-

8/10/2019 Shielding affects of Nylon and cnts

1/16

Synergistic Effects of CarbonFillers on ShieldingEffectiveness in ConductiveNylon 6,6- andPolycarbonate-Based Resins

QUINTON J. KRUEGER, JULIA A. KING

Department of Chemical Engineering, Michigan Technological University, Houghton,Michigan 49931-1295

Received: May 29, 2002Accepted: January 9, 2003

ABSTRACT: Electrically conductive resins can be made by adding electricallyconductive fillers to typically insulating polymers. Resins with an electricalresistivity of approximately 100 cm or less can be used for electromagnetic andradio frequency interference shielding applications. This research focused onperforming compounding runs followed by injection molding and shieldingeffectiveness (SE) testing of carbon filled nylon 6,6- and polycarbonate-basedresins. The three carbon fillers investigated included an electrically conductivecarbon black, synthetic graphite particles, and a milled pitch-based carbon fiber.For each polymer, conductive resins were produced and tested that containedvarying amounts of these single carbon fillers. In addition, combinations of fillerswere investigated by conducting a full 23 factorial design and a complete replicatein each polymer. The objective of this study was to determine the effects andinteractions of each filler on the SE properties of the conductive resins. Carbon

Correspondence to:Julia A. King; e-mail: [email protected] grant sponsor: National Science Foundation.Contract grant number: DMI-9973278.

Advances in Polymer Technology, Vol. 22, No. 2, 96111 (2003)C2003 Wiley Periodicals, Inc.

-

8/10/2019 Shielding affects of Nylon and cnts

2/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

black caused the largest increase in SE. Also, each singlefiller and each twofillerinteraction caused a statistically significant increase in SE. C 2003 WileyPeriodicals, Inc. Adv Polym Techn 22: 96111, 2003; Published online in WileyInterScience (www.interscience.wiley.com). DOI 10.1002/adv.10040

KEY WORDS: Composites, Fillers, Nylon, Polycarbonates, Shielding

Introduction

M ost polymer resins are electrically insulating.Increasingthe electrical conductivity of theseresins allows them to be used in other applications.An electricallyconductive resin canbe usedfor staticdissipative, semiconductive (e.g., fuel gages), andelectromagnetic interference (EMI)/radio frequencyinterference (RFI) shielding applications (e.g., com-

puter and cellular phone housings). The advantagesof conductive resins as compared to metals (typi-cally used) include improved corrosion resistance,lighter weight, and the ability to adapt the conduc-tivity properties to suit the application needs.

Electrical resistivity (1/electrical conductivity)values forvarious materials aretypicallyin therangefrom 1014 to1017 for polymers, 102 for carbon black,104 for highly graphitized pitch-based carbon fiber,105 for high purity synthetic graphite, and 106

for metals such as aluminum and copper (all val-ues in cm). One approach to improving the elec-trical conductivity of a polymer is through the addi-

tion of a conductive filler material, such as carbonand metal.1,2 Conductive resins with an electricalresistivity (ER) ranging from approximately 1010 to103 cm can be used for static dissipative applica-tions. Conductive resins with ER ranging from ap-proximately102 to101 cm can be used for semicon-ductive applications. Those with ER approximately100 cm or less can be used for EMI/RFI shieldingapplications.3

EMI is electrical energy, either in the electromag-netic or in the radio frequency range, that is emitted

by computer circuits, radio transmitters,fluorescentlamps, electric motors, overhead power lines, light-

ning, etc. EMI/RFI can interfere with the operationof other electronic equipment near it, such as caus-ing the unwanted operation of garage door openers,corrupting data in computer systems, and causingpacemakers to malfunction. Federal Communica-tions Commission regulations control the amount ofenergy that can be emitted by an electronic product.The need for EMI/RFI materials is growing because

of more stringent regulation on electronic noise, aswell as the increased need for smaller, more denselypacked electronic components. A shielding materialis typically used to encase an electronic product toprevent the enclosed product from emitting electro-magnetic or radio frequency energy. The shieldingmaterial either absorbs or reflects the energy withinthe material.4 The shielding effectiveness (SE) of amaterial is the ratio of the power received with andwithout a material present for the same incidentpower. It is expressed in units of decibels (dB), asshown in Eq. (1).5

SE = 10 log(P1/P2) (1)

where P1 is the received power with the materialpresent andP2 is the received power without the ma-terial present. For EMI/RFI shielding applications,typically a SE of at least 20 dB (indicates that 99% ofthe electromagnetic (EM) energy is reflected or ab-sorbed by the material) is needed.6 A SE of 30 dBindicates that 99.9% of the EM energy is reflected orabsorbed by the material, with only 0.1% exiting the

shielding material.There are many studiesconcerning adding a vary-

ing amount of a single conductive filler to a polymermatrix so as to produce an electrically conductive,shielding material. For example, carbon black, car-

bon fibers, stainless steel fibers, and nickel-coatedcarbon fibers have been used.6,7 Bushko, Stokes, andWilson showed that a conductive resin containing24 wt% carbon fiber in polycarbonate provided a SEof 35 dB at a frequency of 100 MHz.6 Bigg showedthat adding 11 vol % carbon black to polypropy-lene produced a material with a SE of 20 dB at100 MHz.8 Versiek reported that for polycarbonate-

based resins, adding 2.5 and 6.0 wt % stainless steel(302 alloy) fibers resulted in SE values of 30 and40 dB, respectively.9 Murthy reported a SE of ap-proximately 35 dB at 1000 MHz for a conductiveresin containing 10 wt % nickel-coated carbonfiberin polycarbonate.10

In this work, researchers performed compound-ing runs followed by injection molding and SE

ADVANCES IN POLYMER TECHNOLOGY 97

-

8/10/2019 Shielding affects of Nylon and cnts

3/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

testing of carbon-filled resins. Two different poly-mers were used: nylon 6,6 and polycarbonate. Thethree carbon fillers investigated included an elec-trically conductive carbon black, synthetic graphiteparticles, and a milled pitch-based carbon fiber. Foreach polymer, 14 formulations that contained vary-

ing amounts of these single carbon fillers were pro-duced and tested. In addition, combinations offillerswereinvestigatedbyconductingafull23 factorial de-sign and a complete replicate in each polymer. Thegoal of this project was to determine the effects andinteractions of eachfiller on the SE properties of theconductive resins.

