Slight 1 Sulfur and ferrite-based thermochemical cycles for water splitting Martin Roeb SFERA WinterSchool 2011, Zurich, March 24 th 2011 Slide 2 Outline Ferrite based thermochemical cycle: HYDROSOL Materials System Model Prototypes and tests Pilot plants Scale-up, economics Sulphur based thermochemical cycle: HycycleS Materials Prototypes Modelling Scale-up Summary SFERA Winter School Solar Fuels & Materials Page 36

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Slight 1

Sulfur and ferrite-based thermochemical cycles for water splitting

Martin Roeb

SFERA WinterSchool 2011, Zurich, March 24th 2011

Slide 2

Outline

Ferrite based thermochemical cycle: HYDROSOL

Materials

System Model

Prototypes and tests

Pilot plants

Scale-up, economics

Sulphur based thermochemical cycle: HycycleS

Materials

Prototypes

Modelling

Scale-up

Summary

SFERA Winter School Solar Fuels & Materials Page 36

Slide 3

1. Ferrite based thermochemical cycle

Slide 4

The HYDROSOL CONSORTIA

HYDROSOL

APTL (GR)

DLR (D)

Heliotech (DK)

Johnson Matthey (GB)

HYDROSOL-2

APTL (GR)

DLR (D)

STC (DK)

Johnson Matthey (GB)

CIEMAT (ES)

HYDROSOL-3D

APTL (GR)

DLR (D)

CIEMAT (ES)

Total (F)

Hygear (NL)

SFERA Winter School Solar Fuels & Materials Page 37

Slide 5

Thermochemical Cycle using Mixed Iron Oxides: Reaction Scheme

2. Step: Regeneration

1. Step: Water Splitting

H2O + MOred MOox + H2

MOox MOred + ½ O2

Net reaction: H2O H2 + ½ O2

Typical redox materials:

ZnFe2O4, NiZnFe2O4, MnFe2O4 CoFe2O4

Slide 6

H2

H2O

O

O

O

OH

HOH

HH

H

O H

HMOreduced MOoxidized

MOreduced MOoxidized

The HYDROSOL process concept

1200 °C

800-900 °C

SFERA Winter School Solar Fuels & Materials Page 38

Slide 7

The HYDROSOL Process

Basic Features

Use of solar radiation absorbing ceramic honeycomb structures

Synthesis of active water-splitting redox nanomaterials with non-conventional techniques

Fixing/coating of the redox materials on the channels of the honeycomb

Advantages

No circulation of (hot) solid reactants

Product separation straightforward

No movable components at high temperatures

Slide 8

Objectives of HYDROSOL-2

to design and build a solar Hydrogen pilot plant (100 kWth) based on thermo-chemical water-splitting, carried out on monolithic ceramic honeycombs coated with active redox materials

To set the stage for further scale-up of the HYDROSOL technology and its effective coupling with solar thermal concentration systems, in order to exploit and demonstrate all potential advantages

To develop and identify redox materials most suitable for this cycle

To develop and verify suitable process strategies, in particular control strategies

To develop a fully scalable receiver-reactor to carry out the reactions involved

SFERA Winter School Solar Fuels & Materials Page 39

Slide 9

Objective: Integration in a Solar Tower System

Solar tower

Heliostats

“MODULAR” DESIGNAny final size from the

same initial pieces

Slide 10

Materials development

and characterisation

SFERA Winter School Solar Fuels & Materials Page 40

Slide 11

Consideration of Thermodynamics

Phase analysis

Efficiency

Yield

Pre-SelectionPre-SelectionPre-Selection

Slide 12

Phase analysis (calculated with FACTsage)

Reduction of CoFe2O4

Spinel

CoO - Monoxide

FeO

- Mon

oxid

e

Fe2O3 - Monoxide

O2

Reduktionstemperatur [°C]

Sto

ffm

eng

e [m

ol]

1000 1100 1200 1300 1400 15000,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

0,80

0,90

1,00

SFERA Winter School Solar Fuels & Materials Page 41

Slide 13

Yield (calculated)

Simulation of mixed oxides type MFe2O4 (M=Co, Ni, Mn, Mg)

Oxidation Treg = 1500°CH

ydro

gen

yie

ld[m

ol

per

mo

l fe

rrit

e]

Slide 14

Ellingham-Diagram: Transition Metals

300 600 900 1200 1500 1800 2100600

500

400

300

200

100

0

100

200

G0=RT

lnp(O

2)[kJp

er0.5molO

2]

