AUSTRALIAN NATIONAL MAJOR PROJECT REVIEW REPOWER AUSTRALIA’S BRINGS CLEAN ENERGY TO VICTORIA AUS $14.95 (INC GST) PRINT POST APPROVED PP: 255003/07071 APRX26P12 9 771449 734009 02 ISSN 1449-7344 ALSO INSIDE: SANCTUM BY CROWN Crown Group TARCUTTA BYPASS Leighton Contractors UNSW TYREE ENERGY TECHNOLOGIES BUILDING Brookfield Multiplex CAMDEN VALLEY WAY BMD Constructions HALCYON APARTMENTS Probuild OAKLANDS HILL WIND FARM REpower Australia ANCHOR POINT RETIREMENT VILLAGE JG King Projects HARVEY NORMAN & IKEA DEVELOPMENT Probuild VICTORIAN DESALINATION PROJECT Thiess Degrémont ZEN APARTMENTS PDG Corporation BREAKWATER ROAD REALIGNMENT McConnell Dowell AUSTRALIAN SYNCHROTRON Kane Constructions RIVER HOMES PRECINCT Mirvac Group M80 RING ROAD UPGRADE BMD Constructions NORTHPARK PRIVATE HOSPITAL MELBOURNE SEAFOOD CENTRE Xerri NORTHERN PIPELINE INTERCONNECTOR Northern Network Alliance BRUCE HIGHWAY Abigroup BRISBANE CONVENTION & EXHIBITION CENTRE South Bank Corporation CANELAND CENTRAL SHOPPING CENTRE Lend Lease ROBINA HOSPITAL Baulderstone ELEVEN 78 HAY STREET Diploma ONE SYDNEY AVENUE The Doma Group KINGSTON BYPASS Department of Infrastructure, Energy & Resources SIW REGIONAL DISTRIBUTION CENTRE Qanstruct

The Australian National Construction Review

Mar 08, 2016

The Australian National Construction Review

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

AUSTRALIAN NATIONAL

MAJOR PROJECT REVIEWCONSTRUCTION

PP255003/07071A

USTRALIA

N N

ATIO

NA

L CO

NSTRUC

TION

- MA

JOR PRO

JECT REV

IEW

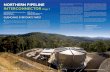

HILLWIND FARMREpowER austRalia’s

brings clean energy to victoria

IT’S NO WELD IT’S MODULAR IT’S ROBUST …SAVING TIME & MONEYEASILY INSTALLED, GALVANISED HANDRAIL & BALUSTRADE SYSTEMS

COMBINING STRENGTH, SAFETY & STYLE

− No onsite fabrication or welding, eliminates corrosion − Modular design, reduced lead times & rapidly installed − Easily configured & colour matched to suit any application − Australian Standards, NCC/BCA, DDA & WHS compliant

CALL 1800 663 339 WEB moddex.com.au

SPECIFIED & SOLD AUSTRALIA WIDE

AUS $14.95 (INC GST)PRINT POST APPROVEDPP: 255003/07071 APRX26P129

771449734009

02ISSN

1449-7344

ALSO INSIDE:SANCTUM BY CROWN Crown Group TARCUTTA BYPASS Leighton Contractors UNSW TYREE ENERGY TECHNOLOGIES BUILDING Brookfield Multiplex CAMDEN VALLEY WAY BMD Constructions HALCYON APARTMENTS Probuild OAKLANDS HILL WIND FARM REpower Australia ANCHOR POINT RETIREMENT VILLAGE JG King Projects HARVEY NORMAN & IKEA DEVELOPMENT Probuild VICTORIAN DESALINATION PROJECT Thiess Degrémont ZEN APARTMENTS PDG Corporation BREAKWATER ROAD REALIGNMENT McConnell Dowell AUSTRALIAN SYNCHROTRON Kane Constructions RIVER HOMES PRECINCT Mirvac Group M80 RING ROAD UPGRADE BMD Constructions NORTHPARK PRIVATE HOSPITAL MELBOURNE SEAFOOD CENTRE Xerri NORTHERN PIPELINE INTERCONNECTOR Northern Network Alliance BRUCE HIGHWAY Abigroup BRISBANE CONVENTION & EXHIBITION CENTRE South Bank Corporation CANELAND CENTRAL SHOPPING CENTRE Lend Lease ROBINA HOSPITAL Baulderstone ELEVEN 78 HAY STREET Diploma ONE SYDNEY AVENUE The Doma Group KINGSTON BYPASS Department of Infrastructure, Energy & Resources SIW REGIONAL DISTRIBUTION CENTRE Qanstruct

For further information including location of the ThyssenKrupp office nearest you, please visit:www.thyssenkruppelevator.com.auTel: +61 2 8303 9000 Fax: +61 2 9310 [email protected]

Extraordinary engineering, a highly developed control system and an exemplary safety concept are united in the revolutionary TWIN elevator system. An intelligent control system coordinates elevator movement within the shaft. The latest safety technology constantly monitors the movements of both cars to keep them a safe distance apart. This technology, exclusively supplied by ThyssenKrupp Elevator, was made possible by our world class research and development facilities around the world.

The challenge To optimize

passenger flow while maximising

floor space

Our solutionTWIN: the only

elevator system withtwo cabs movingindependently in

one shaft

For further information including location of the ThyssenKrupp office nearest you, please visit:www.thyssenkruppelevator.com.auTel: +61 2 8303 9000 Fax: +61 2 9310 [email protected]

Extraordinary engineering, a highly developed control system and an exemplary safety concept are united in the revolutionary TWIN elevator system. An intelligent control system coordinates elevator movement within the shaft. The latest safety technology constantly monitors the movements of both cars to keep them a safe distance apart. This technology, exclusively supplied by ThyssenKrupp Elevator, was made possible by our world class research and development facilities around the world.

The challenge To optimize

passenger flow while maximising

floor space

Our solutionTWIN: the only

elevator system withtwo cabs movingindependently in

one shaft

CONSTRUCTIONAUSTRALIAN NATIONAL

MAJOR PROJECT REVIEW

CONTENTSREpower Australia's,Oaklands Hill Wind FarmImage by Pat Cameron

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW

PUBLISHERK.M. Hanson

GENERAL MANAGERPhil Reynolds

GRAPHIC ARTISTSPeta Brunell, Charlotte McLaren

SALES MANAGERChris Randles, Ben Newell

SALESMichael Matthews, Emma Stemp, Blake Dawson, Madison Turner

BUSINESS DEVELOPMENTSarah Giles

ADMINISTRATIONJenny Bow, Michelle Tyson

DISTRIBUTIONGordon & Gotch

PUBLISHED BYTrade Media Group Pty LtdACN 118312404t. 02 4322 1200f. 02 4322 1400www.ancr.com.auwww.trademediagroup.com.au

WRITERSWillow Aliento, Kylie Scott, Prue Clark, Keeli Cambourne, Lisa Madden, John Davies, Rowena Robertson

PHOTOGRAPHERSMike Chorley, Michael Embelton, Lewis Krebs, Rod Vella, José Figlioli, Adam Sutton, Molly Pacitti, Lisa Madden, Lael McAvoy, Paul Hotchkin, Pat Cameron, Jeff Janus, Alastair Bett, Di Harris, Sarah Shepherd, Tracey Togni, Molly Pacitti, Ben Andrews, Julie Emonson-Clyde, Darren Daley

COPYRIGHTAll material in this publication is copyrighted to the publisher and/or its advertisers and contributors. No material or portion of this publication may be reproduced in whole or part without the express written permission of the publisher.

DISCLAIMERThe Australian National Construction Major Project Review and the publisher reserve the right to alter or omit any advertisement, editorial, or advertorial. Advertisers and/or their representatives indemnify the Australian National Construction Major Project Review and the publisher in relation to defamation, slander, breach of copyright, infringements of trademarks of name of publication titles, unfair competitor or trade practices, royalties or violation of rights and privacy and warrant that their material complies with all the relevant laws and regulations and that its publication will not give rise to any rights against or liabilities against the Australian National Construction Major Project Review, its publisher, its servants or agents. The Australian National Construction Major Project Review and the publisher are not liable for inaccuracy in any advertisement or editorial and do not accept responsibility for any claims made by advertisers. Any material supplied to the Australian National Construction Major Project Review or the publisher are at the contributors risk. No responsibility will be taken by the Australian National Construction Major Project Review, its publisher, its servants or agents. Opinions published in The Australian National Construction Major Project Review are not necessarily those of the publisher or staff of The Australian National Construction Major Project Review.

