Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

© 2010 PACCAR INC - All Rights Reserved

This manual illustrates and describes the operation of features or equipment which may be either standard or optional on this vehicle. This manual may also include a description of features and equipment which are no longer available or were not ordered on this vehicle. Please disregard any illustrations or descriptions relating to the features or equipment which are not on this vehicle.

Peterbilt reserves the right to discontinue, change specifications, or change the desing of its vehicles at any time without notice and without incurring any obligation.

The information contained in this manual is proprietaary to Peterbilt. Reproduction, in whole or in part, by any means is strictly prohibited without prio written authorication from PACCAR Inc.

Quick Table of Contents

Introduction . . . . . . . . . . . . . . . . . . 1

Cab And Frame Access . . . . . . . . . . . . 6

Getting To Your Engine . . . . . . . . . . . . . . 11

Controls And Displays. . . . . . . . . . . . . . . . . . . 14

Seat And Restraint Systems . . . . . . . . . . . . . . . . . 75

Driver’s Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Starting And Operating The Vehicle . . . . . . . . . . . . . . . . . . 93

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Vehicle Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Consumer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Subject Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Y53-6032.book Page 2 Monday, May 24, 2010 3:37 PM

PART 1: INTRODUCTION HOW TO FIND WHAT YOU WANT

(R05/10) Y53-6032 – 1 –

PART 1: INTRODUCTION

This manual contains useful information for the safe andefficient operation of your Peterbilt Model 587. It also pro-vides information on maintaining your vehicle in the bestcondition, with an outline for performing safety checks andbasic preventive maintenance inspections.

We have tried to present the information you’ll need tolearn about your vehicle’s functions, controls, and opera-tion—and to present it as clearly as possible. We hopeyou’ll find this manual easy to use.

Please remember, though—this manual is not a trainingmanual. It can’t tell you everything you need to knowabout driving your Peterbilt vehicle. For that you need agood training program or truck driving school. If you havenot been trained, get the proper training before you drive.Only qualified drivers should drive this vehicle.

There will be times when you need to take this manual outof your Peterbilt. When you do, please be sure to return itto the cab when you are finished using it. That way it willbe there when you need it the next time or when you passthe vehicle on to the next user.

How To Find What You WantThere are several tools built into this manual to help youfind what you need quickly and easily.

First is the Quick Table of Contents. Located at the frontof the manual, this lists the main subjects covered andgives page numbers where you can find these subjects.Use the Quick Table of Contents to find information on alarge subject like “Maintenance.”

Cross-referenced citations also help you get the informa-tion you need. If some other part of the manual containsfurther information on the subject you are reading about,we’ll indicate that in a cross-reference like this: (See“PART 6: DRIVER’S CHECKLIST”). You won’t have to gosearching for more information.

Finally you’ll find a helpful Subject Index. It’s in the backof the manual and alphabetically lists the subjects cov-ered. So if you want information on brakes, for example,just look under Brake in the Subject Index. You’ll find allthe pages listed where brakes or braking are discussed.

Y53-6032.book Page 1 Monday, May 24, 2010 3:37 PM

A SPECIAL WORD ABOUT REPAIRS PART 1: INTRODUCTION

– 2 – Y53-6032 (R05/10)

A Special Word About RepairsYour Peterbilt dealer’s service center is the best place tohave your vehicle repaired. You can find Peterbilt dealers allover the country with the equipment and trained personnelto get you back on the road quickly—and keep you there.

Your vehicle is a complex machine. Anyone attemptingrepairs on it needs good mechanical training and theproper tools. If you are sure you have these requirements,then you can probably perform some repairs yourself.However, all warranty repairs must be performed by anauthorized Peterbilt service facility. If you aren’t an experi-enced mechanic, or don’t have the right equipment,please leave all repairs to an authorized service facility.They are the ones equipped to do the job safely and cor-rectly.

WARNING! Attempting repair work without suf-ficient training, service manuals, and the propertools can be dangerous for yourself and others.You could be injured or you could make yourtruck unsafe and cause death or serious injury.Do only those tasks you are fully qualified to do.

Maintenance Manuals. If you do decide to do any com-plex repair work, you’ll need the Peterbilt Maintenancemanuals. Order them from your authorized dealer. Pleaseprovide your Chassis Serial Number when you order, tobe sure you get the correct manuals for your vehicle. Allowabout four weeks for delivery. There will be a charge forthese manuals.

Final Chassis Bill of Material. A complete, nonillustratedcomputer printout listing of the parts used to custom-buildyour Peterbilt vehicle is available through the Peterbiltdealer from whom your purchased your vehicle.

WARNING! Modifying your vehicle can make itunsafe. Some modifications can affect yourtruck’s electrical system, stability, or otherimportant functions. Before modifying yourvehicle, check with your dealer to make sure itcan be done safely.

Additional Sources of InformationOperator’s manuals are also supplied by the manufactur-ers of components such as the engine, seats, transmis-sion, and radio in your Peterbilt. If you are missing any ofthese manuals, ask your Peterbilt dealer to supply them.

Y53-6032.book Page 2 Monday, May 24, 2010 3:37 PM

PART 1: INTRODUCTION SAFETY SIGNALS

(R05/10) Y53-6032 – 3 –

Another place to learn more about trucking is a local truckdriving school. Contact one near you to find out whatkinds of instruction it offers.

Federal agencies such as The National Highway TrafficSafety Administration and the Federal Motor CarrierSafety Administration also have information and variousagencies in state governments are sources for regulationsthat differ from state to state.

Safety SignalsA number of alerting messages are in this manual. Pleaseread and follow them. They are there for your protectionand information. These messages can help you avoidinjury to yourself and others, as well as prevent costlydamages to the vehicle.

Key symbols and “signal words” are used to indicate whatkind of message is going to follow. Pay special attention toinstructions prefaced by symbols and the signal words“WARNING”, “CAUTION”, and “NOTE”. Please do notignore any of these alerts.

WARNING

When you see this word, the message that fol-lows is especially vital. It signals a potentiallyhazardous situation which, if not avoided, couldresult in an injury or death. This message will tellyou what the hazard is, what can happen if youdon't heed the warning, and how to avoid it.

Example:

WARNING! Never carry additional fuel con-tainers in the vehicle. Such containers, full orempty, may leak, explode or cause a fire in theevent of a collision.

CAUTION

Signals a potentially hazardous situationwhich, if not avoided, could result in property orvehicle damage.

Example:

CAUTION: Continuing to operate your vehiclewith insufficient oil pressure will cause seri-ous engine damage.

Y53-6032.book Page 3 Monday, May 24, 2010 3:37 PM

VEHICLE SAFETY PART 1: INTRODUCTION

– 4 – Y53-6032 (R05/10)

NOTE

Provides general information: for example, thenote may suggest how to operate the vehiclemore efficiently.

Example:

NOTE: Pumping the accelerator will not assist instarting the engine.

Vehicle SafetyMake sure your Peterbilt is in top working condition beforeheading out on the road—it is the responsible driver's dutyto do so. Inspect the vehicle according to “PART 6:DRIVER’S CHECKLIST”.

WARNING! Do not drink and drive. Yourreflexes, perceptions, and judgment can beaffected by even a small amount of alcohol.You could have a serious—or even fatal acci-dent—if you drive after drinking. Please donot drink and drive or ride with a driver whohas been drinking.

WARNING! The use of alcohol, drugs, and cer-tain medications will seriously impair percep-tion, reactions, and driving ability. Thesecircumstances can substantially increase therisk of an accident and death or personalinjury.

Please remember, this manual is not a training manual. Itcannot tell you everything you need to know about drivingyour Peterbilt vehicle. For that you need a good training

Please take the time to read these messages when you see them, and remember:

WARNING!

Something that could seriously injure or kill you or oth-ers.

CAUTION:

Something that could cause property or vehicle dam-age.

NOTE:

Useful information.

Y53-6032.book Page 4 Monday, May 24, 2010 3:37 PM

PART 1: INTRODUCTION VEHICLE SAFETY

(R05/10) Y53-6032 – 5 –

program or truck driving school. If you have not beentrained, get the proper training before you drive. Onlyqualified drivers should drive this vehicle.

Safe driving is only possible with the proper concentrationon the driving task. Keep distraction to a minimum toimprove your concentration. Examples of distractionsmay include radio controls, GPS navigation controls, cel-lular telephone calls, cellular text messages, reading orreaching for something on the floor. Minimizing your dis-tractions will improve safe driving and will help avoid anaccident involving death or personal injury.

Be aware of local regulations that may prohibit the use ofcellular telephones while driving. In addition to being anunsafe practice, it may be against local ordinances to usecellular devices while operating the vehicle.

