Applied Surface Science 256 (2010) 6269–6278 Contents lists available at ScienceDirect Applied Surface Science journal homepage: www.elsevier.com/locate/apsusc Surface modification of an epoxy resin with polyamines via cyanuric chloride coupling David Schaubroeck a,∗ , Johan De Baets a , Tim Desmet b , Peter Dubruel b , Etienne Schacht b , Luc Van Vaeck c , André Van Calster a a Centre for Microsystems Technology (CMST)/ELIS, IMEC, Ghent University, Technologiepark 914A, B-9052 Ghent, Belgium b Polymer Chemistry & Biomaterials Research Group, Ghent University, Krijgslaan 281, Building S4 bis, B-9000 Ghent, Belgium c Department of Chemistry, University of Antwerp (UIA), Universiteitsplein 1, B-2610 Wilrijk, Belgium article info Article history: Received 30 March 2010 Received in revised form 1 April 2010 Accepted 1 April 2010 Available online 9 April 2010 Keywords: Surface characterization Cyanuric chloride Polyethylenimine Electroless copper deposition Adhesion abstract The presence of polyamine groups on the surface of dielectric resins potentially improves the adhesion with electrochemically deposited metals. In this article, first cyanuric chloride is covalently bound to the surface hydroxyl groups of the epoxy resin. The remaining reactive sites on the coupled cyanuric chloride molecule are then used to anchor polyamines. New data on the triazine coupling is presented. The surface reactions are monitored and characterized by means of ATR-IR, SEM-EDS, XPS and ToF-S-SIMS. Crown Copyright © 2010 Published by Elsevier B.V. All rights reserved. 1. Introduction Today, most of the printed circuit boards (PCBs) are composed of multiple alternating layers of patterned copper and dielectrics. The production of high density interconnects for integrated circuits (ICs) requires additional sequential build-up (SBU) layers, including microvias and very fine copper lines, on both sides of the PCB core [1]. New technologies and processes are developed to support the manufacturing of these SBU layers. A key issue for the reliability of the interconnections is to obtain good adhesion between the deposited copper and the dielectric layers. Surface properties of dielectric materials have a large impact on the adhesion strength of electrochemically deposited metals. Increased adhesion can be achieved via physical and/or chemi- cal modification of the epoxy surface. The introduction of surface roughness via wet chemical treatment (swelling and etching) is a cheap method to increase the adhesion. This process has been optimized and is reported by our [2–7] and other [8–12] research groups. However, the rapid evolution of microelectronics industry translates itself into a need for higher density substrates with smaller features [3,11]. In order to fulfill these requirements, one ∗ Corresponding author. Tel.: +32 9264 5514; fax: +32 9264 5374. E-mail address: [email protected] (D. Schaubroeck). has to minimize the roughness treatment of dielectric materials for two reasons. First, smaller features require the use of thin con- ductors. Second, low roughness is needed to avoid high frequency losses caused by the skin effect [13,14]. Since surface roughness is one of the key treatments for the improvement of (metal) adhe- sion, chemical surface modification can compensate this lower adhesion. Generally, the electrochemical copper deposition on dielectric materials involves two processes: electroless and electrolytic cop- per deposition [15]. The electroless or autocatalytic deposition is the result of a redox reaction at the dielectric surface between a chemisorbed catalyst (mostly Pd) and Cu species in solution. The sensitization of catalytically active palladium species on sub- strates evolved from a two-step to a one-step activation procedure [16]. In the two-step procedure, the substrate is immersed in an acidic SnCl 2 solution (sensitization) followed by an immersion in an acidic PdCl 2 solution (activation). Later on, a one-step process has been developed. In this process, the substrate is immersed into a SnCl 2 –PdCl 2 colloidal dispersion. Both of the above-mentioned processes aim to generate Pd 0 species on the surface via chemical reduction of Pd II species: Pd II + Sn II → Pd 0 + Sn IV The core of the colloids in the one-step process contains a Pd-rich, zerovalent, crystalline Pd–Sn alloy. This core is surrounded by a stabilizing -stannic shell with an inherent negative charge. After 0169-4332/$ – see front matter. Crown Copyright © 2010 Published by Elsevier B.V. All rights reserved. doi:10.1016/j.apsusc.2010.04.003

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Sc

DLa

b

c

a

ARRAA

KSCPEA

1

oT(m[mod

oIcraog

ts

0d

Applied Surface Science 256 (2010) 6269–6278

Contents lists available at ScienceDirect

Applied Surface Science

journa l homepage: www.e lsev ier .com/ locate /apsusc

urface modification of an epoxy resin with polyamines via cyanuric chlorideoupling

avid Schaubroecka,∗, Johan De Baetsa, Tim Desmetb, Peter Dubruelb, Etienne Schachtb,uc Van Vaeckc, André Van Calstera

Centre for Microsystems Technology (CMST)/ELIS, IMEC, Ghent University, Technologiepark 914A, B-9052 Ghent, BelgiumPolymer Chemistry & Biomaterials Research Group, Ghent University, Krijgslaan 281, Building S4 bis, B-9000 Ghent, BelgiumDepartment of Chemistry, University of Antwerp (UIA), Universiteitsplein 1, B-2610 Wilrijk, Belgium

r t i c l e i n f o

rticle history:eceived 30 March 2010eceived in revised form 1 April 2010ccepted 1 April 2010

a b s t r a c t

The presence of polyamine groups on the surface of dielectric resins potentially improves the adhesionwith electrochemically deposited metals. In this article, first cyanuric chloride is covalently bound to thesurface hydroxyl groups of the epoxy resin. The remaining reactive sites on the coupled cyanuric chloridemolecule are then used to anchor polyamines. New data on the triazine coupling is presented. The surface

vailable online 9 April 2010

eywords:urface characterizationyanuric chlorideolyethylenimine

reactions are monitored and characterized by means of ATR-IR, SEM-EDS, XPS and ToF-S-SIMS.Crown Copyright © 2010 Published by Elsevier B.V. All rights reserved.

lectroless copper depositiondhesion

. Introduction

Today, most of the printed circuit boards (PCBs) are composedf multiple alternating layers of patterned copper and dielectrics.he production of high density interconnects for integrated circuitsICs) requires additional sequential build-up (SBU) layers, including

icrovias and very fine copper lines, on both sides of the PCB core1]. New technologies and processes are developed to support the

anufacturing of these SBU layers. A key issue for the reliabilityf the interconnections is to obtain good adhesion between theeposited copper and the dielectric layers.