The Australian National Construction Major Project Review is not related to any other publication.

PROJECTS

• NSW SANCTUM BY CROWN - Crown Group .36 TARCUTTA BYpASS - Leighton Contractors .44 UNSW TYRee eNeRgY TeChNOlOgieS BUildiNg - Brookfield Multiplex .52 CAMdeN vAlleY WAY - BMD Constructions .60 hAlCYON ApARTMeNTS - Probuild .64

• viC OAklANdS hill WiNd fARM - REpower Australia .72 ANChOR pOiNT ReTiReMeNT villAge - JG King Projects .82 hARveY NORMAN & ikeA develOpMeNT - Probuild .86 viCTORiAN deSAliNATiON plANT - Thiess Degrémont .106 zeN ApARTMeNTS - PDG Corporation .116 BReAkWATeR ROAd ReAligNMeNT - McConnell Dowell .122 AUSTRAliAN SYNChROTRON - Kane Constructions .130 RiveR hOMeS pReCiNCT - Mirvac Group .136 M80 RiNg ROAd UpgRAde - BMD Constructions .144 NORThpARk pRivATe hOSpiTAl .152 MelBOURNe SeAfOOd CeNTRe - Xerri .158

• Qld NORTheRN pipeliNe iNTeRCONNeCTOR - Nor thern Network Alliance .164 BRUCe highWAY - Abigroup .186 BRiSBANe CONveNTiON & exhiBiTiON CeNTRe - South Bank Corporation .192 CANelANd CeNTRAl ShOppiNg CeNTRe - Lend Lease .198 ROBiNA hOSpiTAl - Baulderstone .206 • WA eleveN 78 hAY STReeT - Diploma .212

• ACT ONe SYdNeY AveNUe - The Doma Group .216

• TAS kiNgSTON BYpASS - Depar tment of Infrastructure, Energy & Resources .224 SiW RegiONAl diSTRiBUTiON CeNTRe - Qanstruct .232

NeWS .06 ARChiTeCTURe & eNgiNeeRiNg NeWS .12 SAfeTY NeWS .14 pROjeCT MANAgeR NeWS .15

feATUReS iNTeRvieW eNgiNeeRiNg MANAgeMeNT- Stuart Fowler, Norman Disney & Young .16 SpeCiAl fOCUS .18

CONTeNTS

5WWW.ANCR.COM.AU

CONSTRUCTION

Lend Lease and Sekisui House’s residential development Serrata in Melbourne’s Victoria Harbour has been awarded Australia’s third only Green Star residential v1 rating from the Green Building Council of Australia.

The 4 Star Green Star - Multi Unit Residential v1 certified rating recognises and rewards residential developments that go ‘above and beyond’ minimum requirements to reach best practice outcomes in sustainable design.

Paul Shaw, Head of Lend Lease’s Apartments business said it was a great achievement that reaffirms our commitment to creating safe, healthy and sustainable communities.

“Serrata sets a new benchmark in sustainable design with a number of features that not only contribute positively to the environment, but reduce the operating costs for the purchaser.”

“The 15 level apartment building is the latest sustainable addition to Victoria Harbour; a

SERRATA RECOgNISEd AS ONE Of AUSTRALIA’S gREENEST RESIdENTIAL BUILdINgS

precinct that boasts the highest concentration of Green Star rated buildings in Australia. These include The Gauge, which is Australia’s first 6 Star Green Star Office As Built rated building and Convesso, Australia’s most environmentally sustainable luxury residential tower that has a 4 Star Green Star - Multi Unit Residential Pilot Rating. Its twin Concavo is also set to achieve the rating,” said Mr Shaw.

Serrata, known for its bold design and creative urban edge is a joint venture with Japan’s largest home builder, Sekisui House. Toru Abe, President and Managing Director for Sekisui House Australia Pty Limited said the company believes strongly in the importance of sustainable communities and receiving the green rating was further acknowledgement of their efforts.

“We’re proud to receive this rating with Lend Lease as it shows our dedication to creating environmentally thoughtful developments that will have a positive impact well into the future,” said Mr Abe. The Victoria Harbour Precinct is

working towards Climate Positive* certification which aims to set a new global benchmark for leadership in large-scale urban development to minimise environmental impacts.

Serrata’s key sustainability features include:• Installation of smart meters in all apartments which allow residents to monitor and manage their energy and water consumption in real time and historical figures, leading to the reduction in usage and costs.• Low-E glazing double glazed windows to reduce the use of heaters and air conditioners. The glazing rejects the heat in summer months and retains warmth in winter months. • Natural light and ventilation to the corridors which reduce the ongoing operating costs and provide fresh air and natural light to the corridors. • A rain water tank for garden irrigation and toilet flushing. • Materials chosen with low volatile organic compounds and low formaldehyde resulting in improved indoor air quality by reducing irritations and increasing comfort.• A superior acoustic performance that reduces external and inter tenancy noise.• Bicycle storage for all dwellings as well as a secure visitor bike storage room with access to local cycle paths.

The central location of Serrata allows residents to take advantage of public transport, local amenity and sustainable travel. Residents are in walking distance to Merchant Street shops including a full line supermarket, cafes and restaurants and the Collins Street tram provides direct access to the CBD and Southern Cross Station.

Construction for Serrata commenced in October 2010 and since launching there has been extensive interest with more than 50 per cent of apartments sold within the first week and more than 90 per cent sold to date. The project is on track for a June 2012 completion date.

Visit www.serrataliving.com.au for further information. * Climate Positive is a joint initiative between the Clinton Climate Initiative and the U.S. Green Building Council.

Now working with the Industry Capability Network to

maximise Australian content in major projects

To find out more, or to register to use the Australian Made logo, visit www.australianmade.com.au or phone 1800 350 520

5625

AM

comment

7ANCR CONSTRUCTION NEWS

The Federal Labor Government is taking major steps to improve the productivity, sustainability and liveability of our major cities. Historically, cities policy has been left largely to the States and Territories. The fact is our cities are facing great challenges. Congestion, sprawl, housing affordability, and servicing the needs of an ageing population are just some of them

Our cities have become too important to ignore. While Australia might be famous for its agricultural and mineral production, it is cities that produce 80 per cent of our national wealth. And it is our cities that are home to three out of four Australians. We need better cities for the people who live in them, for the people who work in them and for the people who depend on them.

Last May, I released Our Cities, Our Future – a national urban policy for a productive, sustainable and liveable Australia. It was the first time a government had outlined its overarching goals for the nation’s 18 major cities with populations above 100,000.

While State and Territory Governments and local councils remain the hands-on planners and designers of our cities, the Federal Government is helping reform their planning processes and strengthen the networks between them. Under an agreement secured around the COAG table, all States and Territories from 1 January this year now have in place strategic planning systems for their capital cities.

These planning systems must meet nine nationally-agreed criteria. For instance cities must show how they are providing for nationally-significant economic infrastructure such as transport corridors, airports and ports, intermodal connections, communications and utilities.

They must show how they are providing for evidence-based land release and an appropriate balance of infill and greenfield development. And

By Anthony Albanesefederal Minister for

Infrastructure andTransport

MAJOR CITIES PLANNING AND DEVELOPMENT

continues page 11

Now working with the Industry Capability Network to

maximise Australian content in major projects

To find out more, or to register to use the Australian Made logo, visit www.australianmade.com.au or phone 1800 350 520

5625

AM

Interested parties and the general public alike will be able to check the progress of the new Royal Adelaide Hospital via a webcam which has been installed with the start of construction.

Slated for completion in 2016, the multi million dollar complex will be delivered as a Public Private Partnership (PPP), and will provide world-class health care facilities for South Australians. The new hospital will be centrally located on North Terrace in the heart of the CBD, and will replace the existing Royal Adelaide Hospital which opened in 1840.

kEEPINg AN EYE ON ROYAL PERTh hOSPITAL

Under the South Australian Government’s Partnership SA model, the SA Health Partnership consortium includes Leighton Contractors, Macquarie Capital Group, Hansen Yuncken and Spotless, who collectively will undertake the financing, design, construction and facility management services to the hospital over 35 years, while SA Health operates the hospital and provides its core clinical services.

