So you thought they were clean enough?... Harpreet Kaur

So you thought they were clean enough?... Harpreet Kaur.

Dec 22, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

So you thought they were clean enough?...

Harpreet Kaur

Introduction

The extensive use of cytotoxic drugs in the treatment of cancer patients represents a health risk for all staff involved in the preparation and handling of such drugs.

This qualifies as an occupational health hazard and the two groups with the highest levels of exposure are pharmacists who dispense these drugs and nursing staff who administer them [1]. Equally other staff involved in their compounding, as well as logistical and training personnel are likely to be exposed.

Introduction

According to the ISOPP Standards of Practice [7], manufacturers are obliged to provide cytotoxics in containers guaranteed to be free from contamination. Further, manufacturers should be able to provide certification that the vials and primary packaging are not contaminated with cytotoxics.

While there are no thresholds on the permissible levels of contamination on the surface of vials and primary packaging [1], the ISOPP guidelines recommend that the purchase of such drugs should preferentially be from manufacturers who can verify the absence of such contamination [7].

Background: So why the concern? NIOSH Definition of Hazardous Drugs:- Carcinogenicity- Teratogenicity or other developmental toxicity- Reproductive toxicity- Organ toxicity at low doses- Genotoxicity- Structure and toxicity that mimic existing hazardous drugs

(NIOSH, 2004)

Although increased incidence of cancers for occupationally exposed groups has been investigated with varying results, a formal risk assessment of occupationally exposed pharmacy workers by Sessink et al. [8] estimated that cyclophosphamide causes an additional 1.4 to 10 cases of cancer per million workers per year [2].

Background: Contamination of vials a real risk

Several studies [2,3,4,5] have shown that the cytotoxic drug vial itself can be a source of such exposure as residues of the drug may remain on the outer surface of the vial during the filling process during manufacture [6].

Favier et al.: External Contamination of Vials-Vials of 5-FU, Etoposide, Ifosfamide, Cyclophosphamide, Doxorubicin, Docetaxel-100% had contamination on outer surfaces-Contamination/vial ranged 0.5-2500ng-Differences between manufacturers

(Favier et al: J Oncol Pharm Pract (2003); 9:15-20)

Background

Since the 1970s there have been worldwide attempts to prevent exposure of healthcare workers

Measures include [1]:

-centralisation of cytotoxic drug preparation in hospital pharmacies

- provision of equipment and clothing for personal protection

-development of specific guidelines and protective measures

-training development for safe handling of cytotoxic drugs

-establishment of continuous monitoring of workers’ health and safety to ensure that correct handling, treatment, storage, and disposal procedures are being followed

Background: So how should vials be cleaned?

Decontamination may be defined as cleaning or deactivating.

Deactivating a hazardous substance is preferred but no single process has been found to deactivate all currently available hazardous drugs.

The MSDSes for many hazardous drugs recommend sodium hypochlorite solution as an appropriate deactivating agent [2].

Question: So what other deactivating agents may be used?

Cleaning Effectiveness: No. Wipes to Remove Drug (<LOD)

Test detergent

5-FU (WFI)

5-FU (N/S)

CP (WFI)

CP (N/S)

DOX (WFI)

DOX (N/S)

WFI 1 3 1 1 1 1

Criti-Klenz 1 1 1 1 2 2

CIP 150 1 1 1 1 3 3

CIP 100 1 1 1 1 2 2

Renu-Klenz

1 1 1 1 1 1

NpH-Klenz 1 1 1 1 1 1

Cage-Klenz

1 1 1 1 1 1

CIP 220 1 1 1 1 1 1

CIP 200 1 1 1 1 1 1

IMS 1 1 1 1 1 1

Hazardous Medicines: Current Issue and Future Challenges (Graham Sewell, Professor of Clinical Pharmacy, Kingston University).

Cleaning Effectiveness of other agents

Criti-Klenz- Alkaline liquid detergent CIP 150, 100- Phosphate-free alkaline detergents Renu-Klenz, NpH Klenz- pH neutral detergents Cage-Klenz- Acid-based detergent CIP 220, 200- Hydroxyacetic acid based detergents IMS- 70% alcohol

-Water has relatively good efficacy

-However, the most effective are the neutral, acid-based and

hydroxyacetic acid-based detergents, and 70% alcohol.

Purpose of this study?

Exposure to cytotoxic drugs= Health HazardContamination of vials = Real RiskSo what is our risk of exposure to these drugs?Ideal method would be to swab outside of vials

and determine the level of contamination- not feasible

So we set out to obtain information from the various manufacturers on the procedures that they had in place…

Aims of the study

1. To identify all the injectable cytotoxic drugs used in ROHP and their alternative brands licensed for use in the Irish market, and the manufacturers.2. To compare drug brands and their manufacturing companies on their outer vial decontamination procedures on the basis of the information provided.

3. To rate the manufacturing companies on their decontamination procedures using an in-house rating system.

Methods

1. All the injectable cytotoxic drugs used in ROHP and their manufacturers were identified and data entered into a Microsoft Excel® spreadsheet.

2. The generic drug name was used to search for other manufacturers in Ireland of the same drug on the Irish Medicines Board website. This was used to establish the various brands available of the drugs used in ROHP, and their manufacturers.

3. Manufacturing companies were then contacted via email/ telephone, and information on outer vial decontamination procedures of the drugs of interest requested. Reminders were sent, where necessary.