Surface properties of dielectric materials have a large impactn the adhesion strength of electrochemically deposited metals.ncreased adhesion can be achieved via physical and/or chemi-al modification of the epoxy surface. The introduction of surfaceoughness via wet chemical treatment (swelling and etching) ischeap method to increase the adhesion. This process has been

ptimized and is reported by our [2–7] and other [8–12] research

roups.However, the rapid evolution of microelectronics industryranslates itself into a need for higher density substrates withmaller features [3,11]. In order to fulfill these requirements, one

∗ Corresponding author. Tel.: +32 9264 5514; fax: +32 9264 5374.E-mail address: [email protected] (D. Schaubroeck).

169-4332/$ – see front matter. Crown Copyright © 2010 Published by Elsevier B.V. All rioi:10.1016/j.apsusc.2010.04.003

has to minimize the roughness treatment of dielectric materialsfor two reasons. First, smaller features require the use of thin con-ductors. Second, low roughness is needed to avoid high frequencylosses caused by the skin effect [13,14]. Since surface roughness isone of the key treatments for the improvement of (metal) adhe-sion, chemical surface modification can compensate this loweradhesion.

Generally, the electrochemical copper deposition on dielectricmaterials involves two processes: electroless and electrolytic cop-per deposition [15]. The electroless or autocatalytic deposition isthe result of a redox reaction at the dielectric surface betweena chemisorbed catalyst (mostly Pd) and Cu species in solution.The sensitization of catalytically active palladium species on sub-strates evolved from a two-step to a one-step activation procedure[16]. In the two-step procedure, the substrate is immersed in anacidic SnCl2 solution (sensitization) followed by an immersion inan acidic PdCl2 solution (activation). Later on, a one-step processhas been developed. In this process, the substrate is immersed intoa SnCl2–PdCl2 colloidal dispersion.

Both of the above-mentioned processes aim to generate Pd0

species on the surface via chemical reduction of PdII species:

PdII + SnII → Pd0 + SnIV

The core of the colloids in the one-step process contains a Pd-rich,zerovalent, crystalline Pd–Sn alloy. This core is surrounded by astabilizing �-stannic shell with an inherent negative charge. After

ghts reserved.

6270 D. Schaubroeck et al. / Applied Surface Science 256 (2010) 6269–6278

CN su

iaPcr

dcgp1c

s((ai

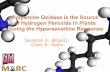

Fig. 1. Overall reaction scheme of the two-step modification of the E

mmersion with these colloids, the �-stannic shell is stripped inn acidic or alkaline solution resulting in the presence of “naked”d0 species on the surface. More detailed information about Pd–Snolloid composition and dimensions can be found in ref. [16] andeferences therein.

The Pd0 complexes are able to reduce CuII at the surfaceuring immersion of the activated substrate in a well-definedopper/NaOH/EDTA/formaldehyde aqueous solution [15,17]. Theenerated Cu0 at the surface acts as an autocatalyst for further cop-er reduction/deposition. Usually, a copper layer with a thickness of–2 �m is obtained. Subsequently, copper is deposited electrolyti-ally in an acidic copper sulfate solution [18].

In the past two decades, surface modification techniques

uch as plasma (N2 or NH3) [9,19–24], plasma-induced graftco)polymerization [25–29], “grafting-from” [30], coating [31],photo patterned) self assembled monolayers (SAMs) [16,32–39]nd wet chemical modifications [40,41] have been applied tontroduce amines, quaternary amines, pyridines or imidazole likerface (up) and chemical structures of DIEN and branched PEI (down).

molecules/polymers on the surface of various dielectric substratesincluding fluoropolymers, polyimide, polycarbonate, epoxy resins,glass and silicon. Surface modification with the above-mentionednitrogen containing molecules mostly resulted in an increasedadhesion with plated metals. However, different activation meth-ods such as the two-step process, the one-step process and Sn-freePd activation methods were used to activate the electroless processwhich makes it difficult to compare them. Moreover, the resultingmetal layers differ in thickness and various methods of adhesionmeasurements are applied such as scotch tape test, peel test (90◦

and 180◦) or pull test.The aim of this work is to introduce ethylene diamine moi-

eties via chemical modification on a photo definable epoxy layer

in order to improve the adhesion with electrochemical depositedcopper. The focus lies on the use of a commercial Pd–Sn colloidalactivating solution. Since the Pd–Sn colloidal solution is very acidic(pH ∼ 1), immersion of these modified substrates generates pro-tonated covalently bonded amine species on the surface. Theseurface

ct

bptiuI[

2

2o

iptoidnsC3a

2

to(Aoi

2

g(tgrfm

2

ifon

2

tAw1

D. Schaubroeck et al. / Applied S

ationic species attract the negatively charged �-stannic shell ofhe Pd–Sn colloids [16].

In this work, cyanuric chloride is used as a coupling moleculeetween hydroxyl groups on the surface of the epoxy resin andolyamines (Fig. 1). In this way, two polyamines are coupled tohe surface: diethylenetriamine (DIEN) and branched polyethylen-mine (PEI). These reactions are monitored and characterizedsing following techniques: ATR-IR, SEM-EDS, XPS and ToF-S-SIMS.

mproved results are obtained compared to previous reported data41].