Check out http://www.sahp.com.au/index.php/construction/webcam.html to follow the construction progress live.

The Mirvac Group has signed as a Major Climate Partner with The Climate Institute joining such other partners as Westpac, Jemena and KPMG.

Established in late 2005, The Climate Institute is a non-partisan, independent research organisation that works with community, business and government to catalyse and drive the change and innovation needed for a low pollution economy and culture.

Their vision is for a resilient Australia prospering in a low carbon global economy, participating fully and fairly in international climate change solutions.

This partnership follows Mirvac’s announcement being internationally recognised as one of the top-scoring companies in the Carbon Disclosure Project (“CDP”) disclosure and performance indices.

Climate Institute CEO John Connor comments:“The central role of business in helping build a smarter, cleaner and more resilient Australia is one of the primary reasons we launched the Climate Partner program in 2010. Mirvac is a great addition to our group of leading businesses who all share an understanding of both the risks and opportunities of the climate challenge.”

Mirvac’s managing director Nicholas Collishaw said: “Our approach is outcomes-based, which is evident in our public commitment to achieving the sustainability actions published in our annual Corporate Responsibility and Sustainability Report. We are proud to become a Major Climate Partner to further enhance our position at the forefront of climate change research and action.”

Mirvac continues to pursue a program aimed at improving the energy efficiency and greenhouse gas performance of their real estate assets.

MIRVAC SIgNS AS MAJOR PARTNER WITh CLIMATE INSTITUTE

ABIGROUP has won contracts for the construction of water treatment plants in Bowen and Proserpine in North Queensland. The project is part of the Whitsunday Regional Council’s $85 million water and sewerage future development scheme which involves the construction of a 16.5 megalitre plant in Bowen on the Proserpine River downstream of the Peter Faust Dam, and a 14.5 megalitre plant in Proserpine on Pound Yard Road.

ABIgROUP TO CONSTRUCT NEW WATER TREATMENT PLANTS

The new treatment plants have been designed to improve the quality of potable water for Bowen and Proserpine as well as meet future demands for the region’s water supply. Work is scheduled to start within the coming months on the plants, and is expected to take 12 to 16 months to complete. The plants have been scheduled for commissioning by mid-2013.

Abigroup recently completed upgrades to the wastewater treatment facility in Townsville.

8 ANCR CONSTRUCTION NEWS

comment

8 ANCR CONSTRUCTION NEWS

The construction industry is facing some of the toughest changes yet with the overhaul of Occupational Health and Safety (OH&S) standards to the new Workplace Health and Safety (WH&S) legislation that was introduced earlier this year.

The new changes have so far been adopted by Queensland and New South Wales and aim to establish a harmonised national model focused on simplifying procedures and creating a more level playing field for businesses and employees across the board.

The move will benefit the entire industry but will be of significant advantage for medium to larger sized companies that have offices in multiple states.

Rising insurance premiums have driven up overall construction costs, adversely affecting many companies and projects across the industry and have sparked a greater push for tighter building deadlines to minimise costs. As a result, safety is sometimes compromised and this issue has been a contributing factor to the overall changes.

There are a number of businesses who are pushing for better OH&S standards across the board with this becoming widely evident in tender applications and in the implementation of dedicated safety officers.

With safety procedures becoming more stringent over the last three years it has become the responsibility of both employers and employees alike to be more proactive in regards to the responsibilities that are part and parcel of working on construction sites, thereby ensuring accountability is shared by all.

Education is the key to facilitating understanding and awareness of the new changes and issues at all levels and is paramount to ensuring everyone from

By Patrick hay, National OhS&E Manager TdA Interiors

continues page 11

Construction has begun on a new $68 million hotel for the Rydges chain at Sydney Airport with a scheduled completion date of mid 2013. The 317 room property is being developed by interests associated with Phillip Wolanski, David Baffsky and John Landerer, and built by Lipman Construction.

The first sod was turned by the NSW Minister for Tourism, George Souris, who said the development was a “vote of confidence” in Sydney.

“Passengers will benefit from greater choice and greater convenience with the hotel to be

NEW hOTEL fOR SYdNEY AIRPORTbuilt at the airport’s revamped international terminal,” he said.

“Sydney Airport plays a major role in promoting tourism not only to the Harbour City and the State, but also the rest of the country (and) it is vital that international travellers have a comfortable and friendly experience when arriving in Sydney.”

When completed, the 4.5-star hotel, located opposite the international terminal at Sydney Airport, will feature a restaurant, bar, meetings and events spaces, a gym and business centre.

The Green Building Council of Australia (GBCA) has certified its 400th Green Star project.

Responding to industry demands, the GBCA launched the Green Star environmental rating system for buildings in 2003 to support the property and construction industry in reducing the environmental impact of buildings, driving innovation in sustainable building practices, improving occupant health and productivity and achieving cost savings.

“Green Star has transformed Australia’s property and construction industry – and our 400th certification is evidence of this fact,” says Chief Executive of the GBCA, Romilly Madew.

“We certified our first project in 2004, and since then Green Star has achieved exponential growth. Today, more than 18 per cent of Australia’s CBD office space is Green Star-certified, and a wide range of building types from schools and hospitals to industrial facilities and shopping centres have achieved Green Star ratings,” Ms Madew says.

The 400th project to be certified is GippsTAFE Chadstone Campus Development in Victoria. Three buildings on the site, including an administration building and two electrical / telecommunications training buildings, have achieved a 5 Star Green Star – Education Design v1 rating, signifying ‘Australian Excellence’.

“Achieving a 5 Star Green Star rating at Chadstone is an important milestone for GippsTAFE,” says Dr Peter Whitley, Chief Executive Officer of GippsTAFE. “As a leading education provider for the energy and

telecommunications industries, the Green Star rating demonstrates GippsTAFE’s position in driving best practice in those sectors. It also highlights GippsTAFE’s overall commitment to sustainability in all of our capital projects.”

Cundall’s Senior ESD Consultant, and Green Star Accredited Professional on the project, Kate Ramchurn, says that “the Green Star process helped the project team prioritise the environmental initiatives that would deliver the best outcomes for the TAFE.” “GippsTAFE’s Chadstone Campus is an appropriate symbol of Green Star’s achievements,” adds Romilly Madew. “We’ve moved beyond office buildings, and have moved beyond certifying single buildings.

As we roll out the Green Star – Communities rating tool later this year, and continue to develop the Green Star – Performance rating tool for existing buildings, we’re confident that Green Star’s ascendance will continue.”

400 gREEN STAR CERTIfIEd PROJECTS – ANd COUNTINg!

GippsTAFE Chadstone Campus Development in Victoria.

NEW WH&S LEGISLATION SEES EDUCATION AS INDUSTRY SAFETY NET

comment

9ANCR CONSTRUCTION NEWS

continues page 11

Investment activity is expected to gather momentum on the back of a boost in confidence this year, according to Jones Lang LaSalle’s (JLL) December National Insolvency Report, with portfolio managers “clearing the decks” in preparation for a market recovery.

However, investment and development activity will continue to be hampered by access to finance, “particularly in smaller markets and secondary grade assets where long-tern tenant pre-commitments are difficult to lock in,” the report says.

Nevertheless. JLL anticipates continued economic expansion, which will support rising demand for space in the retail, industrial and office sectors.

“The current programs of asset sales by banks and other financiers, as well as portfolio realignment by institutional fund managers and A-REITs represents a recognition that markets are stabilising and that values in many cases have been calibrated.”

The report considers secondary market sector sentiment, buoyed by survey results from commercial fund manager Balmain Funds that show respondents expect investment returns to stabilise.

Despite the positive outlook, the results do not indicate a move by investors to aggressive

investment behaviour, but one-third of respondents said they would be prepared to consider new investment purchases or property development.

“While most respondents to the Balmain survey expect the market to be dominated by sellers, in fact, the gap between those survey respondents planning to invest and those planning to divest is relatively narrow (26 percent vs 29 percent),” the report notes.