Materials and ExperimentalMethods

MATERIALS

Two matrix materials were utilized in this project.Thefirst matrix used was DuPont Zytel 101 NC010,an unmodified semicrystalline nylon 6,6 polymer.The second matrix used was Lexan HF 1110-111N,which is an amorphous engineering thermoplasticproduced by GE Plastics. The properties of thesepolymers are discussed elsewhere.1113

Three different carbon fillers were employed inthis project. Akzo Nobel Ketjenblack EC-600 JD,an electrically conductive carbon black, was used.Table I displays the properties of this carbon black.14

The highly branched, high surface area carbon blackstructure allows it to contact a large amount of

TABLE IProperties of Akzo Nobel Kejenblack EC-600 JD

Carbon Black14

Electrical resistivity of 0.010.1 cmcarbon black

Product form Pellet in size from100m to a few mm

Size of carbon black 30100 nm

aggregatesSpecific gravity 1.8 g/cc

Bulk density 100120 kg/m3

Ash, max 0.1 wt %

Moisture, max 0.5 wt %

BET (N2) surface area 1250 m2/g

Pore volume (DBP-absorption) 480510 cm3/100 g

polymer, which results in improved electrical con-ductivity at low carbon black concentrations. Table IIshows the properties of ThermocarbTM TC-300 Spe-cialty Graphite, a high qualitysyntheticgraphite thatis available from Conoco, Inc. Thermocarb was used

because of its high-thermal conductivity and mod-

erately high-electrical conductivity.

15

BP/Amocospitch-based milled (200 m long) carbon fiber, Ther-malGraph DKDX, was usedto improve theelectricaland thermal conductivity and the tensile strength ofthe resin. Table IIIshows theproperties of this carbonfiber.16

In this study, a 23 factorial design (three factorsor fillers in this case at two different loading lev-els) was completed in each polymer. In addition, acomplete replicate of the factorial design was alsocompleted in each polymer. For all fillers, the low-loading level was zero wt %. The high-loading levelvaried for each filler. The high levels were 5 wt% for

Ketjenblack EC-600 JD, 30 wt % for ThermocarbTM

TC-300 Specialty Graphite, and 20 wt % for Thermal-Graph DKD X. Table IV shows the factorial designformulations. Sincethis project focuses on producinghighly conductive composites, the high-loading lev-els were chosen so that the filler amounts would beabove the electrical conductivity percolation thresh-old. Another consideration was that the total wt %filler for the composite with all fillers at the high

TABLE IIProperties of ThermocarbTM TC-300 Specialty

Graphite15

Ash

-

8/10/2019 Shielding affects of Nylon and cnts

4/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

TABLE IIIProperties of BP/Amoco ThermalGraph DKD X16

Tensile strength >1.39 GPa

Tensile modulus 687927 GPa

Electrical resistivity

-

8/10/2019 Shielding affects of Nylon and cnts

5/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

TABLE VSingle Filler Loading Levels for Nylon 6,6 and

Polycarbonate

Filler Loading Levels (wt %)

Kejenblack EC-600 JD 2.5, 4.0 , 5.0, 6.0, 7.5, 10.0

Thermocarb

TM

TC-300 10.0, 15.0, 20.0, 30.0, 40.0Specialty Graphite

ThermalGraph DKD X 5.0, 10.0, 15.0, 20.0, 30.0, 40.0

SE TEST METHOD

The electromagnetic SE of each formulation wasmeasured according to ASTM D 4935-89 (Reap-proved 1994), for planar materials using a plane-wave, far-field EM wave.5 This method is valid overa frequency range of 30 MHz to 1.5 GHz. An Electro-

Metrics, Inc. SE test fixture (model EM-2107A) wasused to hold the sample. A HP 8752C network ana-lyzer was used as the signal generator and receiver.Foreach formulation,one reference sampleand threeload samples were tested at the following frequen-cies: 30, 100, 200, 300, 400, 500, 600, 700, 800, and1000 MHz. The SE for a material is the difference

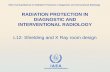

Atmospheric

Vent

Atmospheric

Back VentSide Stuffer Side Stuffer Main Feed

40D 36D 32D 28D 24D 20D 16D 12D 8D 4D

GFA

2-30-30

GFA

2-30-90

GFA

2-40-90

GFA

2-30-60

GFA

2-40-90

KB5-2-30-60

KB5-2-30-30

KB5-2-30-90

KB5-2-30-60

KB5-2-30-30

KS1-2-10E

GFA

2-30-60

GFA

2-40-90

GFA

2-40-90

KB5-2-30-90

KB5-2-30-60

KB5-2-30-30

KB5-2-30-60

GFA

2-20-30

GFA

2-30-90

GFA

2-40-90

KS1-2-10A

0D

For Screw Type Elements

GFA-d-ee-ff

G = co-rotating

F = conveying

A = Free-Meshing

d = number of threadsee = pitch (length in millimeters for one complete rotation)

ff = length of screw elements in millimeters

Kneading disks

KBj-d-kk-ll

KB = kneading block

j = number of kneading segments

d = number of threads

k = length of kneading block in millimetersl = twisting angle of the individual kneading segments

