposals and material lists.

Learn to turn your proposals into sales with Simpson Strong-Tie® DeckTools Software®.Visit www.strongtie.com/decktools or call (800)999-5099.

DeckTools version 3.0 is available now. See website or call for details.

©2009 Simpson Strong-Tie Company Inc. DT09 Come see us at IBS booths C755 and C955

FOCUS ON WESTERN WOODS � VIRTUAL MEETINGS � LUMBERYARD AUCTIONS

JJAANNUUAARRYY 22001100

The MERCHANT MagazineTHE VOICE OF THE WEST’S LBM DEALERS & DISTRIBUTORS – SINCE 1922

Claymark® CenturionTM

Exterior Trim that Defies Comparison.

Claymark® CenturionTM Tru-Core® Treated Finger-jointed Radiata Pineis the Next Generation of Primed Exterior Trim.

800-752-0121 • www.wtrask.com

Sleep Soundly at Night Knowing You are Offering Customers a Trim Productthat is Unrivaled by Any Other on the Market Today.

FSC (Forest Stewardship Council) Certified, manufactured in New Zealand to exactingeco-standards from the log to the finished product.

TruCore® protected CenturionTM boards are highlyresistant to rot, decay and termite damage when used as recommended and are backed by Claymark’s 50 Year written limited warranty.

TruCore®fully penetrates to the core of the board.As a result, cut surfaces, ends and drilled holes do not require retreatment at the jobsite. This is ensured by a quality protection program that includes Independent Auditor verification.

The TruCore® protection system is user friendly and does not include volatile organic solvents, heavy metals, arsenic, chromium or similarmetals and has no offensive odor and thus canbe used for interior applications.

The TruCore® protection system components have been used for over 50 years with anexcellent performance history.

The TruCore® protection system componentsare recognized by the Window and Door Manufacturers Association (WDMA) and the American Wood Preservers Association (AWPA).Active ingredients are registered with the U.S.Environmental Protection Agency (EPA).

A new generation acrylic primer system:The prime coat has been formulated withexcellent adhesion, minimum tannin bleed, and maximum filling properties. The undercoat has been formulated via use of modified acrylictechnology delivering maximum toughnesswhile not compromising the exterior durabilityof the product.

(707) 433-3313 • FAX 707-431-2913

800-371-0637www.nuforestproducts.com

44 � The Merchant Magazine � January 2010 Building-Products.com

January 2010Volume 88 �� Number 7

OnlineBREAKING INDUSTRY NEWS, INDUSTRY PHOTO DOWNLOADS, & THE MERCHANT: DIGITAL VERSION

BUILDING-PRODUCTS.COM

THE MERCHANT ON FACEBOOKSEARCH “THE MERCHANT

MAGAZIINE” ON FACEBOOK.COM

THE MERCHANT ON TWITTERTWITTER.COM/MERCHANTMAG

Special Features8 FEATURE STORYLUMBERYARD, INVENTORY AUCTIONS

10 INDUSTRY TRENDSBIGGEST CHANGES OF LAST 25 YEARS

12 MANAGEMENT TIPSTURN A SEMINAR INTO A WEBINAR

14 COMPETITIVE INTELLIGENCEFIFTH-GENERATION GROWTH SPURT

16 PRODUCT SPOTLIGHTLOW-SLOPE ROOFING

24 PRODUCT SPOTLIGHTRADIATA PINE EXTERIOR TRIM

26 SPECIAL FOCUS: WESTERNWOODS11-PAGE SPECIAL SECTION

40 PHOTO RECAPSLUMBERMEN’S HOLIDAY PARTIES

The MERCHANT Magazine

California Timberline, Inc.Sugar and Ponderosa Pine,Douglas Fir, Redwood,

Western Red and California Incense CedarHardwood Lumber & Plywood

Chino, CA 91710 • (909) 591-4811 • FAX (909) 591-4818

The Mark of Responsible ForestrySCS-COC-001973

®1996 Forest Stewardship Council A.C.

In Every Issue6 TOTALLY RANDOM

18 OLSEN ON SALES

20 GREEN RETAILING

22 MOVERS & SHAKERS

37 NEW PRODUCTS

42 BUSINESS CARD ADS

43 ASSOCIATION UPDATE

44 CLASSIFIED MARKETPLACE

44 IN MEMORIAM

45 DATE BOOK

46 IDEA FILE

46 ADVERTISERS INDEX

CHANGE OF ADDRESS Send address label from recent issue ifpossible, new address and 9-digit zip to address below. POSTMASTER Send address changes to The MerchantMagazine, 4500 Campus Dr., Ste. 480, Newport Beach, Ca.92660-1872.The Merchant Magazine (USPS 796-560) is published monthlyat 4500 Campus Dr., Ste. 480, Newport Beach, Ca. 92660-1872 by Cutler Publishing, Inc. Periodicals Postage paid atNewport Beach, Ca., and additional post offices. It is an indepen-dently-owned publication for the retail, wholesale and distributionlevels of the lumber and building products markets in 13 westernstates. Copyright®2009 by Cutler Publishing, Inc. Cover andentire contents are fully protected and must not be reproduced inany manner without written permission. All Rights Reserved. Itreserves the right to accept or reject any editorial or advertisingmatter, and assumes no liability for materials furnished to it.

LPCorp.com/now |

LP® SmartSide® Trim & Siding products offer the beauty of cedar with the advantages of engineered wood. That meansconsistent boards with no knots or voids. An industry-leading warranty that provides a 5-year, 100% labor and replacementfeature and a 50-Year Prorated Limited Warranty on the substrate. And our proprietary SmartGuard® process that ensuresLP SmartSide products resist fungal decay and termite damage. LP SmartSide Trim & Siding. All the advantages you need.

© 2008 Louisiana-Pacific Corporation. All rights reserved. SmartGuard is a registered trademark of Louisiana-Pacific Corporation and S-T-N Holdings, Inc.All other trademarks are owned by Louisiana-Pacific Corporation.

LP® SmartSide® Trim & Siding

The Smartest Advantages In Siding

Merchant 8.08 Layout:M Sig1-nov 03 1-8,41-48 7/29/08 9:06 AM Page 9

TOTALLY RandomBy Alan Oakes

www.building-products.comA publication of Cutler Publishing

4500 Campus Dr., Ste. 480, Newport Beach, CA 92660

Publisher Alan [email protected]

Publisher Emeritus David Cutler

Editor David [email protected]

Associate Editor Karen [email protected]

Contributing EditorsDwight Curran, Carla Waldemar,

James Olsen, Jay Tompt

Advertising Sales Manager Chuck [email protected]

Administration Director/SecretaryMarie Oakes [email protected]

Circulation Manager Heather [email protected]

How to AdvertiseWEST, MIDWEST, SOUTHEAST

Chuck CaseyPhone (949) 852-1990 Fax 949-852-0231

[email protected] Paul Mummolo

404 Princeton Ave., Brick, N.J. 08724Phone (732) 899-8102 Fax 732-899-2758

[email protected] Alan Oakes

www.building-products.comPhone (949) 852-1990 Fax 949-852-0231

[email protected] David Koenig

Phone (949) 852-1990 Fax [email protected]

How to SubscribeSUBSCRIPTIONS Heather Kelly

Phone (949) 852-1990 Fax [email protected]

or send a check to 4500 Campus Dr., Ste.480, Newport Beach, CA 92660U.S.A.: One year (12 issues), $22Two years, $36 Three years, $50

FOREIGN (Per year, paid in advance in US funds):Surface-Canada or Mexico, $48

Other countries, $60Air rates also available.

SINGLE COPIES $4 + shippingBACK ISSUES $5 + shipping

The MERCHANT Magazine

66 � The Merchant Magazine � January 2010 Building-Products.com

Nothing in life is freeFIRST, A BELATED HAPPY NEW YEAR. I hope that you had time to enjoy the holidays

with your families and are ready for the challenges of a new year. In my nativeEngland we have a custom of opening the front and back door to let the old air out and thenew air in. As of midnight December 31, that door should be open for a long, long time!

There doesn’t seem to be any industry that has not had challenging business results in2009, but I have been encouraged in the last few weeks at the small signs of optimism inour industry. The truth is, without optimism and belief, what are we left with? A negativeenvironment only breeds further negativity. The challenge this country faces is that thenegative barometer is set too high! We must find a way to turn the switch that will start usall getting back to how it was—or at least somewhere in the middle of then and now.

We often debate in our office what we can do better or more of to help our readers andadvertisers. I am sure that is a debate held in every company at some time or another. Oneof the comments that invariably comes up—mostly from the sales force—is let’s offerfree this and free that. Now, nothing gets me more excited than trying to benefit our cus-tomers, but I have learned over many years that giving something for nothing is just not agood idea. In fact, it’s the worst business decision you can make. It is tempting whentimes are tough, but once you start down that road, you can never get anyone to pay fortoday’s freebies in the future. Yes, we all see our competitors do stupid things (I hear fromyou on desperate pricing all the time), but I have yet to see a company succeed with sucha strategy in the long term.