“By a small margin, the majority of respondents expect investment returns to be lower in 2012 than in 2011. Activity is expected to be strongest in the residential sector.”

Forty percent of respondents said they expect their commercial property market returns (income and capital) to remain unchanged from the previous 12 months, while over 20 percent expected “slightly higher” returns.

INVESTMENT ACTIVITY fORECAST TO BLOOM IN 2012

The NSW Government has approved a multi-million dollar factory expansion plan for the Rutherford based tile manufacturing facility of ceramic tile manufacturer National Ceramic Industries Australia (NCIA).

The $65 million expansion will see the construction of a second factory at its Centaurus manufacturing plant located in Rutherford in the NSW Hunter Valley region. The expansion contrasts with the latest report on Production of Selected Construction Materials from the Australian Bureau of Statistics. It shows production of materials including bricks, blocks, pavers, tiles, plasterboard and roofing products all down significantly on the previous year.

National Ceramics Industries Australia (NCIA) is the largest tile manufacturer in Australia. Its

NATIONAL CERAMICS INdUSTRIES AUSTRALIA dOUBLES OUTPUT

Centaurus manufacturing plant is located in Rutherford in the NSW Hunter Valley region. The company manufactures tiles from Australian clay for nation-wide distribution as well as distribution in New Zealand.

The second factory will house additional production lines and will reportedly enable the tile manufacturer to double its output to more than 25 million sqm of tiles per year at the Racecourse Road site. The expansion is expected to create 70 new jobs at the facility.

NCIA tiles are suitable for commercial and domestic applications and are said to be independently tested to meet International and Australian standards. NCIA is a subsidiary of South African listed Ceramic Industries.

By Alain Mignot Executive director

The Alliancing Association of

Australasia

ALLIANCING 2011 HIGHLIGHTS AND 2012 FOCUS

Collaborative contracting is alive and well, adapting to meet the changing policy landscape while continuing to tackle project complexity through relationship skill and enhanced productivity.

Public sector agency representatives are actively applying and developing the principles of collaborative contracting to deliver difficult infrastructure projects in 2011, including in disaster-torn communities in Christchurch and Queensland.

An alliance has been formed to plan and deliver reconstruction of the shattered city of Christchurch for an estimated cost of NZ$2 billion, while tremors continue to shake the city’s infrastructure and resolve. Three major earthquake events have left approximately 15,000 of the city’s 300,000 residents unemployed and massive building destruction.

An alliance was the only way to manage this unprecedented, long-term program to rebuild horizontal infrastructure including sewers, water supply, stormwater drainage, wastewater systems and parks.

In Queensland, restoration of flood and cyclone damaged roads in Queensland is being delivered through a collaborative framework as part of the largest reconstruction effort in the state’s history. The Queensland Department of Transport and Main Roads is tackling its largest program ever with $4 - $5 billion of reconstruction works through collaborative arrangements designed to supplement TMR resources and ensure consultants take on TMR behaviours and responsibilities and be responsible for their performance.

Collaborative contracting has great potential to assist the resource sector, which is facing huge opportunity and challenges including a skills shortage. This is driving new thinking in some sectors of the mining industry, including uptake

10 ANCR CONSTRUCTION NEWS

comment

10 ANCR CONSTRUCTION NEWS

Building research in Australia exceeds best practice globally. This is the finding of an assessment undertaken by the Australian Government, which identified Queensland University of Technology (QUT) and University of New South Wales (UNSW) as the leading institutions in this area (http://www.arc.gov.au/pdf/ERA_s4.pdf).

This leadership reflects the strong involvement of major construction companies in significant research projects. Here at QUT we operate on the frontier of emerging knowledge in order to maximise our contribution to improved industry performance through projects in areas such as collaborative contracting, green buildings, construction safety and urban planning. The companies involved include Leighton Contractors, Baulderstone, ARUP and AECOM. QUT has delivered substantial improvement to major project performance through research carried out with our industry partners.

Significant emerging and established initiatives at QUT ensure Australia remains a world leader. These include our Science and Technology Precinct, Project Management Academy, and Sustainable Built Environment National Research Centre. These initiatives have resulted in Australia securing the next triennial World Building Congress, with its focus on major projects.

The Congress will take place at the Brisbane Convention Centre between May 5th and 9th 2013. The congress is the single most important event in global building research and will catalogue the best practice recommendations of thousands of researchers from over 50 countries. The congress will attract 1,000 delegates, primarily from Australia, Asia and Europe. The World Building Congress is the place to be to learn about the state of the art in markets, research and innovation linked to construction and the built environment. See you there! http://worldbuildingcongress2013.com/

By dr karen Manleydeputy director(Research)Project ManagementAcademy QUT

RESEARCH EXCELLENCE AND MAJOR PROJECTS

The largest and most comprehensive survey ever undertaken of innovation in the Australian road industry was completed this year by Queensland University of Technology (QUT). The research project is a collaboration between QUT, the Commonwealth Government, the Queensland Department of Transport and Main Roads, the Construction industry Institute of Australia and the University of New South Wales.

The survey of over 200 construction industry participants covered four sectors, comprising suppliers (manufacturers and distributors), consultants (engineering consultants), contractors (head and subcontractors) and clients (state government road agencies). The survey covered industry participants in Queensland, New South Wales and Victoria.

Data collected by the survey shows that the main obstacle to innovation in the construction industry is the restrictive nature of tender assessment criteria. Despite recent moves away from price-focused tenders towards selection based on previous performance and ability in the industry, this remains a problem. This obstacle arises from (1) the difficulty for clients to effectively assess alternative tender options when focused on selecting a contractor based only on price and (2) the unwillingness of the contractor (and their subcontractors and suppliers) to propose alternative product options during a potentially adversarial price-focused

EXPOSEd! ThE MAIN OBSTACLE TO INNOVATION IN ThE ROAd INdUSTRY

tender process, particularly in project priority areas outside cost-savings.

Contractors rarely develop in-house products; instead they generally ‘broker’ innovative product knowledge to be exploited for their competitive advantage during tender. Contractors’ willingness to exploit the knowledge of their suppliers and subcontractors and propose alternative products probably depends on their expectations. If they know they are being selected only on their competitive price, they are less motivated to seek or propose new products that may be more risky than standard products. Also, the need to be lean in their price submission under a cost-dominated competitive selection process may result in less flexibility for the contractor to experiment with new products. Price-only selection in large complex construction projects can result in less willingness to align with a ‘best-for-project culture’, and may induce an individualist protectionist stance discouraging open dialogue about the potential use of innovative products.

It seems that project performance in the construction industry is still being hampered by restrictive tender assessment criteria. National workshops planned for 2012 will focus on the road industry’s most significant barriers to innovation, including this one. Industry participants are welcome to register their interest in these workshops by emailing [email protected].

Led by BMD Constructions, the Calder Freeway Kings Road Interchange project celebrated a milestone earlier this year with the new road officially opened to the public - almost five months ahead of schedule. About 600 people were employed during construction of the project.

The interchange consists of an overpass over Calder Freeway including on and off ramps in both directions. Kings Road was also extended and upgraded to a four-lane road through to the freeway in the first stage of planned safety and access improvements. The new interchange is projected to greatly reduce congestion and increase safety, as well as improving local access to the growing suburbs of Taylors Lakes, Sydenham and Hillside.Other works on the Kings Road upgrade included a continuation of a shared bicycle and pedestrian path along Kings Road and over the freeway, construction of a direct access road to Keilor public golf

BMd’S CALdER UPgRAdE AhEAd Of SChEdULEcourse from the interchange and the permanent closure of the Robertsons Road/Calder Freeway intersection.Already further upgrades have been earmarked for the Sunshine Avenue and Calder Freeway intersection and the extension of an access road to link Highland Road and Oakbank Road to the Kings Road interchange.

Incorporated in 1979, BMD commenced operations as a civil contractor to the South East Queensland urban development industry. Following completion of the company's first project at Burleigh Waters Estate on the Gold Coast, BMD began to expand and diversify, with the addition of consulting civil engineering services in 1987, joint venture urban development projects in 1990 and the establishment of a major infrastructure construction capability in 1991. Throughout this period, new offices were established to provide locally based services to clients and communities with 14 offices currently throughout Australia.

