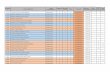

Chapter 2 SLPA Industrial Training Report Department of Electrical Engineering Page 27 University of Moratuwa 2.13 Electrical Field II 2.13.1 Introduction For the first week of my schedule in Ports Authority I was appointed to the Electrical Field II. This section stands for handling the electrical wiring systems of port¶s buildings, yards and streets. Planning, designing, installations and maintenance of the wiring systems are carried out by this section. In addition to that planning the illumination systems of the port¶s buildings and procurement of new accessories for wiring also come under the duties of this section. This section is supervised under the Electrical Engineer Mrs.H.B.A.Subhashini and there is a Work Superintend under her to handle the daily duties. 2.13.2 Domestic Wiring System When I was there I learned the domestic wiring system and I was able to went to a newly built apartment and study its wiring system. And also I learned how to measure the current flowing through a wire using Clipon Meter. A simple block diagram of a single phase domestic wiring system is given below. M C B M C B M C B F R L Neutral Bar RCCB 4 2 3 1 L DP-MCB 4 2 3 1 L N N N Earthing Bar Regulator 1 mm² 16A 6A 2.5 mm² Figure 2.10 BLOCK DIAGRAM OF A SINGLE PHASE DOMESTIC WIRING

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 1/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 27

University of Moratuwa

2.13 Electrical Field II

2.13.1 Introduction

For the first week of my schedule in Ports Authority I was appointed to the Electrical Field II.

This section stands for handling the electrical wiring systems of port¶s buildings, yards and

streets. Planning, designing, installations and maintenance of the wiring systems are carried out

by this section. In addition to that planning the illumination systems of the port¶s buildings and

procurement of new accessories for wiring also come under the duties of this section. This

section is supervised under the Electrical Engineer Mrs.H.B.A.Subhashini and there is a Work

Superintend under her to handle the daily duties.

2.13.2 Domestic Wiring System

When I was there I learned the domestic wiring system and I was able to went to a newly built

apartment and study its wiring system. And also I learned how to measure the current flowing

through a wire using Clipon Meter. A simple block diagram of a single phase domestic wiring

system is given below.

M

C

B

M

C

B

M

C

B

F R

L

Neutral Bar

RCCB

42

31

L

DP-MCB

42

31

L

N

N

N

Earthing Bar

Regulator

1 mm²

16A6A

2.5 mm²

Figure 2.10 BLOCK DIAGRAM OF A SINGLE PHASE DOMESTIC WIRING

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 2/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 28

University of Moratuwa

2.13.3 Circuit Breakers

During that week I was able to learn about the different types of circuit breakers which are used

in domestic wiring systems. A circuit breaker is an automatically-operated electrical switch

designed to protect electrical circuits from damage caused by overload or short circuit. Its basic

function is to detect a fault condition and, by interrupting continuity, to immediately discontinue

electrical flow.

Miniature Circuit Breaker ( MCB )

MCBs are normally used for protecting the wiring circuits from over load or short circuit

faults in residential installations. Rated current of an MCB is not more than 100 A and

they have thermal or thermal-magnetic operation.

Molded Case Circuit Breaker ( MCCB )

This is similar to MCB but has a higher over current rating MCB. MCCBs are used in

distribution panels in large three phase installations and have rated current up to 2500 A.

R esidual Current Circuit Breaker ( R CCB )

RCCBs are used to prevent electrocution by detecting leakages currents which can be

dangerous for humans and disconnect the circuits from the power supply.

2.13.4 Planning Illumination projects and Selection of Luminaries

When I was at the Electrical Field II I studied a Lighting Catalog and obtained a fair knowledge

about various types of lamps, ballasts and lighting fixtures. And also I learned the procedure of

planning an illumination system for a building. First of all the site condition is analyzed and

investigated. Site condition is analyzed by measuring the normal illumination level of the

location. I was able to experience the way of measuring the illumination level using Lux Meter.

After these conditions are investigated an appropriate lighting technique is analyzed. After

calculating all the required factors suitable lamps are selected to give adequate illumination level.

There are some formulas and factors to decide the selection of luminaries and they are provided

in the Annex A15,2,13,4. After deciding the types and number of lamps and fixtures the plan of

illumination is implemented.