Kneading disks

KS1-d-hh-i

KS1 = Kneading disc

d = number of threads

h = length of kneading disc in millimeters

i = A for initial disc and E for end disc

Zones

0D to 4D is Zone 1 (water cooled, not heated)

4D to 8D is Zone 2 and Heating Zone 1

8D to 12D is Zone 3 and Heating Zone 2

12D to 16D is Zone 4 and Heating Zone 316D to 20D is Zone 5 and Heating Zone 4

20D to 24D is Zone 6 and Heating Zone 524D to 28D is Zone 7 and Heating Zone 6

28D to 32D is Zone 8 and Heating Zone 7

32D to 36D is Zone 9 and Heating Zone 8

36D to 40D is Zone 10 and Heating Zone 9Nozzle is Heating Zone 10

FIGURE 1. Extruder screw design.

between the SE value of the load samples minus theSE value of the reference sample. The input powerused was 0 dB and the tests were all conductedinside a Faraday cage to minimize interference forother electronic devices in the area. The dynamicrange (difference between the maximum and min-

imum signals measurable by the system) of the sys-tem was 80 dB. The nylon 6,6-based samples wereall tested dry as molded (DAM). The polycarbonate-

based samples were conditioned at 50% relative hu-midity for 24 h at 23C prior to testing.

FILLER LENGTH AND ASPECTRATIO TEST METHOD

Inordertodeterminethelengthofthecarbon fiberand synthetic graphite in the SE test specimens, sol-vent digestion was used. A 0.2 g sample cut from

the SE test specimen was dissolved at 23

C usingformic acid to remove the nylon 6,6 and methylenechloride to remove the polycarbonate. The fillerswere then dispersed onto a glass slide and viewedusing an Olympus SZH10 optical microscope withan Optronics Engineering LX-750 video camera. Theimages (at 60 magnification) were collected using

100 VOL. 22, NO. 2

-

8/10/2019 Shielding affects of Nylon and cnts

6/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

Scion Image version 1.62 software. The images werethen processed using Adobe Photoshop 5.0 and theImage Processing Tool Kit version 3.0. The lengthand aspect ratio (length/diameter) of each fillerwas measured. For each formulation, between 1000and 6000 particles/fibers were measured. Because

of the extremely small size of the carbon black, thelength and aspect ratio of the carbon black was notmeasured.

FILLER ORIENTATION TEST METHOD

In order to determine the orientation of the car-bon fillers, a polished composite sample was viewedusing an optical microscope. Again, because of thesmall size of the carbon black (aggregates 30100 nmin size), the orientation of only the synthetic graphiteparticles and carbon fibers were determined. Foreach formulation, one 13 mm by 13 mm square wascut from a SE sample. This sample was mounted inepoxy such that the through the sample thickness(3.2 mm) face could be viewed. The samples werethen polished and viewed using an Olympus BX60transmitted light microscope at a magnification of200. Again, the images were collected using ScionImage version 1.62 software. The images were thenprocessed using Adobe Photoshop 5.0 and the ImageProcessingToolKit version 3.0. For eachformulation,the orientation was determined by viewing typically10006000 particles/fibers.

SURFACE ENERGY TEST METHOD

Surface energies for the three fillers were mea-suredusing the Washburn adsorption method.17 Thetwo components of the total surface energy, a po-lar and a dispersive component, were determined.18

This analysis wasperformedusing a Kruss ProcessorTensiometer K12 with an FL12powdercell accessory,and was carried out by Kruss Laboratory Services inCharlotte, NC. The total, polar, and dispersive com-ponents of the polymer surface energy were deter-mined in the melt phase (to simulate extrusion andinjection molding; 270C for nylon 6,6 and 288C

for polycarbonate) using the pendant drop tech-nique by Kruss Laboratory Services (see footnote).A Kruss Drop Shape Analysis System DSA10 wasused.

Personal communication with Kruss Laboratory Services,Kruss USA, Charlotte, NC, August 2001.

X-RAY PHOTOELECTRIC SPECTROSCOPY

X-ray Photoelectric Spectroscopy (XPS) was usedto determine the surface composition of the variouscarbonfillers. Since each element has a unique setof binding energies, XPS can determine the elementspresent in the top 50100 A of the sample surface.

A Perkin-Elmer PHI 1600 XPS system was used inan ultra-high vacuum chamber. The ThermocarbTM

TC-300 Specialty Graphite and the KetjenblackEC-600 JD samples were pressed into 13-mm diam-eter wafers, using a hydraulic press. The Thermal-GraphDKDXpitch-basedcarbonfiber was mountedon the sample holder using double-sided coppertape.19

Results

FILLER LENGTH AND ASPECTRATIO RESULTS

Table VI shows the mean length and aspect ratio(length/diameter) results of the synthetic graphiteparticles and carbon fibers for the factorial designformulations in both polymers after thefillers wereremoved via solvent digestion. The values listed un-der the as received formulation are the length andaspect ratio of thefiller prior to extrusion and injec-tion molding.19,20