CONSTRUCTION

commentscontinued

Alain Mignotcontinued from page 9

Nicholas Wardcontinued from page 14

Anthony Albanesecontinued from page 7

Patrick haycontinued from page 8

david hudsoncontinued from page 15

project managers to tradesmen fully acknowledge and understand all aspects of WH&S and their role in it.

As the construction industry continues to evolve and grow, the need to protect workers and ensure better safety standards across Australian worksites remains a vital issue. There are always better ways of doing things and this can only be achieved through continued consultation and education.

of collaborative contracts by up and coming, entrepreneurial iron ore miners in Western Australia in response to the constraints presented by the mining boom. Their drivers are primarily to secure people, ensure timely infrastructure delivery and to provide greater certainty in the face of rising costs.

Early engagement with contractors is a key strategy to retain these resources and bring forward conversations to better define solutions and assess risks impacting cost-effective and timely delivery of first coal and first gas. Opportunities exist for EPCM contract managers to adopt relationship contracting with their own suppliers

for enhanced outcomes and this is a space the AAA looks forward to actively engaging in over the next 12 months. The upcoming AAA Western Australia Convention will explore these themes and more in June 2012.

they must address big policy issues such as how they are planning for population growth and demographic change, climate change mitigation, housing affordability and how they can better connect people to jobs. Future Commonwealth infrastructure funding will be tied to these plans.

good PM’s is at an all time high; driving up the price of services and allowing PM’s to be selective in their choice of new experiences. My advice to any organisation that has a long term demand for PM’s is simple – start to grow your own. Look for PM talent early, invest in professional development, and make your company an employer of choice so you can retain good talent. I believe that part of being an employer of choice relates to sharpening the corporate saw (Covey) and providing best practice in project methods and tools. Good PM’s are well and truly ‘over’ the job of rowing a project upstream with poor methods and tools as the paddle. AIPM is here to be your partner in all of these areas, whether you are a PM looking to advance in the field or an organisation trying to be a leader in project management.

A corollary to a safer workforce is the reduction in workers’ compensation claim costs, which can be lowered by as much as 30% through effective pre-

employment programs. These economic benefits reinforce the value in conducting effective pre-employment assessments, which can contribute in a real way to lowering the number of construction workers sustaining injury or death at work.

John Holland has secured a $152 million contract for the duplication of a 23km section of Victoria’s Western Highway – the major road link between Melbourne and Adelaide.

The works, between Burrumbeet and Trawalla, are part of a broader project to duplicate the Western Highway between Ballarat and Stawell – a 123km stretch of road.

JOhN hOLLANd WIN WESTERN hIghWAY CONTRACTWork is expected to commence works on the project in the coming months which will upgrade the road to a four-lane divided highway and include a bypass to the south of Trawalla. This is the second contract awarded for the Western Highway duplication project with works on an initial 8km section of road between Ballarat and Burrumbeet commencing in April 2010. This is expected to be completed later in the year.

comment

12 ANCR ARChITECTURE NEWS

ARCHITECTURE

We all want liveable, sustainable, productive communities. How we deliver them has always been the challenge.

This challenge will soon be met with the release of the Green Star – Communities rating tool.

Green Star – Communities is an independent, transparent, national scheme able to assess and certify the sustainability of community-level development projects. It is one of the world’s first rating tools to assess environmental concerns within communities – such as minimising energy and water consumption, and reducing dependence on motor vehicles – alongside broader holistic sustainability issues, such as economic prosperity, liveability and community diversity.

The Green Star – Communities rating tool will benchmark developments at a community scale by assessing them against six categories: liveability; economic prosperity; environment; community design; governance; and innovation.

With some of Australia’s largest greenfield and urban infill projects lining up to pilot the rating tool, and the list of project partners and sponsors growing daily, Green Star - Communities is set to be a ‘game changer’.

Currently, the project is supported by all three tiers of government, including every state government land organisation, as well as Australia’s leading developers. Project partners include the Planning Institute of Australia, the Australian Institute of Architects, Consult Australia, the Australian Sustainable Built Environment Council and the Property Council of Australia.

Green Star – Communities will transform talk about the future of our communities into action and results. For more information, visit: www.gbca.org.au/communities

By Romilly Madew Chief Executivegreen Building Council of Australia

A WHOLE NEW BALL GAME: GREEN STAR – COMMUNITIES

Justice is about to undergo a dramatic change of place in Newcastle, with the design by Cox Richardson for a $94 million courthouse complex in the city’s civic precinct.

Commissioned by the Department of Attorney General & Justice, this will be the largest court development in New South Wales since colonial times, and one of the State’s busiest court complexes. The Hunter Street project will comprise ten court rooms and two tribunal rooms, plus waiting areas, foyer, offices, administration and other specific use

areas, in a seven storey building, and will cater for Newcastle’s Local, District and Supreme Court needs.

The courthouse complex will comprise a podium-like structure that will wrap around the intersection of Hunter Street and Burwood Street, with upper levels set back from the street frontages, and the entire facade featuring extensive glazing. The DA for the development is currently before Newcastle City Council, and the current projected completion date is 2014.

NEW LOOk LAW fOR NEWCASTLE

NH Architecture has joined forces with international firm Populous to create the design for the redevelopment of Melbourne’s Margaret Court Arena. The project will increase capacity by 1,500 to 7,500, and includes an operable roof. This will make Melbourne the world’s first Grand Slam tennis venue to have three feature courts with operable roofs. The plans also include a new indoor concourse and improved amenities and facilities for patrons.

Finer details of the design include the use of glazing for almost the entire perimeter of the arena, allowing for views of the Melbourne skyline from within, a timber feature wall in the foyer with detailing which echoes the movement of a bouncing ball, and a ‘pleated’ roof design, which will give the Margaret Court Arena a unique identity within Melbourne Park. Completion is expected in 2015.

MORE STAdIUM ACTION IN MELBOURNE

ARM Architects went to enormous lengths to ensure their innovative design for the Port Hedland Multi-Purpose Recreation Centre would be successfully constructed. The facade for the project is a rain screen, double skin system, specified for its ability to handle the extreme conditions of the Pilbara. With cyclones, flying debris, extremes of temperature, salt and mine corrosion part of the environmental conditions, extensive testing of the facade panels was required to ensure they would withstand the barrage without losing their aesthetic panache.

ARM gOES ThE EXTRA MILESThe first layer is a vitrified enamel low carbon steel panel, the second a weather seal composed of sealed, galvanised sheet steel. The ARM project team travelled to Shanghai to review the design and observe testing of the 6x6m prototype. Multiple testings were required to iron out issues and ensure the final result would meet the required standards and specifications. The attention to detail has paid off, with the panels successfully installed late last year, and the entire project due for completion this year.

Margaret Court Arena Interior, Melbourne

Angel Building, LondonDarling Quarter, Sydney

13

ENGINEERING

ANCR ENGINEERING NEWS

comment

13ANCR ENgINEERINg NEWS

ENGINEERING

Pubic venues and the construction industry at large are all too conscious of running their businesses sustainably. Increasingly we are seeing a focus on saving energy and as HVAC and refrigeration are amongst the biggest energy users, this has been the focus of a large initiative by AE Smith.

In the lead up to the 2011 Melbourne Cup Carnival, the Victoria Racing Club (VRC) trusted their long time HVAC partner, AE Smith, to design an intuitive and automated energy saving system on select refrigeration plant at Flemington Racecourse.

The Energy Saving Refrigeration System implemented by AE Smith is a first for the VRC. The data gathered looks very positive with savings of 94% recorded in one day alone.

VRC is typical of the issues faced by many large venues where refrigeration is needed periodically with gaps between events. In the meantime empty cool rooms are idly working away, consuming energy.

It’s not as simple as just turning off the fridge to save power – this can lead to a whole host of other hygiene and safety issues in a commercial environment.

Then there are the industry horror stories of hundreds of thousands of dollars worth of produce going off because a fridge decided to stop working. This technology changes all of that, allowing venues to interact with the system the same way they would if they were standing in front of it.