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 3/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 29

University of Moratuwa

2.14 Electrical Field I & IV

2.14.1 Introduction

I was at both EF I and EF IV in the second week of my training at the Colombo Port. Both of

these sections are supervised by the Electrical Engineer Mr.P.A.R.D.Pathiraja and there are two

Work Superintends to control the duties of two sections.

Electrical Field I is mainly responsible for repairing quay cranes which are used to handle

cargos, overhead cranes of workshops, welding transformers, welding generators and fans. This

section has a fan repairing workshop also.

Electrical Field IV is responsible for the electrical repairs of the machines in the machine shop,

carpentry shop and steel fabrication shop. In addition to that repairing the sector lights and search

lamps of the all light houses in Sri Lanka is done by this section. Apart from that repairing and

maintaining the buoy lights is also carried out by this section.

2.14.2 Training Experiences

During that week I involved in a test which was done to check the supply unit of an overhead

crane. The supply cable around the cable reel had been repaired and we went to check weather

power is supplied properly. And also I was able to go with the technicians to check the three

phase power supply connection of a hydraulic lathe machine in the machine shop. AS well as I

helped the technicians in a duty of giving three phase supply to a motor. In addition to that when

I was at the fan repairing workshop I wound a coil of 800 turns using the winding machine and I

observed the way of winding coils in the stator of an exhaust fan motor. While it was being done

I studied its winding patterned and also I learned about the methods and materials which are used

to insulate the coils.

L

N

StartingCoil

RunningCoil

Figure 2.11 WIRING DIAGRAM OF THE SINGLE PHASE EXHAUST FAN

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 4/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 30

University of Moratuwa

2.15 Electrical Field III

2.15.1 Introduction

According to my training schedule I was appointed to the winding workshop of Electrical Field

III for 3 weeks. This section is responsible for repairing AC and DC motors, generators, vehicle

alternators, and other electrical appliances such as fans, boilers, electrical kettles, etc. In addition

to that repairing and maintaining the electrical parts of Unity Container Terminal¶s (UCT) gantry

cranes and transfer cranes also is done by this section. This section is supervised by the Electrical

Engineer Mr.M.S.S. De Costa and there are two Work Superintends to control the day today

duties.

2.15.2 Motor R ewinding

The main task that I was able to experience when I was there is motor rewinding process. The

winding patterns which are used in this workshop to wind the stator coils are different than the

theoretical winding patterns that I have learnt from the university. All the defected motors of

SLPA are sent to this winding workshop to repair. When finding the fault of a motor the

terminals, brush positions and bearings are checked initially without removing separate the

stator. If there is no fault with the above cases the stator is separated and the stator coils are

checked for their continuity. If the coils have been damaged or burnt, the motor should be

rewound. Before remove the coils from the stator some details of the coils are noted down.

Number of poles of the motors is taken from the nameplate of the motor, number of coil turns

per coil set is counted, the gauge of the winding wire is measured using micrometer screw meter

and the winding pattern is noted down by studying it. After that the coils are removed with all its

insulations and thinner is used to soften the tight coil sets. After removing all the existing coils

the stator core is cleaned well. Then the coil sets are prepared with required number of turns.

After applying the insulation papers in the stator slots the coils are wound according to the noted

winding pattern. After completing the rewinding selack insulation liquid is applied to the whole

winding and the unit is baked finally. Before fix the motor again the insulation level is checked

using multi meter.

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 5/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 31

University of Moratuwa

2.15.3 UCT Substation

During that week I was able to visit the UCT Substation and study its indoor type transformers,

protective relay panels, switch panels and feeder panels. UCT Substation has two 11kV

incoming lines from CEB. This 11kV supply is directly feed to 5 another places of Port through

feeder panels. As well as 11kV supply is stepped down to 3.3kV using two 3000kVA indoor type

transformers to supply the power to UCT gantry cranes. And there is another 500kVA

transformer which is used to step down 11kV to 400V and it supplies power for auxiliary usage.

UCT Substation also comprises a 2500kVA diesel generator which can be used within CEB

supply outage.