I remember being trained that you can always go up, but you can’t come down. Whenyou offer something today, it will be remembered and you will negotiate it every time.The salespeople who suggest giving something away don’t get hit in the pocket, so forthem it’s an easy suggestion to make. What does gets hit are your margins. And theynever recover!

To me, there are three issues that you need to deal with. First, teach your sales team tosell. There are too many people in this industry out there selling who have not been ade-quately trained to sell. The goal of sales is to get the order—not at all costs, but to makesure both parties are happy signing on the dotted line and will be happy to do businesstogether in the future. Nothing comes or should come easy. So buyers need to be sold,objections overcome. You can talk all you want about your last golf game or vacation, butunless you walk out with an order or have moved the potential sale further up the funnel,you have failed. I just sense that the current economic mess gives power to negativity, toaccept that it’s okay not to have the order. Following every customer contact, salespeoplemust be self-critical, strategically analyzing what they did or did not do and holding them-selves accountable. Don’t be content with a no! We can blame our troubles on the econo-my or our stupid competitors or…, but how about we blame ourselves?

Second, years ago I heard the saying that when you offer something for nothing youentice cheap customers. And we all know what they are like, right? They are the ones thatnitpick on everything, negotiate every cent, and are never happy. A free lunch isn’t free; itjust cuts your profits and makes you negotiate every order.

Third, think through your unique selling advantages. And if you don’t have any, youhave a much bigger problem than this column can solve. Differentiate, differentiate, dif-ferentiate! If you already possess distinct advantages, let your cus-tomers know what they are—or do you assume they know already?Don’t take anything for granted. Value-add your products. Offerservices that no one else offers. But don’t give them away. Justremember: charging more requires a higher level of sales andmarketing skills, and, frankly, you might not have the right peo-ple in place today to do this.

I have spent my time in every business I have run breakingdown numbers and understanding how every line on my P & Lhas been derived. But at the end of the day, the top line,the gross profit line, and the bottom line will tell you allyou want to know. When the comparative percentageschange for the worse, you know you have issues.

This year will again be challenging, but I thinkwe are at the start of the long road up. Make sureyour company is prepared for the turnaround andget back to doing business the right way!

Alan OakesPublisher

88 � The Merchant Magazine � January 2010 Building-Products.com

Building-Products.com January 2010 � The Merchant Magazine � 99

FEATURE Story

AUCTIONS OF SHUTTERED FACILITIES and surplus invento-ry have become a sure sign of the economy’s effect on

lumber and building material dealers and distributors.“This is a buying opportunity and very indicative of a

major trend in the market today,” said Joshua Olshin, pres-ident of auctioneer Tranzon Integrated Property Group.“Banks are not the only ones selling properties in whatmight be referred to as the current buyer’s market.”In mid-December, Tranzon started auctioning off the

first of 25 surplus properties in 14 states as part of the post-bankruptcy liquidation plan for Stock Building Supply.“On behalf of our client, we have chosen the auction-

process as the most efficient method to market and sell alarge portfolio of properties in order to maximize proceedsin a timely manner,” said Ken Zakin, senior managingdirector of Newmark Knight Frank, an international realestate advisory firm. “Tranzon is a leading auctioneer andwe expect these auctions to allow our client an acceptableexit given a difficult climate.”The Gores Group, a private equity firm based in Los

Angeles, Ca., bought 51% of Stock, while parent Wolseleykept a 49% interest in the company. Of the chain’s morethan 200 locations, only 100 in 19 markets were kept open.The Stock auctions consist of shuttered facilities, as

well as several lots that were acquired for expansion butnever used. The first set of auctions, held Dec. 15 and 16,included properties in Salisbury, Md.; Acworth, Ga.;Sanford, Durham and Hendersonville, N.C., andTimmonsville, S.C.

Going, going, gone…Lumberyard auctions disposeof inventory, properties

OUT OF STOCK: Downsized Stock Building Supply is going the auctionroute to find quick buyers for 25 closed or excess properties in 14 states,including (upper left) a 50,000-sq. ft. facility in N. Durham, N.C., and(above) a 210,000-sq. ft. warehouse/manufacturing plant in Acworth, Ga.

The next round of Stock auctions will be held the mid-dle of this month, disposing of properties in Bakersfieldand Hidden Valley Lake, Ca.; Boise, Pocatello, andPreston, Id.; Orem, Ut.; Kemmer, Wy., as well as in Texas,Ohio, Michigan, Minnesota, Wisconsin, Pennsylvania, andFlorida.Also this month, on Jan. 12, lumber and equipment

from Simmen Wholesale Lumber, Sacramento, Ca., will beoffered by Murphy Auctions. Gary Simmen started thebusiness in 1974 as a brokerage and wholesale operation,but added a distribution yard and remanufacturing facilityin 1980. Last month saw a flurry of LBM auctions. On Dec. 22,

Rosen Systems conducted an online auction of the invento-ry of United Building Products’ final location in Dallas,Tx. The roofing products firm started 20 years ago and wasbased in Albuquerque, N.M.In the preceding weeks, Monticello Lumber,

Monticello, In., auctioned off its building and property;King City Lumber, King City, In., auctioned off excessinventory and equipment from two locations, andNewmeyer Lumber, Rahway, N.J., auctioned off its inven-tory, yard and office equipment and warehouse supplies.

1100 � The Merchant Magazine � January 2010 Building-Products.com

AS WE SLOG OUR WAY through therecession of 2008-2009, hoping

for an end some time in 2010, there’sno question that the downturn haschanged the way most of us do busi-ness. We have reduced inventories tothe bone, cut staff to bare minimums,squeezed efficiencies from thin air,and worked harder than most of us areaccustomed to. Staying profitable hastaken a lot of blood, sweat and tears. The truth is, though, the lumber

business has gone through manychanges in the last 25 years and wehave been forced to adapt or fail.Lions are always waiting to thin theherd by taking down the slow and theweak. Our industry is littered with thecarcasses of producers, distributorsand retail suppliers who failed to reactto change. Some change is positive and helps

us do business more efficiently. Somechange is threatening and forces us toquestion how we do business. Andsome change is benign—you canwatch it and react appropriately whenthe time is right. Identifying changeafter the fact is usually pretty easy.Recognizing and reacting to changeearly in the process is more difficult. The following list of changes have

taken place in the past 25 years andeach has changed the way we do busi-ness.

1. The SpottedOwl.When the

recession of theearly 1980sfinally burneditself out, weenjoyed a decade

of favorable conditions in the lumberbusiness. New construction andremodeling had rebounded nicely andthe material pipeline remained full. Inthe late ’80s, we began to see newspa-per accounts about the plight of thespotted owl—a plight that wasincreasingly being played up by envi-ronmental activists. In 1991, District Court Judge

William Dwyer cancelled 75% ofForest Service timber sales, a movethat would constrain or eliminatemuch of the timber supply our indus-try was dependant upon. Many millswere forced to find new sources ofraw material and those that could notclosed their doors. We continue to feelthe repercussions some 20 years later.

2. The Fax Machine.The first commercially viable fax

machines began to dribble into themarket in the early’80s. They werebig, slow andnoisy, and theysmelled like asmall electricalfire as they labo-riously cranked outtext-covered pagesthat came mysteriously through thewires. The print quality was horrible,but even a bunch of lumber guys couldrecognize this new machine as game-changing technology. Our industry, toits credit, was an early adopter of faxmachines and the efficiencies theybrought to communication.

3. Big Box Stores.Lowe’s and Home Depot began to

rapidly expand in the 1980s and can

now be found in nearly every market.The one-stop-shopping model for thedo-it-yourselfer was embraced bymany customers and it wasn’t clearhow this would affect the traditionallumberyard. Many retailers wereforced to find ways tocompete, and thosethat could not areno longer inbusiness. W h o l e s a l e

suppliers, too,had to learn how todeal with a new breedof hard-nosed buying and supplierpolicies they were unfamiliar with.Many wholesalers were forced tomake a decision: do business with thebig boxes or do business around them?Companies came up with a variety ofstrategies to survive and thrive in thebig box era.

4. Cell Phones.Like the fax machine, we lumber-

men embraced the cell phone as soonas it was small enough to slip comfort-ably into a pocket. Many of us remem-ber the days of circling the block andlooking for a parking spot near aphone booth in order to call the office.Today, if four lumbermen are travel-ing together in a car,it is not unusual forall four to be ontheir phones. We often buy

material we havenever seen andwe often sell it tosomeone we havenever met. Our business is truly abusiness of communication and the

The last 25 years

The 9 biggest changesto how we do business

INDUSTRY TrendsBy Loren Krebs

Building-Products.com January 2010 � The Merchant Magazine � 1111

change—our business.9. The 2008-2009 Recession.Although no group has escaped

entirely, retailers and contractors havebeen hit especially hard during therecent downturn. Companies haveclosed their doors in record numbers,and many of the survivors have circledthe wagons, hoping for a 2010 recov-ery. There will tremendous opportuni-ty for the survivors.So, get ready

for the next 25years. You canlook forward tochanging tech-nology, changingsupplier bases,changing customerbases, and a constantly changing econ-omy. You’ll see competitors go out ofbusiness and new companies take theirplace. New products will come. Oldproducts will go. Personnel changes—your own as well as those of your cus-tomers and suppliers—will affect yourbusiness. Don’t be caught like a deer in the

headlights. When change happens,make decisions.