. Experimental

.1. Preparation of a roughened photo-imageable polymer layern FR4

Probelec XB 7081TM, provided by HuntsmanTM, is a liquid photomageable dielectric (PID). It contains an epoxy cresol novolac (ECN)repolymer solved in 1-methoxy-2-propylacetate, a cationic pho-oinitiator and different types of fillers. ProbelecTM is dip-coatedn an FR4 substrate (10 cm × 10 cm; 1.2 mm thick). The substrates submitted to different drying, illumination and curing steps asescribed previously [42]. The final layer has a uniform thick-ess of approximately 40 �m. Roughness is introduced by 10 minwelling followed by 4 min chemical etching at 80 ◦C in Shipleyircuposit Hole Prep 4425 and KMnO4/NaOH (Shipley Circuposit310) solutions respectively [7]. The obtained roughened samplesre hereinafter referred to as blanco substrates.

.2. Reaction products

Dry toluene, dry dioxane, tetrahydrofuran (THF), diethylene-riamine (DIEN), cyanuric chloride (2,4,6-trichloro-1,3,5-triaziner trichloro s-triazine), branched polyethylenimine (Mw 25,000)PEI) and diisopropylethylamine (DIPEA) are purchased from Sigmaldrich, stored at 4 ◦C and used as received. Nitrogen gas is driedver a CaSO4 (DRIERITETM) column directly before use. MilliQ waters used for solution preparation and in all rinsing steps.

.3. Substrate reaction with cyanuric chloride

Roughened substrates are introduced in a nitrogen flushedlass reactor containing 500 ml of dry solvent. Next, 34 ml DIPEA0.4 mol/l) and 18.4 g cyanuric chloride (0.2 mol/l) are dissolved inhe reaction mixture. The reactor content is heated under nitro-en atmosphere at different temperatures and time intervals. Aftereaction, the substrates are rinsed three times in THF for 10 minollowed by two rinsing steps in ethanol for 5 min. Finally, the

odified substrates are dried by nitrogen blowing.

.4. Coupling of DIEN to a cyanuric chloride modified substrate

A glass reactor, containing an 1 M DIEN solution in isopropanol,s loaded with modified substrates. The reaction mixture is heatedor 24 h. After reaction, the substrates are rinsed three times in copi-us amounts of EtOH. Finally, the modified substrates are dried byitrogen blowing.

.5. Coupling of PEI to a cyanuric chloride modified substrate

10 g of PEI is dissolved in 250 ml isopropanol at 60 ◦C. The reac-or is charged with modified surfaces and heated to 75 ◦C for 92 h.fterwards the samples are rinsed for 30 min, 10 min, 10 min in DIater at 50 ◦C. Finally the samples are rinsed twice in ethanol for

0 min at 45 ◦C and dried by nitrogen blowing.

Science 256 (2010) 6269–6278 6271

2.6. Surface analysis methods

Scanning electron microscope (SEM) analysis is performed ona JEOL JSM-5600. The apparatus is used in the secondary elec-tron mode (SEI). This SEM apparatus is equipped with an electronmicroprobe JED 2300 and an EDS (energy dispersive spectroscopy)detector for elemental analysis. SEM-EDS is capable of detecting allelements from carbon to uranium, with a detection limit of circa0.2 wt% for most elements [43]. Prior to analysis, all samples arecoated with a thin carbon layer via flash evaporation. The presenteddata on chlorine content analysis is a mean of 3 measurements onrandom spots (65 �m × 48 �m). In all cases, the estimated standarddeviation does not exceed 0.05 wt%.

Attenuated total reflection infrared (ATR-IR) spectra areobtained from a Bio-Rad 575c FT-IR spectrometer. Each spectrumconsists of 64 scans with a resolution of 4 cm−1.

XPS (X-ray photoelectron spectroscopy) measurements are per-formed on a ESCA S-probe VG monochromatized spectrometerwith an Al K� X-ray source (1486 eV). A survey scan spectrum istaken from a spot of 100 �m × 200 �m on the sample. The spec-tral information appears from a depth of approximately 5–10 nmfor most polymers. XPS is inherently quantitative. This meansthat the intensity of a peak is proportional to the density of theatom which it derives within the sample volume [44]. The rela-tive atomic concentration CA of any chosen element A is obtainedfrom

CA = IA/SA∑n(In/Sn)

where CA is expressed as at%. IN is the measured peak area and SN isthe relative sensitivity factor for the specific element N. The aboveequation is only valid if the solid sample is homogeneous or at leasthomogeneous within the sample depth.

In all spectra, the carbon 1s peak is set at 285 eV to calibrate thespectrum. After this calibration, following peak maxima are usedto assign and integrate peaks from the other elements observed inthe spectra: 531 eV (O 1s), 400 eV (N 1s) and 201 eV (Cl 2p). TheCasa XPS software package (from Casa Software Ltd.TM, UK) is usedto integrate the peaks. The peak area to measure is defined aftera Shirley background fitting. The relative sensitivity factors (SN) ofthe analyzed elements are provided by the software which uses theScofield yield factors [45]: SC (1s) = 1.00, SN (1s) = 1.80, SO (1s) = 2.93and SCl (2p) = 2.29.