Basic reactions0.5C+0.5O

2>0.5CO

2

C+0.5O2>CO

CO+0.5O2>CO

2

H2+0.5O

2>H

2O

melting/sublimationMetaloxide reactions

3FeO+0.5O2>Fe

3O

4

2Fe3O

4+0.5O

2>3Fe

2O

3

0.5Hf+0.5O2>HfO

2

NiO+2FeO+0.5O2>NiFe

2O

4

Zn+0.5O2>ZnO

0.4Ta+0.5O2>0.2Ta

2O

5

3CoO+0.5O2>Co

3O

4

NbO+0.5O2>NbO

2

2NbO2+0.5O

2>Nb

2O

5

V2O

3+0.5O

2>2VO

2

2Mn3O

4+0.5O

2>3Mn

2O

3

3MnO+0.5O2>Mn

3O

4

T [°C]

1022

1018

1014

1010

106

102

102

106

p(O

2)[bar]

ca 6.0 N2

SFERA Winter School Solar Fuels & Materials Page 42

Slide 15

Ellingham-Diagram: Desired Material

300 600 900 1200 1500 1800 2100600

500

400

300

200

100

0

100

200

basic reactions0.5C+0.5O

2>0.5CO

2

C+0.5O2>CO

CO+0.5O2>CO

2

H2+0.5O

2>H

2O

melting/sublimationperfect materialCe

6O

11+0.5O

2>6CeO

2

~ CeO1.83

NiO+2FeO+0.5O2>NiFe

2O

4

G0=RT

lnp(O

2)[kJp

er0.5molO

2]

T [°C]

1022

1018

1014

1010

106

102

102

106

p(O

2)[bar]

ca 6.0 N2

Slide 16

Reaction Schemes employed for Mixed Iron Oxides synthesis

2k Fe + (1-k) Fe2O3 + x MnO + (1-x) ZnO + 1.5 z O2 (MnxZn1-x)Fe2O4

Solid phase self-propagating high-temperature synthesis (SPSHS)

Liquid phase self-propagating high-temperature synthesis (LPSHS/GC)

2Fe(NO3)3 + x Mn(NO3)2 + (1-x) Zn(NO3)2 + 3 C6O7H8 + 8 NH3 + 9.5 O2

(MnxZn1-x)Fe2O4 + 18 CO2 + 8 N2 + 24H2O

Aerosol spray pyrolysis synthesis (ASP)

2Fe(NO3)3 + x Mn(NO3)2 + (1-x) Zn(NO3)2 + (3 C6O7H8 + 8 NH3 ) + 9.5 O2

(MnxZn1-x)Fe2O4 + 18 CO2 + 8 N2 + 24H2O

Solid state synthesis (SSS)

Fe2O3 + x MnCO3 (Mn3O4) (NiO) + (1-x) ZnO (Mnx (Ni)x Zn1-x)Fe2O4 + x CO2

SFERA Winter School Solar Fuels & Materials Page 43

Slide 17

Materials characterization: specific surface area

SSS

1-2 m2/g

LPSHS/GC

20-40 m2/g

SPSHS

4-5 m2/g

ASP

80-120 m2/g

Slide 18

10 20 30 40 50 60 70 80

1100oC/5hrs

1000oC/5hrs

900oC/5hrs

800oC/5hrs

700oC/5hrs

+

++

o

++

****

**

o o

Diffraction angle (two theta)

Inte

nsity

(arb

itrar

y un

its)

oo

oo o o

o Mn0.5Zn0.5FeO from SHS

raw

o:(Mn,Zn)Fe2O4

: Fe2O3

*: ZnO+: FeO

Fe3O4as-synth. 700oC 800oC 900oC 1000oC 1100oC Fe2O3

Mn0.5Zn0.5FeO

Phase and color evolution during calcination in air

SFERA Winter School Solar Fuels & Materials Page 44

Slide 19

Continuous Hydrogen productionsmall monolith SiSiC coated with YSZ/ Mn-2Fe-O (SHS)

0,0

0,2

0,4

0,6

0,8

1,0

0 10000 20000 30000 40000Time (s)

H2

(% in

N2)

Tests with coated monoliths: Testing of Mn-Fe-O mixed oxide with respect to cyclic H2 production (800 oC)

Slide 20

700 800 9000

1

2

3

4

5

6

7

8

9

10

m

mol

es H

2 p

rodu

ced/

g o

f red

ox

mat

eria

l

Water splitting temperature (oC)

ASP SHS GC

ASP-synthesized materials exhibit the highest H2 yield, followed by the SHS- and GC-produced ones.

For a given synthesis route, there is no significant variation of the amount of H2 produced, within 700-900oC.