Every new Peterbilt vehicle is designed to conform to allFederal Motor Vehicle Safety Standards applicable at thetime of manufacture. However, even with these safety fea-tures, continued safe and reliable operation dependsgreatly upon regular vehicle maintenance. The vehiclemust be operated within the range of its mechanical capa-bilities and the limits of its load ratings. (See the Tire andRim Weight Ratings label on the driver's door edge.)

Y53-6032.book Page 5 Monday, May 24, 2010 3:37 PM

PART 2: GETTING INTO & OUT OF THE CAB AND FRAME ACCESS

– 6 – Y53-6032 (R05/10)

PART 2: GETTING INTO & OUT OF THE CAB AND FRAME ACCESS

Be careful whenever you get into or out of your vehicle’scab. Always maintain at least three points of contact withyour hands on the grab handles and your feet on thesteps.

WARNING! Do not jump out of the cab or getinto the cab without proper caution. You couldslip or fall, possibly suffering death or seriousinjury. You could slip and fall if the steps arewet or icy, or if you step in fuel, oil, grease,snow or mud.

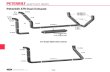

The illustrations that follow show the best ways to enterand exit a cab.

Vehicle With External Grab Handle

02958-A

Y53-6032.book Page 6 Monday, May 24, 2010 3:37 PM

PART 2: GETTING INTO & OUT OF THE CAB AND FRAME ACCESS DOOR LOCK AND KEYS

(R05/10) Y53-6032 – 7 –

Vehicle Without External Grab Handle

Door Lock and KeysDoors can be locked from the inside by using the lock but-ton. Close the door then push the button down to lock.Doors automatically unlock when you open them frominside, and can be locked from the outside with the keyonly. To lock or unlock the doors from outside the cab,insert the key in the lock. Turn the key toward the rear tolock; forward to unlock.

WARNING! To help lessen the chance and/orseverity of death or personal injury in case ofan accident, always lock the doors while driv-ing. Along with using the lap shoulder beltsproperly, locking the doors helps preventdoors from inadvertently opening and occu-pants from being ejected from the vehicle.

Remote Keyless Entry (optional)This vehicle may be equipped with a Remote KeylessEntry (RKE) system that adds security and convenienceto your vehicle. The system will lock or unlock the driver’sdoor and passenger’s door with the key fob and alert youwith parking lights when the selected door’s are locked orunlocked. The system includes two key fobs that providesecure rolling code technology that prevents someonefrom recording the entry signal.

Operation

To unlock the driver’s door, press the UNLOCK buttononce. The driver's door will unlock and the parking lightswill come on for 40 seconds.

To unlock the passenger’s door press the UNLOCK buttononce and press again within 5 seconds.

02958-B

Y53-6032.book Page 7 Monday, May 24, 2010 3:37 PM

DOOR LOCK AND KEYS PART 2: GETTING INTO & OUT OF THE CAB AND FRAME ACCESS

– 8 – Y53-6032 (R05/10)

To lock both doors press the LOCK button. The doors willlock and the parking lights will come on for 2 seconds. Ifthe doors are open they will not lock. The range of theRKE system should be approximately 30 ft. This will bereduced if it is operated close to other RF sources such asTV/radio transmitters and cell towers.

Batteries

The key fob uses one CR2032, 3V battery. Batteriesshould last approximately three years, depending on use.Consistently reduced range is an indicator that the batteryneeds replacement. Batteries are available at most dis-count, hardware and drug stores.

The battery is located under the back cover of the key fob.Be sure to synchonize the key fob every time you replacethe batteries.

Synchronization

The key fob may need to be synchronized to the truckwhen the battery is replaced or when the key fob has notbeen used for an extended period time.

To Synchronize A Key Fob

1. Hold the key fob near the receiver.

NOTE: The receiver is located behind theSpeedometer/Tachometer cluster assembly.

2. Press and hold both the Lock and Unlock buttons atthe same time for approximately 7 seconds.

3. When the key fob is resynchronized, the doors willlock then immediately unlock.

4. If the fob fails to synchronize, it could be programmedto a different truck or could have failed. Contact yourdealer to re-program your key fob.

Y53-6032.book Page 8 Monday, May 24, 2010 3:37 PM

PART 2: GETTING INTO & OUT OF THE CAB AND FRAME ACCESS CLIMBING ONTO THE DECK PLATE

(R05/10) Y53-6032 – 9 –

Climbing Onto the Deck PlateWhen you are climbing onto and off the deck plate, main-tain at least three points of contact with your hands on thegrab handles and your feet on the steps.

NOTE: Any alteration (adding bulkheads, head-ache racks, tool boxes, etc.) behind the cab orsleeper that affects the utilization of grab handles,deck plates, or frame access steps installed byPeterbilt must comply with FMCSR 399.

WARNING! Do not step on vehicle compo-nents without antiskid surfaces or use com-ponents not designed for entry-and-exit use.You could fall and kill or injure yourself if youstep onto a slippery surface. For example:• Do not step onto the surface of a fuel tank.

A fuel tank is not a step. The tank surfacecan get very slippery, and you might not beable to prevent a fall.

• Use only the steps and handholds provided,not chain hooks, quarter fenders, etc.

• Do not climb onto and off the deck plate—use steps and grab handle provided. If thereis no deck plate, or if proper steps and grabhandles are not provided, do not climb ontothe area behind the cab.

• Do not climb onto or stand on the framerails. The frame rails are very slippery andcould cause you to fall, resulting in death orpersonal injury.

• Always reinstall steps before entering thecab or accessing the deck plate. Withoutsteps, you could slip and fall, resulting inpossible injury to yourself.

FCC ID: L2C0031T IC: 3432A-0031TFCC ID: L2C0032R IC: 3432A-0032R

This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry Canada. Operation is subject to the following two condi-tions:

1. This device may not cause harmful interference, and2. This device must accept any interference received, including

interference that may cause undesired operation.

WARNING: Changes or modifications not expressively approved by the party responsible for compliance could void the user's authority to operate the equipment. The term “IC:” before the radio certification number only sig-nifies that Industry Canada technical specifications were met.

Y53-6032.book Page 9 Monday, May 24, 2010 3:37 PM

CLIMBING ONTO THE DECK PLATE PART 2: GETTING INTO & OUT OF THE CAB AND FRAME ACCESS

– 10 – Y53-6032 (R05/10)

Hold handles as you step up

Three points of contact

Three points of contact as you reach the deck area

Three points of contact as you step to the deckplate

Y53-6032.book Page 10 Monday, May 24, 2010 3:37 PM

PART 3: GETTING TO YOUR ENGINE HOOD HOLD DOWNS

(R05/10) Y53-6032 – 11 –

PART 3: GETTING TO YOUR ENGINE

Hood Hold Downs Hood hold downs keep a hood from opening unexpect-edly.

CAUTION: A hood not latched securely couldopen during operation and cause vehicledamage. Be sure to latch the hood securely.

Hood TiltFollow this procedure to tilt the hood.

WARNING! A pivoting hood could hurt some-one or be damaged itself. Before opening orclosing the hood, be sure there are no peopleor objects in the way. Failure to stand in aposition of safety can cause death or personalinjury.

1. To open your hood, unlock the hood hold downs byunlatching them. Put one hand on the top of the hoodfront, one foot on the bumper, and one foot on theground. Tilt the hood forward.

LATCHED

UNLATCHED

Y53-6032.book Page 11 Monday, May 24, 2010 3:37 PM

HOOD TILT PART 3: GETTING TO YOUR ENGINE

– 12 – Y53-6032 (R05/10)

2. Locate the hood anti-blowdown device mounted to thedriver side hood dampener.

WARNING! The hood uses two struts to con-trol movement during opening and closing.Do not tilt the hood with one or both strutsdisconnected. Replace damaged, worn, orleaking struts as soon as possible. Tilting ahood with either strut disconnected or defec-tive may cause the hood to tilt too rapidly.You could be killed or injured and the hoodcould be damaged.

3. Verify that the device was previously reset during thelast hood closing event. This is done by pulling thecollar in the downward direction.

WARNING! Always verify that the hood anti-blowdown device has been reset when open-ing the hood. The device is reset either byfully closing the hood or by manually pullingthe device down. Failure to reset the antiblow-down device may lead to a hood closing unin-tentially which can cause death or personalinjury to anyone under the hood.

Hood antiblowdown device

PULL DOWN TO RESET DEVICE

Y53-6032.book Page 12 Monday, May 24, 2010 3:37 PM

PART 3: GETTING TO YOUR ENGINE HOOD TILT

(R05/10) Y53-6032 – 13 –

4. To close the hood, disengage the hood antiblowdowndevice by pushing it in the upward direction. Thedevice will move about 1/4” up the shaft. You may feela click when the device disengages.

