Solidworks Design Project Brendan O’Leary Darren Gabos Fender ™ Stratocaster ® Advanced CAD in Mechanical Engineering Summer 2015, Session H6 Professor Xing Liu

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Solidworks Design Project

Solidworks Design ProjectBrendan OLeary Darren Gabos Fender Stratocaster

Advanced CAD in Mechanical EngineeringSummer 2015, Session H6Professor Xing Liu

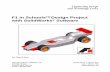

History of the StratOur proposed model for our Final Project will be Solidworks assembly of some of the main parts of an electric guitar- namely, a Fender Stratocaster. This guitar is one of the most iconic instruments of all time, since it is also one of the longest-produced guitars, first entering production in 1954. This guitar was designed originally on another Fender Guitar, the Telecaster. The 'Tele' was designed by electrical engineer Leo Fender, and was a very geometrically pleasing as it had predictable curves, and straight corners and edges. This however was unpleasant to guitarists, and these edges were uncomfortable rubbing against one's body for extended periods of time. As all engineers attempt to make their deigns both technically sound, Leo also desired to make his guitars ergonomically compliant- so, after talking to local musicians about what improvements they'd like to see on an upcoming model, their ideas eventually gave birth to the Stratocaster.

PreparationTeam of Two members

Work on parts every night after work, class

Team Leader Delegates PartsConstant communication kept between members of group to keep both up-to-date on the current status of drawings and reportsBoth team members shared equal amounts of parts, while jobs such as rendering, animation, simulation, and writing were chosen by members based on subject strength

Choosing the StratocasterThe Strat was chosen because it would be a wide-encompassing test of our Solidworks modeling skillsMixes Mechanical and Electrical components with artistic and ergonomic designFun, yet challenging design

This particular Guitar model chosen for its legendary history, being used by some of the greatest guitars of all time

Team Leaders Guitar of choice

Drawing Control & Naming ConventionTo keep part & assembly files easy to access, good drawing control was adoptedDropBox used to mitigate sharing drawings Logical naming conventions allow a designer to find components fast and easily: saves timeSame goes for folder structure: File types group together, and then model types

Part CompatibilityThe Strat has gone through many design iterations in its 50+ years of production, leading to a plethora of factory and 3rd party partsWe chose engineering drawings that had the best and most clearly marked dimensionsTherefore, some parts had inconsistent dimensions that were reference in other parts (ex. Fastener holes)As design process progressed, back-checking older parts was required to ensure a assembly that would have compatible parts mating to one another

Difficult Parts: Body

Difficult Parts: BodyThe body was a difficult part to model due to its numerous curves and contours that were either undefined by engineering drawings, or dependent on which model Strat we were modeling.

We used the help of a sketch picture to sketch over an image of the body, and extrude from there. The routing was done in a similar fashion, but all these cuts and extrudes would have to later be edited to fit parts.

Body contours were made using reference geometry, sketches, and cuts/extrudes, and fillets gave the final product its ergonomic, smooth finish.

Material: Maple (actually alder in production)

Difficult Parts: Pickguard

Difficult Parts: PickguardThe pickguard was difficult to model for the same reasons as the body. Many different curves defined the shape of the pickguard, and all had unique dimensions. The routing for the pickup holes was much easier, however.

Material: Plastic with appearances

Difficult Parts: Headstock

Difficult Parts: HeadstockThe headstock also hosted many difficult curves and radii. However, the engineering drawing was much easier to follow, and led to a accurate sketch which rendered a very realistic model

Material: Maple

Summary of All Parts Functions + Photo

Tuning MachinesSingle- Coil Pickups 5 way selector SwitchVolume knobs TremoloWhammy BarNutStringsScrews

Summary of Parts: Tuning Machine

Summary of Parts: Tuning MachineTuning machine is a geared mechanism that turns shaft when perpendicular knob is turned by hand to tune the strings

Features used to model:Simple 2D SketchingExtrudingCut-ExtrudingReference Geometry Material finish: Polished Gold