Stoichiometry:Zn-Fe oxide material

Hydrogen yield (experiment)

SFERA Winter School Solar Fuels & Materials Page 45

Slide 21

Kinetics of water splitting

Slide 22

Experimental Set-Up

N2

H2O(g)H2O(fl)

H2O+N2

H2+N2

H2O(fl)

Water Splitting

SFERA Winter School Solar Fuels & Materials Page 46

Slide 23

Experimental Set-Up

Slide 24

H2 production curve

Water vapour input

14:50 15:00 15:10 15:20 15:30 15:40 15:50

0

1

2

3

4

5

6

con

cen

tra

tion

c in

%

time of day % O2 % H2 % CO2

H2

peak H2 production

SFERA Winter School Solar Fuels & Materials Page 47

Slide 25

Reaction Model

Reaction Rate Controlling Steps:

1. Film diffusion

2. Internal diffusion

3. Chemical reaction

product layer

gas film

unreacted core

bulk gas

Shrinking Core Model

core surface

H2O

Unreacted solidPartly reacted solid

Slide 26

Shrinking Core Model

Shrinking Core Model derives different approaches for

Xsolid: conversion of solid phase

Xsolid = f(t)

film diffusion internal diffusion chemical reaction

1 solidt k X2 3

2 solid solidt k 1 3 1 X 2 1 X 1 3

3 solidt k 1 1 x

Literature: Levenspiel, O., Chemical Reaction Engineering, 3rd. Edition, New York, Wiley, 1999

SFERA Winter School Solar Fuels & Materials Page 48

Slide 27

Analysis of Water Splitting Step

Conversion vs. Time

Fit function2 3 1 3

1 solid 2 solid solid 3 solidt k X k 1 3 1 X 2 1 X k 1 1 x

0,0

0,1

0,2

0,3

0,4

0,5

0,6

0 400 800 1200 1600 2000

Conversion Curve Fit

time in s

conv

ersi

on fe

rrite

Xfe

r

T = 800 °C

T = 900 °C

T = 1000 °C

T = 1100 °C

T = 1190 °C

Slide 28

Analysis of Water Splitting Step

Results from Shrinking Core Model Curve Fit

Reaction is mainly limited by internal diffusion

Possible film diffusion limitation at about 1200 °C

TSplitting k1 k2 k3

800 0 6312974 0

900 0 800484 0

990 0 210547 0

1100 0 33721 0

1190 1308 7037 0

SFERA Winter School Solar Fuels & Materials Page 49

Slide 29

Milestones of Materials Development

Field evaluation of coated monoliths

0 5 10 15 20 25 30 35 400

2

4

6

8

10

12

14

16

18

5. day4. day3. day2. day

mdo

t,H

2 in

10

-5 g

/s

Time in h

1. day

50-cycles of solar water-splitting

Key milestone

Water-splittingon redox coated

honeycombs

Redoxmaterialcoated SiSiChoneycombs

SEM analysis for the investigation of the quality of

coating and the effect of solar water splitting

Hyd

roge

n Y

ield

Slide 30

Reactor concept and

reactor design

SFERA Winter School Solar Fuels & Materials Page 50

Slide 31

1200° C

1200° C

Reactor for continuous hydrogen production

Reactor with two modules

10 kW two-chamber system

Two different alternating processes:

• Production: 800°C, water steam, nitrogen, exothermic

• Regeneration: 1200°C, nitrogen, endothermic

Transient steps like

• Switching between half cycle

• Start-up / Shutdown

Closed system: quartz window

Four-way-valve

800° C

800° C

H2+N2

O2+N2

O2+N2

H2+N2

Slide 32

HYDROSOL:Continously operating reactor during exposure to sunlight

SFERA Winter School Solar Fuels & Materials Page 51

Slide 33

2004:First solar thermochemical

2 production

2008:Pilot reactor (100 kW)