This system logs the temperature continuously and when it passes a present threshold, the system will send an alert via email, SMS or even Twitter. It can even record and trend when the door has been left open too long.

The results of this project have been incredibly encouraging, so much so we anticipate that VRC can save up to 60 per cent in energy over the course of a year.

By Brad disher, AE Smith Building

Technologies National Sales Manager

and Energy Saving Refrigeration

System Champion

FLEMINGTON RACECOURSE SETS THE PACE IN ENERGY SAVING STAKES

At the other end of the engineering task lies commissioning, where the plans on paper are to put to the actual test. Norman Disney Young (NDY) have just been recognised internationally for their commissioning management work, winning two categories at the prestigious 2012 Chartered Institution of Building Services Engineers (CIBSE) Awards held in London last week.

NDY trumped the Commissioning Project of the Year category for Sydney’s ecologically progressive Darling Quarter, and the Refurbishment Project Award category for the renowned Angel Building in London.

According to CIBSE, the awards “recognise, reward and celebrate the best performance, innovation and practice in design, commissioning, construction, installation and operation of sustainable buildings and the manufacturers whose technologies enable

AWARdS VERIfY EXCELLENT OUTCOMESenergy efficiency. The awards focus on actual, measured performance, not design intent or performance specifications.”

“The Darling Quarter development achieved a 6-star Green Star office V2 Design Rating and is targeting a 6-star Green Star V3 As-Built Rating and 5-star NABERS rating,” says NDY Construction Quality & Commissioning Manager Neil Caswell.

“The project incorporates a number of sustainability initiatives and NDY was engaged to undertake the commissioning management of all services, including the Green Star role of Independent Commissioning Agent.

“We especially acknowledge the leadership and vision shown by Lend Lease who recognised the importance of commissioning and engaged us for a comprehensive role far in excess of that required to fulfil their Green Star requirements.”

Sterilisation for HVAC systems is vital, and new technology from the USA is showing it has the potential to deliver superior results, through the use of UV light.

The sun’s UV light can kill up to 99% of airborne viruses, and the leading-edge Steril-Aire technology successfully and safely uses UV within air conditioning systems. AE Smith has been the first Australian company to adopt the innovation for projects in tropical climates.

“The Steril-Aire product ticks all the boxes for our customers,” said AE Smith North Queensland General Manager, Vic Riella. “It saves a great amount of energy so the pay back is very quick, it kills 99 per cent of all viruses in the air and it also cleans the evaporator coils thoroughly, which reduces maintenance and does away with chemicals - that is a big plus for the environment.”

Riella added that impressive results have been recorded after just three months, even on the worst evaporator coils. Results show the cleanliness and efficiency of the unit is reinstated to about 98 per cent.

Steril-Aire has an extremely high output in the UV-C band, which destroys DNA – killing off the food sources for mould and bacteria as well as eliminating most viruses. Independent studies have also shown the technology improves the heath of asthma and allergy sufferers who are triggered by mould and biofilm.

Successful UV-boosted HVAC system installations by AE Smith include the Ergon Energy buildings, Prince Charles Hospital, The Cairns Post offices, Maroochy Shire Council and Tweed Shire Council.

NEW TEChNOLOgY dELIVERS hEALThIER AIR

Margaret Court Arena Interior, Melbourne

Angel Building, LondonDarling Quarter, Sydney

comment

14 ANCR ENGINEERING NEWS

SAFETY

Safe Work Australia has published two new research reports on workplace injury and fatality rates, which contain some sobering statistics:

• $60.6 billion - estimated total economic cost of worker-related injury and illness in 2008- 2009, which accounts for almost 5% of Australia's GDP (Gross Domestic Product) perannum.• $6.5 billion - amount paid by Australian employers in workers’ compensation premiums in2008-2009,despitedatawhichsuggestsonly 40%of compensableinjuriesanddiseasesare reportedtoclaimsagents.• 337-numberof fatalitiesduetoworker-related traumaticinjuryinAustraliain2010-2011.• 18% - percentage of worker fatalities which occurredintheconstructionindustryin2010- 2011(thethirdhighestof anyindustry.)

While dedicated efforts are being made across the construction sector and the ‘zero harm’ edict is commonplace, the evidence is clear that more needs to be done to make Australian work sites saferenvironments.

Pre-employment assessmentsPre-employment assessments are a valuabletool in reducing the likelihood of workplace injury, by guaranteeing the recruitment of safer employees and promoting a safety-consciousworkculture.Assessmentscanscreenmedical,functional and psychometric variables, or a combination of all three, and resoundingly, they work - screened hires have been foundto have a 3% injury rate, compared to non-screened hires at 33%. Employees who havenot undergone a pre-employment assessmentare 2.4 times more likely to experience amusculo-skeletal injurythanscreenedhires.Inan industry full of labourers, tradespeople and drivers, who combined account for over half of all workplace fatalities, numbers like these are certainlycompelling.

continues page 11

NewLegislationcameintoeffectonJanuary1thisyear, which brought nine of the Australian States and Territories into alignment with occupational health and safety legislation, a process the Governments are calling ‘Harmonizations’.The Workplace Health & Safety Legislation has a variety of implications for all levels of the constructionindustry.Forstarters,nolongerwillwe have ‘OH&S’ managers or management plans, but‘WHS’ones.

There is a lot of new material for busy WHS reps, firstaiders,projectmanagers,SMEoperators

and everyone else to absorb and implement, and to assist with the transition the State and Territory bodies such as WorkCover NSW and WorkSafe Victoria, have a range of information available.Thisincludesdetailof thetransitionalarrangements, which covers such matters as responsibilities within management plans, job titles andduties,andtimeframesforcompliance.

There are also a variety of live and virtual training and information sessions being held foreachregion.Contactyourrelevantbodyforfurtherinformation.

SAFETY’S CHANGE OF IDENTITY

An easy to way to get up to speed on the WHS legislation and what it means at a specific workplace, is to send a representative to SAFETYCON,beingheld24–25May2012atthePerthConvention&ExhibitionCentre.The conference will address key critical issues, including new legislation, managing safety, the

riseinimmigratingworkers,andtwospecificchallenges identified as being of particular concernintermsof riskmanagement–fatigueintheworkplace,anddrugandalcoholabuse.

Key speakers include Dr Herbert Biggs - Associate Professor, Faculty of Health,School of Psychology and Counselling, Centre for Accident Research and Road Safety Qld; Professor Dennis - Else GeneralManagerSustainability, Safety and Health, Brookfield Multiplex; Gary Grant - Principal HSEManager&R3Co-ordinator,Evans&PeckPtyLimited;andKelvinGenn-GeneralManagerSafetyandWellness,SinclairKnightMerz.For further information go to: www.safetycon.com.au

SAFETYCON 2012 - SAFETY IN CONSTRUCTION CONFERENCE 2012

SafetyCulturehavereleasedtheiAuditor-thisisa free iPad app that enables workers to perform safety audits using only their iPad, without the need for clipboards, notepads, checklists or sign-off sheets. The auditing process isstreamlined by a simple interface with clear, concisequestionstobeansweredon-screen.

iAuditor uses the iPad’s camera to record images of workplace issues, which can be attachedtothefinalreport.Detailcanalsobedrawnontheimages.

Theapphasaform-buildertoolwhichallowsusers to make their own forms, quickly and accurately converting their paper audits to digitalformsforrepeateduse.Alternatively,using the SafetyCulture Secure Online Cloud, userscandownloadavarietyof ready-to-useaudittemplatesthatarefreeof charge.Users

then have the option to share their auditing templates with the cloud for other users to downloadanduse.

Once the audit is complete, the app will accept digital signatures direct to the iPad screen, meaning a record of compliance is permanently stored. A PDFincluding any photographs can then be instantly emailed to an email address and opened on any computer, tablet orsmartphone.See : www.safetyculture.com.au

NEW APP FOR WORKPLACE HEALTH & SAFETY

REDUCING WORKPLACE INJURY

By Nicholas WardPrincipal ConsultantKonekt

15

ENGINEERING

ANCR ENGINEERING NEWS

comment

15ANCR ENgINEERINg NEWS

PROJECT

15

ENGINEERING

ANCR ENGINEERING NEWS

comment

15ANCR ENgINEERINg NEWS

MANAGEMENT

I received an interesting comment while chairing a global professional standardisation workshop in Washington DC in March. Some of the delegates had been in Brisbane for international project management conference last October and remarked on the level of visibility of project managers on Australian construction site signage boards. Apparently this level of professional visibility is not altogether common in other countries.