The ToF-S-SIMS (time of flight static secondary ion mass spec-trometry) analysis are carried out on an IONTOF V instrument(IONTOF, Münster, Germany) equipped with a Binq+ (n = 1–5, q = 1,2) liquid metal ion gun (LMIG). Mass spectra are recorded by bom-barding areas of typically 100 �m × 100 �m with 25 keV Bi3+ ionsusing the so-called “high current bunch mode”, featuring high massresolution and a beam spot diameter of about 2 �m. The acquisi-tion time of typically 100 s results in a total ion-dose density of2.5 × 1011 ions cm−2. The pulse length of 1 ns allows a mass reso-lution of 5000 (FWHM) to be achieved at m/z 15, while the massaccuracy is typically within 100 ppm up to a mass of 850. Massspectra are recorded for at least three distinct spots on each sam-ple. Positive ion mass calibration is performed using the ion signalsat m/z 1 (H+), 15 (CH3

+), 29 (C2H5+) and 43 (C3H7

+). For the nega-tive ion mass calibration, the ions at m/z 1 (H−), 12 (C−), 17 (OH−)

and 42 (CNO−) are used. Charge compensation is performed usinglow-energy electrons from a flood gun. Static secondary mass spec-troscopy is widely recognized as the method of choice for molecularsurface analysis with an information depth of essentially one mono-layer.6272 D. Schaubroeck et al. / Applied Surface Science 256 (2010) 6269–6278

Table 1Different reaction conditions applied in the first modification step with cyanuric chloride (CC). XPS and SEM-EDS analysis results are presented.

Substrate nr. Temperature (◦C) Time (h) XPS analysis: EDS analysis

C (at%) O (at%) N (at%) Cl (at%) N/C (%) Cl/C (%) Cl (m%)

Blanco 81 19 – – – – <0.11-CC 23 1 74 23 3 1 4 1 0.92-CC 23 2 78 19 3 1 4 1 1.23-CC 23 4 75 21 4 1 5 1 1.44-CC 23 8 74 21 4 1 5 2 1.55-CC 23 24 75 19 5 1 6 2 2.06-CC 30 1 78 20 2 –((0.3) 2 –((0.4) 1.37-CC 30 2 77 20 3 1 4 1 1.68-CC 30 4 76 19 5 1 6 1 1.89-CC 30 8 78 19 3 1 4 1 2.110-CC 30 24 76 19 4 2 5 2 2.411-CC 40 1 79 19 2 1 2 1 1.5

3

3

p

••

IKoirfSi

••

3

stosvarbrrs[

ddpts

t

and roughly 0.5–8 �m in the case of SEM-EDS. After all modificationreactions, chlorine and nitrogen are observed in the XPS analysiswhich is a first indication for the presence of chloro triazines onthe surface. Longer reaction times mostly result in higher relativechlorine and nitrogen surface concentrations.

12-CC 40 2 78 1913-CC 40 4 76 1914-CC 40 8 75 1915-CC 40 24 78 18

. Results and discussion

.1. Overview of starting material characteristics

The composition of cured ProbelecTM consists of two major com-ounds:

A photo curable epoxy cresol novolac resin.Inorganic fillers: CaCO3–MgCO3 and SiO2.

n this work, the epoxy resin surface is roughened mildly with a hotMnO4/NaOH solution. Indeed, some roughness is still needed tobtain proper adhesion between the epoxy resin and the electrolyt-cally deposited copper. The etching process introduces surfaceoughness via pore formation. In earlier work, the epoxy resin sur-ace was characterized chemically and physically via ATR-IR andEM-EDS before and after etching [41]. Briefly, this etching processncludes two phenomena:

Polymer chain breakdown via chemical oxidation.Decrease of the calcite fillers surface concentration.

.2. The cyanuric chloride coupling to the substrate surface

Cyanuric chloride 1 contains three chlorine atoms which can beubstituted by nucleophiles. An experimentally derived rule stateshat mono-, di- and trisubstitution reactions of cyanuric chlorideccur at 0 ◦C, 25 ◦C and >60 ◦C, respectively [46,47]. This thermaltepwise reactivity is used to initially couple the cyanuric chlorideia reaction with the surface hydroxyl groups of the epoxy resint moderate temperatures (maximum 40 ◦C). The remaining chlo-ine groups on the coupled triazine are subsequently substitutedy amines at higher reaction temperatures (>60 ◦C). An overalleaction scheme is shown in Fig. 1. Previous work indicated thateaction in dry dioxane for 22 h at 40 ◦C using DIPEA as protoncavenger resulted in the highest surface chlorine concentration41].

However, it has come to our attention that long treatment inioxane results in solvent uptake in the epoxy resin. In some cases,ioxane residues can be detected in the ATR-IR spectra through the

resence of a band near 1120 cm−1 (C–O–C stretch) [48]. Next tohis, reaction temperatures below 40 ◦C can reduce the unwantedecond chlorine substitution by traces of water (hydrolysis).Therefore, lower reaction temperature and shorter reactionimes are applied in order to minimize the hydrolysis and solvent

3 1 4 1 1.64 1 6 2 2.74 2 6 2 2.33 1 4 2 2.5

absorption. Table 1 represents the different reaction conditionsapplied for the cyanuric chloride coupling reaction. Reactions at23, 30 and 40 ◦C are carried out for 1, 2, 4, 8 and 24 h. Reactiontemperatures below 10 ◦C are not favored because in these specificconditions (see Section 2) cyanuric chloride is mainly insoluble.

After each reaction the elemental surface composition is mea-sured via XPS and the chlorine content is determined by SEM-EDSanalysis (Table 1). Note that the sampling depth in an organicmatrix for these two techniques differs largely: 5–10 nm for XPS

Fig. 2. ATR-IR analysis of the ECN surfaces before (blanco) and after reactions withcyanuric chloride. The reaction conditions for these numbered substrates are men-tioned in Table 1.

D. Schaubroeck et al. / Applied Surface Science 256 (2010) 6269–6278 6273

oF-S-S

to

•••

Ac

Fig. 3. Positive ion spectrum of the T

In addition, these reactions are monitored via ATR-IR spec-roscopy. After the coupling reaction, several new bands arebserved in the infrared spectra:

804 cm−1: out of plane vibration (A2′′) from the triazine ring 2.