2005:Continuous STC 2 production

Hydrosol technology scale-up

DLR solar furnace

PSA solar tower

Slide 34

Pilot plant installation

and testing

SFERA Winter School Solar Fuels & Materials Page 52

Slide 35

Scale-up: 100kW-pilot-plant

Slide 36

Process strategy for thermal cycling

distance from tower

Focal length of heliostats

Focus 1 (east): Groups 1, 2, 3, 4

Focus 2 (west): Groups 5, 6, 7, 8 x

Switch-over groups (east and west): 0, 9, 10, 11y

Reserve group (east and west): R

Tower

1112

1314

15

2223 24 25

26

21 27

3334 35 36

37

32 38

31 39

4344

4546

47

42 48

41 49

6364

6566

6762

68

6169

8384

8586

87

82

81

51

52

5354 55

56

57

58

71

72

7374 75

76

77

78

91

92

9394 95

96

97

98

B1

B2

B3 B4B5

B6

A1

A2

A3A4

A5

A6

A7

C2C3

C4 C5 C6 C7C8

C9

C1 CA

59 m

67 m

77 m

89 m

97 m

104 m

113 m

122 m

133 m

143 m

156 m

169 m

67 m

136 m

115 m

162 m

97 m

5

6

7

8

1

3

2

4

9

11

10

0

R

SFERA Winter School Solar Fuels & Materials Page 53

Slide 37

Experiments – Solar Flux

Flux Measurement at test operation FluxMaxboth Modules= 115kW/m2

Slide 38

Experiments: Thermal cycling

Slide 38

SFERA Winter School Solar Fuels & Materials Page 54

Slide 39

Parametric study – mass flow

Slide 40

Parametric study – heliostats

SFERA Winter School Solar Fuels & Materials Page 55

Slide 41

First Hydrogen Production

West- Module

East- Module

West- Module

East- Module Heating

Slide 42

Hydrogen production in experimental series in July 2009

0

1

2

3

4

5

6

7

8

9

10:1

4:2

5:00

10:2

3:3

5:20

10:3

2:4

4:07

10:4

1:5

2:96

10:5

1:0

2:50

11:0

0:1

1:62

11:0

9:2

0:68

11:1

8:2

9:71

11:2

7:3

9:00

11:3

6:4

8:32

11:4

6:0

5:43

11:5

6:0

1:18

12:0

5:5

4:21

12:1

5:3

9:75

12:2

5:3

4:45

12:3

5:2

5:87

12:4

5:1

6:01

12:5

5:0

9:93

13:0

5:2

7:85

13:1

5:3

8:89

13:2

5:4

9:78

13:3

6:2

5:34

13:4

6:3

9:26

13:5

7:0

8:35

14:0

7:4

4:28

14:1

7:4

5:50

14:2

8:1

3:50

14:3

8:4

3:34

14:4

8:3

8:73

14:5

9:0

9:28

15:0

9:4

8:46

15:2

0:1

5:14

15:3

0:5

4:76

15:4

1:3

4:09

15:5

2:1

1:10

16:0

2:5

0:15

16:1

3:2

9:14

16:2

3:5

9:71

16:3

4:3

8:90

16:4

5:1

3:87

16:5

4:5

6:40

c(H

2) [%

]

09:36 14:24 19:12

0

200

400

600

800

1000

1200

31-07-2008

Tem

pera

ture

[°C

]

Time [hh:mm]

Left Hand Side - Exhaust Right Hand Side - Exhaust

SFERA Winter School Solar Fuels & Materials Page 56

Slide 43

Hydrogen production on June 18th 2010

Slide 44

Hydrogen production on June 17th 2010

SFERA Winter School Solar Fuels & Materials Page 57

Slide 45

Hydrogen production on June 21st/22nd 2010

13 kg/h steam6.5 kg/h

Slide 46

Modelling of reactor and process

SFERA Winter School Solar Fuels & Materials Page 58

slide 47

Model of Solar Furnace Reactor

Monolith

monolith

slice of themonolith ring of the

slice

Absorber model

slide 48

Overall Model of Solar Furnace Reactor

Model incluces:Irradiation and conduction

among the individual absorberelements

Intrusion of solar irradiationinto the absorber channels

Solar power input: gaussian distribution

Irradiation losses throughthe reactor front window

Thermal losses through thehousing

SFERA Winter School Solar Fuels & Materials Page 59

slide 49

Hydrogen Production

H2 and O2 production

pro

du

ctio

n r

ate

[kg

/s]

0

5.0·10-6

1.0·10-5

1.5·10-5

2.0·10-5

2.5·10-5

3.0·10-5

3.5·10-5

time [s]0 2000 4000 6000 8000 10000 12000 14000

production rate H2 production rate O2 Tmax

tem

pera

ture

[°C

]

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

Peak hydrogen production decreases

slide 50

Ferrite Composition

Oxygen uptake capacity of ferrite

oxy

ge

n u

pta

ke c

ap

aci

ty [

mo

le O

2/g

ferr

ite]

0.0027

0.0028

0.0029

0.0030

0.0031

0.0032

0.0033

0.0034

0.0035

time [s]0 2000 4000 6000 8000 10000 12000 14000

oxygen uptake capacity, central front element oxygen uptake capacity, rear side element Tmax

tem

pera

ture

[°C

]

