Supermarine Aircraft GM Isuzu V6 Engine General over view, aim, reasoning, details and specifications. Testing and analysis with pictures and graphical representatons. Geoff Braddock 26/02/2006 Version One

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Supermarine Aircraft GM Isuzu V6 Engine

General over view, aim, reasoning, details and specifications.Testing and analysis with pictures and graphical representatons.

Geoff Braddock 26/02/2006Version One

Supermarine Aircraft GM Isuzu V6 Engine

Overview

Due to the nature of the MK26 Spitfire, it was always envisaged that a ‘V’ configurationengine would one day be offered. There are any number of V8 engine kits available butall are too heavy and did not fit within the original design criteria, that of a light respon-sive and forgiving aircraft with universal appeal as evidenced by market research andfeedback. Although V8 powered aircraft were talked about, the reality is that most pilotswere looking for an aircraft as outlined in our criteria.The V6 eventually chosen is an all alloy belt driven, quad cam V6 with 4 valves percylinder. This engine is manufactured by Honda Japan under licence for Isuzu and isused in 10's of thousands of vehicles world wide. From our research the reliability of thisengine is extremely good and investigation with the vehicle manufacturers using thisengine has confirmed this reliability record.

Aim

Provide a light, powerful, well engineered, reliable and cost effective automotive derivedfirewall forward engine package with PSRU, looms, cooling system and all associatedhardware suitable for installation in MK26 Spitfire and other kit built aircraft. This pack-age is designed to be installed by the average builder without the need for specialisedtraining, knowledge or tooling and to be maintained with the same view.

Reasoning

Modern aircraft piston engines are for the most part very well engineered, reliable units.However they are very expensive to run and maintain and require the services of spe-cialists to install and maintain them. This does not fit within the design criteria of theMK26 Spitfire. The automotive derived engines available are extremely reliable,cheapand technologically advanced with good specific power output and easily maintained.The V6 engine chosen for the MK26 Spitfire falls well within this criteria and that of theoverall criteria as relates to the MK26.

EnginesThe engine chosen is an all alloy V6 with belt driven overhead cams with non interfer-ance cam timing. They have direct cam over shim on bucket valve actuation and 4valves per cylinder. The fuel and ignition is controlled sequentially by a state of the artaftermarket computer management system. The engine is naturally aspirated through asingle throttle body mounted to the front of the intake manifold with cast equal lengthintake runners.Lubrication is by wet sump high pressure internal oil pump with full pressure feed to allbearing journals. A full flow oil cooler is incorporated into the system with a remotelymounted large capacity oil filter with commonly available screw on filter elements.The engine is internally balanced ex factory.A high output automotive style alternator is used and driven by a multi ‘V’ belt off thefront of the engine.Cooling system is standard automotive, thermostatically controlled using a 50/50 waterinhibitor mix. The coolant pump is driven by the cam belt.The coolant radiator is located below and to the rear of the engine compartment withcooling air ducted via an intake located at the top front of the engine cowl and exhaust-ed via a cockpit controlled cowling below the radiator. This cooling system has provento be extremely effective and efficient with a good margin of safety even in hotAustralian conditions.

Fuel injection and ignition system

The fuel injection and ignition are controlled by a fully programable state of the artMoTeC engine management system. The ignition and injection is sequentially operated,meaning fuel and spark are only supplied when required . This method of operation hasseveral advantages over the more common group fired management systems:(1) Increased engine torque and power(2) Decreased fuel consumption.(3) Decreased load on the electrical system.(4) Less waste fuel in manifold and therefore decreased fire risk.(5) Ability to programme redundancy into system because of the individual drivers within

the management computer.(6) Elimination of unnecessary systems on motor

The spark plugs are fired by individual high output coils, totally eliminating distributors,magnetos and high tension leads. This enables the computer to drive the coils individu-ally and be programmed to allow for redundancy. The engine has been tested with 2cylinders disabled and returned output figures of 140 hp and 160 lbs/ft torque. Seeattached dyno chart Fig (1).A single programable MoTeC computer is used. Originally two computers were going tobe used but after consultation with the manufacturer it was decided to use one comput-er as most engine management malfunctions are caused by sensor failure not comput-er failure. The engine management is comprised of the following:

Computer - Primary sensors - Secondary sensors - Redundant maps.All fuel injected motors require input from primary sensors to establish start and finishsequencing. This system has input from two primary sources, ignition trigger and camangle sensor. Secondary sources comprise of throttle position sensor(TPS) Manifold

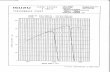

(Fig 1) Dyno printout. 4 cylinders

absolute pressure (MAP), Air temperature sensor (ATS) coolant sensor, oil pressure, RPM,fuel pressure. The ignition and cam sensors being the primary sensors are duplicated and a reliablemethod of switching between the pairs of sensors has been incorporated into the manage-ment system. This is controlled from the cockpit and operated in the same way as switchingbetween conventional ignition systems. There is however no decrease in engine rpm whendoing ‘mag’ checks as the computer is only being told to read the second set of primaryinputs. Typically there will be an audible ‘blip’ when doing pre flight engine checks whenswitching between ‘A and B’ circuits.The engine will function normally on either ‘A’ or ’B’ cir-cuits.All other functions are considered secondary. For example, if the TPS malfunctions the com-puter will read from preset stored maps and MAP sensor augmented by input from theremaining functioning sensors. Altitude operation is taken care of by the MAP sensor (Manifold absolute pressure). As alti-tude increases, air density decreases hence a drop in manifold pressure and therefore alessening demand for fuel. The computer will automatically lean(trim) the fuel and will alsocompensate for lower intake air temperature at altitude. Conversely if there is an increase inmanifold pressure ,ie forced induction or ram induction the computer will increase the fuelrequired (trim) to compensate. Air temp, ignition retard and advance will also see trimming as a function of engine load.The computer has built in self diagnostic functions and the pilot is alerted to any sesor faultor malfunction via an extremely bright LED mounted in the cockpit. If the malfunction is notcorrected by switching from ‘A’ to ‘B’ circuit then it is a secondary sensor malfunction andthe cockpit gauges should be closely monitored to give an indication of the problem andlanding the aircraft is recommended as soon as possible. If the optional MoTeC data dash is installed it will tell the pilot the nature of the malfunctionand they can then decide whether or not to land.The system will function on battery or alternator power in the event one or the other fails.An auxiliary power source can be fitted by the builder if they so wish. Consult the factory rethis however.

Ignition triggers Cam angle sensor MAP sensor TP Sensor

AT sensor Coolant temp sensor Oil pressure sensor Fuel pressure sensor

Fuel SystemThe fuel system comprises paired high pressure fuel pumps delivering fuel to the fuel railvia a manifold compensated fuel pressure regulator. The system is of the full flow type withregulated fuel pypassed back to the fuel tank. The pumps are manually operated from the cockpit , both being on for take off and only one necessary for the engine require-ments at cruise. ( One pump is sufficient for engine demand even at full throttle takeoff power) The normal procedure is both pumps on for take off or landing.

Propellor Speed Reduction Unit ( PSRU)

The PSRU was designed in house specifically for use with the Isuzu V6 engine and to fitwithin the already mentioned criteria for the MK26. It consists of a robust aluminium cast-ing housing the prop drive shaft and bearing carrier, top and bottom drive pulleys andcrank pulley nose bearing. The use of a toothed aramid fibre and rubber belt dampensout torsional and shock loads transmitted from the prop and the mounting of the cage tothe engine mount via integral cast lugs ensures torque, thrust and gyroscopic loads aretransmitted mainly to the engine mount and not through the engine crankcases. Propshaft bearings and bottom crank steady bearing run in a self contained oil system.

Fuel pressure regulator Fuel pumps

The toothed drive belt is of arimid fibre and polymer rubber construction and rated to 320hp and tested continuously at 380 hp for 1000 hours for military use.The prop reduction ratio is 1.755:1.

Engine testing

The engine has been tested on various load dynos to establish its power and torque characteristics and to map the engine management computer. Hundreds of hours have been spent in dyno testing from which has been gained a broad picture of the engines capabilities, reliablity particular attention being focussed around the 3000-4000 rpm area as this is where the engines normal operating range is set.Dyno testing has also been done to establish the engine characteristics under abnormaloperating conditions (see fig 1 dyno sheet) with cylinders disabled, sensors disabled etc.It has been established that the motor will run with only one primary sensor functioning(Crank angle sensor) and 2 cylinders disabled,all other sensors disabled and motor run-ning on maps. This is a very unlikely scenario under normal circumstances with the mostlikely scenario being a sensor malfunction or injector or sparkplug coil malfunction. No malfunction of any sort has been encountered in the course of normal dyno testing.The mapping of the computer has been done on two dirrerent types of dyno, an enginedyno and a rolling road dyno. The computer as mapped has been flown extensively inour test aircraft and has needed no adjustments. All flights to date have been data loggedand an extensive amount of information is on hand regarding the engines operation in allflight regimes including positive G aerobatics. Because the engine is wet sump lubricated