The results in Table VI show that there is a sig-

nificant degradation of the carbon fibers follow-ing the extrusion and injection molding steps. Themean length and aspect ratio of the as received car-

bon fibers was 167.5 m and 16.75, respectively.This compares well to the reported vendor litera-ture value which states a 200 m mean carbonfiberlength.16 In the 20 wt % carbonfiber formulation innylon6,6,the fibers now have a mean length of 95m(aspect ratio = 9.5). In the nylon-based compositescontainingboth carbon fibers and synthetic graphite,the mean length of the fibers was 77 m (aspect ra-tio = 7.7). The fiber results for the polycarbonate-

based composites were similar to those of the ny-

lon composites, with the length decreasing to 82 m(aspect ratio = 8.2) in the 20 wt % formulation, andthen to a 71 m length (aspect ratio = 7.1) in thecomposite containingfibers and synthetic graphite.Overall, processing reduced the carbonfiber lengthand aspect ratio to approximately half of its as re-ceived values. These length results are comparableto those reported by Bigg who showed that carbon

ADVANCES IN POLYMER TECHNOLOGY 101

-

8/10/2019 Shielding affects of Nylon and cnts

7/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

TABLE VIMean Length and Aspect Ratio Results for Factorial Design Formulations19,20

Nylon 6,6 Polycarbonate

Formulation Length (m) Aspect Ratio Length (m) Aspect Ratio

As received carbonfibers (CF) 167.5 16.75 167.5 16.75

As received synthetic graphite (SG) 68.3 1.80 68.3 1.80

SG only composites 74.8 1.68 43.8 1.66

SG only replicate composites 56.0 1.61 49.7 1.70

CF only composites 95.7 9.57 85.7 8.57

CF only replicate composites 94.1 9.41 81.7 8.17

CF (SGCF composites) 71.7 7.17 71.4 7.14

SG (SGCF composites) 59.7 1.84 33.6 1.67

CF (SGCF replicate composites) 82.3 8.23 70.8 7.08

SG (SGCF replicate composites) 41.9 1.72 33.0 1.67

CB: Carbon black; SG: Synthetic graphite; CF: Carbonfiber.

fiber/nylon 6,6 composites hadfiber lengths of ap-proximately 130 m after extrusion and injectionmolding.21

Table VI also shows the lengths and aspect ratiosof the synthetic graphite particles (ThermocarbTM

TC-300 Specialty Graphite). Table VI shows that thelength and aspect ratio of the synthetic graphite par-ticles in the composite specimens remain similar tothat of the as received material. This result is likelydue to the relatively small length and aspect ratioof the as received ThermocarbTM TC-300 Specialty

Graphite. The as received synthetic graphite has amean length of 68 m and a mean aspect ratio of1.8. In the 30 wt % synthetic graphite formulation innylon 6,6, the graphite particles now have a meanlength of 65 m (aspect ratio = 1.65). In the nylon-

based composites containing both carbonfibers andsynthetic graphite, the mean length of the syntheticgraphite was 51 m (aspect ratio= 1.78). The resultsfor the polycarbonate-based composites were simi-lar to those of the nylon composites.

FILLER ORIENTATION RESULTS

As discussed previously, thefiller orientation an-gle was measured by optical microscopy. The an-gle of interest in these measurements was the devi-ation of the filler away from the angle of SE mea-surement. For these measurements, all of the angleswill be between 0 and 90. An angle of 0 signifiesthat the particles/fibers are aligned parallel to the SEmeasurement direction. An angle of 90 means that

the filler is perpendicular to the SE measurementdirection.

Table VII displays the orientation results (mean,standard deviation, and number of filler parti-cles/fibers measured) for the composites containingonly synthetic graphite (ThermocarbTM TC-300 Spe-cialty Graphite) and carbon fiber. The mean orien-tation ranges from approximately 60 to 70. Hence,the orientation angle is closer to 90, indicating thatthe fibers/particles are primarily orientated trans-verse to the SE measurement direction. A photo-

micrograph showing this filler orientation for acomposite containing 20 wt % ThermocarbTM TC-300 Specialty Graphite in polycarbonate is locatedelsewhere.22

SURFACE ENERGY AND XPS RESULTS

Table VIII displays the polar and dispersive sur-face energy components for all the materials used.The total surface energy for the pure nylon 6,6 wasmeasured to be 45.92 mJ/m2 in the melt phase.The pure polycarbonate has a total surface energyof 38.05 mJ/m2 in the melt phase. The total sur-

face energy of the carbon black was measured to be21.77 mJ/m2. The carbon fiber has a total surfaceenergy of 22.23 mJ/m2, and the synthetic graphitehas a total surface energy value of 24.00 mJ/m 2.Since all the filler surfaces are composed of essen-tiallypurecarbonwhichhasnotbeensurfacetreated,one would expect the surface energy results for thesefillers to be similar.

102 VOL. 22, NO. 2

-

8/10/2019 Shielding affects of Nylon and cnts

8/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

TABLE VIISingle Filler Orientation Results in Nylon 6,6 and Polycarbonate19,20

Orientation ()

Formulation Nylon 6,6 Polycarbonate

Synthetic graphite (wt %)

10 58.72 23.92 (n= 733) 66.47 21.48 (n= 2690)

15 60.24 23.48 (n= 2118) 67.92 20.79 (n= 3173)

20 61.55 24.63 (n= 3755) 66.35 22.34 (n= 5271)

30 57.46 25.02 (n= 3784) 67.20 22.70 (n= 4945)

40 58.25 25.72 (n= 3235) 66.99 22.12 (n= 1180)

Carbonfiber (wt %)

5 72.48 21.30 (n= 831) 77.35 17.92 (n= 1636)

10 71.61 21.83 (n= 2058) 69.47 22.14 (n= 1819)

15 66.45 24.74 (n= 2595) 66.54 23.72 (n= 6321)

20 68.56 22.45 (n= 4183) 64.47 24.39 (n= 4599)

30 63.37 23.81 (n= 4405) 61.11 25.02 (n= 4014)

40 65.11 22.54 (n= 4142) 62.26 24.66 (n= 4516)

The surface polarity values (polar surface energycomponent/total surface energy) are also given inTable VIII. These results can be used to determinewhich polymer would provide for more completedispersion with each of the fillers. Materials thathave similar surface polarity values provide im-proved dispersion in the composites.23 The resultsin Table VIII indicate that the polycarbonate matrixhas a surface polarity more comparable to that of thecarbonfillers; and hence, should provide for a more

complete dispersion of each of the carbon fillers ver-sus nylon 6,6.