0

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

Low temperatures at the absorber rearside

poor regeneration

SFERA Winter School Solar Fuels & Materials Page 60

slide 51

Scale-up

slide 52

Flow sheet of HYDROSOL process

SPLT 3Q=-0

RECREGQ=28

N2T NK

M X2

H2OTNK

SPLT 1Q=-0

SPLT 2Q=7

RECSPLTQ=299

M X1

CHOKE1

COM PW=5643

COOLX1Q=-35

HEATX3Q=5

M X3

HEATX1Q=35

COOLX3Q=-5

COOL2Q=-8

COOL3Q=-8

HEATX5Q=17

MIXER

H20T REAT

CHOKE3

HEATX4Q=4

COOLX4Q=-4

CHOKE2

COOLX5Q=-17

800

6421

700

263

300

18

23

300

8

24

98

56

9

1100

1

8

1100

119

4

60

1

17

60

1

16

95

022

60

71

28

60

71

6

95

119

27

-180

119

14

-170

63 30

-170

56 29

317

89

2

98

56

26

265

119

13

136

119

35

357

100

71

33

100

71

38

325

71105

34

-120

119

12

150

8

39

60

71 20

H2O

O2

H2

N2

Deioni-sation

Puri fi ca tion (PSA)

1to 6bar

200 to 1 bar

1,5 to 1bar

99

56

31

60

1

32

1 to 0,3bar6 to 1.5 bar

287

18

41

100

119

42444

-170

56

45

300

26

1517

40

SFERA Winter School Solar Fuels & Materials Page 61

Slide 53

Economics

29%

18%13%

10%

30%

14%10%

8%

44%24%

Heliostats Tower Receiver Components Support systems

Hydrosol1 MW*)

Hydrosol50 MW

Hybrid-SulphurCycle

WaterElectrolysis

Total investment 1.46 1.07 2.03 0.18 €/kgH2

Operational costs 13.02 5.73 2.64 6.32 €/kgH2/year

By-product credits 23,277 3,484,955 3,140,705 2,069,475 €/a

Hydrogen production costs 15.38 6.75 5.35 5.80 €/kgH2

Aswan Seville

Slide 54

Hydrosol 3D

The principal objective of HYDROSOL-3D is the in-detail preparation of a plant for solar thermo-chemical hydrogen production from water via the HYDROSOL technology, in a 1 MW scale on a solar tower.HYDROSOL-3D focuses on the next step towards commercialization and involves all activities necessary to prepare the erection of a HYDROSOL-technology-based 1 MW solar demonstration plant.In this respect HYDROSOL-3D is concerned with the complete pre-design and design of the whole plant including the solar hydrogen reactor and all necessary upstream and downstream units needed to feed in the reactants and separate the products and the calculation of the necessary plant erection and hydrogen supply costs.

SFERA Winter School Solar Fuels & Materials Page 62

Slide 55

Process variation: synfuels

Slide 56

CO2 reduction using metal oxides

2-step synthesis of CO using multi-valent metal oxides

1. Step: Reduction

MOoxidiert MOreduziert + ½ O2

2. Step: Oxidation oder CO2 splitting

MOreduziert + CO2 MOoxidiert + CO

SFERA Winter School Solar Fuels & Materials Page 63

Slide 57

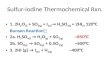

2. Sulphur Based Thermochemical Cycles

Slide 58

Sulphur-Iodine Process

WaterH2O

OxygenO2

Heat800–1200 °C

HydrogenH2

Examples of Sulphur based thermochemical cycles

Electrolysis (90°C)

HH22SOSO44 + H+ H2 2 SOSO22 + 2 H+ 2 H22O O

HH22HH22OO

OO22

HH22SOSO44

SOSO22

WWäärmerme

800800°°C C –– 12001200°°CC

HH22SOSO44 HH22O + SOO + SO33

SOSO33 SOSO22 + + ½½OO22

+ H+ H22OO

HH22SOSO44 + H+ H2 2 SOSO22 + 2 H+ 2 H22O O

HH22HH22OO

OO22

HH22SOSO44

SOSO22

800800°°C C –– 12001200°°CC

HH22SOSO44 HH22O + SOO + SO33

SOSO33 SOSO22 + + ½½OO22

+ H+ H22OO

HeatHeat

Electrolysis (90°C)