1538 cm−1: in plane vibration (E′) from the triazine ring 2.±1735 cm−1: C O stretch from the keto form of hydrolyzed

chloro-triazines 3.dditional references on infrared analysis of (hydrolyzed) cyanurichloride and substituted triazines can be found in ref. [41].

Fig. 4. Negative ion spectrum of the ToF-S-S

IMS analysis of the blanco substrate.

Fig. 2 shows spectra obtained from the etched substrate (blanco)and modified substrates 4-CC, 9-CC, 11-CC, 14-CC and 15-CC. Thechloro triazine substitution is clearly noticed in the spectra ofthe modified surfaces through the additional bands at 804 and1538 cm−1. Longer reaction times (Fig. 2, spectra 11-CC, 14-CCand 15) result in more intense bands at the above-mentionedwavenumbers. Moreover, the XPS and SEM-EDS analysis confirm

these result via increased chlorine and nitrogen (surface) concen-trations (Table 1). The band at 1735 cm−1 is observed in all spectraof the modified substrates. This band is larger in the case of sub-strate 5-CC which possibly means that more hydrolyzed triazinesare present in the case of higher reaction temperatures. In addition,IMS analysis of the blanco substrate.

6274 D. Schaubroeck et al. / Applied Surface Science 256 (2010) 6269–6278

e ToF-

dirtp

awiF

ta((efpmsmK

TR

Fig. 5. Negative ion spectrum of th

ioxane presence is visible through a band at 1120 cm−1. This bands only observed in the case of high reaction temperatures and longeaction times (Fig. 2, spectrum CC-15). Consequently, the reac-ion temperatures of the cyanuric chloride coupling preceding theolyamine modifications will be limited to maximum 30 ◦C.

To confirm the above-mentioned results, ToF-S-SIMS analysisre performed on an initial etched surface (blanco) and comparedith the spectrum of a modified surface (substrate 5-CC). Both pos-

tive and negative spectra of the blanco substrate are shown inigs. 3 and 4, respectively.

In the positive spectrum of the blanco surface, three differentypes of ions are observed: hydrocarbon ions, metal ions and ionsttributed to the epoxy cresol novolac resin. The peaks at m/z 65C5H5

+), 77 (C6H5+), 91 (C7H7

+), 115 (C9H7+), 135 (C9H11O+), 152

C12H8+•) and 165 (C13H9

+) arise from the fragmentation of thepoxy cresol novolac resin. The metal ions Ca+ and Mg+ originaterom the Ca–Mg carbonate fillers. Their presence is visible through

+ + +

eaks at m/z 24 (Mg ), 40 (Ca ) and 57 (CaOH ). Other signals frometal ions such as Na+ and K+ are also observed. The presence ofodium and potassium through peaks at m/z 23 (Na+) and 39 (K+) isost likely a consequence of the preceding etching treatment in a

MnO4/NaOH solution. Finally, hydrocarbon contamination leads

able 2eaction conditions for the second modification step with DIEN. The XPS results (after re

Substrate nr. Reaction temperature in step 1 (◦C) XPS analysis

C (at%) O (at%) N (at%) Cl

Blanco – 81 19 – –16-DIEN 23 76 18 6 –17-DIEN 23 76 17 7 –18-DIEN 23 76 16 8 –19-DIEN 23 76 17 8 –20-DIEN 23 75 17 9 –21-DIEN 30 78 17 6 –22-DIEN 30 72 18 10 –23-DIEN 30 75 17 8 –24-DIEN 30 74 18 8 –25-DIEN 30 73 17 9 –Ref. 41 40 78 16 6 –

S-SIMS analysis of substrate 5-CC.

to the observation of following peaks: m/z 29 (C2H5+), 39 (C3H3

+),41 (C3H5

+), 43 (C3H7+), 53 (C4H5

+), 55 (C4H7+) and 57 (C4H9

+).In contrast to the positive spectrum, the negative spectrum of

the blanco surface does not provide so much additional informa-tion. Two peaks at m/z 65 (C5H5

−) and 121 (C8H9O−) arise from thefragmentation of the epoxy cresol novolac polymer backbone. Theoccurrence of carbonate species is determined through a peak atm/z 60 (CO3

−). The peaks below m/z 30: 12 (C−), 13 (CH−), 16 (O−),17 (OH−), 24 (C2

−) and 25 (C2H−), are structurally non-specific frag-ments. Sulfate contamination results in additional peaks at m/z 80(SO3

−), 81 (HSO3−) and 97 (HSO4

−).ToF-S-SIMS analysis of the cyanuric chloride modified substrate

5-CC results in additional peaks in the negative spectrum (Fig. 5).Four new peaks are noticed below m/z 50: 26 (CN−), 35 (35Cl−),37 (37Cl−) and 42 (CNO−). Thus, chlorine and nitrogen contain-ing species are present at the surface. However, these observationsdo not provide any evidence for the presence of (chlorine substi-

tuted) triazine molecules at the surface. A more detailed inspectionof the additional peaks in the region m/z 100–200 leads to someinteresting results. Additional peaks at m/z 146 (C335ClHN3O2−),

164 (C335Cl2N3O−) and 166 (C3

35,37Cl2N3O−) can be assigned tothe anions of 3 and 2, respectively. To the best of our knowl-

action) and SEM-EDS (before and after reaction) are presented.