Results from the XPS analysis for all three fillersused are also in Table VIII. Only two elements werepresent on the filler surface, carbon and oxygen. Thistable shows that, as expected, all the fillers consistedmainly of carbon. Also, as expected, as the amount

TABLE VIIISurface Energy and XPS Resultsa

Polar Component Dispersive Component Total Surface Surface Oxygen on Filler

Material (mJ/m2

) (mJ/m2

) Energy (mJ/m2

) Polarity (%) Surface (Atomic %)

Zytel 101 NC010 17.24 28.68 45.92 37.5

Lexan HF1110-111N 8.55 29.50 38.05 22.5

Carbon black 2.18 19.59 21.77 10.0 1.3

Synthetic graphite 3.99 20.01 24.00 16.6 1.8

Pitch-based carbonfiber 5.47 16.76 22.23 24.6 3.7

aRef. 19 and Personal Communication with Kruss Laboratory Services (Kruss USA, Charlotte, NC, August 2001).

of oxygen present on thefiller surface increased, thepolar component of the surface energy increased.

SE RESULTS

TheSE forthe compositescontaining only varyingamounts of carbon black in both polymers is shownin Fig. 2 at 300 and 800 MHz. Each data point shownin Fig. 2 is the mean of three load samples and onereference sample tested per formulation. Figure 2

shows that adding carbon black to both resins causesthe SE to increase significantly from 0 dB for theneat polymer to approximately 22 dB for 10 wt %(6.6 vol % in nylon, 6.9 vol % in polycarbonate) car-

bon black in both polymers. The SE results are similarfor both polymers and for both frequencies (300 and800 MHz).

ADVANCES IN POLYMER TECHNOLOGY 103

-

8/10/2019 Shielding affects of Nylon and cnts

9/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

0

5

10

15

20

25

0 1 2 3 4 5 6 7 8

Volume % Carbon Black

Shielding

Effe

ctiveness

(dB)

300 MHz in Nylon 6,6 800 MHz in Nylon 6,6

300 MHz in Polycarbonate 800 MHz in Polycarbonate

FIGURE 2. Shielding effectiveness of composites containing only carbon black.

Figure 3 shows the SE of the 5 wt % carbon black(3.2 vol % in nylon, 3.4 vol % in polycarbonate) in

both polymers over the entire frequency range mea-sured.Thesecompositeswereextrudedandinjectionmolded into test specimens twice; hence, one set islabeledreplicatefor each polymer in Fig. 3. FromFig. 3, one notices that the SE is approximately 2 dBhigher in polycarbonate as compared to nylon.

The SE results for the composites containing onlyvarying amounts of ThermocarbTM TC-300 Specialty

0.00

2.00

4.00

6.00

8.00

10.00

12.00

14.00

16.00

18.00

0 200 400 600 800 1000 1200

Frequency (MHz)

Shielding

Effectiveness

(dB)

5 Wt% Carbon Black in Nylon

5 Wt% Carbon Black Replicate in Nylon

5 Wt% Carbon Black in Polycarbonate

5 Wt% Carbon Black Replicate in Polycarbonate

FIGURE 3. Shielding effectiveness of composites containing 5 wt % carbon black in nylon 6,6 and in polycarbonate.

Graphite, which is a high purity synthetic graphite,in both polymers are shown in Fig. 4 at 300 and800 MHz. Figure 4 shows that adding syntheticgraphite to both resins causes the SE to increase,

but not as much as was evident by adding car-bon black. Typically, the SE values at 800 MHz areslightly higher than what were observed for thesame material at 300 MHz. Once again, the SE of thepolycarbonate-based composite is higher than thatof the nylon-based composite.

104 VOL. 22, NO. 2

-

8/10/2019 Shielding affects of Nylon and cnts

10/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

0

2

4

6

8

10

12

14

0 5 10 15 20 25 30

Volume % ThermocarbTMSpecialty Graphite

Shielding

Effecti

veness

(dB)

300 MHz in Nylon 6,6 800 MHz in Nylon 6,6

300 MHz in Polycarbonate 800 MHz in Polycarbonate

FIGURE 4. Shielding effectiveness of composites containing only ThermocarbTM TC-300 Specialty Graphite.

Figure 5 shows the SE of the 30 wt % Thermo-carbTM TC-300 Specialty Graphite (17.9 vol % in ny-lon, 18.7 vol % in polycarbonate) in both polymersover the entire frequency range measured. Onceagain, one notices that the SE is slightly higher in

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

0 200 400 600 800 1000 1200

Frequency (MHz)

Shielding

Effectiveness(dB

)

30 Wt% Thermocarb TM Specialty Graphite in Nylon

30 Wt% Thermocarb TM Specialty Graphite Replicate in Nylon

30 Wt% Thermocarb TM Specialty Graphite in Polycarbonate

30 Wt% Thermocarb TM Specialty Graphite Replicate in Polycarbonate

FIGURE 5. Shielding effectiveness of composites containing 30 wt % ThermocarbTM TC-300 Specialty Graphite innylon 6,6 and in polycarbonate.

polycarbonate as compared to nylon and that the SEincreases as frequency increases.