– Loren Krebsbegan his career inthe lumber businessin 1969 and recentlyretired as purchas-ing department man-ager after 25 yearswtih Disdero Lum-ber, Clackamas, Or.He can be reachedat [email protected].

cell phone has allowed us to commu-nicate better. 5. Email.Most of us use email today and rec-

ognize it as another communicationtool that has changed the way we do

business. (I do, how-ever, know of somecu rmudgeon l yholdouts whoprefer to com-municate on thephone.) For many

things, though, emailis the best tool available. Suppose youhave a truckload of very expensiveclear cedar arrive in your yard and youdiscover that the side of one unit hasbeen raked and pillaged by an errantforklift driver. You can take a digitalpicture and immediately send it toyour supplier with a note that says,“What’s up with this?” 6. The Internet.Generally speaking, other than a

few cutting edge, spike-haired, tattoo-covered geeks, we lumbermen havebeen slow to adopt theInternet as a way toput deals together.One reason forthis is there are alot of movingparts in mostlumber transac-tions. Puttingtogether a good deal forbuyer and seller works better whenboth parties are fully engaged. It’spretty hard to add a truckload of lum-

ber to your “shopping cart.” However, most of us have company

websites, and this is another great wayto communicate and share informa-tion.7. Shrinking Producer Base.One of the biggest changes affect-

ing the way we do business is the con-tinuing shrinkage of our producerbase. As mills grapple with environ-mental constraints, lack of harvestable

timber, and the cur-rent lacklustereconomy, manyhave been forcedto curtail orclose indefinite-ly. Traditional

supply chains havebeen disrupted, and

many suppliers are gone forever. Thischange is ongoing, and we all need tonavigate through this minefield.8. Young People.For many years we had few young

people coming into our industry, butthis trend has changed.You need onlyattend a showsuch as theN A W L ATraders Marketto see the change.Some of us olderguys are slowingdown or calling it a day, and we havea new generation of lumbermen join-ing our fraternity. This group is bright,ambitious, aggressive, technologicallysavvy, and not afraid to work. Theyhave changed—and will continue to

P.O. Box 1802, Medford, OR 97501 • Fax 541-535-3288(541) 535-3465 • www.normandist.com

Superior Service, Products & Support100% of the Time

Distributed By

1122 � The Merchant Magazine � January 2010 Building-Products.com

MANAGEMENT TipsBy Patricia Fripp

WITH TECHNOLOGY RISING buttravel budgets shrinking, more

companies are turning to the Internetto stage their customer and employeepresentations, meetings and seminars.Yet running a successful webinar hasdifferent requirements than deliveringan in-person presentation.Here are tips to catch and keep a

webinar audience:BEFORE YOU START,USE LOOPING SLIDES

Once your audience tunes in, howdo you make sure they are entertainedand feel involved even before theevent starts? The best way is with aseries of looping slides. Loopingslides are a great way to conveyimportant information and to keepattendees entertained while waiting foryour presentation to begin.

Hold your nextmeeting over the Internet

REGIONAL associations have been at the forefront of the lumber industry’s entry into webinars,hosting sessions on topics such as OSHA regulations, forklift safety, customer service, sales, collec-tions and certification. Northeastern Retail Lumber Association even maintains an online archive ofpast webinars.

These slides need to communicate: • when the session will begin,• the conference dial-in number,• a photo, name and title of the pre-

senter,• what the audience is going to

learn, and• what to do in case of problems.You may also have quotes about

the content they will be learning.BE MORE VISUAL

Be creative. Think Hollywood! Tellstories and give examples as you gothrough your program, the same wayyou would in person. However, yourwebinar needs more visuals to helpengage the audience. Use more slidesthan with an in-person presentation.Add bullet points one at a time as you“build.” Don’t present a list of all yourpoints before you discuss them. Keep

it simple, keep it moving, and interactoften.

PLAN YOUR STRUCTUREOutline your presentation on paper

or flip chart and then build thePowerPoint. You have to get “messy”before you get tidy! It is better to havefewer points and illustrate them well. Be sure you:• Introduce your objective. • Sell the benefits.• Explain the agenda and timing of

your session.• Add any logistics and how they

will interact with you.OPEN WITH A GRABBERAfter a “grabber” slide, it’s up to

you to engage your audience immedi-ately with a powerful, relevant open-ing that includes the word “you.” Yourgrabber opening might be:• A catchy fact: “It may interest

you to know Ferraris hold their valuemore than polo ponies! I first learnedthis lesson when…” • A startling statistic: “Did you

know that if you had spent $1 milliona day, every day since Jesus was born,you would not have spent a trilliondollars? Please keep that in mind aswe strategize how to increase sales byonly 5%…”• An intriguing challenge: “Ten

years ago we were the market leaders.This year we are 13th. You are now inan exciting position to turn thataround…”Grabber openings get the attention

of your audience. Then it is up to youto keep it. Never start by saying,“Good morning.” Instead, say some-thing like, “Welcome! You are in for atreat! You are about to learn howto…” As you introduce the session,sell the listeners on how they aregoing to benefit. Keep them glued.Remember, they can’t see you, so it isall too easy for them to answer their

Building-Products.com January 2010 � The Merchant Magazine � 1133

What’s a webinar?A webinar, or “Web-based

seminar,” is an interactive confer-ence, meeting or presentation that isconducted on the Internet.

How can webinars be used in the LBM industry?

• Sales meetings• Product knowledge classes• Employee training• Virtual roundtable discussions• New product/promotion

announcements• Sales pitches• Association board/member

meetings• Association-sponsored seminars

AVOID NON-WORDSHmm—ah—er—you know what I

mean—. On a webinar, this habit willonly be emphasized. Are you doing it?Why not have a run-through andrecord yourself. As with in-personpresentations, as Michael Caine says,“Rehearsal is the work, performance isthe relaxation.”

REVIEWAs with an in-person presentation,

always review your key ideas. Thensay, “Before my closing remarks, whatare your questions?”STRESS THEIR NEXT STEPSBe clear what their next logical

steps should be. Send them off ener-gized and focused.

CLOSE ON A HIGHYour last words linger. Make sure

they are yours (don’t quote anyoneelse) and make sure they are powerful.HAVE BACKUP COMPUTERS!Here is a practical suggestion that

will pay off for you. Have two com-puters tuned in to the webinar. Thisway, if one computer freezes, you canquickly get your second computer tothe place where the first had frozen. Itwill already be tuned in to the webi-nar, so it only takes a few moments toget on with the show. With technolo-gy, you never know!

– Patricia Fripp is an executive speechcoach, sales presentation trainer, andauthor of Get What You Want! Reach herat (415) 753-6556 or [email protected].

email or go get a cup of coffee.INTRODUCE YOURSELF

Once you have sold the session,you can introduce yourself if someoneelse is not doing it. Do not do it first.Just as with an in-person session, saysomething the listeners care about, andthen they care about who you are.

FORGE A CONNECTIONThe most powerful communication

combines both intellectual and emo-tional connections. Intellectual meansappealing to educated self-interestwith data and reasoned arguments.Emotion comes from engaging the lis-teners' imaginations, involving them inyour illustrative stories by frequentuse of the word “you” and fromanswering their unspoken question,“What’s in this for me?” Use a highyou/I ratio. For example, don’t say, “I’m going

to talk to you about webinars.”Instead, say something like, “In thenext 56 minutes, you will learn the sixsecrets of making a webinar work, thefour benefits of using webinars as partof your client interaction, and the threemistakes your competitors are makingwhen they use them.”

BUILD IN INTERACTIONDepending on the technology you

are using, make sure you interactwhenever logical. For example, stopand ask, “Based on what you haveheard so far, what are your ques-tions?”USE MEMORABLE STORIESPeople rarely remember your exact

words. Instead, they remember themental images that your words inspire.Support your key points with vivid,relevant stories. Help them “make themovie” in their heads by using memo-rable characters, exciting situations,dialogue, and humor. With a combina-tion of your examples and visuals, itwill be a memorable presentation.

USE EFFECTIVE PAUSESGood music and good communica-

tion both contain changes of pace,pauses, and full rests. This is whereyour listeners think about what theyhave just heard. If you rush on at fullspeed to crowd in as much informa-tion as possible, chances are you’veleft your listeners back at the station.It’s okay to talk quickly, but wheneveryou say something profound or proac-tive or ask a rhetorical question,pause.