HH22SOSO44 + H+ H2 2 SOSO22 + 2 H+ 2 H22O O

HH22HH22OO

OO22

HH22SOSO44

SOSO22

WWäärmerme

800800°°C C –– 12001200°°CC

HH22SOSO44 HH22O + SOO + SO33

SOSO33 SOSO22 + + ½½OO22

+ H+ H22OO

HH22SOSO44 + H+ H2 2 SOSO22 + 2 H+ 2 H22O O

HH22HH22OO

OO22

HH22SOSO44

SOSO22

800800°°C C –– 12001200°°CC

HH22SOSO44 HH22O + SOO + SO33

SOSO33 SOSO22 + + ½½OO22

+ H+ H22OO

HeatHeat

Hybrid Sulphur Cycle

SFERA Winter School Solar Fuels & Materials Page 64

Slide 59

Project Overview: HycycleS

Deutsches Zentrum für Luft- und Raumfahrt e.V. / DLR

Commissariat à l’Energie Atomique

Aerosol and Particle Technology Laboratory / CERTH-CPERI

EC - Joint Research Center

Ente per le Nuove tecnologie, l'Energia e l'Ambiente / ENEA

Empresarios Agrupados

ETH Zürich

Boostec Industries

The University of Sheffield

The Consortium

Deutsches Zentrum für Luft- und Raumfahrt e.V. / DLR

Commissariat à l’Energie Atomique

Aerosol and Particle Technology Laboratory / CERTH-CPERI

EC - Joint Research Center

Ente per le Nuove tecnologie, l'Energia e l'Ambiente / ENEA

Empresarios Agrupados

ETH Zürich

Boostec Industries

The University of Sheffield

The Consortium Main topics:Suitability of construction and catalyst materials for H2SO4decomposition section

Material and design of H2SO4 decomposer (as heat exchanger)

Material and design of H2SO4 decomposer (as solar receiver-reactor)

Materials and design of SO2/O2 separator(membranes for enhancingthe performance of SO3

decomposition)

HycycleS - Materials and components for Hydrogen production by sulphur based thermochemical cyclesEU FP7 - ENERGY Duration: January 2008 – March 2011

Slide 60

Solar reactor development, testing and simulation

SFERA Winter School Solar Fuels & Materials Page 65

Slide 61

Objective

Development of a solar receiver-reactor (multi-chamber concept)Evaporation and decomposition of sulphuric acidVolumetric receiver-reactor concept

Testing in DLR solar furnaceVariation of operating conditions and configurationAnalysis of different catalyst systems

DLR solar furnaceHYTHEC receiver-reactor

Slide 62

H2SO4 decomposition in 2 steps

1. Evaporation of liquid sulphuric acid (400°C)

SiSiC foam

SiSiC honeycomb

Absorbers:

2. Decomposition (reduction) of sulphurtrioxide (850°C)

H2SO4 (aq) H2SO4 (g) + H2O (g)

SFERA Winter School Solar Fuels & Materials Page 66

Slide 63

Procedure of technology development

1. Preliminary design of a multi-chamber concept

2. numerical analysis: FEM, Dymola, CT and continuum model

3. Finalization of the design

4. Construction and assembling of the reactor

5. Initial operation followed by first testing series

6. Optimisation of the set-up followed by second testing series

7. Further optimisation and testing (if necessary)

Slide 64

Design of multi-chamber solar reactor

Front view ofevaporator and decomposer

Rear view

H2SO4

SO3 + H2O

SO2 + O2 + H2OSolar radiation(focus 2)

Solar radiation(focus 1) honeycomb

foam

SFERA Winter School Solar Fuels & Materials Page 67

Slide 65

HycycleS solar reactor

H2SO4 SO3 + H2O

SO3 SO2 + ½ O2

Construction materials

Solar absorbers

SiSiC foam

SiSiC honeycomb

Piping

High-alloyed steel

Catalyst materials

Coated on SiSiC honeycomb

850°C

400°C

Slide 66

Assembling of the solar reactor

SFERA Winter School Solar Fuels & Materials Page 68

Slide 67

Solar furnace of DLR in Cologne

57 m2 heliostat159 concentrator mirrors

experiment

22 kW max. power

Slide 68

Power regulation of the two chambers

Segment shutter with 14 lamellae on each side

SFERA Winter School Solar Fuels & Materials Page 69

Slide 69

Receiver-Reactor during operation

Slide 70

Testing and qualification of the receiver-reactor

09:30 10:00 10:30 11:00 11:30 12:00 12:30

0

200

400

600

800

foa

m te

mpe

ratu

re [°

C]

time [hh:mm]

middle right bottom left outlet gas

0

2

4

6

8

10

vol

ume

rate

H2S

O4 [m

l/min

]

11:15 11:30 11:45 12:00 12:150

20

40

60

80

100 volume rate decomposition rate

deco

mpo

sitio

n r

ate

[%]

time [hh:mm]

0

1

2

3

4

5 v

olum

e ra

te H

2S

O4 [m

l/min

]

Con

vers

ion

[%]

Temperature of the evaporator Performance of the SO3 decomposer

SFERA Winter School Solar Fuels & Materials Page 70

Slide 71

Conversion of SO3: experiment and equilibrium

2

3

3

SO ;ausSO

SO ;ein

VU

V

Slide 72

Reactor efficiencies

1 2 3 4 5 6 70

20

40

60

net,evap (SiSiC for decomp.)

net,evap

(Fe2O

3 for decomp.)