2.15.4 Other Training Experiences

When I was there I visited the gantry cranes of UCT and studied the control mechanism, PLC

panels, motors, transformers, and braking methods of the cranes. During that week I observed the

way of removing burnt stator coils from a quick brake induction motor and I studied the double

layer winding pattern of the motor while the coils were being removed. And I studied the way of

winding the stator coils in stator slots after applying lomax insulation papers in stator slots. As

well as I got the chance to wind a coil of 1028 turns for the primary winding of a small

transformer. And also I wound the brake coil of a quick brake induction motor after studying its

magnetizing pattern. In addition to that I got the opportunity to remove the burnt stator coils of

an exhaust fan motor and rewind its coils.

Figure 2.12 WINDING ARRANGEMENT OF THE EXHAUST FAN MOTOR

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 6/16

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 7/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 33

University of Moratuwa

2.17 Air Conditioner & R efrigerator R epair Workshop

2.17.1 Introduction

I obtain a good training at the Air conditioner and Refrigerator repair workshop and I was there

for one week. This section is responsible for repairing, maintaining and installing the air

conditioners, refrigerators and water dispensers in the Port. Repairing and refrigerant gas filling

of the automobile air conditioner units also done by this section. This workshop is supervised by

the Electrical Engineer Mr.P.S.P.Peiris and there is a Work Superintend at the workshop to

handle the day to day duties.

2.17.2 Air Conditioning Cycle

When I was at there I obtained a fair knowledge about the mechanism of air conditioners and

learned the refrigeration cycle as well.

Evaporator

Compressor

Accumulator

Condenser Condenser

fan

Evaporator

fan

Capillary tube

Drier

Figure 2.14 AIR CONDITIONING CYCLE DIAGRAM

Warm

air out

Cool

supply

air out

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 8/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 34

University of Moratuwa

2.17.3 Types of Air Conditioners

There are four types of air conditioners as window type, split type, package type and chilled

water type. The efficiency of the large scale air conditioners are than the small types. There are

thermostats to identify the temperature and maintain the temperature automatically in air

conditioners. Window type air conditioner contains its evaporator and condenser in the same unit

and they are mounted on the wall so as evaporator is fitted inside the room and the condenser is

in the outside across the wall and can be used only for small areas. In the split type air

conditioners they have indoor and outdoor units separately and this type can be used for larger

areas than that of the window type. Package type air conditioners are widely used in larger areas

such as conference halls. In this type, cooled air at the evaporator is transferred through duct

lines. Chilled water type air condition plants are used in very large scale systems and water flows

through ducts is used to cool the air at evaporator. The water circulation is done by separate

pumps.

2.17.4 Other Training Experiences

Apart from the above mentioned experiences I was able to observe the way of repairing a water

dispenser and I studied the mechanism of the dispenser. And I observed the way of vacuuming

the gas tube of the dispenser using a vacuum pump. As well as I observed how to assemble the

components separately of the indoor and outdoor units of an air conditioner. When I was there Iwas able to go to check a cooling tower of a duct line air conditioner unit and identified the fault

which was due to block of the water outlet. And also I studied the mechanism of the cooling

tower at there. In addition to that I got the chance to go to install an outdoor unit of the air

conditioner of a Navy checkpoint and observed the way of filling refrigerant gas to the cycle.

During that week I was able to observe and study the chilled water type air conditioner unit of

the port¶s museum.

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 9/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 35

University of Moratuwa

2.18 Floating Craft Section

2.18.1 Introduction

I was trained in this section for one week. Floating Craft electrical section is responsible for

repairing and maintaining the electrical systems in tug crafts, dredgers, pilot boats and other

types of floating crafts owned by SLPA. This section is supervised by two Electrical Engineers

and I trained under the Electrical Engineer Mr.S.M.Udagedara.

2.18.2 Tug Crafts

Tug Crafts are normally used to assist the ships when berthing or sailing the ship inside the port.

Unlike the massive ships tug crafts contain two powerful engines coupled to two propeller

systems which can be rotated 360 º and they have no rudders to control the direction. Controlling

the direction is done only by these two propellers. During that week I was able to visit the

Dheera tug craft which was being repaired. And I studied the switch board, feeder panels, engine

room and generators of the vessel. As well as I visited the Gotaimbara tug craft and that tug has

two 165kW generators and a 150kW standby generator.