The SE results for the composites containing onlyvaryingamountsofcarbon fiber in both polymers areshown in Fig. 6 at 300 and 800 MHz. Figure 6 shows

ADVANCES IN POLYMER TECHNOLOGY 105

-

8/10/2019 Shielding affects of Nylon and cnts

11/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

0

2

4

6

8

10

12

14

16

18

20

0 5 10 15 20 25 30

Volume % Carbon Fiber

Shielding

Effective

ness

(dB)

300 MHz in Nylon 6,6 800 MHz in Nylon 6,6

300 MHz in Polycarbonate 800 MHz in Polycarbonate

FIGURE 6. Shielding effectiveness of composites containing only carbonfiber.

that adding carbon fiber to both resins also causesthe SE to increase. For example, at 800 MHz the SEwas 15.5 dB for the 40 wt % carbonfiber in polycar-

bonate sample as compared to 12.0 dB for 40 wt %ThermocarbTM TC-300 Specialty Graphite in poly-carbonate. Of all the single fillers at 800 MHz, the SEwas the highest at 21.9 dB for the resin containing

10 wt % carbon black in polycarbonate. The obser-vation that adding 10 wt % carbon black produceda composite with higher SE than that measured oncomposites containing 40 wt % carbonfiber is notsurprising since the electrical resistivity (4.90 0.7cm for 10 wt % carbon black/polycarbonate; 10.51.1 cm for 40 wt % carbon fiber/polycarbonate)was also lower for the composites containing carbon

black.13

Figure 7 shows the SE of the 20 wt % carbonfiber(11.7 vol % in nylon, 12.2 vol % in polycarbonate) in

both polymers over the entire frequency range mea-sured. Figures 6 and 7 again show that the SE values

at 800 MHz are slightly higher than what is observedfor the same material at 300 MHz and that the SE ofthe polycarbonate-based composites are higher thanthat of the nylon-based composites.

The observation of generally increasing SE valuewith increasing frequency is expected and has beennoted elsewhere.6 As frequency increases, the wave-length of the electromagnetic wave decreases and

becomes more comparable to the size of the filler.Thus, the higher frequency waves are more likelyto encounter filler embedded in the polymer matrix.The fillers are more likely to reflect or absorb thewave, as compared to the polymer rich areas. Hence,SE increases as frequency increases.

The observation of higher SE in polycarbonate

as compared to nylon is interesting. Several fac-tors (filler length, orientation, and adhesion) could

be involved. Longerfiller lengths in polycarbonatecould cause higher composite electrical conductiv-ity, which could cause higher SE results. However,the filler length data shown in Table VI typicallyindicate slightly lowerfiller lengths in polycarbon-ate as compared to nylon. The filler orientation re-sults in Table VII indicate similar values for thepolycarbonate- and nylon-based samples. The sur-face energyresults in Table VIII indicate that all threecarbonfillers have a surface polarity value closer tothat of the polycarbonate (as compared to nylon).

Hence, the polycarbonate, having a surface polar-ity which is more comparable to that of the carbonfillers, should provide for more complete dispersionof thefiller in the conductive resin. It is speculatedthat this increased dispersion of the carbon fillers inthe polycarbonate causes the SE to be higher.

Table IX shows the mean SE and standard de-viation for each factorial design formulation for

106 VOL. 22, NO. 2

-

8/10/2019 Shielding affects of Nylon and cnts

12/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

0 200 400 600 800 1000 1200

Frequency (MHz)

ShieldingEffectiveness(dB)

20 Wt% Carbon Fiber in Nylon

20 Wt% Carbon Fiber Replicate in Nylon

20 Wt% Carbon Fiber in Polycarbonate

20 Wt% Carbon Fiber Replicate in Polycarbonate

FIGURE 7. Shielding effectiveness of composites containing 20 wt % carbonfiber in nylon 6,6 and in polycarbonate.

the nylon-based resins. Table X gives the SE re-sults for each factorial design formulation for thepolycarbonate-based resins. A complete replicate ofthe full factorial was completed in each resin. Hence,

TABLE IXShielding Effectiveness Results at 300 and 800 MHz

for Factorial Design Formulations in Nylon 6,6

Shielding Effectiveness (dB)

Formulation Original Replicate

MeanShielding

Effectiveness

(dB)

300 MHz

Nofiller 0.03 0.05 0.07 0.19 0.05

CB 7.35 0.23 7.42 0.03 7.39

SG 1.30 0.06 1.74 0.08 1.52

CBSG 23.11 0.40 22.90 0.26 23.01

CF 2.32 0.16 2.34 0.17 2.33

CBCF 21.00 0.45 20.19 0.36 20.60

SGCF 10.08 0.06 12.81 0.23 11.45

CBSGCF 42.63 0.32 40.88 0.40 41.76

800 MHz

Nofiller 0.10 0.04 0.07 0.05 0.09

CB 7.17 0.20 7.18 0.01 7.18

SG 2.22 0.04 3.04 0.17 2.63

CBSG 23.11 0.10 23.09 0.23 23.10

CF 4.24 0.28 4.25 0.13 4.25

CBCF 20.88 0.40 19.89 0.15 20.39

SGCF 13.08 0.17 15.34 0.17 14.21

CBSGCF 42.44 0.83 42.01 0.32 42.23

there is a columnlabeled Original and Replicate.These columns show the mean and standard devi-ation. For each formulation, three load specimensand one reference sample were tested. As stated pre-viously, Table IV defines the factorial design formu-lations in both polymers.