CAUTION: Attempting to close a hood withoutdisengaging the hood antiblowdown devicemay cause equipment or vehicle damage.

5. Firmly push upward and rearward on the hood orna-ment to start the hood tilting backwards. Continue topush until the hood comes is fully closed.

6. Secure the hood latches on both sides of the vehicleto hold the hood in the closed position.

WARNING! If the hood is not latched securely,it could open during operation and cause anaccident involving death or injury. Be sure thehood is latched securely before moving thevehicle.

PUSH UP TO DISENGAGE DEVICE

Y53-6032.book Page 13 Monday, May 24, 2010 3:37 PM

YOUR INSTRUMENT PANEL PART 4: CONTROLS AND DISPLAYS

– 14 – Y53-6032 (R05/10)

PART 4: CONTROLS AND DISPLAYS

This part explains the location of the various features onyour vehicle and describes their function. For informationon using these features in driving, see the paragraphsbelow.

Your Instrument PanelPlease remember that each vehicle is custom-made. Yourinstrument panel may not look exactly like the one in thepictures that follow.

We have tried to describe the most common features andcontrols available, so your vehicle may not have some ofthe ones that appear in this section. You can pick out theparts that apply to you and read them to be fully informedon how your particular vehicle operates.

WARNING! Use extreme caution when usingdevices while driving (such as cellular tele-phones) that distracts you from safe drivingpractices. Failure to properly concentrate onthe driving task can result in an accidentinvolving death or personal injury. Limit theuse of such devices to when it is safe to doso; not while operating the vehicle.

Y53-6032.book Page 14 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS YOUR INSTRUMENT PANEL

(R05/10) Y53-6032 – 15 –

Typical Cab Instruments and Controls LEFT SIDE

1. Hazard Switch 10. Oil Pressure

2. Ignition Switch 11. Primary Air Pressure

3. Headlight Light Switch 12. Secondary Air Pressure

4. ID/Clearance Lamps Switch 13. Fuel

5. Voltmeter 14. Cigarette Lighter

6. Engine Coolant Temp 15. Menu Control Switch

7. Tachometer 16. Rear A/C Switch

8. Driver Information Display 17. Dome Light Switch

9. Speedometer 18. Panel Dimmer18

17

16

15

14

13

121110876

5

4

3

9

21

Y53-6032.book Page 15 Monday, May 24, 2010 3:37 PM

YOUR INSTRUMENT PANEL PART 4: CONTROLS AND DISPLAYS

– 16 – Y53-6032 (R05/10)

RIGHT SIDE

1. Parking Brake Valve 12. Optional

2. Trailer Air Supply Valve 13. Engine Brake

3. Heater/AC Control Panel 14. Engine Brake Sel

4. Engine Fan Switch 15. Interaxle Differential LockSwitch

5. Floor Light Switch 16. 5th Wheel Lock Switch

6. Regeneration Switch 17. Air Suspension Switch

7. Load Light Switch 18. Radio

8. Fog Lights Switch 19. CB Radio

9. Cruise Control Switch 20. Traction Control Switch

10. Transmission Temperature 21. Mirror Heater Switch

11. Cruise Control Sel Switch

19

18

20

21

12

3

4

5

6

7

8

9

10 11 12 13 14 15

16 17

Y53-6032.book Page 16 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

(R05/10) Y53-6032 – 17 –

Instruments And ControlsMenu Control Switch (MCS)The MCS is used to navigate the Driver Information Dis-play unit. The Menu Control Switch is located on the D Panelas shown in the illustration below.

The MCS has the following functions:

• Rotating the MCS

– Selecting display

– Setting values

• Pushing the MCS

– Confirming desired selection

Standard Warning Lights and Audible AlarmThe warning lights and audible alarm may indicate a sys-tem malfunction. Check the lights frequently, and respondproperly as soon as you see one go on. These lights couldsave you from a serious accident.

WARNING! Do not ignore a warning light oraudbile alarm. These signals tell you some-thing is wrong with your vehicle. It could be afailure in an important system, such as thebrakes, which could lead to an accidentinvolving death or personal injury. Have theappropriate system checked immediately.

1. Driver Information Display 2. Status Indicator

3. Light Bar

3

2

1

Y53-6032.book Page 17 Monday, May 24, 2010 3:37 PM

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

– 18 – Y53-6032 (R05/10)

Warning lights and indicator symbols will be shown in bothareas 1 and 2. Area 3 includes the turn and high beamindicator symbols.

1. Driver Information Display:

The display can show up to six warning lights. Warnings do not have fixed positions and are displayed in order of criticality. The most critical warning will be displayed on the top row and to the left. If more than six warnings are active, the menu control switch (MCS) can be used to scroll through the additional warnings.

2. Status Indicator:

Additional lights and indicator symbols are displayed inthe Status Indicator. They are limited to:

a. Park Brake b. Transmission Gear (Automatic transmissions

only)c. Warnings:

d. Cruise Control - activee. Clock alarm bell

Refer to “Warning Light / Indicator Symbols” on page 20for information on each symbol.

Instrument System Self Test:

When the ignition switch is turned on the instrumentationsystem will undergo a Self Test. This test will verify theoperation of the gauges and warnings.

During the Instrumentation System Self Test, threescreens will sequentially display warning icons (approxi-mately 3 seconds each screen) on the Information Dis-play. These are:Number of active warnings.

A red warning is active.

An amber warning is active.

Y53-6032.book Page 18 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

(R05/10) Y53-6032 – 19 –

Refer to “Warning Light / Indicator Symbols” on page 20for information on each symbol.

Completing this sequence will indicate a successful SelfTest. Have your instrumentation system checked by aqualitfied service technician if does not successfully com-plete.

Audible Alarm:

The audible alarm will sound during the InstrumentationSystem Self Test. The audible alarm will also sound inconjunction with most warning lights. These events

include but are not limited to headlight on, fifth wheel, stopengine, primary/secondary air, and driver door openwarnings.

Optional Lights:

Additional lights may be operational depending on individ-ual vehicle specifications. These will be included in theInstrument System Self Test.

NOTE: Some optional lights may illuminate eventhough your vehicle is not equipped with that par-ticular feature.

First

Second

Third

Y53-6032.book Page 19 Monday, May 24, 2010 3:37 PM

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

– 20 – Y53-6032 (R05/10)

Warning Light / Indicator Symbols

The following is a list of Warning Light / Indicator Symbols.Reading left to right, the table header identifies

• the Symbol Name

• the appearance of the Symbol

• the Symbol Color when it is illuminated

• whether the symbol is standard (Std) or optional (Opt)

• the Page Number reference for additional information

Symbols are listed by major component sections.

Example: Engine, and then in alphabetical order.

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

1. Active Warnings, Exclamation Point Red 23

2. Active Warnings, NumberYellow 23

3. Active Warnings, TriangleYellow 23

4. AlternatorRed 23

5. Anti-Lock Brake System (ABS) Yellow 23

6. Anti-Lock Brake System (ABS), Trailer Yellow 24

7. Axle, Inter-Axle Differential Locked (Tandem Axles) Yellow 24

8. Clock, Alarm BellYellow 24

9. Cruise Control, ActiveYellow 24

Y53-6032.book Page 20 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

(R05/10) Y53-6032 – 21 –

10. Dump Truck, Body UpYellow 24

11. Dump Truck, Trailer Body UpYellow 25

12. Emissions, Diesel Particu-late Filter (DPF) Yellow 25

13. Emissions, High Exhaust System Temperture (HEST) Yellow 25

14. Emissions, Malfunction Indi-cator Lamp Yellow 26

15. Emission, Diesel Exhaust Fluid Lamp

Yellow26

16. Engine, Check EngineYellow 26

17. Engine, Ether StartGreen 26

18. Engine, HeaterYellow 26

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

19. Engine, Low Coolant LevelYellow 26

20. Engine, OverspeedRed 27

21. Engine, Retarder (Brake)Green 27

22. Engine, Stop EngineRed 27

23. Engine, Wait To StartYellow 27

24. Fifth Wheel, King Pin LockRed 27

25. Fifth Wheel, Slide UnlockedRed 27

26. Lights, High BeamBlue 28

27. Message WaitingGreen 28

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

Y53-6032.book Page 21 Monday, May 24, 2010 3:37 PM

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

– 22 – Y53-6032 (R05/10)

28. Park BrakeRed 28

29. Power Take-off (PTO)Green 28

30. Power Take-off (PTO), Pump Mode Green 28

31. RefrigeratorGreen 28

32. Seat Belt, FastenRed 28

33. Suspension DumpYellow 28

34. Tire InflationYellow 29

35. Transmission, AuxiliaryYellow 29

36. Transmission, CheckRed 29

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

37. Transmission, Do Not ShiftRed 29

38. Transmission, Oil FilterYellow 29

39. Transmission, Oil Tempera-ture High Yellow 29

40. Turn Signal, LeftGreen 29

41. Turn Signal, RightGreen 29

Warning Light / Indicator Symbols

Symbol Name Symbol Color Std Opt Page

Y53-6032.book Page 22 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

(R05/10) Y53-6032 – 23 –

Warning Light/Indicator Symbol Descriptions

1. Active Warnings, Exclamation Point

Illuminates when a red warning is active. Usethe MCS knob to view the warnings that areactive. Refer to the preceeding Figure ,“Warning Light / Indicator Symbols,” onpage 20 for warning color classification.