1144 � The Merchant Magazine � January 2010 Building-Products.com

IN TRYING TIMES LIKE THESE, a littlehistory lesson can help. “A hun-

dred-year-old company [like ours] hasseen downturns before—the GreatDepression and two world wars,” saysDavid Marling, millwork manager ofWisconsin-based Marling Lumber.The business was launched by hisgreat-great-grandfather in 1904 andhis father, Kurt, now serves as c.e.o. David calls himself “a rookie”—a

young, 10-year employee in the firmhe grew up in—a company that’s seenit all and survived. No, scratch that:Make it “grown and prospered.” Andthis round is no different. “We’re get-ting ready for the rebound—we’rebuilding for that. Good times,” he’ssure, “are coming back. “We’re differ-ent! No way are we hunkered down.We’re looking to the future.”Not just a pretty metaphor, Marling

has seized the opportunity to expand.It recently completed a $2-million,17,000-sq.-ft. HomeWorks showroomin Janesville, Wi., and relocated com-pany headquarters to the site.

After five generations,it’s time to grow

FOURTH & FIFTH GENERATIONS: MarlingLumber is led by (left to right) David Marling,millwork & Janesville operations manager; TomMarling, purchasing manager & Madison opera-tions manager; Kurt Marl ing, c.e.o., andBrandon Marling, commercial manager.

“Our former headquarters inMadison,” half-an-hour distant, henotes, “was an 80-year-old building:worn out, inefficient. We’d run out ofroom. The new location gives usopportunity for growth, plus the abili-ty to consolidate our operations underone roof—manufacturing, humanresources, managers and such.” Marling also has operated a lum-

beryard in Janesville (and a secondone in Madison) and a door plant innearby Edgerton in addition to theoriginal Madison HomeWorks,launched in 1996, and satelliteHomeWorks showrooms opened inFebruary in Waukesha and Green Bay,Wi. The manufacturing plant, whichwas the first in the region to producehollow metal doors, turns out wallpanels and more to add to the compa-ny’s offerings—and profits.But HomeWorks—a showroom

we’ll visit in more detail in just aminute—was the big motivator inlooking for a longterm anchor asMarling planned ahead, a habit it’sfostered for five generations andcounting. “We decided that home improve-

ment was the wave of the future, theway the market is going,” affirmsDavid. “The traditional lumberyard of50 years ago is a thing of the past.You’ve got to diversify to stay ahead,and [all-inclusive, one-stop-shopping]showrooms are the way to go.People—especially women, the deci-sion-makers—have done research onthe Internet. Now, they want to touchand feel the products.”Furthermore, he predicts, “the cur-

rent recession will result in arearrangement: a sorting-out of manu-facturers and suppliers. Some willdrop out. So you’ve got to anticipatethat in planning your showroom.”Thus, among its 100-plus Janesville

employees, Marling has hired certifieddesigners who can turn out completehome blueprints; others who can assistwith kitchen, bath, and deckingremodeling projects; and several whoare uniquely schooled in demandslikely to mushroom in the near future:handicap-access and aging-in-placespecialists, who can advise commer-cial and home builders alike in mattersfrom elevators and stairlifts to wheel-chair-width aisles, knobs and grabbars. “You’ve got to diversify,” Davidseconds his own motion.And that can mean finding new

partners. Marling’s new buildingadjoins a grain elevator, so to expandinto lawn and garden products, thenew site displays gondolas, gazebosand barbecues, while their neighborhandles plants and landscaping materi-als. “We’ve also partnered with a localflooring company,” David adds. “Wechoose partners that are like us—fami-ly-owned, three or four generations.And it’s been very successful foreverybody involved,” he testifies.Marling also partners with its contrac-tor customers, whom it refers to home-owners seeking installation.Monitoring consumer trends is

vital, David maintains. So, picking upon the growing popularity of stay-cations, HomeWorks has pumped upits patio and deck capabilities, as wellas indoor amenities such as fancy fire-places.That’s in line with what Marling

has decided is most important forfuture viability, and that’s dealingdirectly with homeowners. “In thepast, our business was almost 100%pro, and we still offer contractors spe-cial staff, services, pricing and creditterms,” he adds. But the new show-room was expressly designed to enticehomeowners directly with elaboratedisplays, including a functioning

COMPETITIVE IntelligenceBy Carla Waldemar

Building-Products.com January 2010 � The Merchant Magazine � 1155

kitchen, closet, bath and office cabi-nets, and energy-efficient products—another huge growth area.Marling has also fingered the pulse

of the region’s demographic, andit’s—duh!—growing older. So thecompany has become a leader in newservices, such as those handicap-access and aging-in-place features.To get the word to consumers that

they’re welcome here, the companybuys “all sorts of advertising, fromprint to TV.” But maybe the best adwas the new building itself, whoseprogress people noted daily as theypassed it on the busy highway.Thinking ahead once again, Marling iswooing the younger, tech-savvy audi-ence of today and tomorrow with useof Facebook and Twitter.Right now, while others falter,

remodeling has kept the companysolidly in the black. “Looking ahead,it’s been our focus for the past fewyears; today, it’s 80% of our busi-ness,” David says.When the company undertook its

new building, it expressly added aseminar room to conduct classes—notonly for its own employees, but alsofor its customers. Contractors can gaineducation credits in classes like codingchanges and the stimulus package.Then these same pros are tapped asinstructors in seminars for homeown-ers in everything from decking toenergy-efficiency, which goes beyondwindow replacement to features theymay not have considered, like re-insu-lation. “We’re out to inform them, not

SHOWROOM DISPLAY features windows in a spinner, each trimmed out with different profiles anddifferent species, including purpleheart (center) and zebrawood (far right).

just sell the product,” David under-scores.Competitors? Sure. Menards and

Depot reside just down the road—“and they have their purpose,” Davidallows. “But our prices are the sameand sometimes even cheaper, because,with our various locations, we havebuying power. Even more important isour knowledgeable customer service.Many of our employees are contrac-tors who’ve hung up their hats, or for-mer city inspectors. We’ll not only sellyou something, but tell you how toinstall it, maintain it, and clean it. Andif ever there’s a problem, we don’thide. We say, ‘Come back to us.’”Marling treats those employees like

family, giving them their say in deci-sion-making. “We ask for their inputbecause they’re the ones who dealwith things, hands on. Many havebeen here 20, 30 years.”That’s David’s life plan, too. “My

mom and dad never said I had to gointo the business; I’m here because Ilove it. I’m a nostalgia guy, very senti-mental. I like being part of history.Very few businesses can boast a fifthgeneration. That’sneat to be a part ofit.” And the story

doesn’t end here…

Remanufacturing andWholesale Distribution of

High Quality NorthAmerican Softwoods

Now distributing PanelCraftersCedar Knotty Plywood

Stocking Distributor ofQuality Redwood produced by Agwood

Superior®

Brand siding 100% useableSTK Sidings & TrimExclusively Produced and

Distributed by Lausmann Lumber

WRC • SPF • Pine/ESLP• Ipé • Redwood • WRC FJ

• Specialty Sidings3370 Rippey Rd., Loomis, CA 95650

1-800-626-1233www.lausmannlumber.com

PPAANNEELLCCRRAAFFTTEERRSS

A Division of

LLaazzyy SS LLuummbbeerr

1166 � The Merchant Magazine � January 2010 Building-Products.com

PRODUCT SpotlightLow-Slope Roofing by Dan Thomas, GenTite

THE WINTER MONTHS BRING coldtemperatures, freeze/thaw cycles,

and wind. These conditions can dam-age more than our morale. They cando quite a number on roofs, too. Aswe begin to look forward to spring,it’s not too early to start preparing forthose spring roof repairs.Even though steep-slope roofs are

most common in residential architec-ture, many homes have flat sectionsover porches, dormers, carports orgarages. There are distinct differencesin how to address low-slope (flat) roofissues and extend the life and perfor-mance of a homeowner’s investment.Help contractors and homeowners

care for their flat roofs by asking threebasic questions:1. Should the roof be repaired or

replaced?A primary factor is the age of the

roof. The lifespan of a low-slope roofvaries significantly based on the com-ponents of the roof assembly. A well-installed roof should perform as statedby the manufacturer, so refer to thewarranty for the best indication ofhow long it should last. Most war-ranties are good for 10 years, but someproducts offer no warranty, whilesome new commercial-grade productscome with a lifetime warranty.Along with the age of the roof, con-

Repair or replace?