EDS analysis: after step 1 EDS analysis: after DIEN

(at%) N/C (%) Cl/C (%) Cl (m%) Cl (m%)

– – <0.1 –8 – 0.8 –((0.1)9 – 0.9 –((0.1)

10 – 1.2 –((0.1)10 – 1.5 –((0.1)11 – 2.0 –((0.1)

8 – 1.2 –((0.1)14 – 1.4 –((0.1)11 – 1.7 –((0.1)11 – 2.0 –((0.1)13 – 2.6 –((0.1)

8 – 2.7 0.3

D. Schaubroeck et al. / Applied Surface

FD

estst

tctt4s

3

3

atNpbtci

irtt

overlap with the relatively strong signal from the N–H deformation(1581 cm−1) of DIEN and the C C aromatic stretches (1584 cm−1)[41] of the underlying ECN resin. Indeed, the depth of analysis forATR-IR is generally several micrometers.

ig. 6. ATR-IR analysis of the ECN substrates before and after modification withIEN.

dge, these findings have not been not reported in the literatureo far. These molecules are also observed in the ATR-IR spectrahrough different bands at ±1735 cm−1 (keto form of hydroxyl sub-tituted triazines), 804 cm−1 and 1538 cm−1 (chlorine substitutedriazines).

There is not much difference between the positive spectrum ofhe blanco substrate and 5-CC (not shown). Only one additionalompound in small amounts is noticed. The signal at m/z 130 referso the protonated DIPEA (C8H20N+). Its presence is confirmed byhe peaks at m/z 114 (C7H16N+), 86 (C5H12N+), 72 (C4H10N+) and4 (C2H6N+), due to the logically expected amine fragments andubsequent rearrangement products.

.3. Grafting of polyamines to surface coupled triazines

.3.1. Grafting of DIEN to surface coupled triazinesIn a subsequent step, the residual C–Cl bonds on the coupled tri-

zine molecules are used to anchor amine functionalized moleculeso the surface. Isopropanol (IPA) is chosen over diluted aqueousaOH solution (applied in ref. [41]) as reaction solvent for multi-le reasons. The main reason is to reduce the hydrolysis of the C–Clonds during the reaction. Second, the boiling point of IPA is higherhan 60 ◦C which is the minimum temperature needed for the thirdhlorine substitution. The final reason is that DIEN dissolves readilyn IPA.

In the case of reaction with DIEN, modified epoxy surfaces are

ntroduced in a 1 M DIEN solution in IPA at 75 ◦C for 24 h. After theeaction, the substrates are rinsed several times in ethanol. Duringhese rinsing steps, side products such as amine salts, adsorbedriazines and amines are removed from the substrates.Science 256 (2010) 6269–6278 6275

Table 2 shows the XPS and SEM-EDS elemental concentrationsfor different reaction conditions. Chlorine is not detectable withXPS after the reaction with DIEN. The nitrogen surface concentra-tions measured with XPS increase in comparison with the valuespresented in Table 1. In addition, EDS analysis results in a strongdecrease of the chlorine content in all cases. Compared to previ-ously reported methods where an aqueous alkaline solution is usedas a reaction medium (Table 2), increased nitrogen surface concen-trations are obtained except from entries 16-DIEN and 21-DIEN. Inthese cases, the substrates are activated with cyanuric chloride foronly 1 h in Step 1.

After the modification reactions, oxygen is still present. Thismeans that the surface is not fully covered with amines or theprobing depth of the XPS analysis larger than the thickness of themodified layer.

At first sight, the ATR-IR analysis of the DIEN modified sub-strates reveals new bands in the region of 1500–1700 cm−1 (Fig. 6).The presence of DIEN is visible through the occurrence of a newband around 1655 cm−1 and an increased intensity of the band at1581 cm−1. The bands at 1655 cm−1 and 1581 cm−1 are attributedto the N–H deformation vibration of primary and secondary amines,respectively [49]. Next, the out of plane vibration of the triazinering at 804 cm−1 is shifted to 812 cm−1. This means that triazinemoieties are still present and that the nature of its substituentsis altered. The band at 1538 cm−1 decreased in intensity. Nor-mally this band shifts towards higher frequencies due to aminesubstitution [50]. However, this shifted band is not visible due to

Fig. 7. ATR-IR analysis of the ECN substrates before and after modification with PEI.

6276 D. Schaubroeck et al. / Applied Surface Science 256 (2010) 6269–6278

Table 3Reaction conditions for the second modification step with PEI. The XPS results (after reaction) and SEM-EDS (before and after reaction) are presented.

Substrate nr. Reaction temperature in step 1 (◦C) XPS analysis EDS analysis: after step 1 EDS analysis: after PEI

C (at%) O (at%) N (at%) Cl (at%) N/C (%) Cl/C (%) Cl (m%) Cl (m%)

Blanco – 81 19 – – – – <0.1 NA1- PEI 23 72 18 10 – 13 – 0.9 – (0.1)2- PEI 23 73 17 10 – 13 – 1.2 – (0.1)3-PEI 23 73 16 11 – 15 – 1.4 – (0.1)4-PEI 23 73 16 11 – 15 – 1.5 0.35-PEI 23 73 16 12 – 16 – 2.0 0.46-PEI 30 74 17 9 – 12 – 1.3 – (0.1)7-PEI 30 72 19 8 – 12 – 1.6 0.28-PEI 30 71 19 11 – 15 – 1.8 0.3

––

3

mlritcvpargTttnti

9-PEI 30 71 18 1110-PEI 30 72 18 10

.3.2. Grafting of PEI to surface coupled triazinesIn contrast to the reaction with DIEN, the PEI modification needs

uch longer reaction times. This can be explained in terms of thearge difference in molar mass of these two reagents. After 92 h ofeaction in isopropanol at 75 ◦C, chlorine is no longer detectablen the XPS spectra (Table 3). However, EDS measurements afterhis reaction result in chlorine contents from 0.1 to 0.4 m%. Thisan be explained by the much larger probing depth of SEM-EDSersus XPS. Due to the porous structure of the substrates, it isossible that some reactive C–Cl bonds are somehow not reach-ble for the PEI even after long exposure times. When the XPSesults of Tables 1 and 3 are compared, one can see that the nitro-en content after this modification increases with roughly 10 at%.his proves the presence of PEI on the surface. Also important is

hat the oxygen content decreases only slightly. This implicateshat the surface is not fully covered with PEI or that the thick-ess of the modified layer is smaller than the probing depth ofhe XPS analysis. Angle-resolved XPS studies could provide morenformation. Unfortunately, the porous structure of the sampleFig. 8. ToF-S-SIMS analysis spectra of substrate 20-DIEN (positiv

15 – 2.1 0.414 – 2.4 0.5

surfaces [7,41] makes it nearly impossible to apply this tech-nique.