[%

]

VH2SO4

[ml/min]1 2 3 4 5 6 7

0

5

10

15

20

25

net,decomp (SiSiC for decomp.)

net,decomp

(Fe2O

3 for decomp.)

[%]

VH2SO4

[ml/min]

evaporator decomposer

SFERA Winter School Solar Fuels & Materials Page 71

Slide 73

Reactor efficiencies

0 1 2 3 4 5 6 70

10

20

30

40

50

reactor

net

[%]

VH2SO4

[ml/min]

Total reactor

Slide 74

Energy Losses

Net power evaporator

17%

Net power decomposer

8%

Sensible heat16%

Loss evaporator-window

7%

Loss decompser-

window31%

Loss housing12%

Rest9%

15 %net,decomp

39 %net,evap

82 %Conversion

852 °CThc,mean

6 ml/minVH2SO4

Fe2O3Catalyst

1141 WPS,decomp

870 WPS,evap

15 %net,decomp

39 %net,evap

82 %Conversion

852 °CThc,mean

6 ml/minVH2SO4

Fe2O3Catalyst

1141 WPS,decomp

870 WPS,evap

SFERA Winter School Solar Fuels & Materials Page 72

Slide 75

System Model of the Decomposer

Slide 76

Discretisation of the Absorber

7 Ring elements x10 Slices

70 elements

20 cellsper elementfor chemical reactionmodelling

SFERA Winter School Solar Fuels & Materials Page 73

Slide 77

, ,cond a radialQ

, ,cond b radialQ, ,rad b radialQ

, ,rad a radialQ

convectionQ , ,cond d axialQ, ,cond c axialQ

Symmetry axis of absorber

solarQ

Heat balance of solid volume elements

Heat balance of gas volume elements

Kinetic model of SO3 reduction

3

3

2 2

2 2

[ ] , [ 1]

, [ 1] , [ 1]

SO

SO O

n

i SO out i gas

n n

back SO out i gas O out i gas

v k x c

k x c x c

reaction0 in in out out convectionm h m h Q Q

, , , , , ,

, , , , , ,

0 p cond a radial cond b radial cond c axial

cons d axial rad a radial rad b radial solar convection

Tm c Q Q Q

t

Q Q Q Q Q

0

10

20

30

40

50

60

70

80

0 2 4 6 8 10 12 14 16 18 20

Total Volume Flow in m3/h

Re

act

or

Effi

cie

ncy

in %

Simulation

Experiment

Simulation of the SO3 Decomposer

Slide 78

Modelling of Radiation

0

100

200

300

400

500

600

700

800

900

-0,125 -0,075 -0,025 0,025 0,075 0,125

Radius in m

So

lar

Flu

x D

en

sit

y in

kW

/m2

Vertical Cut

Horizontal Cut

Average

Approx. Gauss

0,001

0,01

0,1

1

0 20 40 60 80 100 120 140

Absorber Depth in mm

Fra

cti

on

of

So

lar

Po

we

r (l

og

ari

thm

ic)