2.18.3 Pilot Boats

The pilot boats are the vessels that used to take the pilot who handle the ships inside the harbor,to or from the ships. These pilot boats have only one engine, one propeller and one rudder.

During that week I was able to visit the Pilot 15 boat which was being repaired. And also I got

the chance to go on an out harbor trial after completing the repair.

2.18.4 Dredger Ships

Dredger ships are used to maintain an adequate depth inside the harbor basin by monitoring the

depth and dredging the sand and soil continually. During that week I was able to visit the

Hansakawa dredging ship and I studied its engine room and generators.

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 10/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 36

University of Moratuwa

2.19 Telecommunication Section

2.19.1 Introduction

During my training period I was appointed to the Telecommunication Section for one week. As

the SLPA premises comprise a vast area it has a large intercommunication system. There are two

telephone networks as internal network and SLT network inside the port. Therefore a separate

section stands to maintain this large network. Maintaining and upgrading the Exchange, Main

Distribution Frame, underground telephone cables and repairing telephones are the

responsibilities of this section. This section is supervised by the Electrical Engineer

Mr.S.K.Vijithananda.

2.19.2 Main Distribution Frame ( MDF )

When I was there I was able to visit the MDF room and learn about the Main Distribution Frame.

Main distribution frame is the interface between Exchange side and Underground cable side and

it is stands as the terminating point of both sides. All the incoming lines to the MDF have been

connected to the terminal box and then to the fuse panel which includes 100 fuse. The fuses

operate using gas interruptions for the protection purpose. Any terminal of the Underground

cable side can be connected using jumpers to any terminal of the exchange in this MDF.

2.19.3 Telephone Cable Colour Code

Two types of underground cables are used in SLPA in the

communication system. They are unshielded twisted pair cables and

twisted pair cables. Unshielded twisted pair is the most common

kind of copper telephone wiring. When the number of pair is high it

is difficult to identify both ends. Therefore a universal colour code

has been introduced for this twisted cable pairs. During that week I

learned the colour code of a 25 pair cable and also I got the chance

to connect a 100 pair cable to the MDF draping board using the

draping tool. It was a wonderful experience for me.

Figure 2.15 THE UNIVERSAL COLOUR

CODE OF THE TWISTED PAIR CABLE

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 11/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 37

University of Moratuwa

2.19.4 Pair Gain System

Pair Gain System is used to multiply the capacity of telephone lines by obtaining number of

independent voice channels over a single channel. Single loop can be divided to two, four,

sixteen or sixty channels by using this system. The system consists of two devices. They are

PCM Exchange Unit (EU) which contains a MUX and A to D converter and PCM Remote Unit

(RU) which contains a DMUX and D to A converter. Less UG cable consumption is the main

advantage of this system. But modern facilities such as ADSL cannot be provided through these

divided lines. And another disadvantage is if any fault is occurred in the copper cable pair all the

telephone lines given by that pair will be interrupted. Block diagram of a Pair Gain System is

given below.

MDF Main Distribution Frame

PCM Pulse Code Modulation

EU Exchange Unit

RU Remote Unit

Exchange

EX

C

H

A

N

G

E

Side

C

A

B

L

E

Side

PCM

EU

Cabinet

Distribution

Point

PCM

RU

Customers

Analog

Signal

Analog

Signal

Digital

Signal

Figure 2.16 BLOCK DIAGRAM OF A PAIR GAIN SYSTEM

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 12/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 38

University of Moratuwa

2.20 Jaya Container Terminal ( JCT)

2.20.1 Introduction

As the final training location of my training period I was appointed to the Jaya Container

Terminal of SLPA for 3 weeks. Jaya container terminal is the largest container terminal in South

Asia handles more than 2 million per year earning remarkable profits to the SLPA while being

the heart of the port of Colombo. JCT has been divided to 4 sections to maintain its operation.