2. Active Warnings, Number

Illuminates the total number of red and yellowactive warnings. Use the MCS to view theactive warnings if the display shows a > sym-bol.

3. Active Warnings, Triangle

Illuminates when an yellow warning is active.Use the MCS knob to view the warnings thatare active. Refer to the preceeding Figure ,“Warning Light / Indicator Symbols,” onpage 20 for warning color classification.

4. Alternator

Illuminates if the alternator is not charging.(For alternators with warning lamp outputsignal.)

5. Anti-Lock Brake System (ABS)

Illuminates during the Instrumentation Sys-tem Self Test. Have the ABS system checkedby a Peterbilt dealer if the ABS WarningLamp stays on for more than 3 seconds.

Illuminates during normal operating condi-tions to indicate a problem with the ABS Sys-tem. See “ABS Warning Lamps” on page 109for more information.

Illuminates when a problem exists with theoptional Wheel Spin Control feature. See“Advanced ABS with Stability Control” onpage 106 more information.

Y53-6032.book Page 23 Monday, May 24, 2010 3:37 PM

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

– 24 – Y53-6032 (R05/10)

6.Anti-Lock Brake System (ABS), Trailer

Illuminates during the Instrumentation Sys-tem Self Test and the tractor/truck is con-nected with a ABS equipped trailer.

Illuminates during normal operating condi-tions to indicate a problem with the TrailerABS System. This should be checked by aPeterbilt dealer as soon as possible. See“Truck/Tractor ABS Warning Lamp” onpage 109 for more information.

NOTE: Tractors/Trucks and trailers built after 3/1/01 must be able to turn on an In-Cab Trailer ABSWarning Lamp (per U.S. FMVSS121). The indus-try chose Power Line Communication (PLC) asthe standard method to turn it on. See “Trailer ABSWarning Lamp” on page 110 for more information.On trailers built prior to 3/1/01 verify trailer ABSsystem status via the required external warninglamp mounted on the trailer. The indicator lampon the trailer should be yellow and identified withthe letters "ABS".

7. Axle, Inter-Axle Differential Locked (Tandem Axles)

Illuminates when the inter-axle differentialswitch is ON thus locking the inter-axle differ-ential. This powers the forward rear and therear rear differentials equally. When theswitch is turned off (inter-axle differentialunlocked) the engine power is allowed to flowto any of the 4 drive tires based on the differ-ential effect (mostly to the forward rear differ-ential). (This feature is standard on alltandem axles).

8.Clock, Alarm Bell

Illuminates when the alarm is set. It will flashwhen the clock alarm is active.

9. Cruise Control, Active

Illuminates when cruise control is active.

10.Dump Truck, Body Up

Illuminates when Truck Dump Body is up.

Y53-6032.book Page 24 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

(R05/10) Y53-6032 – 25 –

11.Dump Truck, Trailer Body Up

Illuminates when Trailer Dump Body is up.

12.Emissions, Diesel Particulate Filter (DPF)

Illuminates when diesel particulate trap isplugged. This warning will also illuminatewhen regeneration operation is disabled.

NOTE: Refer to “Exhaust After-Treatment Sys-tem” on page 126 for more information regard-ing this warning icon.

13.Emissions, High Exhaust System Tem-perture (HEST)

Illuminates when the exhaust gas tempera-ture and exhaust components becomeextremely hot.

Refer to “Exhaust After-Treatment System” onpage 126 for more information regarding this warn-ing icon.

WARNING!Temperatures of the exhaustpipes and at the outlets of the exhaust sys-tem during and shortly after a regenerationevent will be extremely hot. If the HighExhaust System Temperature (HEST) warn-ing lamp is on:

•Do not park in an area of combustible vaporsor materials. You must keep combustibles atleast five (5) feet away from the side and topof the vehicle while the HEST light is illumi-nated. Always park your vehicle outside. Fail-ure to do so could ignite an explosion or harmbystanders which could result in death orserious injury.

•Do not park in an area where people areclose by. You must keep bystanders at leastfive (5) feet away from the exhaust outletwhile the HEST light is illuminated. Failure todo so could result in death or serious injury.

•The exhaust piping, diesel particular filter(DPF) or tail pipe become extremely hot dur-ing engine operation or any regenerationevent and can cause death or serious burns

Y53-6032.book Page 25 Monday, May 24, 2010 3:37 PM

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

– 26 – Y53-6032 (R05/10)

to the skin. Allow adequate cooling time beforeworking on or near any part of the exhaust sys-tem.

14.Emissions, Malfunction Indicator Lamp

Illuminates when an engine emissions failurehas occurred. The vehicle can be safelydriven but should be serviced to correct theproblem. The situation should not be consid-ered an emergency. In some cases, the Mal-function Indicator Lamp wil l activate inconjunction with the High Exhaust Tempera-ture, Diesel Particulate Filter (DPF) and Die-sel Emission Fluid (DEF) Warning Lights.

15. Emission, Diesel Exhaust Fluid Lamp

Illuminates when the Diesel Exhaust Fluid(DEF) tank level is low. The vehicle can besafely driven but the DEF tank should be filledat the next opportunity. The situation shouldnot be considered an emergency.

16.Engine, Check Engine

Illuminates when a problem exists, but thevehicle can still be safely driven. Vehicleshould be serviced to correct the problembut the situation should not be consideredan emergency.

17.Engine, Ether Start

Illuminates when ether start switch is on.

18. Engine, Heater

Illuminates when Engine Heater switch is on.

19. Engine, Low Coolant Level

Illuminates with an audible alarm indicatingcritically low coolant level. The vehicle mustbe serviced to correct the problem but the sit-uation should not be considered an emer-gency.

Y53-6032.book Page 26 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

(R05/10) Y53-6032 – 27 –

20. Engine, Overspeed

Illuminates when engine RPM is exceeded.

21. Engine, Retarder (Brake)

Illuminates when the engine retarder (com-pression brake or exhaust brake) switch isturned on. (Engine retarders are an option.)

22. Engine, Stop Engine

Illuminates and an audible alarm tone willsound when a major engine system problemexists.

WARNING! This should be consideredan emergency. You should stop the vehi-cle as safely as possible and turn OFFthe ignition. The vehicle must be ser-viced and the problem corrected beforedriving again. Failure to do so may causesevere engine damage or cause an acci-dent involving death or personal injury.

23. Engine, Wait To Start

Illuminates when engine grid heater is on(Cummins ISB and ISC engines).

24. Fifth Wheel, King Pin Lock

Illuminates when air actuated fifth wheel KingPin is unlocked.

25. Fifth Wheel, Slide Unlocked

Illuminates and an audible warning tone willsound when the air operated sliding fifthwheel switch is on, thus unlocking the slidingfifth wheel. The light and an audible warningtone should NOT be considered an emer-gency but simply as a reminder to turn off theswitch to lock the sliding fifth wheel beforedriving. This switch should not be operatedwhile driving. (Sliding fifth wheels are anoption).

Y53-6032.book Page 27 Monday, May 24, 2010 3:37 PM

INSTRUMENTS AND CONTROLS PART 4: CONTROLS AND DISPLAYS

– 28 – Y53-6032 (R05/10)

26. Lights, High Beam

Illuminates when the high beams are on.This icon will flash with audible alarm if theheadlamps are left on when the door is open.In addition, this icon will flash, but without anaudible alarm, if there is a problem with thelow beam headlights or the low beam head-light wiring. In such event, the high beamheadlights will turn on at 50% normal bright-ness.

27. Message Waiting

Illuminates with telematic equipped messag-ing.

28. Park Brake

Illuminates in the status indicator when park-ing brakes are applied and the vehicle is sta-tionary. This symbol will also illuminate in theDriver Information Display if the parkingbrakes are applied and the vehicle is inmotion.