TABLE XShielding Effectiveness Results at 300 and 800 MHz

for Factorial Design Formulations in Polycarbonate

Shielding Effectiveness (dB)

Formulation Original Replicate

Mean

ShieldingEffectiveness(dB)

300 MHz

Nofiller 0.10 0.00 0.07 0.06 0.09

CB 10.19 0.25 10.43 0.15 10.31

SG 3.03 0.21 3.23 0.31 3.13

CBSG 27.87 0.26 28.37 0.89 28.12

CF 3.10 0.10 3.43 0.06 3.27

CBCF 27.07 0.06 26.77 0.32 26.92

SGCF 16.95 0.15 17.83 0.35 17.39

800 MHz

Nofiller 0.00 0.00 0.03 0.06 0.02

CB 10.73 0.21 10.83 0.25 10.78

SG 5.27 0.32 5.60 0.44 5.44

CBSG 27.60 0.10 27.70 0.30 27.65

CF 5.43 0.12 5.87 0.06 5.65

CBCF 26.10 0.10 26.33 0.06 26.22

SGCF 18.70 0.10 19.40 0.30 19.05

ADVANCES IN POLYMER TECHNOLOGY 107

-

8/10/2019 Shielding affects of Nylon and cnts

13/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

0.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

40.00

45.00

50.00

0 200 400 600 800 1000 1200

Frequency (MHz)

Shielding

Effectiven

ess(dB)

Nylon Carbon Black Synthetic Graphite

Carbon Fiber Carbon Black + Synthetic Graphite Carbon Black + Carbon Fiber

Synt het ic Graphi te + Carbon Fiber Carbon Black + Sy nt het ic Graphi te + Carbon Fiber

FIGURE 8. Shielding effectiveness results for the nylon 6,6-based factorial design formulations.

Figure 8 shows the mean SE for the nylon-basedfactorial design formulations over the entire rangeof frequencies measured. Figure 9 shows the meanSE for the polycarbonate-based factorial design for-mulations over the entire range of frequencies mea-sured. Several observationscan be made by studyingthe results in Tables IX and X and in Figs. 8 and9. First, for the same formulation, the SE at 300

and 800 MHz are similar. Second, for the same for-mulation, the original and replicate SE values aresimilar. Third, for each formulation with the sameconcentration offiller, the SE is slightly higher forthe polycarbonate-based resins as compared to thenylon-based resins. Fourth, the composite contain-ing all three fillers in nylon at 800 MHz had a SEof 42 dB, which is higher than the any resin con-taining only one filler (maximum SE in nylon withsingle filler was 10 wt% carbon black at 21 dB).While it is apparent that the combinations offillersproduces higher conductivity results, the exact ef-fect of the combinations is not obvious without

the application of statistical experimental designcalculations.

FACTORIAL DESIGN ANALYSIS: SE

Using the results shown in Tables IX and X, ananalysis of the factorial design was completed. Thiswas performed using the Minitab version 13 Statis-

tical Software package. Calculations were also per-formed using MicrosoftExcel 2000 so as to verifyandunderstand the results obtained with the Minitabcalculations. For this analysis, the effects and P val-ues for the SE results were calculated. For all sta-tistical calculations, the 95% confidence level wasused.

Factorial designs were used in the project since

they are the most efficient type of experiment to de-terminethe effect of each fillerandanypossibleinter-actions betweenfillers. By using factorials, one candetermine the effect that each factor (filler) has onthe system by calculating a single value to quantifythe changein SEas the weightpercentof a filler is in-creased. These calculated effects can then be rankedto determine which fillers and combinations offillersproduced a larger change.24

The effects and P values for the nylon 6,6-basedcomposites are given in Table XI, showing the val-ues for all of the filler combinations. Further inves-tigation of Table XI yields some important informa-

tion regarding the effects that fillers have on SE at300 and 800 MHz. First, all the effect terms are pos-itive, which indicates that the addition of any fillerincreases the SE of the composite. Second, the ef-fects and P values are similar for 300 and 800 MHz.Third, the effect term is the largest for carbon black,which indicates that carbon black causes the largestincrease in composite SE. Fourth, the effect terms for

108 VOL. 22, NO. 2

-

8/10/2019 Shielding affects of Nylon and cnts

14/16

-

8/10/2019 Shielding affects of Nylon and cnts

15/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

than what would be expected from the individ-ual additive effect of synthetic graphite and carbon

black.Table XII shows the results of the factorial design

analysis for the polycarbonate-based composites at300 and 800 MHz. Once again, the effects and P val-

ues are similar for 300 and 800 MHz. In addition,as was the case for nylon, carbon black causes thelargest increase in composite SE, followed by syn-thetic graphite and carbon fiber, which once againhave similar effect values. The rest of the statisticallysignificant effects, in order of their ability to increaseSE of the composite, are the combination of carbon

black and synthetic graphite, the combination of car-bon black and carbon fiber, and last the combinationof synthetic graphite and carbon fiber. All of thesefillers and combinations offillers are statistically sig-nificant at the 95% confidence level (P < 0.05). Theseresults agree with what was obtained for the nylon-

based composites.One important result from this study is that the

combinations of two different carbon fillers, namely,carbon black and synthetic graphite, carbon blackand carbonfiber, and synthetic graphite and carbonfiber were statistically significant. The fact that allthe two filler interaction terms were significant in-dicates that the composite SE is higher than whatwould be expected from the additive effect of eachsinglefiller.24 To the authorsknowledge, this is thefirst time in the literature that a synergistic effect of

TABLE XIIFactorial Design Analysis for Polycarbonate-Based

Conductive Resins at 300 and 800 MHz

Term Effect P

300 MHz

CB 24.32 0.000

SG 15.97 0.000

CF 15.44 0.000

CB*SG 7.30 0.000

CB*CF 6.63 0.000

SG*CF 5.46 0.000

800 MHz

CB 21.39 0.000

SG 15.14 0.000

CF 14.53 0.000

CBSG 5.73 0.000

CBCF 4.90 0.000

SGCF 3.99 0.000

combining different carbonfillers on the compositeSE has been observed. It is likely that conductivepathways are formed that link the high surfacearea carbon black, synthetic graphite particles, andcarbonfibers.