sider the recurrence of the problemand ask if other solutions have beentried. The key to a successful repair isusing similar materials to thosealready on the roof. Using a productthat is drastically different from theexisting material won’t provide a per-manent fix, as the solvents and chemi-cal makeup of the products will workagainst each other. A mineral surfaceroll or torch down roof should berepaired with asphalt-based products.Roofs with single-ply membranessuch as TPO or EPDM require ther-moplastic or rubber products, respec-tively, for repairs.If the homeowner has attempted to

repair the roof several times, in theappropriate way, and still has a prob-lem, it may be necessary to reroof.The common options are:• EPDM is a rubber-based single-

ply membrane roofing material. It’savailable in a commercial grade and iseasy to install.• TPO (thermoplastic polyolefin) is

a single-ply product ideal for warmerclimates, as the white surface reflectsthe sun to reduce energy costs.• Asphalt-based torch down roofing

can create a weather-tight roof surface.Safety precautions are critical, asinstallation involves open flame.• A mineral surface roll is a low-

Add-On Sales toRoof Inspectors• Safety Barrier or harness

to prevent falling• Safety Boots to deter slipping and

prevent foot injury from dropped items• Gloves to protect skin from chemicals

and sharp objects• Knee Pads

• Safety Glasses

slope alternative. The lifespan isshorter, but the price point is signifi-cantly lower.2. Is the roof subject to a signifi-

cant amount of foot traffic?Most roofs are not expected to

have heavy foot traffic. If the roofwill have a lot of traffic, there are twooptions: installing a thicker membraneor placing a deck over the roof. Athicker membrane better resists punc-tures, the most common cause of roofleaks. Commercial-grade EPDM andTPO membranes are available inthicknesses of 45 or 60 mil for thebest resistance to punctures.A better option is to install a deck

over the roof. The roofing materialitself will protect against freezing,thawing and the sun, while the deckwill protect the roofing material.3. Has the homeowner estab-

lished a maintenance routine?Proper maintenance is critical to

getting the longest life from the roof.Always reference the manufacturer’srecommendations and warranty infor-mation for specific maintenanceguidelines. Following them will keepthe roof’s warranty intact. Every year, the homeowner should

visually inspect the roof for black ordiscolored streaks, which indicatemold, algae or fungus. Spots shouldbe cleaned with a household cleanerto stop them from spreading and toprevent roof damage. Inspect all membrane seams, pay-

ing particular attention to flashingsaround curbs and penetrations.Finally, trim overhanging limbs toprevent branches from sweepingagainst the roof, gutter, soffit and/orflashing. This will minimize leafdebris and increase the roof’s abilityto withstand severe weather.

– Dan Thomas, business developmentmanager for GenTite Residential RoofingSystems. Reach him via www.gentite.com.

Building-Products.com January 2010 � The Merchant Magazine � 1177

Friedman’s Home Improve-ment is targeting an August 1, 2011opening for a proposed 80,000-sq. ft.store with drive-thru lumberyard and20,000-sq. ft. garden center inPetaluma, Ca.

Orland Ace Hardware, Orland,Ca., opened Jan. 2 at 21,8000 sq. ft.—nearly twice the size of the previousbuilding destroyed by fire in Oct. 2008.

Owner Ben Pforsich said the largersize accommodates more merchandiseand new departments, including lumberand building materials.

Healdsburg Lumber Co .,Healdsburg, Ca., has acquired door/window retailer The WindowWarehouse, Corte Madera, Ca.,from Steve Campodonico.

Campodonico wil l stay on tobecome sales mgr. for Healdsburg.

Home Depot broke ground on a465,000-sq. ft. distribution center inSalem, Or., for a spring 2011 opening.

The company has discontinuedRalph Lauren paint and now stockspaint, cleaning products, and closetorganization products from MarthaStewart Living.

The chain also presented MakitaUSA with the Marketing InnovationAward at its annual supplier partnermeeting in Atlanta, Ga.

Lowe’s opened a new home cen-ter Dec. 4 in central San Jose, Ca.;received planning commission approvalto buld a 111,348-sq. ft. store on thesite of a former Home Depot inCovina, Ca., and is seeking approval tobuild in Carlsbad and Santa Rosa, Ca.

DEALER BriefsFoxworth-Galbraith PullsBack in Arizona, ColoradoFoxworth-Galbraith Lumber Co. is

pulling out of the Tucson, Az., market,closing its local Arizona Sash & Doorunit by the end of the month.On Dec. 3, FoxGal shut down lum-

beryards in Payson and Lakeside, Az.,and Pueblo, Co. The Pueblo store’sinventory was transferred to otherlocations, as the chain considerswhether to lease or sell the site, whichit acquired in 1999 from Brookhart’sBuilding Centers.

Weyerhaeuser Converting toReal Estate Investment TrustWeyerhaeuser, Federal Way, Wa.,

announced it will convert to a realestate investment trust (REIT) in thenear future, to increase profitability. “This conversion will position us to

be more competitive in our timber-lands business,” said president andc.e.o. Dan Fulton. Although a date has not been set,

chairman Chuck Williamson predicted“the most likely date would be 2010.”Factors under consideration include

the state of the economic recovery, thedistribution of earnings and profitsrequired under tax laws for REIT elec-tion, and changes in tax policy, includ-ing shareholder tax rates.Conversion to a REIT would result

in a special dividend of undistributedprofits, most of it in the form of stock.By the beginning of 2010, the compa-ny expects earnings and profits to totalslightly less than $6 billion.

Murphy Adding Plywood MillMurphy Co., Eugene, Or., has

agreed to acquire Panel Products’idled plywood mill in Rogue River,Or.—hours before it was supposed tobe auctioned off.The $3.6-million deal, made with a

court-appointed receiver, requiresapproval by the judge. In the mean-time, if another bidder makes a higheroffer, Murphy would receive a kill fee.Murphy reportedly plans to restart

the mill this month. Panel Products, Milwaukie, Or.,

purchased the 164,000-sq. ft. plant on51 acres from Louisiana-Pacific at theend of 2003, then spent millions con-verting the veneer drying operationinto a plywood plant. The high-qualityequipment made the facility particu-larly attractive to competitors, after itfell into receivership in May.Panel Products’ other facility, a

veneer plant in White City, Or., wassold in November to Bob Jonas andDaniel Lavenbarg for $522,500.

Weyerhaeuser SellingOregon Mill to Hampton Weyerhaeuser Co., Federal Way,

Wa., has agreed to sell its Warrenton,Or., sawmill to Hampton Affiliates,Portland, Or. The deal, expected to close later

this month, includes both the facilityand land.Hampton plans to idle the mill for

nine to 12 months for extensivemachinery upgrades. The facility cur-rently employs 94, after 46 were laidoff indefinitely last March.

Southland Yard Battles Blaze The outdoor supply yard of Artesia

Building Supplies, Artesia, Ca., wasconsumed by fire Dec. 10. Flammable materials such as wood

and propane tanks were stored in theyard. Authorities suspect that tres-passers may have started the fire. Theowners of the 50-year-old business saypeople have jumped the fence at nightin the past to steal building materials.No one was injured in the blaze,

and the business will remain open.

1188 � The Merchant Magazine � January 2010 Building-Products.com

IN THE MOVIE Dumb and Dumber, Jim Carrey playsLloyd, a kind-hearted yet obtuse limo driver who falls

instantly, madly in love with a passenger he drops off at theairport. Lloyd drives across country to reunite with Mary.She is confused by his attention and behavior, and wants

to let him down easily, but—really—there’s no way.Lloyd: I like you, Mary. I like you a lot. I want to ask

you a question, straight out, flat out, and I want you to giveme an honest answer. What do you think the chances are ofa guy like you and a girl like me, ending up together?Mary: Well, Lloyd, that’s difficult to say, I… we really

don’t…Lloyd: Hit me with it! Just give it to me straight. I came

a long way just to see you, Mary. The least you can do islevel with me. What are my chances?Mary: Not good.Lloyd: You mean like not good like one out of a hun-

dred?Mary: I’d say more like one in a million.Lloyd: (Pause) So you’re telling me there’s a chance.

(Pause) Yeah! (Pause, giving Mary a conspiratorial look) Iread ya.When we talk with customers there will be objections.

We must maintain Lloyd’s innocence and sense of the pos-sible; too many of us are so tied to our perceived realitythat we get in our own way. When I traded lumber, we would sometimes get offers

that seemed ridiculous. Buyers would often say, “I can’ttake that to my mill. They won’t take that number.” Ourresponse was, “Don’t say no for the sawmill.” More oftenthan not, the deal was made.Similar negative conversations can play out in our heads

as salespeople:“This guy hates me.”