Major function of JCT is handling containers and it is the major revenue collection operation in

SLPA. Daily Container Handling Static report of Port of Colombo in March of 2010 is provided

in the Annex A16,2,20,1. JCT consists of four main container vessel berths and two feeder

berths. JCT has three types of equipment to handle containers. They are Ship to Shore Gantry

Cranes, Rubber Tired Gantry Cranes and Rail Mounted Gantry Cranes. There is a separate

section in JCT to repair and maintain the electrical side of these cranes. There are eight Electrical

Engineers to supervise these repairs. During those three weeks I was trained under the Electrical

Engineer Mr.E.G.S.Dinendra De Silva.

2.20.2 Ship to Shore (STS) Gantry Cranes

Boom

Front Legs

Trolley

Spreader

Rear Legs

Machinery House

Back Tension Bar

Tension Bar

Figure 2.17 COMPONENTS OF AN STS CRANE

STS cranes are also known as Portainers are

very large cranes which are used to load and

unload container vessels and can be only seen

at container ports. These cranes have a special

lifting device called the spreader for the loading

and discharging of containers. The spreader has

four twist locks which lock and unlock into the

corner casting of the containers and can be used

in 20', 40' or 45' positions depending on the size

of the containers. The boom of the crane allows

the containers to be lifted from the hold and

moved toward the centre of the crane, and

lowered to the dockside below.

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 13/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 39

University of Moratuwa

JCT has 14 STS cranes which have a safe working load of 40 T.

Container cranes are generally classified according to their lifting capacity and the size of the

container ships which they can load or unload containers. JCT comprises 8 Panamax STS cranes

and 6 Post-Panamax STS cranes. A Panamax crane can fully load and unload containers from a

container ship capable of passing through the Panama Canal. A Post-Panamax crane can fully

load and unload containers from a container ship too large to pass through the Panama Canal.

Descriptions of the 14 Portainers in the JCT are provided in the Annex A17,2,20,2. Portainer has

four main functions.

Hoist Function

When a container is handled from the yard to the vessel or vise versa, the hoist and lower

operations are done by moving the spreader vertically.

Trolley Function

There is an operator cabin connected to the trolley of the portainer and its movement to

the forward and backward directions (Sea side and Land side) perpendicular to the

direction of portainer traveling is known as trolley function.

Gantry Travel Function

Portainer can be traveled to the left and right directions along the rails.

Boom Operation

The boom is raised to an almost upper level when the crane is not in operation and

lowered when it is in operation.

In JCT Portainers there are two DC Generators to supply the power for the above mentioned

operations. One generator stands to give the power to hoist operation, boom operation and gantry

travel function while the other generator stands only to supply the power for the trolley function.

This type of arrangement has been implemented to allow the hoist function and trolley travel

function simultaneously. Then a container can be hoisted or lowered while the trolley is being

traveled and it helps to save the loading and unloading time.When doing the hoist operation speed controlling of the hoist motor is very important. This is

done by two methods. First method is varying the armature voltage of the hoist motor by keeping

its field current at rated value. Armature voltage of the motor is changed by varying the

generating voltage of the DC generator. The other method of controlling the speed is varying the

field current of the motor by keeping the motor armature voltage at a fixed value.

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 14/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 40

University of Moratuwa

All the Portainers at JCT are powered by an external 3.3kV AC power supply

from the dock. All the main functions of the cranes are done using DC power and hence DC

power is generated using two DC generators. The supply arrangement of an STS gantry crane is

given below.

When I was there I was able to go with the technicians to replace the main hoist DC generator of

J-10 STS gantry crane. The existed generator was removed for its service. At the machinery

house of the crane I studied its motor and generator arrangements and also I studied its PLC

panels. And also I visited the only analog controlled STS gantry crane of JCT, J-4 and studied its

analog control mechanism which consists of AC magnetic control relays and magnetic

contactors.

Figure 2.18 STS GANTRY CRANE POWER SUPPLY ARRANGEMENT

400V

3.3kV 11kV

AC-DC

Rectifier

PLC100V230V

Field windings of

motors and

generators

Auxiliary

Supply

Cable Pit

Flat

cable

Cablereel

3.3kV

Supply Panel

Gantry travel motor motors

(DC)

Boom

Hoist

motor

(DC)

Main

Hoist

motor

(DC)

Trolley

motor

(DC)

Main

Generator

(DC)

3-phase

Induction Motor

3.3kV

Trolley

travel

Generator

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 15/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 41

University of Moratuwa

2.20.3 R ubber Tired Gantry Cranes (R TGC)

Rubber Tired Gantry Cranes are also known as Transtainers and have in various models with

span of between 5 and 8 containers in width and hoisting heights 1 over 3 to 1over 5 containers.

