By GROUP 1 Amrit(05) Pratiksha (22) Sandeep (30) Sneha (33) Tandrima (37) DELL: FORD

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

By GROUP 1 Amrit(05) Pratiksha (22) Sandeep (30) Sneha (33) Tandrima (37)

Comparison of Buying ExperiencesBuying car online Personal in nature. Needed to be touched High involvement at all stages of buy Restricted Customization Safety & reliability concerns Buying Dell laptop Generic in nature Low involvement for second or third buy Extreme Customization No safety & reliability concerns

Nature of Product: Primary reason for differences

What is virtual integration and what benefits Dell derives from virtual integration? How important are these advantages in the auto business? Virtual integration is a new form of value chain management. Under such a system, the links of the value chain are brought together by informal arrangements among suppliers and customers. Shipments of the components that the firm needs can be easily arranged through the Internet or a networked computer system. The same type of arrangement allows the firm to fully serve their customers in ordering, services, or any other needs.

A way of capturing the advantage of vertical integration without actually vertically integrating Vertical integration solves production problems related to communications, coordination, and control but at a cost of the increased overhead needed to arrange production organization

Virtual integration therefore is the ability to achieve the advantage of vertical integration without incurring the overhead.

Communication and coordination Business partners treated as insiders of the company. Control The prospect of improved control over the actions of suppliers is another important rationale for virtual integration. Un-integrated partners can exert power over each other as transactions unfold over time

Real time responsiveness and inventory management Real-time updating of order status and the ability to check order status regardless of where the order is in the fulfillment process provided Dell with differentiating capabilities. Inventory velocity

Forecasting

Dell s direct relationship with customers are key to forecasting. Dell has easy access to data useful for forecasting; most of the data are already in Dell s systems In case of Ford, the dealers own most of the direct data about customer demand. Ford has a very base of individual customer unlike Dell that has a relatively small number of institutional customers

Direct model in case of Auto Industry Many components such as tyres, windscreen wipers, and electrical components are sourced from large suppliers and are same for all companies. These products are well suited to a closer integration of supply - virtual integration. Difficult in case of model specific component. Being powerful and large company make it difficult to develop virtual integration.

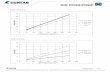

Compare the enterprise models of Dell & Ford. Do you think the financial performances the two firms are linked to their enterprise models?

SimilaritiesCustomers frequently steered to PCs with high availability to balance supply and demand Suppliers maintain nearby ship points; delivery time 15 minutes to 1 hour External logistics supplier used to manage inbound supply chain Focused on strategic partnerships: suppliers down from 200 to 47

DifferencesSuppliers own inventory until it is used in production Demand forecasting is critical changes are shared immediately within Dell and with supply base Demand pull throughout value chain information for inventory substitution

Financials Only assembly facilities in case of Dell reducing cost of manufacturing set ups. Inventory confined to suppliers in case of Dell reducing inventory cost No dealers cut down dealer s margin Employees less in no. in case of Dell leading due to save on expenses.

What do you think is the ideal use of internet in the autobusiness vis--vis its use in PC industry (you may focus on marketing & distribution, production & purchasing, after sales service, new product development)? Ford must think about its relationships with suppliers, dealers and customers. As supply chain systems staff members study the Dell model in particular, they come to appreciate that virtual integration must include design not only of the supply chain but also of fulfillment, forecasting, purchasing, and a variety of other functions that had long been considered separately within the Ford hierarchy. Needs to change how it is historically operated internally and how it has interacted with important partner constituencies (including dealers)

Focus on digital advertisement Online marketing surveys aimed at customers. Online customer feedback centre. Customer interactive forum Enabling MIS.

What historical legacies and operational issues do you think will affect Ford s ability to move to a Builtto-order model? Ford is 100 yrs old Founded 1903, Dell on the other hand was founded 15 years ago Product variety Necessitates the management of large number of individual component inventories Production capacity for individual components get set long in advance and cannot be changed quickly

Process Complexity A large number of suppliers 3 tiers of suppliers Business was usually over the phone and fax Ford a $150billion company enjoy a tremendous leverage over its suppliers Annual component price decrease and open book

Powerful independent dealer network Unionized labor force Incompatible systems Ford credit DEC Parts and service IBM Suppliers and dealers Variety of systems

What practical challenges must Ford address as it tries to establish internet linkages with its supply base and its customers? Difficulties in establishing business to business linkages Difficult to determine feasible and appropriate redesign of the process Ford supplier network had many more layers and many more companies as compared to Dell New globe approach needed technology be used to overcome geographical constraints on information flow Lack of technology and technological sophistication that prevail in the supply chain, especially at lower tiers To create consistency in technology standards and processes in supplier network At Dell, purchasing activities reported into product development organisation but at Ford, purchasing organizationally independent of product development

Customer responsiveness initiatives that Ford took to position the company favorably for success Reduce the customer order to product delivery time to 15 days Forecasting of customer demand from the dealers Having regional mixing centers that optimize scheduled deliveries of finished vehicles Creating an experience for the customer in the showrooms that would make him come back frequently Superior selling service and more service outlets Launched a public internet site by mid-1995

Recommendations If Ford is to successfully emulate Dell then they are best able to do this in areas where they have similarities. The most notable congruency is in the area of supply of generic components. Here Ford should continue its process of building strategic relationships. Where components are of a more specialised nature then Ford should examine the relationships to ascertain whether bringing suppliers closer to the company will offer benefits to both parties.

Ford should work on its' internal culture. Integration of supply chains on the scale practiced by Dell can only occur in an environment where information flows freely to all points of the supply network. As outlined in the case documents; Ford maintains a high degree of separation of the purchasing departments from marketing and production. Ford will not be able to provide focus up and downstream unless they themselves are committed to an open culture where logistics information is a part of the life blood of the company.

The relationship with customers is more difficult. The dealer network will probably be averse to Ford moving towards direct sales, as it will threaten their livelihood. They can reap some of the benefits by introducing a web based ordering service for cars, allowing clients to specify the car that they want and then matching the requirement to the cars already in stock through out the network. If a client prefers they could order a vehicle built to order and supplied to a local dealer. This will enable Ford to become closer to the needs of clients, seeing accurately what they want rather than what they buy because it is available.

This compromise will give the company some benefits: Information about customer wishes. Opportunity to reduce both dealer stocks and Fords' stocks by avoiding duplication. Delaying the final form of the product by increasing the range of dealer fitted items will enable Ford to simplify manufacture, whilst offering a greater degree of 'real customisation' to clients. Delay of final form will increase dealer revenues, buying their enthusiasm and consent for the next stages of coordination.

Related Documents