“He only buys from…”“He always buys from the other guy.”“They’re always too cheap.”“I never sell this guy.”“They’ll hang up if I say that.”“He’ll never pay that price.”We don’t live in reality as salespeople, we create it. We

cannot let our own negative attitudes or those of othersaffect how we sell. We are always positive, even in the faceof what can seem to be insurmountable odds. When I traded at Forest City, we had Silver and Gold

Circle traders. I remember like yesterday the first year Imade Silver. Ray Haroldson, my boss, called me into hisoffice. I was expecting a pat on the back and warm congrat-ulations. Instead, Ray said, “You know, James, if you hadput a couple more bucks a thousand (+$2/MBF) on every-thing you sold this year you would have gone Gold insteadof Silver.” I left Ray’s office feeling he was the most unapprecia-

tive SOB I had ever met in my life. I was mad at him forweeks. My thought was, “You have no idea how hard Iwork just to get the prices I am getting!”I started thinking about what he had told me. I started to

add a couple bucks over our list price to everything I pro-moted. And surprise of surprises, I started to get higherprices! (Unappreciative? Ray was just a great motivator!)My reality was tied to Cascade Empire’s list price (reality),when I should have made my own list price (reality).Is selling tough? Yes. Thank goodness! If it weren’t

tough, we wouldn’t get paid great money to do it. It wouldalso be deathly boring. Can selling make us crazy? If thegreat salespeople I know are any indication, yes. Embracethe insanity!We’ve already got enough reality.

It’s even on TV now—ugh! What weneed is more imagination, inno-cence and perseverance. Like ourfriend Lloyd. So the next timesomeone (especially us!) begins tofill our heads with (supposed andnegative) reality, let’s shout thebattle cry of great sales-people: So you’retelling me there’s achance!

So you’re telling methere’s a chance…

OLSEN On SalesBy James Olsen

James OlsenReality Sales Training

(503) 544-3572james@

reality-salestraining.com

Building-Products.com January 2010 � The Merchant Magazine � 1199

The fifth annual Bread ‘n’ Boardsfundraiser at Sears Trostel Lumber &Millwork took place Dec. 5 at thecompany’s location in Riverside, Co.,and raised more than $17,000 for alocal food bank.“This year, there was some real

gravity to doing it and doing it well,”said store manager Matt Chavez. Dueto the bad economy, the food bankexpected to distribute 7.5 million lbs.of food in 2009—up from 6 millionlbs. in 2008. More than 500 cutting boards in

four different shapes were auctionedoff during the event. Each one camewith a bottle of finishing oil, plus acoupon for a free loaf of bread from alocal bakery. Top price was $200, fora “signature” board made by a crafts-man who’s also a customer of thestore. “We wanted to involve morepeople and wanted to add more varietyto the signature boards,” said Chavez

Colorado Lumberyardʼs Fundraiser Feeds Locals

of the boards created by local crafts-people.Every board sold at the event was

made from hardwood scraps collectedat the company’s millwork facility andglued into blanks. These were thenrouted and shaped by employees andcustomer-volunteers at the Riversidelocation—half before the event andhalf during, so attendees could witnessthe process.

EVENT raised $17,000+ for a local food bank.

TOP BOARD at fundraiser fetched $200.

EMPLOYEES and volunteers create boardsduring the fundraising event.

Weyerhaeuser Co. will close itsiLevel DC in W. Sacramento, Ca., bymid-February and expand its Stockton,Ca., DC to serve the added territory.

MJ Forest Products, Linden,Ca., a wholesale trading office withlumber and plywood remanufacturing,was started by Max Jones, JanneJones, and Mike Mackin.

Steve Seley, owner of mothballedPacific Log & Lumber, Ketchi-kan, Ak., is seeking federal assistanceto convert to young-growth and fuelwood. USDA will decide on his propos-al by spring.

Burton Saw & Supply ,Eugene, Or., agreed to buy the assetsof fellow mill equipment manufacturerSequoia Saw & Supply, Eureka,Ca. The deal is set to close Feb. 1.

Simpson Door Co., McCleary,Wa., extended the warranty on its inte-rior wood doors to 10 years.

Norman Distribution, Med-ford, Or., is now distributing Ains-worth’s Durastrand.

Snavely Forest Products isnow stocking Georgia-Pacific’sBroadspan I-joist, LVL and Rim Boardengineered wood products.

CertainTeed’s Decoustics Qua-drillo, Solo and Solo M ceiling productswere FSC certified by RainforestAlliance’s SmartWood program.

Simpson Strong-Tie’s SteelStrong-Wall structural shearwall is nowcode listed for use in two-story con-structions applications.

SUPPLIER Briefs

2200 � The Merchant Magazine � January 2010 Building-Products.com

THERE’S AN OLD BIT OF BUSINESSWISDOM that goes something like,

“You can’t improve what you don’tmeasure.” It seems appropriate tospend a little time thinking about that.For one thing, it’s January, a naturaltime to assess where we are, resolve tomake improvements, and chart acourse for the rest of the year. Foranother, it’s a fundamental principleunderlying every serious sustainablebusiness initiative. It’s a simple formula: identify the

right things to measure, create bench-marks, set goals for improvement,monitor performance, and adjust asnecessary. Whether the economy in2010 comes roaring back or staysabout the same, it’s clear that there arerevenue-boosting and cost-saving ben-efits for companies that get seriousabout sustainability. For dealers, the core business is all

about the product mix, with basic met-

The Home Depot rolled out itsEcoOptions program in 2007 with3,000 products and announced a goalof increasing that number to 6,000 by2009. Their website claims to havesold over one billion such productssince the program’s inception. Proctor & Gamble also announced

an initiative to benchmark chemicalsused in their products with a goal ofreducing toxics. All of these effortshave garnered positive press and“greened” their respective reputations. The basis of these kinds of goals

and marketing claims are the assess-ments, but these kinds of programs,and their benefits, are not exclusive tobig companies. My firm recentlyhelped a group of much smaller com-panies create green product criteriaagainst which we characterized about250,000 individual SKUs. The resultis a starting point from which thesecompanies can create meaningfulbusiness goals, merchandising pro-grams, and marketing campaigns.More importantly, they now have anew set of metrics that will help themmeasure performance and progresstoward their goals. Imagine a dealer or distributor who

wants to become the energy efficiencyleader in their market, but they haveno idea how many Energy Star orother energy-saving products theyalready sell. They’re literally in thedark with a meaningless, maybe evendubious, goal unless and until theyknow their starting point. Only afterassessing their product mix, can thisimaginary dealer resolve to double thenumber of Energy Star products, prop-erly train and incentivize staff, andbegin to make the marketing claimsthat would lead them to their goal.For real-world dealers and distribu-tors, the benefits of such benchmark-ing could lead to greater sales, deepero r g a n i z a t i o n a lknowledge, andcompetitive advan-tages. By anymeasure, that’s nota bad way toapproach the newyear.

Jay TomptManagingPartnerWm. Verde &Associates(415) [email protected]

GREEN RetailingBy Jay Tompt

Taking stock ofyour green stock

rics tracking sales, velocity, inventory,etc. Assuming staff is trained andproducts are merchandised well, thesemetrics can be useful for identifyingthe poorest performing SKUs to elimi-nate and which categories to strength-en. But to address the needs anddesires of the growing number of“green” customers, these metrics fallshort. How many of your productswould contribute to LEED credits?What percentage is Energy Star-ratedor would qualify for rebates? Whichproducts are heavy energy consumersor contain the most toxic chemicals?And where are they manufactured:locally or the other side of the planet?Some “big box” retailers and major

mainstream product manufacturershave benchmarking programs in placeand are mobilizing their marketingteams around them. For example,WalMart introduced its SupplierScorecard a couple of years ago andlast year announced its SustainabilityIndex Consortium, an effort to definestandards for a variety of product cate-gories. They’ve also announced goalsto reduce packaging and increase thenumber of green products on shelves.

Building-Products.com January 2010 � The Merchant Magazine � 2211

DOMESTIC SALES:Jerry Long, Michael Parrella, Janet Pimentel,Pete Ulloa, George Parden, Vince Galloway,Steve Batick, Chris Hexburg, Matt Wright,Brad Applegate, Scott Crutchfield.

INTERNATIONAL SALES:Nestor Pimentel.

PORTLAND WHOLESALE Lumber Associa-tion honored Bill Hallstrom (right, with son KarlHallstrom), Zip-O-Log Mills, Eugene, Or., asLumberman of the Year at its recent holidayluncheon. (See next month for more photos ofthe event.)

BMHC Okayed To EmergeBMC West parent Building

Materials Holding Corp., Boise, Id.,received bankruptcy court approval tocomplete financial restructuring inhopes of emerging from Chapter 11 onJan. 4. “As a result of this process, we will

be in a much stronger financial posi-tion, having reduced our outstandingindebtedness to $135 million uponemergence,” said chairman and c.e.o.Robert Mellor, who under the planwould step down. “We have stream-lined our cost structure significantlyand have secured exit financing of $90million to support our ongoing opera-tions and future growth.”