negative G manouvres are not permitted.To date (26/02/2006 was the most recent flight of our test aircraft) no malfunctions of anysort have been experienced or recorded in flight.See Dyno sheets for typical data recorded during dyno runs.Fig 1 and 2 See MoTeC data logging print outs for typical data recorded during course of flights.

Vibration TestingDuring the course of engine testing a series of dyno and in flight viabration tests were con-ducted to establish if there were any ‘No Go’ operational areas for this engine package.A Vibrex 2000 plus spectral viabration analyser was used and a typical spectral analysis graph can be seen at Fig 5. There were no vibration problems recorded in either dynotesting or flight testing especially in the areas of normal operation 3000-4000 rpm.

Wiring Looms

Particular attention has been paid to the manufacture of engine and fuselage looms with bothbeing manufactured in MIL spec wiring and raychem covered. All terminals are of the positiveclick and lock style with the major firewall plug being a military style bayonet lock type. (seeFig 6). All looms are triple tested before being sealed and then tested on the engine stand inconjunction with the engine testing of the motors pror to packing and shipping.No engines leave the factory without being tested. (See Fig 7)

Fig 4

Fig 1

Fig 2

Fig 5Typical spectral analysis graph for 3000 rpm. (Note decreasing viabration orders with rpm)

Fig 6 Bayonet firewall plug Fig 7 Engine run prior to packing and shipping

Anciliary items

All engines are purchased brand new in their crates and all automotive hardware is removed.This is all replaced with purpose made mounting hardware and looms. All hosing is replacedwith high quality ‘20’ year reinforced silicon hose. All necessary sensors are fitted, fuel railsreplaced with Billet aluminium rails and high pressure screw on hose fittings are used.Where possible all plastic fittings are replaced with brass or steel and any interference pushin type fittings replaced with screw in fittings. Any hose clamps used are stainless steel withrolled edges. Coolant and oil radiators are made from aluminium specifically to our designs.Exhaust system is manufactured in stainless steel

Billet alloy fuel rails and steel fittings Bronze fittings and silicon hose

High quality Oil line fittings Silicon hose at water header with rolled edge stainless clamps

Exhaust system

Technical specifications

3.5 litre fuel injected V6 with belt driven overhead cams operating 4 valves per cylinder bydirect cam over shim buckets.Cam train is of non interference design.8.6:1 compression ratioCast in cylinder block liners with water coolingBore and stroke: 93.4mm x 85.0mmValve clearance(cold) Intake .28mm

Exhaust .30mmOil capacity: 5.3 litres (Engine only). Use SAE 0w-40 Full synthetic oil.

Performance Data

See dyno charts Figs 1 and 2.Max Hp 266.5 @ 5200 rpmMax Torque 274 lbs/ft @ 4500 rpmMax engine speed 5500 rpmMax take off (full throttle) 4800-5000 rpm @ 28-29 manifoldCruise (75% throttle) 3600-3800 rpm @ 24-26 manifoldIdle speed 650-800 rpm

Service information (recommended until further notice)

Engine TBO 1500 hrsSpark plug change 100 hrsTappet adjustment check. 200 hrs (Adjust if necessary)Engine oil change. 25 hrs initial run in, then 50 hrs normal operation or 6 months. Oil filter change. 25 hrs initial run in, then 50 hrs normal operation or 6 months.Fuel filter change (injection) 50 hrs normal operation or 6 monthsFuel filter change (in line) 25 hrs normal operation or 3 monthsCoolant change 100 hrs PSRU oil change. 25 hrs initial run in, then 100 hrs normal operationCam belt change 500 hrsPSRU belt change 500 hrsAlternator belt change 200 hrs

Related Documents

![[Crowood Press] [Aviation Series] Supermarine Seafire](https://static.cupdf.com/doc/110x72/55cf9d38550346d033acbbfc/crowood-press-aviation-series-supermarine-seafire.jpg)