, , ,TR TR conus TR window TR ambienceQ Q Q Q

, 12

4 4

GrenzTR ambient Absorber ambient

S Absorber Absorber ambient

Q a

C A T T

Heat losses: Thermal radiation

Thermal radiation through quartz window

SFERA Winter School Solar Fuels & Materials Page 74

Slide 79

Validation: conversion and reactor efficiency

0

5

10

15

20

25

30

35

40

45

0 1 2 3 4 5 6

Total Volume Flow in Nm3/h

Re

ac

tor

Eff

icie

nc

y in

%

Simulation

Experiment40

50

60

70

80

90

100

900 950 1000 1050 1100 1150 1200 1250

Operating Temperature in °C

Co

nv

ers

ion

in %

Experiment

Simulation

2 4 3,reactor

H SO dissociation SO decomposition sensible heatnet reactor

solar solar

Q Q QQ

P P

Slide 80

Efficiency of the SO3-decomposition

Tinlet = 450 °C, w = 96 %, lAbsorber = 0.15 m

0

10

20

30

40

50

60

0 50 100 150 200 250 300 350 400 450 500

Solar Flux Density in kW/m2

Eff

icie

nc

y in

%

Conversion = 50 %

Conversion = 80 %

Tinlet = 450 °C, w = 96 %, lAbsorber = 0.15 m

0

5

10

15

20

25

30

0 1 2 3 4 5 6 7 8 9

Mass Flow Rate in g/s

Eff

icie

nc

y in

%

61 kW/m²,1000 W

123 kW/m², 2000 W

307 kW/m², 5000 W

491 kW/m², 8000 W

two different fixed minimum conversions

SFERA Winter School Solar Fuels & Materials Page 75

Slide 81

Case studies: Gradient of Solar Flux

Tinlet = 350 °C, w = 96 %, lAbsorber = 0.15 m, Mass Flow = 2 g/s

600

700

800

900

1000

1100

1200

0 1 2 3 4 5 6 7

Radius in cmT

em

pe

ratu

re in

°C

Case 1

Case 2

Case 3

Case 1: The prototype test reactor as used in the solar furnace(Gaussian flux profile)

Case 2: Like case 1 but with an ideal homogeneous distribution of the solar flux density.

Case 3: Adiabatic absorber element of a large receiver-reactoron a solar tower.

Slide 82

Higher Conversion in a Large Scale Receiver-Reactor

T in = 350 °C, w = 96 %, Mass Flow = 2 g/s, l Absorber = 0.15 m

0

10

20

30

40

50

60

70

80

90

100

700 800 900 1000 1100 1200 1300 1400 1500 1600

Operating Temperature in °C

Co

nve

rsio

n in

%

Test Reactor

Absorber Module (Solar Tower)

SFERA Winter School Solar Fuels & Materials Page 76

Slide 83

Case Studies: Efficiency

Tinlet = 350 °C, w = 96 %, lAbsorber = 0.15 m, Mass Flow = 2 g/s

30

35

40

45

50

55

60

65

70

75

10 20 30 40 50 60 70 80 90 100

Conversion in %

Eff

icie

nc

y in

%

Case 1

Case 2

Case 3

Tinlet = 350 °C, w = 96 %, lAbsorber = 0.15 m, Mass Flow = 2 g/s

10

12

14

16

18

20

22

24

26

28

600 700 800 900 1000 1100 1200 1300 1400 1500 1600

Operating Temperature in °C

Eff

icie

nc

y in

%

Case 1

Case 2

Case 3

Slide 84

Model of the evaporator (ETH)

SFERA Winter School Solar Fuels & Materials Page 77

Slide 85

Foam characterization by CT and digitalisation

SiSiC sample (uncoated, 20ppi dnom = 1.27mm):

photo micronCT 3D rendered

5mm 5mm

submicronCT

0.1mm

no internal porosity

Slide 86

Characterisation of the foam

Geometrical Characterisation

Radiative Characterisation

Convective Characterisation

Heat Transfer Characterisation

Mass Transfer Characterisation

SFERA Winter School Solar Fuels & Materials Page 78

Slide 87

Continuum model based on Energy conservation, solid and fluid

Mass- & Species conservation, fluid

Momentum conservation, fluid

will be able to predict: optimum and maximal mass flow of acid

Variations in:position of acid inlet

porosity and nominal diameter of foam

solar input

…

lead to a deeper understanding of the process and its optimization for maximum solar-to-chemical energy conversion efficiency

Development of a continuum model

Slide 88

Validation of model using experimental data from solar furnace campaigns

SFERA Winter School Solar Fuels & Materials Page 79

Slide 89

Temperature maps and flow regimes of the foam vaporiser

Slide 90

Influence of process parameters on reactor’s energetic and chemical efficiency and mean outlet temperature

SFERA Winter School Solar Fuels & Materials Page 80

Slide 91

Scale-up

Slide 92

Implementation in to a Solar Tower

SFERA Winter School Solar Fuels & Materials Page 81

Slide 93

Summary

Volumetric Receiver-Reactors well suited for thermochemical hydrogenproduction

Observed yield close to therodynamic limits

Efficiency of the reactor can still be drastically improved (Slow kinetics, high re-radiation losses)

Materials: Optimum solutions by far not yet reached for redox materials, catalysts, construction materials

A bunch of capable reactor and process models developed and nowavaiable for a broad variety of purposes and applications

The more one gets into the details of process design, the higher are theproduction cost

Slide 94

Acknowledgements

The authors acknowledge the co-funding of the European Commission for the projects HYTHEC, HycycleS, HYDROSOL, HYDROSOL-2 and HYDROSOL-3D.

Many thanks for your attention!

SFERA Winter School Solar Fuels & Materials Page 82

Related Documents