29.Power Take-off (PTO)

Illuminates when the PTO is engaged.

NOTE: Do not drive vehicle with PTOengaged.

30.Power Take-off (PTO), Pump Mode

Illuminates with remote throttle application.Indicates pump mode is active.

31. Refrigerator

Illuminates to indicate that the refrigerator ison and ignition is off.

32. Seat Belt, Fasten

Illuminates when the ignition key is turned onas a reminder to fasten your seat belt.

33.Suspension Dump

Illuminates when suspension air bags aredeflated.

Y53-6032.book Page 28 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS INSTRUMENTS AND CONTROLS

(R05/10) Y53-6032 – 29 –

34. Tire Inflation

Illuminates when tire pressures need to bechecked. (Tire Pressure Monitoring Systemis an option)

35. Transmission, Auxiliary

Illuminates to indicate auxiliary transmissionis in neutral.

36. Transmission, Check

Illuminates when transmission has recordeda fault code. This icon may also appear in theTransmission Display menu of the DriverInformation Display unit (see item G; page33). If the user is in this display menu, theicon does not indicate a fault code.

37. Transmission, Do Not Shift

Illuminates with automatic transmissionsequipped with “Don’t Shift” output.

38. Transmission, Oil Filter

Illuminates when service is required (Allisontransmissions only).

39. Transmission, Oil Temperature High

Illuminates when transmission lubricant tem-perature is too high.

CAUTION: This should be considered anemergency. You should stop the vehicle assafely as possible and turn OFF the ignition.The vehicle must be serviced and the prob-lem corrected before driving again. Failure todo so may cause severe transmission dam-age.

40. Turn Signal, Left

Blinks when the left turn signal or the hazardlight function is operating.

41. Turn Signal, Right

Blinks when the right turn signal or the haz-ard light function is operating.

Y53-6032.book Page 29 Monday, May 24, 2010 3:37 PM

DRIVER INFORMATION DISPLAY PART 4: CONTROLS AND DISPLAYS

– 30 – Y53-6032 (R05/10)

Driver Information Display

WARNING! Do not look at the Driver Informa-tion Display for prolonged periods while thevehicle is moving. Only glance at the monitorbriefly while driving. Failure to focus to thevehicle’s road position could lead to an acci-dent involving death, possible personal injuryor equipment damage.

The Driver Information Display, located at the top of theinstrument cluster, displays important vehicle informationthrough a constant monitoring of systems when any of thefollowing conditions are met:

• ignition key in ON or ACC positions

• ignition timer is active

• MCS button is pushed (independent of ignition keyswitch position)

• clock alarm sounds

• driver or passenger door is opened

• hazard warning lamp switch is on

The various functions may be accessed by navigatingthrough Menu Screens using the MCS. Refer to “MenuControl Switch (MCS)” on page 17 for more detail for theMCS.

The bullets in the Menu Bar allow access to each item bypushing the MCS when the desired bullet is highlighted.

Y53-6032.book Page 30 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DRIVER INFORMATION DISPLAY

(R05/10) Y53-6032 – 31 –

In addition to a blank screen, the following are menu itemsand the information available within each menu selec-tions.

NOTE: Some Driver Information Display functions areonly accessible when the vehicle is parked. Otherfunctions are accessible while the vehicle is movingor when parked. Each function is identified in the fol-lowing descriptions.

A. Fuel Economy (Accessible while parked or driving)

1. Current fuel economy - Indicates instantaneousfuel economy.

2. Trip fuel economy - Indicates trip fuel economy.

B. RPM Detail (Accessible while parked or driving)

RPM reading of actual engine RPM. Engine RPMwithin the bar graph indicates the engine is operat-ing in the most efficient RPM range. The displaycolor will change if you are operating outside of thisrange.

C. Ignition Timer (Accessible while parked only)

Ignition timer is set from this menu. The ignitiontimer may be set for up to 30 minutes.

Y53-6032.book Page 31 Monday, May 24, 2010 3:37 PM

DRIVER INFORMATION DISPLAY PART 4: CONTROLS AND DISPLAYS

– 32 – Y53-6032 (R05/10)

D. Trip Information

NOTE: When accessing the trip informationmenu, push the MCS on this menu (bullet).To exit, push the MCS again. To reset the tripvalues, press the Trip Odometer Reset But-ton on the main gauge instrument cluster.

Certain Trip Information functions area accessiblewhen driving or when parked:

– Trip Economy

– Trip Average Speed

Other Trip Information functions are accessible onlywhen parked:

– Trip Distance

– Trip Engine Hours

– Trip Idle Hours

– Trip Idle Percentage (%)

– PTO Hours

– PTO Trip Hours

– PTO Trip Percentage (%)

To reset the Trip Values, press the Trip OdometerReset Button on the main gauge instrument cluster.

E. Truck Information (Accessible only while parked)

NOTE: When accessing the truck informa-tion menu, push the MCS on this menu (bul-let). To exit, push the MCS again.

1. Chassis Number

2. Engine Make

3. Engine Model

4. Engine SW Version

5. Transmission Make

6. Transmission Model

Y53-6032.book Page 32 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DRIVER INFORMATION DISPLAY

(R05/10) Y53-6032 – 33 –

7. Transmission SW Version

8. ABS (Antilock Braking System) Make

9. ABS Model

10. ABS SW Version

11. CECU (Cab Electronic Control Unit) SoftwareVersion

12. CECU Hardware Version

F. Diagnostic Display (Accessible only while parked)

NOTE: “Faults Found” will only be active if ared or yellow warning lamp is illuminated.

The diagnostic display menu (bullet) will indicate afault that is generated by the vehicle's Engine, ABSand/or Transmission systems. While on this menuitem the display will either indicate "No Faults

Found" or "Faults Found". If "Faults Found" is active,pushing the MCS will display new menus for moreinformation.

G. Transmission Display (Automated Transmissionsonly - Accessible while parked or driving)

NOTE: Refer to the Automated TransmissionOperator’s Manual for additional information.

This menu will show gear number that coincides withthe current transmission gear selected. The menualso displays the transmission icon to let the userknow what screen they are in. (Does not indicate afault code.)

H. Settings Menu (Accessible only while parked)

The Settings menu screen allows the driver to viewand/or change the following menu items:

Y53-6032.book Page 33 Monday, May 24, 2010 3:37 PM

DRIVER INFORMATION DISPLAY PART 4: CONTROLS AND DISPLAYS

– 34 – Y53-6032 (R05/10)

• Display Format 12 Hour (AM/PM) or 24 Hour(military)

• Home/Local Time

• Alarm ON/OFF

• Alarm Time

• Units of measure

• Language (English, Spanish or French)

To Set Clock Display Format:

1. When in the Settings Menu, scroll through thelist of menu items to "Format".

2. Press the MCS to display either 12 hour (AM/PM) or 24 hour (military) time.

To Set Home, Local or Alarm Time:

1. When in the Settings Menu, scroll through thelist of menu items. Press the MCS to select theitem to change.

2.

3. Rotate the MCS knob to change the hour. Pressthe MCS.

Y53-6032.book Page 34 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS STEERING COLUMN-MOUNTED CONTROLS

(R05/10) Y53-6032 – 35 –

4. Rotate the MCS knob to change the minutes.Press the MCS.

5. Rotate the MCS to toggle AM/PM. Press theMCS

6. Rotate the MCS to select Exit. Press the MCS toexit the settings function.

To Turn Alarm ON/OFF:

1. When in the Settings Menu, scroll through thelist of menu items to "Alarm". Press the MCS.

2. Press the MCS to turn the alarm ON or OFF.

To Set Units of Measure:

1. When in the Settings Menu, scroll through thelist of menu items to "Units". Press the MCS.

2. Press the MCS to display either Standard orMetric units.

To Set Language:

1. When in the Settings Menu, scroll through thelist of menu items to "Language". Press theMCS.

2. Rotate the MCS to display either English, Span-ish or French. Press the MCS knob to select thedesired language.

Steering Column-Mounted ControlsTurn Signal and Indicator Lights

NOTE: The ignition key must be turned to ON forthe signal/switch to operate.

Your turn signal lever is mounted on the left side of the steer-ing column below the steering wheel. Green directional indi-cator lights appear on the instrument panel. To operate thesignal, move the lever in the direction of the turn. Each timethe turn indicator is activated the audbile alarm emits a shortbeep.

Y53-6032.book Page 35 Monday, May 24, 2010 3:37 PM

STEERING COLUMN-MOUNTED CONTROLS PART 4: CONTROLS AND DISPLAYS

– 36 – Y53-6032 (R05/10)

High Beam HeadlampsNOTE: The headlamps must be “ON” for the highbeam switch to operate.