Construction professionals face increasing challenges; delivering a job on time and cost, sourcing and managing resources in a hot market, running a crystal ball for weather, meeting environmental and sustainability hurdles, and, yet still, delivering on time and cost. The secret to success lies in a subtle blend of core construction professional skills on one hand and project management skills on the other. Industry is unanimous that these are two complimentary but distinct skill sets.

AIPM is the lead professional body for project management in Australia. Many of our 10,000 members are construction professionals who value the contact with the project management side of their skill set. The AIPM award of ‘Certified Practicing Project Manager’ is the country’s leading professional PM certification. CPPM is a competency based award, so it is a genuine stamp of an individual’s workplace skills and knowledge. In 2012 we will back this with a new award of ‘Certified Senior Project Manager’ award. CSPM will appeal to the top 10% of PM’s who can take that tough project brief and still get the very best out of the project. AIPM’s senior PM award will set a credible benchmark for those who aspire to senior PM roles and for those organisations that are looking for third party endorsement of senior PM talent.

Project managers don’t grow on trees, and they don’t hang around coffee shops waiting for your HR director to snap them up. The demand for

By david hudson fAIM, MAIPM, CPPd

AIPM

PROJECT MANAGEMENT IN CONSTRUCTION – CHALLENGES AND OPPORTUNITIES

continues page 11

Excellence in Project Management relies not only on the skills of the project manager themselves, but also the ability to create and coordinate a cohesive team. Goals need to be clearly communicated, and workable strategies formulated for their achievement.

Actually quantifying the success of the project manager task is complex, with factors including the achievement of key milestones in a timely manner, safety records, dispute resolution, working within the budget and successfully resolving both foreseen and unforseen challenges all playing their part.

The AIPM holds annual awards which recognise excellence in project management, with entries due for the 2012 Project Management Achievements Award by June 1, 2012. Projects may be submitted for up to three categories, including both organisational and individual awards.

Last year the big winner was the WA Water Corporation’s Southern Seawater Desalination Plant, This project was completed three months ahead of schedule, and involved a number of engineering and construction challenges, scrupulous e n v i r o n m e n t a l management and a high degree of community scrutiny.

It is also a vital part of the water security strategy for WA’s metropolitan and goldfields areas.

AIPM named the SSDP as its Project of the Year, with the project also winning the category award for Construction/Engineering over $100 million. The WA Water Corporation’s Project Director, Nick Churchill won Project Director of the year and Project Team member of the Year also went to one of the WA Water Corporation team, Suzanne Brown.

Other winners included Beca Consultants and Adelaide Airport winning Construction/Engineering under $100 million, for the Adelaide Airport Runway and Taxi Overlay project; Brisbane City Council won the Sustainable Projects category for Three New Community Pools; Lindsay Charles from the NSW Department of Public Works won the Project Manager of the Year category for the South Coast Correctional Precinct; and Arup won the Small Projects category for Greenhouse by Joost, in Sydney.

National PMAA Chair Peter Fowler said the 2011 finalists provided high calibre solutions for their respective organisations.

“We had many examples of complex and challenging projects, which had been managed well and obviously contributed to the successes for their own organizations,” he said.

For further information about the 2012 PMAA Awards, including prospectus, submission guidelines and to lodge an Expression of Interest, go to https://www.aipm.com.au/html/pmaa_portal.cfm

RECOgNISINg ThOSE WhO STEER PROJECTS TOWARdS EXCELLENCE

NSW Department of Public Works, South Coast Correctional Precinct

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW16 ANCR INTERVIEW ENGINEERING MANAGEMENT

STUART fOWLERAuSTrALIAN rEGIoNAL DIrECTor, NorMAN DISNEy & youNG

INTERVIEWENGINEERING MANAGEMENT

There’s nothing new about ESD for leading consulting engineering firm, Norman Disney & Young (NDY). For over 50 years their

expertise has been contributing to innovation and excellence in the built environment, with projects across buildings, sustainability, health, transport, mission critical, defence, industrial and utilities. With offices in every mainland Australian capital city, New Zealand, the UK and Dubai, NDY can leverage an international knowledge base while creating individual, value-adding solutions for every client.

New Australian Regional Director, Stuart Fowler, has been with the firm since he graduated with his Bachelors of Mechanical Engineering. With over 20 years experience on NDY projects across Australia and New Zealand, including Eureka Tower and AMP Bourke Place, he has a hands-on understanding of what makes projects tick, and has worked at the leading edge of promoting sustainability in engineering solutions for major projects. Willow Aliento interviewed Stuart about where he thinks the company, and the industry, are headed.

WA What are some of the goals you have for yourself in the role of NDY Australian Regional Director?

SF The NDY Board has defined clear KPI’s for the Australian Regional Director role. These include focusing on developing closer working relationships with national client groups and development of greater levels of understanding of our clients’ businesses; focusing on a range of staff welfare and personal development initiatives; working with the

offices in the region to improve productivity and profitability; improve the collaboration, resource and IP sharing between offices; improve our document production and design processes; and continue to improve the quality of our deliverables, our responsiveness as a business, our customer service, and to broaden our engagement with the community.

WA What are some of the directions where you envisage future growth for NDY in the region?

SF We have embarked on a strategy of diversification within the business, and much of our planning for growth is based upon a more diversified offering, particularly from within Australia. Projects in the resource and mining sectors and in transport infrastructure, for instance, are adding significantly to our revenue stream and we see significant growth for NDY in these sectors.

In addition, we are continuing to focus on the skills development of our staff, and on the incorporation of new technologies into our business to improve our productivity and earnings potential.

WA What are the advantages of being a multidisciplinary firm? Can it deliver better value for projects?

SF We’re a multi-disciplined MEP engineering business, without Civil and Structural disciplines. So in some respects we’re a niche player, which we believe is a strength that allows us to focus on those disciplines which we know we deliver excellently. We have no interest in an “all things to all comers” approach. Our business model is focused on technical and service excellence in the disciplines in which we are proficient.

We do cover a wide range of disciplines within the MEP space, and we see huge value in an integrated offering to that extent, particularly in light of the co-ordination processes that are undertaken internally to deliver engineering design solutions to our clients. The technology delivery tools also lend themselves to an integrated offering, especially some of the more recent developments in the BIM and 3D modelling areas.

That said, I don’t believe the ability to add value is all about being multi-disciplinary or not. Our role is to understand our client’s business drivers, and deliver solutions appropriate to those drivers. Good ideas are not just about spending more money. The best ideas inevitably deliver value to a project as well as respond intelligently to a functional need.

WA How would you say the increasing importance of ESD has changed the approach NDY takes to engineering?

SF Throughout its history, NDY has always had a strong focus on efficiency in its designs. In many respects, the increasing importance that society and industry has placed on environmental sustainability has played to our business strengths. I believe that our industry’s broader focus on sustainable environmental outcomes has allowed strong, design led organisations like NDY to really shine. We’ve always been a strong, design led business and we have always placed huge importance on life cycle.

WA What have been the benefits of the prioritisation of ESD for the engineering disciplines as a whole?

SF There is a direct benefit in terms of environmental and social impact - clearly that’s the greatest upside. But it’s also meant far greater innovation

in the engineering design space. We’ve seen incredible growth in new and diverse technologies and systems being applied to projects, and that is ultimately a huge positive.

There is now far greater focus on minimising the environmental and life cycle impact of what we design and construct as a profession, and this has led to some tremendously clever engineering initiatives. Ultimately, that also makes the profession far more attractive to the kids at school - the engineers of the future. So there are positives on many levels.

WA Where do you see the greatest need for future innovation lies? What can we do better in our built environment?

SF There needs to continue to be a greater focus on renewable energy technologies, and a greater willingness by the relevant parties to adopt district or precinct energy and waste systems. As our urban centres continue to develop and increase in density, existing infrastructure systems reach their limits. There will need to be greater flexibility and greater innovation around infrastructure solutions related to the issues of increasing urban density.