Colorado Ace Owner StrickenA series of business setbacks may

have contributed to the brainaneurysm that put an Ace Hardwareowner in Colorado into intensive care. Vicky Anderson, who co-owns the

store in Wellington with her husbandDoug, was stricken on Oct. 28—justdays after the couple tried to renegoti-ate their business loans with a Utahbank. The loans had been sold to thebank after the FDIC took over theiroriginal bank, First National ofArizona, just one week before thestore opened.“I have hit the perfect storm,” said

Doug Anderson. “Our survival isbased on the ability to be as resource-ful as we possibly can in an economythat has flat-lined.”Even though the couple traveled to

Utah to meet with bank officials, nonew loans were offered. As a result,the Andersons had to invest nearly amillion of their own money to launchthe store, plus another $220,000 to

keep it afloat in a bad economy.After the Andersons returned home

from Utah, Vicky Andersen had totake a break because of stress and highblood pressure. Her husband believesthe stress caused her health problems. “A legitimate profitable business

can’t do business because of thescrew-ups of the banks,” he said.

Bloch Put on Auction BlockAll assets of Bloch Lumber, a 50-

year-old distributor based in Chicago,Il., were seized by its primary lenderand set to be auctioned off Dec. 29. The Chicago, Il.-based wholesaler

operated 26 facilities in 17 states,including sales offices in Portland,Or., and Denver, Co.

2222 � The Merchant Magazine � January 2010 Building-Products.com

Ca. Chad Griffith, ex-LumberProducts, is now handling outsidesales in Wa., Or., Id., Mt., Wy.,Co., and Ok., from his base inSpokane, Wa.

Bob Lackey, veneer sales, IdahoVeneer, Post Falls, Id., added thetitle of sales mgr.-lumber products.

John Parr, ex-Certified ForestProducts, has been promoted topresident of McKillican American,Inc. He will be based in Orinda, Ca.

Dixie Tibbets has retired after 26years in the industry, the last 13with Swanson Group Sales,Glendale, Or.

Justin Norman has been promoted tov.p.-sales & marketing at WoodfoldMfg., Forest Grove, Or.

Tom Czlapinski, ex-TimberTech, isnew to outside sales at CaliforniaRedwood Co., Arcata, Ca., cover-ing So. Ca., Az., Ut., N.M., andTx., from his office in Temecula,

MOVERS & Shakers Rick Palmiter, ex-Idaho Veneer, hasjoined Idaho Forest Group LLC,Coeur d’Alene, Id. Erol Deren hasbeen named v.p.-sales & market-ing, and Jim Scharnhorst is nowv.p.-market development, focusingon export, new markets, and spe-cialty products.

Chris Graham has rejoined McCoy’sBuilding Supply as store mgr. inHobbs, N.M.

John Steward, ex-Plum Creek, is newto the sales staff at Silver CityLumber, Three Forks, Mt.

Shawn Roehr has been promoted topresident at Arrow Lumber &Hardware, Eatonville, Wa. JeffWertenberger is now v.p./chieffinancial officer; Lloyd Gentry,v.p./director-store operations,Orting, Wa.; Steve Putney, v.p./store mgr., Eatonville; GregSimpson, v.p./store mgr., Randle,Wa., and Chris Peterson, v.p./store mgr., Port Orchard, Wa.Cadian Hendricks will serve asv.p./store mgr. of a planned 8,000-sq. ft. facility that is awaiting abuilding permit.

Todd Perry is now focusing on lum-ber and panel sales in the westernU.S. for Taiga Building Products,Burnaby, B.C. Cam White willbecome president and c.e.o. April1, following the retirement of JimBradshaw, who joins the board.Kevin Bradshaw is now executivev.p.-supply management; TrentBalog, executive v.p.-operations,and Grant Sali, executive v.p.-allied products & treated wood.

Marc Brinkmeyer, Idaho ForestGroup, Coeur d’Alene, Id., wasnamed chairman of the newAmerican Wood Council. Immedi-ate past chair is Ray Tennison,Simpson Investment, Tacoma, Wa.;1st vice chair Joe Patton, Wester-velt; 2nd vice chair Brian Luoma,L-P; lumber rep Adrian Blocker,West Fraser; EWP rep Rob Taylor,Weyerhaeuser; panels rep FritzMason, G-P; other products repAndrew Miller, Stimson Lumber,Portland, Or., and Canadian WoodCouncil rep Diana Blenkhorn.

Larry Greene has been named direc-tor of sales for Calibre DoorClosers, Orange, Ca.

Kevin Surace, Serious Materials,Sunnyvale, Ca., was named Entre-preneur of the Year by Inc.

Rich Returns is now investment mgr.at Mungus-Fungus Forest Products,Climax, Nv., report owners HughMungus and Freddy Fungus.

HUFF LUMBER COMPANYSANTA FE SPRINGS, CALIFORNIA

800-347-4833

OOlldd WWoorrlldd CCrraaffttssmmaannsshhiippIInn TTooddaayy’’ss DDeessiiggnnss

TTrruu--DDrryyTTiimmbbeerrss

Geo. M. Huff Lumber Companyhas teamed up with Forest GroveLumber to become the exclusiveSouthern California stockingdistributor of Tru-Dry Timbers.

All FGL Tru-Dry timbers aredried in “HeatWave USA’s RFV”kilns, which use clean, renewableenergy and have zero emissions.

Tru-Dry timbers are dried com-pletely and evenly throughout soyou won’t experience the stickyproblems often encountered withbeams that are not dried to the core.

Combine our selection ofDouglas fir timbers along with ourskilled milling staff and you’ve gotone of the best resources inSouthern California.

Building-Products.com January 2010 � The Merchant Magazine � 2233

GOOD JOB: Gary Spliethof, Boise Cascade,Woodinville, Wa., was presented Vendor of theYear Award from Hadlock Building Supply, PortHadlock, Wa., by Bill Kraut and Morris James.

Certifiers Ul and ICC Unite Underwriters Laboratories and ICC

Evaluation Service have teamed up tostreamline evaluations that ensurebuilding products are compliant withappropriate codes and product safetystandards.The new dual evaluation and certi-

fication program will simplify the test-ing and evaluation, conduct testing toUL safety standards, show code com-pliance via an ICC-ES evaluationreport, and get simultaneous postingsof compliant products in UL’s onlinecertifications directory and code corre-lation database. “This partnership brings two indus-

try leaders together to create a one-stop-shop for building materials test-ing and evaluation needs in the builtenvironment,” said Chris Hasbrook,an UL v.p. and general manager. He added that the “dual evaluation

and certification program will providemanufacturers faster turnaround timesand speed to market, while givingtheir customers two more reasons totrust the quality, safety and efficiencyof their products.”UL has also enhanced the usability

of its product certification informa-tion. Its code correlation database con-nects product certifications directlywith specific applicable model instal-lation code sections to help codeauthorities and other industry profes-sionals find ICC-ES code-compliantproducts. “This is just one of the many bene-

fits of working with a trusted partnerin safety like UL,” said Mark Johnson,president of ICC-ES. “We continue tolook for new opportunities to expandthis partnership to better serve ourcustomers and members.”

2244 � The Merchant Magazine � January 2010 Building-Products.com

Radiata pine makes itsmark in exterior trim

ALTHOUGH GOOD, OLD WOOD con-tinues to hold the lion’s share of

the exterior trim market, sturdieralternative materials have been mak-ing inroads.There are fast-growing cellular

PVC products, such as AzekMouldings, Royal Mouldings’ QuickTrim, Koma Trimboards, andCertainTeed Restoration Millwork.There are engineered products,including LP SmartSide, and hard-board trim, including Collins’TruWood. And fiber cement, such asfrom James Hardie and Plycem, alsoremains hot. That doesn’t mean wood has sat

idly by. Stronger, more versatile

PRODUCT SpotlightRadiata Pine Exterior Trim

wood products have arrived, particu-larly from the radiata pine forests ofNew Zealand and Chile. To justify the long-distance ship-

ping, the first radiata pine to arrive inthe U.S. two decades back were high-grade, clear products. Due to theirnatural good looks, they initially tar-geted interior millwork applications.Over the last half-dozen years, how-ever, radiata pine producers haveattempted to expand and diversify bylooking outdoors.Since, once outdoors, it will

inevitably end up primed and painted,radiata pine exterior trim is now tout-ing selling points beyond appearance.Among the advantages:

STARTED BY NATURE, FINISHED BY BODYGUARD

www.bodyguardwood.com

Distributed by The Kelleher Corporation. Call now for more information. Telephone (707) 938 4001.

There is no man made material that can compare with the beauty, warmth, or naturalness of wood; and now we’ve made it better.We’ve taken renewable New Zealand pine and enhanced it as Bodyguard, providing durability and effective prevention from insect damage and rot, all with a 30 year limited warranty.

Lifespan exterior trim and siding photo by Tenon

Building-Products.com January 2010 � The Merchant Magazine � 2255

• Sourced from sustainably man-aged plantations. (Several, in fact, areFSC certified.)• Pressure treated for durability,

insect resistance, and moisture protec-tion.• Covered by decades-long war-

ranties again rot, fungal decay, andtermites.• Treated with organic, non-corro-

sive preservatives.• Machine finished with primer

and/or paint.• Require no special tools, cutting

equipment, or fixing methods.• Kiln-dried and defects removed

prior to fingerjointing for a smoothfinish.• Can also be used indoors.“It’s a perfect product—and it’s

proven,” said John Barry, sales man-ager for ITI Americas, which pro-duces DesignPine radiata pine from astate-of-the-art facility in Chile. “It’sbeen used extensively in Australia,New Zealand, and Indonesia, so dueto its popularity we needed a largersource of supply and went to Chile.”