4. The information provided was then evaluated

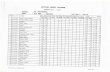

Results: A comparison of the brands of injectable cytotoxics and their manufacturers

Total number of injectable cytotoxics used in ROHP= 23; current manufacturers= 15

Total number of alternative brands for 23 drugs= 39; new manufacturers identified = 2

76.5% of the total number of manufacturers had a decontamination procedure in place

61.5% of these manufacturers had validated the procedure

The identification of a LOD was seen to be the least complied with measure and was performed by only 2 manufacturers for a total of 5 out of the 62 brands of interest

Therefore, despite having a validated procedure in place, most manufacturers could not guarantee that their vials were free from contamination (and below a pre-determined LOD)

Criterion Drug brands (n=62)

Manufacturers

(n=17)

Decontamination

procedure

57 13

Procedure validated

41 8

Physical barrier on

vial

(e.g. Oncotain®)

30 5

Limit of detection

5 2

Table 1. In-house criterion as applied to drug brands and their manufacturers

Results: A comparison of the brands of injectable cytotoxics and their manufacturers

Figure 1. Overview of external vial decontamination

•The decontamination procedure common to all manufacturers, who observed such a procedure, was the rinsing of the outside of the vials with purified water followed by their blow-drying with compressed air (Water has been shown to be an effective agent- Slide 9).

•HPLC was the validation procedure of choice

•Some manufacturers also used spiked vials in worst case scenarios to further evaluate their decontamination procedures

0

10

20

30

40

50

60

Dec

onta

min

atio

npr

oced

ure

inpl

ace

Dec

onta

min

atio

npr

oced

ure

valid

ated

Phy

sica

l bar

rier

on v

ial

Lim

it of

dete

ctio

nid

entif

ied

Nu

mb

er Drug brands (n=62)

Companies (n=17)

Results: In-house rating system as applied to manufacturers

Rating Decontt pro Pro validated

Phy barrier on vial

Limit of detection

*1 No No No No

2 Yes No No No

3 Yes No Yes No

4 Yes Yes No No

5 Yes Yes Yes No

6 Yes Yes No Yes

7 Yes Yes Yes Yes

Table 2: Criteria used in rating manufacturers

*Companies that did not provide the requested information were also placed in this category.

Results: In-house rating system as applied to manufacturers The order of preference employed in the rating system : Decontamination

pro> Pro validated >Limit of detection > Physical barrier on vial ‘Physical barrier on vial’ was placed last in the order of preference because

in the information provided by manufacturers there was nothing to suggest that this was done in surroundings distinct from the manufacturing area. Consequently, there may be contamination present on the outside of the barrier itself.

0

1

2

3

4

5

1 2 3 4 5 6 7

Rating

Co

mp

an

ies

Figure 1. Manufacturers’ performance as per the rating system

Results: So how did the manufacturers compare?

Rating level Nos. Names

1 4 Schering Plough, Asta Medica, Genzyme, Celgene

2 2 Medac, Pfizer

3 3 Teva, Pharmachemie BV, Eli Lilly

4 4 Baxter, Ebewe, Fresenius Kabi, GSK

5 2 Hospira, Actavis

6 2 Sanofi Aventis, Pierre Fabre

7 1 Accord

Conclusions Several studies have shown that external vial

contamination is a cause for concern for healthcare staff involved both directly and indirectly with cytotoxic drugs.

The results from this study suggest that the majority of manufacturers (76.5%) had a procedure in place to ensure that their cytotoxic drug vials were free from contamination and 61.5% of these manufacturers had their procedure validated. However, none of the manufacturers were able to meet all the criteria of our study.

38.9% of manufacturers were not able to provide any form of certification to guarantee that the vials underwent decontamination procedures before they left the manufacturing site.

Conclusions

The trends of compliance with our in-house criteria were proportional across the various drug brands and their manufacturers, with the specification of a limit of detection being the least complied with requirement suggesting the lack of quantification of any possible contamination. This implies that most manufacturers cannot guarantee absence of contamination.

While internationally recognised guidelines such as ISOPP provide the necessary framework, there is a need for strict legislative measures that ensure that all vials of cytotoxic drugs are free from external vial contamination before leaving the manufacturing site, and that manufacturers demonstrate full compliance with such a requirement.

References1. Preventing occupational exposures to cytotoxic drugs in hospital

pharmacies. EJHP Practice 2010/3; 16: 26-292. Sessink PJM, Boer KA, Scheefhals APH, et al. Occupational exposure to

antineoplastic agents at several departments in a hospital: Environmental contamination and excretion of cyclophosphamide and ifosamide in urine of exposed workers. Int Arch Occup Envron Health. 1992; 64: 105-12

3. Kiffmeyer TK, Ing KG, Schoppe G. External contamination of cytotoxic drug packing: Safe handling and cleaning procedures. J Onc Pharm Practice. 2000; 6: 13.

4. Connor TH, Sessink PJM, Harrison BR, et al. External contamination on chemotherapy drug vials: defining the problem and evaluation of new cleaning techniques. Am J Health Syst Pharm 2005; 62: 475-84

5. Favier B, Gilles L, Ardiet C, et al. External contamination of vials containing cytotoxic agents supplied by pharmaceutical manufacturers. J Oncol Pharm Pract 2003; 9: 15-20

6. ASHP Guidelines on Handling Hazardous Drugs, November 2005 7. ISOPP Standards of Practice: Safe Handling of cytotoxics. J Oncol

Pharm Pract 2007(supplement); 13: 1-818. Sessink PJM, Kroese ED, van Kranen HJ, et al. Cancer risk assesssment

for health care workers occupationally exposed to cyclophosphamide. Int Arch Occup Environ Health. 1995; 67: 317-23.

Related Documents