To switch your headlamps to lower or higher beam, gentlypull the turn signal lever towards the steering wheel, untilyou hear the switch click and the beam changes. The blueindicator light in the instrument panel will be ON when thehigh beam is being used.

To return to previous beam: pull the lever towards thesteering wheel again.

Headlamp FlashTo activate headlamp flash, gently push the turn signallever away from the steering wheel until you hear and feelthe switch click. Release lever to deactivate.

• If your headlamps are off, low beams will flash on.

• If your headlamps are on, they will dim. Maximumduration of dimming is 3 seconds. When the functionends, your headlamps will return to low beams.

ID And Clearance Lights FlashTo flash, press the button on the end of the turn signallever and hold. To cancel the flash, release the button.

If your ID and clearance lights are on, they will flash off.

Press Button For ID and Clearance Lights Flash

Press In For Washer PumpRotate To Change Wiper Mode

Y53-6032.book Page 36 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS STEERING COLUMN-MOUNTED CONTROLS

(R05/10) Y53-6032 – 37 –

Windshield Wipers/WasherYour vehicle is equipped with a two-speed, intermittentwindshield wiper system. A seven-position rotary wiperswitch (located on the turn signal lever) operates the wind-shield wipers and washer (see next illustration). Rotatethe end of the turn signal lever to change the wiper mode.

NOTE: The ignition key must be turned to ON orACC for the wiper/washer switches to operate.

The first position after OFF is the intermittent #1 cycle.The next positions are intermittent #2, #3, and #4. The lasttwo positions are wiper low speed and wiper high speed.See the wiper switch settings table that follows for inter-mittent delay times.

To Wash The Windshield

Push the rotary wash/wipe knob in (towards steering col-umn), hold for more than 0.8 seconds and then release.Hold the knob in to extend the washing cycle. After the

Wiper Switch Settings

Wiper Switch Position Wiper Speed

Off Off

Intermittent #1 20 Second Delay

Intermittent #2 17 Second Delay

Intermittent #3 7 Second Delay

Intermittent #4 4 Second Delay

Low Low Speed

High High Speed

Y53-6032.book Page 37 Monday, May 24, 2010 3:37 PM

STEERING COLUMN-MOUNTED CONTROLS PART 4: CONTROLS AND DISPLAYS

– 38 – Y53-6032 (R05/10)

lever is released, the wipers will shut off automatically orresume the wiper’s setting speed.

To activate the wipers for one swipe without activating thewasher (“mist” function), push the turn signal lever in(towards the steering column) and release in less than 0.5seconds. The wipers will perform a single swipe and thenresume the wiper’s setting speed.

WARNING! Clean blades regularly with adamp cloth to remove road film and wax build-up. Do not drive with worn or dirty wiperblades. They can reduce visibility, makingdriving hazardous which may lead to an injuryaccident resulting in death or personal injury.

CAUTION:

• Do not use antifreeze or engine coolant inthe windshield washer reservoir—damage toseals and other components will result.

• If the electric pump is operated for a longperiod (more than 15 seconds) with a dry res-ervoir, the pump motor may be damaged.

Check the windshield washing fluid level daily. If neces-sary, fill to top.

Clean all inside and outside windows regularly. Use analcohol-based cleaning solution and wipe dry with either alint-free or a chamois cloth. Avoid running the wiperblades over a dry windshield to prevent scratching theglass. Spray on washer fluid first. A scratched windshieldwill reduce visibility.

Y53-6032.book Page 38 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS STEERING COLUMN-MOUNTED CONTROLS

(R05/10) Y53-6032 – 39 –

Hazard Flasher

The four-way Hazard Flasher switch is on the turn signalbody, just underneath the turn signal lever. It will operatewith the key switch in the ON or OFF position. Use yourhazard flasher whenever you are off the road or on theside of the road, or in a potentially hazardous situation.Pull it out to activate the system. All turn signals will flashat once. To turn it off, move the turn signal lever up ordown.

WARNING! Use your Hazard Flasher WarningSystem any time you have to stop the vehicleon or off the road, day or night. A hard-to-seevehicle can result in an accident causingdeath or personal injury. Another vehiclecould run into you if you do not set your flash-ers and follow the placement of emergencysignals per FMCSR 392.22. Always move thevehicle a safe distance off the road whenstalled or stopped for repairs. A disabled vehi-cle can be dangerous for you and others.

Of course, in normal stopping in traffic, such as at a stoplight, you do not use your flashers.

WARNING! Your disabled vehicle can be dan-gerous for you and others. The hot exhaustsystem could ignite dry grass, spilled fuel, orother substances. Do not park or operate yourvehicle where the exhaust system could con-tact dry grass, brush, spilled fuel, or any othermaterial that could cause a fire resulting indeath or personal injury.

Y53-6032.book Page 39 Monday, May 24, 2010 3:37 PM

STEERING COLUMN-MOUNTED CONTROLS PART 4: CONTROLS AND DISPLAYS

– 40 – Y53-6032 (R05/10)

Electric HornYour Peterbilt has an electric horn. To sound the horn,press on the bar in the center of the steering wheel

Electric Horn Bar

Air HornYour vehicle has an air horn in addition to an electric horn.Control the air horn by pulling on the lanyard extendingfrom the overhead header panel.

Trailer Brake Hand Valve

This hand valve provides air pressure to apply the trailerbrakes only. It operates independently of the foot treadlevalve.

NOTE: The trailer brake is not to be used as themain means of braking. To use this brake fre-quently instead of using the foot brake will wearout the trailer brake sooner.

To operate the trailer brake hand valve: pull down onthe lever under the right side of the steering wheel.

02975A

Y53-6032.book Page 40 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS TILT-TELESCOPING STEERING COLUMN

(R05/10) Y53-6032 – 41 –

See the Index, under Brake Safety and Emergency formore complete information on when and how to use yourtrailer brake

WARNING! It is dangerous to use air-appliedtrailer brakes for parking or holding a vehicle.Air system pressure can bleed down andrelease the brakes. You could have a vehicleroll-away resulting in an accident involvingdeath or personal injury. Always apply theparking brakes for parking or holding yourvehicle on grade.

Tilt-Telescoping Steering Column

Tilt-Telescope Lever

The telescoping feature of the steering wheel allows for-ward and rearward movement of the wheel. The tilting fea-ture allows you to move the wheel up and down.

WARNING! Make all adjustments to the steer-ing mechanism while the vehicle is stopped.Adjusting the Tilt-Telescoping Steering Wheelwhile the vehicle is in motion could causeloss of control. You wouldn’t be able to steerproperly and could have an accident resultingin death or personal injury.

To position the wheel: Locate the Tilt-Telescope Leveron the floor, to the left of the steering column. Push thislever toward the floor. Move the steering wheel to thedesired angle and height. Release the lever to lock in thecorrect position.

Dash-Mounted FeaturesKeys and LocksThe same key fits your ignition, doors, and sleeper lug-gage compartment. Frame-mounted tool box locks, lock-ing fuel tank caps, and glove boxes each have individualkeys.

Y53-6032.book Page 41 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 42 – Y53-6032 (R05/10)

Ignition Switch

Your ignition switch has four positions:

• ACC (Accessory): With your key in this position youcan play the radio or use other accessories, but yourengine won’t start.

• OFF: In this position all systems are off, and you canremove your key.

• IGN & ACC: This position allows you to turn on theengine and all accessory power.

• START: Starter activation to start engine.

HeadlampsThe headlamps are controlled by the control panel switchshowing the next symbol. When the headlights are ON,the dash lights, side, and tail lamps are also on.

WARNING! Do not use daytime running lights(DRL) during periods of darkness or reducedvisibility. Do not use DRL as a substitute forheadlamps or other lights during operationsthat require lighting of your vehicle. Doing socould lead to an accident involving death orpersonal injury.

On vehicles equipped with daytime running lights (DRL), thehigh-beam headlamps go on automatically at reduced

02977B

Y53-6032.book Page 42 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 43 –

brightness if the engine is running and the headlamp switchis turned off. The daytime running lights are turned off auto-matically while the parking brake is engaged. If the head-lamp switch is turned on, the DRL system is overridden &headlamps operate normally

Panel Light Knob

The Panel Light Knob lets you vary the brightness of yourinstrument panel lights.

To Operate Your Panel Light Knob:

1. Turn on either the headlights or clearance lights.2. To brighten the instrument lights, rotate the thumb-

wheel up.3. To dim the instrument lights, rotate the thumbwheel

down.