Radiata PineExterior Trim Producers

BodyguardBodyguard trimboard

www.bodyguardwood.comwww.kelleher.com

Boston CedarTiO2 Titanium White trimboard

www.bostoncedar.com

Claymark USACenturion trimboardwww.claymark.com

CMPC Maderas Selex trimboard

www.cmpc-usa.com

COMMCOKlearChoice trimboard

www.commcoklearchoice.com

Fletcher Wood SolutionsLifespan, Fletcher Select, and Fletcher

Prime trimboardwww.fletcherwoodsolutions.com

ITI AmericasDesignPine trimboardwww.itiamericas.com

WindsorONEWindsorONE trimboardwww.windsorone.com

2266 � The Merchant Magazine � January 2010 Building-Products.com

WESTERN WOODS

“NEVER BEFORE.” “Historic.” “Unprecedented.”“Worst Ever.”

These and many other adjectives have been used todescribe lumber markets this past year. While the worstmay be over, the depth of the downturn in U.S. lumberdemand and production has created new challenges andwill likely hold back the pace of recovery in the future,according to a lumber market outlook from Western WoodProducts Association.Demand for softwood lumber in 2009 plummeted to the

lowest point in more than three decades. The collapse ofthe housing market, fueled by a U.S. economy roiled byfinancial crisis, has impacted the lumber business dramati-

Historic downturnsets the stage forslow lumber recovery

cally. As demand for lumber evaporated, lumber pricesdeclined, in some cases by 60% or more from levels offour years earlier.Housing long has been a key market for lumber,

accounting for 45% of annual consumption. After peakingat 2.068 million in 2005, housing starts declined steadilybefore tumbling in 2009 to post-World War II lows.Just 551,000 houses are expected to be built in 2009,

down 39% from the previous year, predicts WWPA. Thattotal is the lowest since 1945, when 326,000 homes werebuilt.As a result, just 7.2 billion bd. ft. of lumber will be used

in new construction in 2009, compared to the 27.6 billion

Building-Products.com January 2010 � The Merchant Magazine � 2277

RESIDENTIAL CONSTRUCTION should begin the long, slow road torecovery this year.

bd. ft. used in housing just four years earlier.Overall demand for lumber is expected to total just 31

billion bd. ft. in 2009—less than half of what was used in2005. That would be the lowest annual volume of lumberused since 1975.Repair and remodeling uses, the second largest market

for lumber, has fared slightly better than home building,but is still weak. An estimated 11 billion bd. ft. of lumberwill be used in repair and remodeling in 2009, down 26.6%from the previous year.The unprecedented decline in demand has taken its toll

on lumber producers. Western lumber production in 2009is forecast to decrease 21%. The 10.2 billion bd. ft. pro-duced by western mills is the lowest since the 1930s andrepresents a little more than half the volume the same millsproduced five years earlier.Sawmills in the South have reduced production as well,

decreasing to 11.6 billion bd. ft. in 2009. In all, U.S. lum-ber production will total 21.8 billion bd. ft. for the year,down 21% from 2008.Canada and other foreign lumber suppliers have fallen

on even harder times in selling to U.S. markets. Lumberimports from Canada are predicted to total 7.9 billion bd.ft. in 2009, a decrease of 32% from the previous year.Other imports, including lumber from Europe and Latin

America, should decline by double-digit percentages forthe fourth straight year and lose more market share todomestic producers.Looking ahead to 2010, lumber markets are expected to

show some recovery as home construction activity picksup. But given the weak economy, continued high homeforeclosure rates, and a financial system struggling for sta-

bility, the gains in lumber demand and production will bemodest.WWPA is forecasting lumber demand to rise 11% in

2288 � The Merchant Magazine � January 2010 Building-Products.com

2010 to 34.5 billion bd. ft. Housingstarts will increase 21% to 668,000.While that is an improvement, thenumber of homes built in 2010 will bejust half the total of what was con-structed in 2007.U.S. lumber production should

move higher to meet the slow grow-ing demand. Western mills areexpected to produce 11 billion bd. ft.of lumber in 2010, up 8%. Sawmillsin the South will match that growthand increase production to 12.6 bil-lion bd. ft.Canada may begin to regain some

of the market share lost over the past

few years. Softwood lumber imports from

Canada are expected to rise 18.8% in2010 to 9.4 billion bd. ft. Volumes from Europe and Latin

America will also increase to just over1 billion bd. ft.Beyond 2010, both lumber demand

and production are expected to followan upward trend as economic activityand housing construction continues torise. Housing starts, though, are notforecast to move above 1 million unitsuntil 2012. Lumber demand will fol-low those gains, but it may be sometime before volumes come close to

those recorded in 2005.As recovery takes hold, hopefully

the industry will find more positiveadjectives to describe the lumberbusiness.

Find Sawmills,Products withOnline UtilityHistoric declines in the western

lumber industry have caused manychanges in the supply chain, withdistributors looking for new sourcesfor lumber and services. An onlinelocator can give wholesalers andretailers a head start on finding newlumber suppliers.

Available at www.wwpa.org, theOnline Lumber Buyers Guide can beused to generate a list of westernmills based on species, product, ser-vice, even transportation mode.Once the criteria is selected, mill list-ings can be generated showing thesales contacts, phone and emailaddresses.

Product selections range fromdimension lumber to boards to spe-cialty products such as fingerjointedlumber or pattern stock. All majorwestern species can be sourced,including Douglas fir-larch, white fir,and ponderosa pine.

Retailers selling product to greenbuilding projects can use the guideto find western mills making FSC orSFI certified lumber. Mills cutting forexport markets can also be identi-fied.

Product services that can beselected range from heat treated(HT) stock, end waxing, double endstamping and long lengths.Transportation selections cover themajor railroads—direct and reload—as well as truck or barge.

3300 � The Merchant Magazine � January 2010 Building-Products.com

WESTERN WOODS

Sawmills preparingfor “new normal”EMERGING FROM THE DEEPEST downturn in the industry’s

history, lumber sales professionals at western sawmillsare preparing for a “new normal” in selling and servingtheir distributor customers as markets recover.Both mills and distributors have seen dramatic changes

in the past few years. Demand for lumber plummeted bymore than 50% from 2005 to 2009. Mills cut output asprices crashed, with some product such as framing lumberselling for 60% less than four years ago.On the distribution side, scores of lumberyards and

wholesalers closed or filed for bankruptcy. The pace ofconsolidation accelerated, while economic conditions putstress on financing and credit for lumber purchases.Relationships between mills and customers—long a key

part of the lumber business—will take on even greaterimportance as sales start to recover. Many mill sales exec-utives said fortifying those relationships are a priority.Steve Schmitt, vice president of marketing at Stimson

Lumber Co., Portland, Or., said his sales staff has beentraveling more to meet with dealers. “We pride ourselvesin standing behind our products. Going out to meet withour customers is the best way to demonstrate that commit-

ment,” he said.Other mills are becoming more involved with their cus-

tomers’ businesses. Mark Porter, mill sales manager withHampton Lumber Sales, Portland, said his company hasspent more time evaluating what their customers need,

WESTERN MILLS are tweaking their capabilities and product lines toremain competitive in a tough market.

Building-Products.com January 2010 � The Merchant Magazine � 3311

from product offerings to training.“We’ve been doing this with many

of our key buyers and have been suc-cessful,” said Porter. “Even with thedown markets, we’ve been able toincrease our business to these cus-tomers.”Mills are changing how they sup-

ply lumber to customers. SierraPacific Industries lumber sales man-ager Bob Shepherd said his mills areselling more specified tallies andmixed cars than before, reflecting thechanging buying patterns of their cus-tomers.J.D. Deisher of Georgia-Pacific

West is finding ways to get more vari-ety of lengths in smaller shipments forcustomers. Simpson Lumber Co. installed

double trim saws at its mills to cutshorter lengths. “We now have moreflexibility in cutting to 8-, 10- and 12-foot products that our customerswant,” noted Laurie Creech, Simpsonsales manager.Other mills have expanded their

product offerings. John Stembridge atSwanson Group Manufacturing,Glendale, Or., said their mills are nowcutting wider widths, up to 2x12,instead of the 2x4 and 2x6 productsthey cut predominately in the past. Jim Scharnhorst, Idaho Forest

Group, Coeur d’Alene, Id., said hismills are expanding in cedar productsin addition to their framing and pineboard offerings. SPI has added 4x4 and 4x6 white

fir to its product line.Enhancing lumber quality and