Summary of Parts: Single-Coil Pickups

Summary of Parts: Single-Coil Pickups Single Coil- Pickup: a wound copper solenoid that generates an induced magnetic field from a supplied current, and the changing magnetic field of moving ferromagnetic strings causes a response in the current which is projected as sound by way of an amplifier

Methods used to model:Simple 2D SketchingExtrudingCut-ExtrudingReference Geometry Material Finish: Low Gloss Plastic and Cast Iron

Summary of Parts: 5 Way Selector Switch

Summary of Parts: 5 Way Selector Switch5 Way selector switches between a combination of the three single coil pickups

Methods used to model:Simple 2D SketchingExtrudingRevolveReference Geometry LoftMaterial Finish: Low Gloss Plastic and Silver

Summary of Parts: Volume Knobs

Summary of Parts: Volume KnobsVolume and Tone knobs simply adjust the guitars controls

Methods used to model:Simple 2D SketchingExtrudingCut-ExtrudingReference Geometry Circular Sketch PatternMaterial Finish: Low Gloss Plastic

Summary of Parts: Tremolo Block

Summary of Parts: Tremolo Block

Tremolo block is a mass used to counter the spring forces of the two sides of the guitar to change pitch (whammy bar component)

Features used to model:Simple 2D SketchingExtrudingCut-ExtrudingReference Geometry Material Finish: Cast Iron and Polished Gold

Summary of Parts: Tremolo Bar

Summary of Parts: Tremolo Bar

Tremolo Bar, also known as the whammy bar, is a moment lever used to move the tremolo block out of equilibrium and either raise or lower the pitch of the played notes

Features used to model:Simple 2D SketchingExtrudingLoftRevolveReference Geometry Material Finish: Polished Gold and Low gloss plastic

Summary of Parts: Nut

Summary of Parts: Nut

The Nut is a small grooved piece of plastic or bone used to separate the strings of the guitar at the point where the headstock meets the neck

Features used to model:Simple 2D SketchingExtrudingReference Geometry Cut Extrude

Material Finish: Low gloss plastic

Summary of Parts: Strings

Summary of Parts: StringsThe guitar strings are 6 individual wires with different diameters that hold different tunings on the guitarFeatures used to model:Simple 2D SketchingExtrudingReference Geometry Sweep Cut (Twist along path)

Material: Steel

Adding Decal

Solidworks appearances functions used to import decal onto surface of headstock, and aligned.

White background not removed

Design Production Feasibility3D PrintingSome parts did not have dimensions on certain features, leaving us to guess

Choosing proper dimensions for strong but efficient part

Testing to see if design is able to be produced- Volume knob printed with 3D printer

Shows need for good design QC

Solidworks AnimationAssembly of Strat modeled with both exploded and collapsed views

Useful for demonstration of assembly techniques and logistics

Exploded view included with draw diagram

Animation: Explode Video

Animation: Collapse Video

Finite Element Analysis: Guitar Neck WarpingGuitar Necks are constantly being subjected to forces/moments from both a statically applied tension, and a random increased application of instantaneous and/or periodic tensions (due to playing and bending strings, increasing tension) that will deform the neck over time

Values for tension forces found using online data

Custom Solidworks Material made for Guitar neck Maple wood typeProperties found in Mechanical Properties texts

The Strat is designed to counter this deformation

Examples of Neck Deformation

ResultsError using actual neck: interference of curves; not solved

Dumb neck was created with a similar shape and used same material to continue simulation

Results

Results

With additional time.More complex features could be modeled (Neck, Body Contours)Body Routing more realisticRoute electronics/wiringWork to fix interference problem with neck simulationMake sure every part is defined fully so no interference problemsAdd strings to assembly

SummaryThis was a very fun project to work on. The parts were all unique and interesting to model, however frustrating some of them turned out to be. Working as a team was beneficial, as many ideas and skillsets could utilized for a better final product. The push for trying out more complicated Solidworks features not covered in class also added value to the course.

Related Documents