ID and Clearance Lights SwitchesThese are the amber lights on top of your cab, the lights onthe front and sides of the trailer and the red lights on therear of a truck or trailer. They may be turned on and off bythe switch located on the lower left control panel labeledCL LPS and showing the symbol below.

When your clearance lights are turned on, you may blinkor flash them by operating the flash switch located on theright side of the dash showing the symbol below. Pressand release this rocker switch to flash your clearancelights.

02892

Y53-6032.book Page 43 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 44 – Y53-6032 (R05/10)

Fog/ Driving Lights Switch

If your vehicle has fog/driving lights, turn them ON or OFFwith the control panel switch shown above.

NOTE: State requirements vary as to when highbeams and fog lights can and cannot be usedtogether. Further, some states allow only fourlights to be used together; some allow more.Whether you have dual or composite lights willaffect how many lights you can have on at onetime. Always comply with the state requirementswhere you are driving.

Dome Light Switch

A momentary switch controls the main dome light:

• OFF (O) Position: Light is off.

03912-1

0302102894A

I

O

Y53-6032.book Page 44 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 45 –

• ON (I) Position:

– Press once: Light will turn on at high intensity.

– Press again: Light will shift to low intensity.

– Press a third time: Light will turn off.

Air Suspension Deflate Switch (Dump Valve)

This vehicle may have an air suspension deflation switchthat allows the air in the suspension to be exhausted froma switch on the dash. The purpose of this feature is toallow you to lower your tractor to get under a trailer. You

will notice a guard over the switch. This prevents you fromaccidentally deflating the suspension.

WARNING! Operating the Air SuspensionDeflate Switch (Dump Valve) while driving canlead to an accident causing death or personalinjury. Sudden deflation while your vehicle ismoving can affect handling and control. Usethis switch only when your vehicle is not mov-ing.

CAUTION: Operating a vehicle with air suspen-sion bags either overinflated or underinflatedmay cause damage to driveline components. If avehicle must be operated under such condi-tions, do not exceed 5 mph.

03035

Y53-6032.book Page 45 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 46 – Y53-6032 (R05/10)

Engine Fan Switch

The engine fan switch allows you to control the engine fanmanually or automatically. With the ignition key switch ONand the fan switch in the ON position, the engine fan willbe on regardless of engine temperature. With the enginefan switch in the AUTOMATIC position, the engine fan willautomatically turn on when the engine coolant reaches atemperature of about 200°F.

WARNING! Do not work on the fan with theengine running. Anyone near the engine fanwhen it turns on could be killed or seriouslyinjured. If it is set at ON, it will turn on anytime the ignition key switch is turned to theON position. In AUTOMATIC, it could engagesuddenly without warning. Before turning onthe ignition or switching from AUTOMATIC toON, be sure no one is near the fan.

CAUTION: The fan or equipment near it could bedamaged if the fan turns on suddenly when youdon’t expect it. Keep all tools and equipmentsuch as rags away from the fan, and take care noone turns on the ignition when someone isworking near the fan.

CAUTION: Do not operate the engine fan in themanual (ON) position for extended periods oftime. The fan hub was designed for intermittentoperation. Sustained operation will shorten thefan hub’s service life as well as reduce fueleconomy.

I

003023

Y53-6032.book Page 46 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 47 –

Mirror Heat Switch

Mirror heat is controlled by the control panel switch shownabove. If the vehicle is equipped with this switch, mirrorheat can be switched on to help remove frost and ice fromthe mirror glass.

Power Mirror Switch

The power mirror control controls the adjustment of theright or left outside mirrors, depending on the optionselected. It is located in the driver side armrest.

NOTE: The Power Mirror Switch does not controlthe adjustment of the convex mirrors.

I

03022

O

Y53-6032.book Page 47 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 48 – Y53-6032 (R05/10)

WARNING! Convex mirrors can distort imagesand make objects appear smaller and fartheraway than they really are. You could have anaccident resulting in death or personal injury ifyou are too close to another vehicle or otherobject. Keep plenty of space between yourvehicle and others when you turn or changelanes. Remember that other objects are closerthan they may appear.

Cruise Control Switch

The master switch turns the cruise control ON or OFF.The second switch allows you to SET the desired speed

or RESET the desired speed after the cruise control hasbeen interrupted.

WARNING! Do not operate the cruise controlwhen operating on road surfaces with poortraction (wet, icy, or snow covered roads) or inheavy traffic. Accelerations caused by thenormal operation of the cruise control couldcause you to lose control of the vehicle result-ing in an accident causing death or personalinjury.

NOTE: Cruise control functions and features mayvary depending upon which engine you have. Forspecific explanation of your cruise control, seethe cruise control or engine manual included withyour vehicle.

This vehilcle’s electronic system will perform a ‘rationalitycheck’ every time the vehicle is started. This check is toensure that the service brakes are working before allow-ing cruise control to function. This safety feature isdesigned to ensure that a driver is able to cancel thecruise set speed by using the service brake pedal. Thesystem will not allow cruise control operation if it does notpass the ‘rationality check’. The Driver Information Display

Y53-6032.book Page 48 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 49 –

will prompt you to press the service brake pedal if it hasnot been pressed since the vehicle has been started.

Engine Brake

When an engine brake is energized, the power-producingdiesel engine is converted into a power-absorbing aircompressor to retard the vehicle.

• The brake is energized whenever the driver’s foot iscompletely removed from the accelerator pedal.

• The brake is deenergized during driving by pressureon the accelerator pedal, and during shifting bydepressing the clutch pedal.

The ON/OFF toggle switch turns the system ON or OFF.

• In PACCAR, Caterpillar- and Cummins-powered vehi-cles equipped with a Jacobs Engine Brake, a secondtwo- or three-mode switch is incorporated in theinstrument panel. With this system, you can selecteither LOW or HIGH or LOW/MEDIUM/HIGH retard-ing.

For more information on when and how to use the enginebrake in your vehicle, see the Engine owner’s manual forthe engine brake.

Y53-6032.book Page 49 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 50 – Y53-6032 (R05/10)

WARNING! Using the engine brake whenoperating on surfaces with poor traction(such as wet or icy, slippery roads or gravel)could cause an accident involving death orpersonal injury.

Two-Speed Rear Axle (Range) Switch

If your vehicle is equipped with a two-speed rear axle, youcan select the axle range by the dash mounted switchshown above.

• The low range provides maximum torque for operatingoff-highway.

• The high range is a faster ratio for highway speeds.

For information on how to operate your two-speed rearaxle properly and safely, see “PART 7: STARTING &OPERATING THE VEHICLE”.

Interaxle Differential Lock Switch

The interaxle differential allows differential action betweenthe forward rear and the rear rear driving axles. The inter-axle differential lock switch allows the operator to LOCK orUNLOCK the differential. The guard over this switch pre-vents you from accidentally activating the lock. See “Inter-axle Differential” on page 101 for more information onusing your interaxle differential.

03030

2

SHIFT AT ANY SPEED EXCEPT IF A WHEEL IS SPINNING

03029

Y53-6032.book Page 50 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 51 –

WARNING! Do not engage the differential lockif the vehicle is moving or if the tires are slip-ping. Otherwise, the vehicle may move in anunexpected direction, and could cause anaccident involving death or personal injury.This may also lead to equipment damage.Bring the vehicle to a complete stop andensure that all wheels are not spinning beforeengaging the differential lock switch.

Regeneration SwitchIn order to meet EPA engine emission requirements, vehi-cles will have a either a two or three position switch to helpcontrol and maintain the exhaust Diesel Particulate Filter.Please refer to “Exhaust After-Treatment System” onpage 126 for more information about the emission controlsystem and how it affects normal operating procedures.

START

Depressing the button in the START direction for 4 to 8seconds will initiate a parked regeneration. Be sure torelease the button to ensure that the system will beginthe regerenation cycle.

CENTER (three position switch only)

Center is the normal position of the switch.

The center position will allow an automatic regenera-tion to occur.

STOP (three position switch only)

When STOP is pressed the system will not regenerateunder any conditions.

CAUTION: Do not leave the three position switchin the STOP position unless you need to cancelor stop regeneration. Leaving the switch in theSTOP position for extended periods of time willresult in increased soot levels in the DPF.

Two Position Three Position

Y53-6032.book Page 51 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 52 – Y53-6032 (R05/10)

Fifth Wheel Lock (Slider Adjustment) Switch

Vehicles having an air slide fifth wheel have a fifth wheelslider lock controlled by a switch on the instrument panel.By placing the switch in the unlock position, you can slidethe fifth wheel to various positions to adjust weight distri-bution. There is a guard over this switch to protect youagainst accidentally activating or releasing the lock.