There is a hoist motor with wire rope reviewing drum to hoist and a motor drives trolley to move

a container across the lane. The RTGC is available in either 8 or 16 wheel configuration. These

cranes are used for handling containers from the container yard to a container-carrying vehicle

and vise versa. There are 39 RTGCs working in the JCT yard. Simultaneous hoisting, trolley

traveling and gantry travel motion is possible in these cranes.

When I was there I visited the RTG-11 crane which was being serviced and I studied its control

mechanism. At there I got the chance to go to its operator cabin and I learned how to operate the

crane.

In earlier times a system called WireTAS has been used to identify the movement of RTGCs.

When the gantry is travelled, the moving direction variation is identified by this system. There is

a wire which is carrying current underneath the travelling track of the crane. Two coils are fixed

under the crane and two sides of the current flowing path. Speed of the travel motors is adjusted

according to the induced variation in the two coils.

2.20.4 R ail Mounted Gantry Cranes (RMGC)

RMGC is also a type of transfer crane which is used for handling of empty containers from the

container yard to a container-carrying vehicle and vise versa. There are 4 RMGCs in the JCT

yard. These cranes are specifically designed for the intensive container stacking requirements of

today¶s port environment. These cranes are operated by an inverter controlled 3.3kV supply.

2.20.5 JCT 3 & 4 Substation

During my training at JCT I was able to visit the JCT 3 & 4 Substation and I studied its

transformers and control panel boards. This is the largest Substation in the port, supplies power

to JCT 3 & 4 stages. Supplying power for Gantry cranes J-10 to J-14 and the four Rail Mounted

Transfer Cranes is done by this Substation. There are four 1500kVA transformers for supplying

power to the STS and RMG cranes by stepping down 11kV to 3.3kV. And also there are three

750kVA transformers for supplying power to the auxiliary usage by stepping down 3.3kV to

400V. In addition to that, this Substation comprises four 2000kW diesel generators to be used

within CEB supply outage.

8/6/2019 SLPA Exp

http://slidepdf.com/reader/full/slpa-exp 16/16

Chapter 2 SLPA Industrial Training Report

Department of Electrical Engineering Page 42

University of Moratuwa

Nameplate data of 1500kVA transformers

y Rated Voltage ± Primary : 11000V

Secondary : 3300V

y Rated Current ± Primary : 78.7A

Secondary : 262A

y Phase : 3

y Frequency : 50Hz

y Type of cooling : AN

y Vector Group : Dd0

Features of four NISHISHIBA Synchronous Generators

y Output : 2000kW

y Voltage : 3300V

y P.F : 0.8

y Poles : 8

y Phase : 3

2.20.6 Colombo Port Expansion Project

The proposed Colombo South Harbor will be located west of the present south west Breakwater

in an area of approximately 600 hectares. The proposed harbour will have 4 terminals of over

1200m in length each to accommodate 3 berths alongside depths of 18m and provision to deepen

to 23m to accommodate deeper draft vessels of the future. The channel width of the harbor is to

be 560 m and depth of 20m, with harbor basin depth of 18m and a 600m turning circle. The

constructions of the project are conducted by Hyundai Construction Company.

I was able to attend a presentation which was conducted to explain the current progress and

future targets of the project during my training period at JCT. And also I got the chance to visit

the construction site and I observed the constructions of the breakwater. A Bird eye view of the

proposed Colombo South Harbor and the Cross section of its Breakwater are provided in the

Annex A18,2,20,6.

Nameplate data of 750kVA transformers

y Rated Voltage ± Primary : 3300V

Secondary : 400V

y Rated Current ± Primary : 131A

Secondary : 1083A

y Phase : 3

y Frequency : 50Hz

y Type of cooling : AN

y Vector Group : Dy11

y Speed : 750 rpm

y Frequency : 50Hz

y Amps : 438 A

y Coolant Temperature : 40 ºC

y Excitation Voltage : 115V

Related Documents