WA What do you see as the most critical infrastructure issues in our region?

SF Within Australia there are differences state-by-state. But in each of our capital cities, there are the typical infrastructure constraints that go hand in hand with population growth - energy, water and transport.

A major task of government is to ensure that our infrastructure keeps up with demand, and this is a major challenge for Australia into the future. Our solid reliance on fossil fuels also remains a major challenge for us into the future. Investment in infrastructure to resolve these challenges doesn’t come cheaply, but it is investment that we must ultimately make. WA In resolving these, what comes first, public policy or private practice?

SF In an ideal world, the two can go hand in hand. Although, I recognise that in establishing a balanced regulatory environment, Government will ultimately steer the private sector to lead the innovation push to deliver appropriate outcomes. WA Do you think there is sometimes an element of ‘catch-up’ in public policy, for example, mandated energy-efficiency?

SF Yes on occasion. However, there are other examples where industry has led the way in the absence of any government policy, so it’s not a black and white argument. What is important is that Government has the capacity to respond quickly and set appropriate benchmarks, or appropriate minimum standards, where industry fails to self-regulate.

WA Looking forward, what are the things you are most positive about?

SF I’m certainly very positive about the medium to longer-term growth opportunities for the NDY business. I’m also positive about Australia generally, given our solid economic fundamentals, and our strategic geographic position in the region. We do live in the best country in the world; we enjoy a wonderful lifestyle and an excellent standard of living by any measure. We have a very strong education system which, through continued investment, will help to ensure our future success as a smart country. There is a great deal to be positive about in our part of the world.

17ANCR INTERVIEW ENGINEERING MANAGEMENTWWW.ANCR.COM.AU

STUART fOWLERAuSTrALIAN rEGIoNAL DIrECTor, NorMAN DISNEy & youNG

INTERVIEWENGINEERING MANAGEMENT

There’s nothing new about ESD for leading consulting engineering firm, Norman Disney & Young (NDY). For over 50 years their

expertise has been contributing to innovation and excellence in the built environment, with projects across buildings, sustainability, health, transport, mission critical, defence, industrial and utilities. With offices in every mainland Australian capital city, New Zealand, the UK and Dubai, NDY can leverage an international knowledge base while creating individual, value-adding solutions for every client.

New Australian Regional Director, Stuart Fowler, has been with the firm since he graduated with his Bachelors of Mechanical Engineering. With over 20 years experience on NDY projects across Australia and New Zealand, including Eureka Tower and AMP Bourke Place, he has a hands-on understanding of what makes projects tick, and has worked at the leading edge of promoting sustainability in engineering solutions for major projects. Willow Aliento interviewed Stuart about where he thinks the company, and the industry, are headed.

WA What are some of the goals you have for yourself in the role of NDY Australian Regional Director?

SF The NDY Board has defined clear KPI’s for the Australian Regional Director role. These include focusing on developing closer working relationships with national client groups and development of greater levels of understanding of our clients’ businesses; focusing on a range of staff welfare and personal development initiatives; working with the

offices in the region to improve productivity and profitability; improve the collaboration, resource and IP sharing between offices; improve our document production and design processes; and continue to improve the quality of our deliverables, our responsiveness as a business, our customer service, and to broaden our engagement with the community.

WA What are some of the directions where you envisage future growth for NDY in the region?

SF We have embarked on a strategy of diversification within the business, and much of our planning for growth is based upon a more diversified offering, particularly from within Australia. Projects in the resource and mining sectors and in transport infrastructure, for instance, are adding significantly to our revenue stream and we see significant growth for NDY in these sectors.

In addition, we are continuing to focus on the skills development of our staff, and on the incorporation of new technologies into our business to improve our productivity and earnings potential.

WA What are the advantages of being a multidisciplinary firm? Can it deliver better value for projects?

SF We’re a multi-disciplined MEP engineering business, without Civil and Structural disciplines. So in some respects we’re a niche player, which we believe is a strength that allows us to focus on those disciplines which we know we deliver excellently. We have no interest in an “all things to all comers” approach. Our business model is focused on technical and service excellence in the disciplines in which we are proficient.

We do cover a wide range of disciplines within the MEP space, and we see huge value in an integrated offering to that extent, particularly in light of the co-ordination processes that are undertaken internally to deliver engineering design solutions to our clients. The technology delivery tools also lend themselves to an integrated offering, especially some of the more recent developments in the BIM and 3D modelling areas.

That said, I don’t believe the ability to add value is all about being multi-disciplinary or not. Our role is to understand our client’s business drivers, and deliver solutions appropriate to those drivers. Good ideas are not just about spending more money. The best ideas inevitably deliver value to a project as well as respond intelligently to a functional need.

WA How would you say the increasing importance of ESD has changed the approach NDY takes to engineering?

SF Throughout its history, NDY has always had a strong focus on efficiency in its designs. In many respects, the increasing importance that society and industry has placed on environmental sustainability has played to our business strengths. I believe that our industry’s broader focus on sustainable environmental outcomes has allowed strong, design led organisations like NDY to really shine. We’ve always been a strong, design led business and we have always placed huge importance on life cycle.

WA What have been the benefits of the prioritisation of ESD for the engineering disciplines as a whole?

SF There is a direct benefit in terms of environmental and social impact - clearly that’s the greatest upside. But it’s also meant far greater innovation

in the engineering design space. We’ve seen incredible growth in new and diverse technologies and systems being applied to projects, and that is ultimately a huge positive.

There is now far greater focus on minimising the environmental and life cycle impact of what we design and construct as a profession, and this has led to some tremendously clever engineering initiatives. Ultimately, that also makes the profession far more attractive to the kids at school - the engineers of the future. So there are positives on many levels.

WA Where do you see the greatest need for future innovation lies? What can we do better in our built environment?

SF There needs to continue to be a greater focus on renewable energy technologies, and a greater willingness by the relevant parties to adopt district or precinct energy and waste systems. As our urban centres continue to develop and increase in density, existing infrastructure systems reach their limits. There will need to be greater flexibility and greater innovation around infrastructure solutions related to the issues of increasing urban density.

WA What do you see as the most critical infrastructure issues in our region?

SF Within Australia there are differences state-by-state. But in each of our capital cities, there are the typical infrastructure constraints that go hand in hand with population growth - energy, water and transport.

A major task of government is to ensure that our infrastructure keeps up with demand, and this is a major challenge for Australia into the future. Our solid reliance on fossil fuels also remains a major challenge for us into the future. Investment in infrastructure to resolve these challenges doesn’t come cheaply, but it is investment that we must ultimately make. WA In resolving these, what comes first, public policy or private practice?

SF In an ideal world, the two can go hand in hand. Although, I recognise that in establishing a balanced regulatory environment, Government will ultimately steer the private sector to lead the innovation push to deliver appropriate outcomes. WA Do you think there is sometimes an element of ‘catch-up’ in public policy, for example, mandated energy-efficiency?

SF Yes on occasion. However, there are other examples where industry has led the way in the absence of any government policy, so it’s not a black and white argument. What is important is that Government has the capacity to respond quickly and set appropriate benchmarks, or appropriate minimum standards, where industry fails to self-regulate.

WA Looking forward, what are the things you are most positive about?

SF I’m certainly very positive about the medium to longer-term growth opportunities for the NDY business. I’m also positive about Australia generally, given our solid economic fundamentals, and our strategic geographic position in the region. We do live in the best country in the world; we enjoy a wonderful lifestyle and an excellent standard of living by any measure. We have a very strong education system which, through continued investment, will help to ensure our future success as a smart country. There is a great deal to be positive about in our part of the world.

AUSTRALIAN NATIONAL CONSTRUCTION REVIEW18 ANCR SPECIAL FOCUS

CORDELLINfORMATIONGIVE YOUR COMPANY THE GO-AHEAD TO GREATER OPPORTUNITY

Staying on top of the flood of information required to undertake pro-active marketing of your construction business can be a full time job – several full time jobs if undertaken in-house. Cordell Information can take on the vast amount of legwork and paper chasing involved in keeping track of opportunities, setting your people free to focus on building the business.