WARNING! Do not move the fifth wheel whilethe tractor-trailer is in motion. Movement ofthe fifth wheel while a tractor-trailer is movingcan cause a serious accident involving deathor personal injury. Your load could shift sud-denly, causing you to lose control of the vehi-cle. Never operate the vehicle with the switchin the unlock position. Always inspect the fifthwheel after you lock the switch to be sure thefifth wheel is engaged.CAUTION: Both the fifth wheel plate and theslide tracks (if a slider) should be cleaned andlubricated periodically to ensure smooth turningand sliding action. Failure to keep these sur-faces lubricated can lead to frame or drivelinedamage.

03031

Y53-6032.book Page 52 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 53 –

Parking Brake Valve and Trailer Air Supply Valve

Your parking brake valve is a yellow diamond-shapedknob located below the right instrument panel. It controlsthe parking brakes.

To apply all parking brakes, pull the yellow, or parkingbrake, knob out. The truck or tractor parking brakes willset, and the Trailer Air Supply Valve (red octagon knob)will automatically trip (“pop out”) and set the trailer parkingbrakes. To release both truck/tractor and trailer parkingbrakes, push in BOTH yellow and red knobs. For full infor-mation on using parking brakes, see section titled “Park-ing Brakes and Their Use” on page 118 for moreinformation.

WARNING!

• Do not leave the cab without applying theparking brake. The truck could roll and causean accident involving death or personal injury.Always apply the parking brake before youleave the cab

• Do not pull out the parking brake valvewhile the vehicle is moving. Stopping with theparking brake controls can cause a suddenwheel lock-up, loss of control, or over-take byfollowing vehicles possibly resulting in anaccident involving death or personal injury

• Do not use the trailer hand brake or servicebrakes to park and hold an unattended vehi-

cle—use the parking brakes. Because servicebrakes work with air pressure, these brakes couldslowly release. Your vehicle could roll, causing aserious accident. Someone could be hurt orkilled. Never rely on the service brakes to hold aparked vehicle.

Y53-6032.book Page 53 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 54 – Y53-6032 (R05/10)

WARNING! Before operating your vehicle afterit has been parked, do not forget to push inthe parking brake valve to release the parkingbrakes. Failure to release your parking brakesbefore putting the vehicle into motion cancause fire or loss of control of the vehicle,which can result in death or personal injury.

Heater-Air Conditioning ControlsYour heat and air conditioning controls are mounted in theright hand instrument panel. Additionally, the sleeper com-partment may also contain a separate heating and coolingsystem with separate controls.

WARNING! Exhaust fumes from the enginecontain carbon monoxide, a colorless andodorless gas. Do not breathe the engineexhaust gas. A poorly maintained, damagedor corroded exhaust system can allow carbonmonoxide to enter the cab. Entry of carbonmonoxide into the cab is also possible fromother vehicles nearby. Failure to properlymaintain your vehicle could cause carbonmonoxide to enter the cab/sleeper and causedeath or serious illness.

WARNING! ever idle your vehicle for pro-longed periods of time if you sense thatexhaust fumes are entering the cab or sleeper.Investigate the cause of the fumes and correctit as soon as possible. If the vehicle must bedriven under these conditions, drive only withthe windows open. Failure to repair thesource of the exhaust fumes may lead todeath, injury or personal harm.

NOTES:Keep the engine exhaust system and thevehicle’s ventilation system properly maintained.It is recommended that the vehicle’s exhaust sys-tem and cab be inspected

•by a competent technician every 15,000 miles

•when a change is noticed in the sound of theexhaust system

•if the exhaust system, underbody, or cab is dam-aged

NOTE: To allow for proper operation of the vehicleventilation system, keep the inlet grille at the baseof the windshield clear of snow, ice, leaves andother obstructions at all times.

Y53-6032.book Page 54 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 55 –

NOTE: Do not stay in the vehicle with the enginerunning or idling for more than 10 minutes withthe vehicle’s Heater / AC ventilation system inRECIRC or at LOW FAN SPEED. Even with theventilation system On, running the engine whileparked or stopped for prolonged periods of time isnot recommended.

NOTE: If you are required to idle your vehicle forlong periods of time, install an auxiliary heater orautomatic idle control. These auxiliary devicescan reduce fuel consumption and save youmoney.

NOTES:When idling for short periods of time

•Set the heating or cooling system to Heat orA/C

•Set the fan to Medium or High speed

•Set the controls to FRESH AIR

NOTE: If other vehicles are parked next to youidling, move your vehicle or do not stay in yourvehicle for prolonged periods of time.

To Set the Heater-Air Conditioning Controls

The cab’s control panel may have up to six controls (seeillustration below):

• A rotary knob (A) in the upper left portion controllingthe blower speed with four settings.

• A rotary knob (B) in the upper center portion control-ling the movement of air within the cab. This control iscontinuously variable through five modes (clockwisefrom left):

– Panel

– Panel/Floor

– Floor

– Defrost/Floor

– Defrost

• A rotary knob (C) in the upper right portion controllingthe air temperature.

• A rocker switch (D) in the lower left portion to engagethe air conditioner compressor.

Y53-6032.book Page 55 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 56 – Y53-6032 (R05/10)

• A rocker switch (E) on the lower center portion to sendpower to the “bunk” or sleeper control panel.

• A rocker switch (F) in the lower right portion to selecteither fresh or recirculated air mode.

The sleeper control panel will have two controls (see nextillustration):

• A rotary knob in the left portion controlling the blowerspeed with four settings.

• A rotary knob in the right portion controlling the airtemperature.

The cab “bunk” control rocker switch must be ON for thesleeper controls to function.

• To heat the cab, select the desired air mode and setthe temperature knob to hot (the red position on thecontrol) and the blower to whatever speed makes youmost comfortable.

WARNING! Do not drive with visibility reducedby fog, condensation, or frost on the wind-shield. Your view may be obscured, whichcould result in an accident involving causingdeath or personal injury. For clear visibility

02980B

4

A B C

D E F

321

02981B

4321

Y53-6032.book Page 56 Monday, May 24, 2010 3:37 PM

PART 4: CONTROLS AND DISPLAYS DASH-MOUNTED FEATURES

(R05/10) Y53-6032 – 57 –

and safe driving, it is extremely important foryou to follow the instructions pertaining tothe function and use of the ventilation/heatingand defogging/defrosting system. If in doubt,consult your dealer. Maximum heating outputand fast defrosting can be obtained only afterthe engine has reached operating tempera-ture.

CAUTION: During extreme cold weather, do notblow hot defroster air onto cold windshields.This could crack the glass. Turn the air flow con-trol lever to Defrost and adjust the fan speedaccordingly while the engine warms. If theengine is already warm, move the temperatureselector to Cool, then gradually increase thetemperature when you see that the windshield isstarting to warm up.

• To defog the windshield, select the Defrost modeand turn the blower speed to high. Set the tempera-ture knob to hot (the red position on the control). Theair conditioner is automatically activated to removemoisture from the cab. After the windshield is clear,adjust the mode, blower speed, and temperature toyour comfort.

• To cool the cab, turn on the A/C switch, set the tem-perature knob to cool (the blue position on the con-trol), and the blower to high until the cab becomescool. Then you can turn down the blower if you wish.

For Efficient Cooling:

1. Be sure all heater - air conditioner controls are off.2. Start the engine. Allow time for warm-up.

CAUTION:

• A cold compressor can cause refrigerant toliquefy and warp the valve plates or cause ahydraulic lock. Warm the engine before start-ing the air conditioner.

• Turn off all controls when the system is notin use. Doing so will avoid damage to the airconditioning system components.

3. Set the air control in the RECIRC mode.4. Close all windows.5. Idle the engine between 1000 and 1500 RPM and

turn the blower speed control to high.6. After the cab temperature cools to a comfortable level,

adjust the blower speed and controls to keep thedesired condition.

Y53-6032.book Page 57 Monday, May 24, 2010 3:37 PM

DASH-MOUNTED FEATURES PART 4: CONTROLS AND DISPLAYS

– 58 – Y53-6032 (R05/10)

NOTE: When the air conditioner isn’t in regularuse, operate it for at least 15 minutes at leastonce a month or every 5,000 miles(8,000 Km),whichever comes first. This will lubricate the sealsin the air conditioning system. The air condition-ing system is active when the Defrost mode isselected.

Cigarette Lighter

Lighter

To operate your lighter, push the knob in. After a fewmoments the lighter will automatically pop out, ready touse. After use, insert the knob, but don’t push it in. Thelighter circuit is protected by a 10-ampere polyswitch toprevent damage should the lighter get stuck in the IN posi-