LMC, 18/1/2012 TDI BEAM SCREEN ISSUE

TDI Beam screen issue

Dec 31, 2015

TDI Beam screen issue. LMC, 18/1/2012. Acknoledgements. B. Salvant, G. Arduini, M. Giovannozzi, O. Aberle, F. Loprete, A. Masi, M. Di Castro, S. Sgobba, the Vacuum group…. Facts. Throughout 2011 the following has been observed on the two TDIs: Abnormal heating of the extremities - PowerPoint PPT Presentation

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

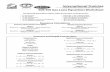

LMC, 18/1/2012

TDI BEAM SCREEN ISSUE

Acknoledgements

B. Salvant, G. Arduini, M. Giovannozzi, O. Aberle, F. Loprete, A. Masi, M. Di Castro, S. Sgobba, the Vacuum group…

Facts

Throughout 2011 the following has been observed on the two TDIs: Abnormal heating of the extremities Higher Impedance than what anticipated

from simulations (and previous measurements?)

Instability of the position measurements by more than 100 microns

Aperture limitations in Point 2 ? (in the region between TCTVB and TDI) but not precisely localised

Facts

Last Thursday, during an inspection of the TDI.4L2 to verify the status of the Ti coating of the hBN blocks, a relevant deformation of the beam screen has been observed

TDI.4L2 from downstream

The beam screen around the jaw is lowered by about 1 cm.

No other macroscopic defect visible

TDI.4R8 (from upstream)

The beam screen is lowered by 16 mm

There is a bump at the level of the third hBN block

The Bump, lower part of the screen

25 mm

~38 mm

The Bump, higher part of the screen

~15 mm

Further facts

The material of the beam screen is Copper Due to the porous material of the jaw, a

long bake-out (several days) is necessary After bakeout in surface (even 3 months)

no deformation was observed. The first TDI installed in P8, after several

bakeout cycles and the short operation of 2008 has been dismantled. The beam screen had no visible deformation.

What might have happened

The beam screen copper has become extremely soft after bake-out. Due to the fact that there is a lever arm of ~0.7 m (weight is carried only by the RF fingers), the extremity of the screen is lowered by creep under the effect of gravity.

From the LHC Design report:

The jaw

The Bump, lower part of the screen

What might have happened

The incident with 36 bunches lost on the jaw may have released stresses in the beam screen and deformed the softened copper.

What we can do now

Unfortunately nothing in situ. We have all the materials to build one spare, and some

parts for a second one They were put in stand-by to wait for the result of the

investigation on impedance and anomalous heating. We need (optimistically) 6 weeks to assemble the first We then need to bake it out in surface

(3 to 4 weeks) before installation. It means ready for installation end of March at the earliest

Installation, including bake-out in situ takes again 3 to 4 weeks.

The second can be ready at the end of the year (some critical materials to be procured, need ~6 months for that)

What we can do now

The two TDIs are symmetric, therefore not identical.

It looks like the priority is TDI.4R8, so we will prepare the first spare for that. Once done, we cannot use it for TDI.4L2.

We investigate (with MME), for a beam screen in stainless steel. We shall mount it already in the first spare for 4R8 (schedule for production and feasibility to be confirmed).

Open question: new bakout

We need now to bake out again to reach a good vacuum level. Will the bakeout worsen the situation?

The risk is to accelerate creep and therefore bending of the extremity of the screen.

Creep velocity, depending of the type of copper, is 3 to 10 times higher at 170 C wrt 120 C.

So lowering the bake-out temperature will certainly help.

Will the screen correctly slide to accommodate for the thermal expansion or deform more?

Central support of the screen

The Bump, lower part of the screen

Open question: new bakout

Also, stresses are now certainly stored into the material, will we release them and deform more?

Bakeout is a risk, keeping the temperature low helps, is this possible?

Conclusions

Need to decide on: Bakeout yes or no? At what temperature and for how long?

1 spare only can be prepared by end of march TDI.4R8 is the worse, so we prepare the

spare for it TDI.4L2: spare available for LS1.

Will replace copper beam screen with copper plated stainless steel

Spare slides

Position Instability

TDI.4R8 Drift observed on TDI.4R8 on axes Left

Upstream and Left downstream on 17 June 2011

Deformation of the jaw?

LVDT Modification TDI.4R2 for jaw deformation study

TDI.4R2

Previous situation

After intervention during last TS: The LVDT 2 has been moved in a measurement point symmetric with respect to the motorization axis along the jaw. A jaw deformation should give an opposite drift on the two LVDTs if the drift is caused by a real jaw deformation

Modification of LVDT holding supports on TDI.4L2 and TDI.4R8 (TS Nov 2011)

8 Dec 2011 9 Dec 2011 10 Dec 2011

15 um drift on TDI.4R8 Right Upstream LVDTs Temperature Variation : 0.5 oC

29 Nov 2011, 07:00 30 Nov 2011, 03:00 30 Nov 2011, 18:00

10 um drift on TDI.4R8 Left Upstream LVDTs Temperature Variation : 0.2 oC

Related Documents