Scope •To convert manual or PLC based autoclave to a dedicated and fully automatic system. • Existing product with Heater and low water sensor (Bimetallic or other). • Water Inlet/outlet valve, Vacuum inlet/outlet valve, Steam Inlet/outlet. • Any specific requirement specification based on knowledge sharing. Input • Technical Documentation including user manual, assembly manual, service manual, wiring diagram, system installation training etc. and production training. • Tested and ready to use control system based on per unit rate. Deliverables • Safe and reliable solution to meets international standard for high pressure equipment. • To meet Bowie & Dick Equipment control algorithms and sequence. Confidential © Real Time Consultant Case Study: Automatic Autoclave/ Sterilizer • Selectable temperature of 121 or 135 Degrees Celsius. • Automatic operation through all the Bowie & Dick Equipment control cycles. • Thermal printer based report generation. • Microcontroller based digital and graphical indication for Temperature, Pressure, Lapse time and executed cycle status. • Datalogging: 1000 record with complete details. • Fuzzy logic based solenoid valve control for precise temperature, pressure, vacuum (Vacuum pump), drying cycle, water feed control. • Water quality measurement and display parameter pH and TDS. Challenges Value Addition

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Scope•To convert manual or PLC based autoclave to a dedicated and fully automatic

system.

• Existing product with Heater and low water sensor (Bimetallic or other).• Water Inlet/outlet valve, Vacuum inlet/outlet valve, Steam Inlet/outlet.• Any specific requirement specification based on knowledge sharing.

• Existing product with Heater and low water sensor (Bimetallic or other).• Water Inlet/outlet valve, Vacuum inlet/outlet valve, Steam Inlet/outlet.• Any specific requirement specification based on knowledge sharing.

Input

• Technical Documentation including user manual, assembly manual, service manual, wiring diagram, system installation training etc. and production training.

• Tested and ready to use control system based on per unit rate.

• Technical Documentation including user manual, assembly manual, service manual, wiring diagram, system installation training etc. and production training.

• Tested and ready to use control system based on per unit rate.

Deliverables

• Safe and reliable solution to meets international standard for high pressure equipment.

• To meet Bowie & Dick Equipment control algorithms and sequence.

• Safe and reliable solution to meets international standard for high pressure equipment.

• To meet Bowie & Dick Equipment control algorithms and sequence.

Confidential © Real Time Consultant

Case Study: Automatic Autoclave/ Sterilizer

• Selectable temperature of 121 or 135 Degrees Celsius.• Automatic operation through all the Bowie & Dick Equipment control cycles.• Thermal printer based report generation.• Microcontroller based digital and graphical indication for Temperature,

Pressure, Lapse time and executed cycle status.• Datalogging: 1000 record with complete details.• Fuzzy logic based solenoid valve control for precise temperature, pressure,

vacuum (Vacuum pump), drying cycle, water feed control. • Water quality measurement and display parameter pH and TDS.

• Selectable temperature of 121 or 135 Degrees Celsius.• Automatic operation through all the Bowie & Dick Equipment control cycles.• Thermal printer based report generation.• Microcontroller based digital and graphical indication for Temperature,

Pressure, Lapse time and executed cycle status.• Datalogging: 1000 record with complete details.• Fuzzy logic based solenoid valve control for precise temperature, pressure,

vacuum (Vacuum pump), drying cycle, water feed control. • Water quality measurement and display parameter pH and TDS.

Challenges

Value

Addition

Confidential © Real Time Consultant

Automatic Autoclave/ Sterilizer-Basic

Heater

Core power Supply

Real Time Clock

Pressure Sensor

Interface

Water Sensor

Microcontroller Vacuum

Pump

RS-232/485 Interface

Pt-100 Sensor

interface

OnBoard SSR

EEPROM

Contactor/ Relay

Contactor/ Relay

pH Sensor Interface

TDS Sensor Interface

EMI/EMC Filter and protection

Solenoid valve-Water Outlet

Solenoid valve-Water inlet

Pt-100 Sensor

Pressure Sensor 4-

20mA/ VoutPrinter

TDS Sensor

Door Status

Door Sensor

pH Sensor

Heater with

Bimetallic

Solenoid valve-Vacuum Inlet

Solenoid valve-Vacuum Outlet

Solenoid valve-Steam Inlet.

Solenoid valve-Steam Outlet

FND and Keypad

Confidential © Real Time Consultant

Automatic Autoclave/ Sterilizer-Advance

Heater

Core power Supply

Real Time Clock

Pressure Sensor

Interface

Water Sensor

Microcontroller Vacuum

Pump

RS-232/485 Interface

Pt-100 Sensor

interface

OnBoard SSR

EEPROM

Contactor/ Relay

Contactor/ Relay

pH Sensor Interface

TDS Sensor Interface

EMI/EMC Filter and protection

Solenoid valve-Water Outlet

Solenoid valve-Water inlet

Pt-100 Sensor

Pressure Sensor 4-

20mA/ VoutPrinter

TDS Sensor

Door Status

Door Sensor

pH Sensor

Bimetallic

Solenoid valve-Vacuum Inlet

Solenoid valve-Vacuum Outlet

Solenoid valve-Steam Inlet.

Solenoid valve-Steam Outlet

20-12-08 21:34Proc.: SterilizationRead Temp: 135°CPressure: 21.5 PSIG

Pre-Vacuum

Pulse-1

Steriliz-ation

Pulse+2

ExhaustDrying

Display and Keypad

Confidential © Real Time Consultant

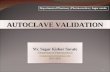

134°C

0-4 min

Bowie & Dick Equipment control

Time

Pre

ssu

re

Atmospheric pressure

Negative Pressure

Positive Pressure

Pre-Vacuum Pulsing-1

Pulsing-2

Sterilization

Automatic Autoclave/ Sterilizer

Confidential © Real Time Consultant

Area of co-operation

Product Design as per given specification. Ready to use solution based on Embedded H/W and Software.We deliver ready to use solution for your product with latest feature and requirement.Latest technology to meets international standard and feature.Complete customization of product as per customer requirement.Product design as per IEC/UL standard guideline (Safety :IEC60601-1 and EMI-EMC: IEC60601-1-2) Sourcing. Vendor development. Mechanical Design Support.Free onsite support and evolution sample available.No development charges, only per unit rate is charged after product approved by the customer.

Confidential © Real Time Consultant

Automatic Autoclave/ Sterilizer

Contact for support and evaluation sample.

Real Time ConsultantDelhi: B-232/1, Chatterpur Extn.

Mehrauli-110074.09350831213, 09958700553.

Mumbai: 101, A-Wing, Lake Bloom Appartment, Andheri (E), Powai, Mumbai09322245924

Related Documents