ATR-IR analysis of the PEI modified substrates reveals the samechanges as with the DIEN modification. The presence of PEI is vis-ible through the occurrence of a new band around 1655 cm−1 andan increased intensity of the band at 1581 cm−1 (Fig. 7). Comparedto the DIEN modifications these bands are more pronounced. Next,longer reaction times in step 1 with cyanuric chloride lead to moreintense signals from the amine bend vibrations. The out of planevibration of the triazine ring at 804 cm−1 is shifted to 812 cm−1

and the band at 1538 cm−1 decreases in intensity. In contrast tothe infrared analysis of DIEN modified samples, the presence of–CH2CH2NHR– units can be observed through a small increaseof absorption around 1430 cm−1 (C–H deformation vibration in

–CH2NHR units).3.3.3. ToF SIMS analysis of DIEN and PEI modified surfacesAfter reaction, one substrate modified with DIEN (substrate 20-

DIEN) and one with PEI (substrate 10-PEI) are subjected to ToF-SIMS

e spectrum) and 10-PEI (positive and negative spectrum).

D. Schaubroeck et al. / Applied Surface Science 256 (2010) 6269–6278 6277

rovid

apD35nat31a(

4

otccvnioc

ppa

A

sc

R

[

[

[

[

[

[

[[[

[

[

[

[

[

[

[[

[

[

[[

[

[[

[

[

[

[

[

[

[

[

Fig. 9. Possible fragments of DIEN and PEI p

nalysis. Both positive spectra (Fig. 8) exhibit the same additionaleaks compared to substrate 5-CC. The additional peaks arise fromIEN or PEI [51] degradation fragments (see Fig. 9): m/z 28 (CH2N+),0 (CH4N+), 42 (C2H4N+ or CNO+), 44 (C2H6N+), 54 (C3H4N+) and6 (C3H6N+). In the case of 10-PEI these peaks are more pro-ounced. The negative spectra (Fig. 9) show peaks at m/z 26 (CN−)nd 42 (CNO−), which are structurally non-specific nitrogen con-aining fragments. The peaks from the chloride ion (m/z: 35 and7) and the chlorine substituted triazine compounds (m/z: 146,64 and 166) are not observed. Sulfate contamination results indditional peaks at m/z 80 (SO3

−), 81 (HSO3−) and 97 (HSO4

−)not shown).

. Conclusions

We have successfully introduced polyamines on the surfacef ECN resins via chemical modification. This chemical modifica-ion strategy consists of an initial coupling reaction with cyanurichloride followed by grafting of polyamines. A detailed surfaceharacterization after each reaction step is provided. New andaluable data on ToF-S-SIMS analysis on the coupling of cya-uric chloride on ECN resins followed by polyamine substitution

s presented. Different surface concentrations of DIEN and PEI arebtained by varying the reaction time or temperature of the pre-eding cyanuric chloride coupling reaction.

In future work, the modified substrates will be plated with cop-er via the electroless deposition method. The influence of theolyamine modifications and their surface concentrations on thedhesion properties will be evaluated.

cknowledgements

The FWO-Flanders is gratefully acknowledged for the financialupport. The authors appreciate technical support and valuable dis-ussions with Ms. A. Gielen, Dr. D. Cuypers and eng. V. Boterberg.

eferences

[1] C.F. Coombs, Printed Circuits Handbook, 5th ed., McGraw-Hill, New York,2001.

[2] S. Siau, A. Vervaet, A. Van Calster, I. Swennen, E. Schacht, Journal of the Electro-chemical Society 151 (2004) J54–J61.

[3] S. Siau, A. Vervaet, A. Van Calster, I. Swennen, E. Schacht, Applied Surface Science237 (2004) 456–461.

[4] S. Siau, A. Vervaet, E. Schacht, A. Van Calster, Journal of the ElectrochemicalSociety 151 (2004) C133–C141.

[5] S. Siau, A. Vervaet, S. Nalines, E. Schacht, A. Van Calster, Journal of the Electro-chemical Society 151 (2004) C831–C849.

[6] S. Siau, A. Vervaet, S. Nalines, E. Schacht, A. Van Calster, Journal of the Electro-

chemical Society 151 (2004) C816–C830.[7] S. Siau, A. Vervaet, L. Van Vaeck, E. Schacht, U. Demeter, A. Van Calster, Journalof the Electrochemical Society 152 (2005) C442–C455.

[8] J. Ge, M.P.K. Turunen, J.K. Kivilahti, Thin Solid Films 440 (2003) 198–207.[9] H. Hayden, E. Elce, S.A.B. Allen, P.A. Kohl, IEEE Transactions on Advanced Pack-

aging 32 (2009) 758–767.

[

[

[

ing secondary ions in ToF-S-SIMS analysis.

10] D. Schroer, R.J. Nichols, H. Meyer, Electrochimica Acta 40 (1995) 1487–1494.

11] J. Ge, R. Tuominen, J.K. Kivilahti, Journal of Adhesion Science and Technology15 (2001) 1133–1143.

12] M.P.K. Turunen, P. Marjamaki, M. Paajanen, J. Lahtinen, J.K. Kivilahti, Microelec-tronics Reliability 44 (2004) 993–1007.

13] H.W. Johnson, M. Graham, High-speed Signal Propagation: Advanced BlackMagic, Prentice Hall, Professional Technical Reference, Upper Saddle River, NJ,2003.