Conclusions

As a result of this study, the following conclusionscan be made:

Extrusion and injection molding reduced thelength and aspect ratio of the carbon fiber inthe conductive composites to approximatelyhalf of its original length (168 m) and as-pect ratio (16.8). However, the length (typi-cally 6070 m) and aspect ratio (typically1.71.8) of the ThermocarbTM TC-300 SpecialtyGraphite in the composite specimens remainsimilar to that of the as received material.This high purity synthetic graphite likely main-tained its size better as compared to carbonfiber since the as received ThermocarbTM TC-300 material has a smaller length and aspectratio.

For the SE samples, the synthetic graphite parti-cles and carbon fibers are mainly oriented trans-verse to the direction of SE measurement.

By studying the SE factorial experiment results

in both nylon and polycarbonate, severalconclusions can be made at the 95% con-fidence level for both polymers. First, car-

bon black caused the largest increase in SE,followed by ThermocarbTM TC-300 SpecialtyGraphite and carbon fiber, which have asimilar effect. Adding two different fillersalso causes SE to increase in the followingorder:

Carbon Black/ThermocarbTM TC-300 SpecialtyGraphite> Carbon Black/Carbon Fiber> Thermo-carbTM TC-300 Specialty Graphite /Carbon Fiber

To the authors knowledge, this is the firsttime in the literature that a synergistic effect ofcombining different carbon fillers on compositeSE has been observed. It is likely that conduc-tive pathways are formed thatlinkthe highsurface area carbon black, synthetic graphiteparticles, and carbon fibers, which results inimproved composite SE.

110 VOL. 22, NO. 2

-

8/10/2019 Shielding affects of Nylon and cnts

16/16

SHIELDING EFFECTIVENESS IN NYLON 6,6- AND POLYCARBONATE-BASED RESINS

Acknowledgments

The authors thank Conoco, Akzo Nobel,BP/Amoco, and DuPont for providing polymersand carbonfillers.

References

1. Donnet, J.-B.; Bansal, R. C.; Wang, M.-J. Carbon Black, 2nded.; Marcel Dekker: New York, 1993.

2. Huang, J.-C. Adv Polym Technol 2002, 21, 299.

3. Bigg, D. M. Polym Compos 1987, 8, 1.

4. White, D. R. J. A Handbook Series on ElectromagneticInterference and Compatibility; Don White Consulatants,Germantown, MD, 1971; Vol. 5.

5. ASTM Standard D 4935-89 Reapproved 1994; American

Society for Testing and Materials, Philadelphia, PA, 1996.6. Bushko, W. C.; Stokes, V. K.; Wilson, J. In Proceedings of the

Society of Plastics Engineers Annual Technical Conference,ANTEC 1999, New York, May 1999; p. 1499.

7. Bigg, D. M. Adv Polym Technol 1984, 4, 255.

8. Bigg, D. M. Polym Engr Sci 1977, 17, 842.

9. Versieck, J. In Proceedings of the Society of Plastics Engi-neers Annual Technical Conference, ANTEC 2000, Orlando,FL, May 2000; p. 1438.

10. Murthy, M.In Society of Plastics Engineers Regional TechnicalConference, Chicago, IL, June 1988.

11. DuPont Zytel Nylon Resin Product and Properties, DuPontEngineering Polymers, Version 95.9; Wilmington, DE.

12. GE Engineering Thermoplastics Product Guide: Lexan PCResin,CDC-6621(2/98) CA;GE Plastics, Pittsfield, MA01201.

13. Clingerman, M. L.; Weber, E. H.; King, J. A. Polym Compos2002, 23, 911.

14. Akzo Nobel Electrically Conductive Ketjenblack Product

Literature; 300 S. Riverside Plaza, Chicago, IL 60606,1999.

15. Conoco Carbon Products Product Literature; Conoco Inc.,Houston, TX 77252-2197, 1999.

16. Amoco Performance Products: High Thermal ConductivityPitch Based Graphite Fibers; Amoco Polymers, Alpharetta,GA 30005.

17. Rulison, C. Kruss Technical Note No. 302; Kruss USA,Charlotte, NC.

18. Fowkes, F. M. Industrialand Engineering Chemistry1964, 56,40.

19. Clingerman, M. L. Development and Modelling of Electri-cally Conductive Composite Materials, Ph.D. Dissertation;Michigan Technological University, Houghton, MI, 2001.

20. Weber, E. H. Development and Modeling of Thermally Con-ductive Polymer/Carbon Composites, Ph.D. Dissertation;Michigan Technological University, Houghton, MI,2001.

21. Bigg, D. M. Polym Compos 1985, 6, 20.

22. Weber, E. H.; Clingerman, M. L.; King, J. A. J Appl Polym Sci2003, 88(1), 112.

23. Rulison, C. In 24th Annual Meeting of Adhesion Society,Williamsburg, VA, March 2001.

24. Montgomery, D. C. Design and Analysis of Experiments, 5thed.; Wiley: New York, 2001.

ADVANCES IN POLYMER TECHNOLOGY 111