14] A. Deutsch, C.W. Surovic, R.S. Krabbenhoft, G.V. Kopcsay, B.J. Chamberlin, IEEETransactions on Advanced Packaging 30 (2007) 279–287.

15] G.O. Mallory, J.B. Hajdu, Electroless Plating: Fundamentals and Applications,American Electroplaters and Surface Finishers Society, Orlando, FL, 1990.

16] D. Zabetakis, W.J. Dressick, ACS Applied Materials & Interfaces 1 (2009) 4–25.17] T. Ogura, M. Malcomson, Q. Fernando, Langmuir 6 (1990) 1709–1710.18] M. Schlesinger, M. Paunovic, Modern Electroplating, 4th ed., John Wiley, New

York, 2000.19] D. Bhusari, H. Hayden, R. Tanikella, S.A.B. Allen, P.A. Kohl, Journal of the Elec-

trochemical Society 152 (2005) F162–F170.20] D. Nicolas-Debarnot, M. Pascu, C. Vasile, F. Poncin-Epaillard, Surface & Coatings

Technology 200 (2006) 4257–4265.21] M. Charbonnier, M. Romand, E. Harry, M. Alami, Journal of Applied Electro-

chemistry 31 (2001) 57–63.22] M. Charbonnier, M. Alami, M. Romand, Journal of Applied Electrochemistry 28

(1998) 449–453.23] M. Charbonnier, M. Alami, M. Romand, Journal of the Electrochemical Society

143 (1996) 472–480.24] M. Charbonnier, M. Romand, International Journal of Adhesion and Adhesives

23 (2003) 277–285.25] S.Y. Wu, E.T. Kang, K.G. Neoh, K.L. Tan, Langmuir 16 (2000) 5192–5198.26] G.H. Yang, E.T. Kang, K.G. Neoh, Y. Zhang, K.L. Tan, Langmuir 17 (2001) 211–

218.27] M.C. Zhang, E.T. Kang, K.G. Neoh, K.L. Tan, Journal of the Electrochemical Society

148 (2001) C71–C80.28] W.H. Yu, Y. Zhang, E.T. Kang, K.G. Neoh, S.Y. Wu, Y.F. Chow, Journal of the

Electrochemical Society 149 (2002) C521–C528.29] Z.J. Yu, E.T. Kang, K.G. Neoh, Polymer 43 (2002) 4137–4146.30] O. Azzaroni, Z.J. Zheng, Z.Q. Yang, W.T.S. Huck, Langmuir 22 (2006) 6730–

6733.31] H. Lee, S.M. Dellatore, W.M. Miller, P.B. Messersmith, Science 318 (2007)

426–430.32] Y.J. Chen, E.T. Kang, K.G. Neoh, W. Huang, Langmuir 17 (2001) 7425–7432.33] W.J. Dressick, C.S. Dulcey, J.H. Georger, G.S. Calabrese, J.M. Calvert, Journal of

the Electrochemical Society 141 (1994) 210–220.34] M.S. Chen, S.L. Brandow, C.S. Dulcey, W.J. Dressick, G.N. Taylor, J.F. Bohland,

J.H.G. Georger, E.K. Pavelchek, J.M. Calvert, Journal of the Electrochemical Soci-ety 146 (1999) 1421–1430.

35] A. Holtzman, S. Richter, Journal of the Electrochemical Society 155 (2008)D196–D202.

36] A.M. Bittner, X.C. Wu, K. Kern, Advanced Functional Materials 12 (2002)432–436.

37] P.X. Zhu, Y. Masuda, K. Koumoto, Journal of Materials Chemistry 14 (2004)976–981.

38] M.S. Chen, S.L. Brandow, T.L. Schull, D.B. Chrisey, W.J. Dressick, Advanced Func-tional Materials 15 (2005) 1364–1375.

39] W.J. Dressick, C.S. Dulcey, J.H. Georger, J.M. Calvert, Chemistry of Materials 5(1993) 148–150.

40] S. Siau, A. Vervaet, E. Schacht, U. Demeter, A. Van Calster, Thin Solid Films 495(2006) 348–356.

41] D. Schaubroeck, J. De Baets, T. Desmet, S. Van Vlierberghe, E. Schacht, A. VanCalster, Applied Surface Science 255 (2009) 8780–8787.

42] S. Siau, A. Vervaet, S. Degrande, E. Schacht, A. Van Calster, Applied SurfaceScience 245 (2005) 353–368.

43] J. Goldstein, Scanning Electron Microscopy and X-ray Microanalysis, 3rd ed.,Kluwer Academic/Plenum Publishers, New York, 2003.

44] D. Briggs, J.T. Grant, Surface Analysis by Auger and X-ray Photoelectron Spec-troscopy, IM Publications, Chichester, 2003 (SurfaceSpectra Limited).

6 urface

[

[[

[

[49] G. Socrates, Infrared and Raman Characteristic Group Frequencies: Tables and

278 D. Schaubroeck et al. / Applied S

45] J.H. Scofield, Journal of Electron Spectroscopy and Related Phenomena 8 (1976)

129–137.46] G. Blotny, Tetrahedron 62 (2006) 9507–9522.47] S.G. Shafer, J.M. Harris, Journal of Polymer Science Part A: Polymer Chemistry

24 (1986) 375–378.48] F.E. Malherbe, H.J. Bernstein, Journal of the American Chemical Society 74

(1952) 4408–4410.

[

[

Science 256 (2010) 6269–6278

Charts, 3rd ed., Wiley, Chichester, New York, 2001.50] W.M. Padgett, W.F. Hamner, Journal of the American Chemical Society 80

(1958) 803–808.51] P. Kingshott, J. Wei, D. Bagge-Ravn, N. Gadegaard, L. Gram, Langmuir 19 (2003)

6912–6921.

Related Documents