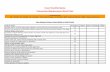

Document No. Revision No. Effective Date SUPPORTING DOCUMENT Page TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST 20 - MAIN HOIST GEARBOX / REDUCER Description Location Observation 1. Gearbox oil - Inspect oil level and oil condition Gearbox #1 Good( ) / Not Good( ) Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( ) 2. Structure & Frame - Inspect mounting bolts tightness and crack Gearbox #1 Good( ) / Not Good( ) Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( ) 3. Bearing - Inspect abnormal sound Gearbox #1 Good( ) / Not Good( ) Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( ) 4. Temperature (40 ~ 60 degree) Gearbox #1 : _________degree Good( ) / Not Good( ) Note : Fill up where applicable Gearbox #2 : _________degree Good( ) / Not Good( ) 5. Housekeeping All location Done( ) / Not Done( ) 30 - MAIN HOIST DRIVE & BLOWER MOTOR Description Location Observation 1. Sound inspection Motor #1 Good( ) / Not Good( ) Note : Fill up where applicable Motor #2 Good( ) / Not Good( ) 2. Check heater Motor #1 Good( ) / Not Good( ) Note : For DC motor only Motor #2 Good( ) / Not Good( ) 3. Visual check - Check coupling motor & gear box (Bush Coupling) Motor #1 Good( ) / Not Good( ) - Check terminations Motor #2 Good( ) / Not Good( ) - Check mounting bolts and frame Motor #3 Good( ) / Not Good( ) Note : Fill up where applicable Motor #4 Good( ) / Not Good( ) 4. Check blower motor cond. Motor #1 Good( ) / Not Good( ) - Check rotation Motor #2 Good( ) / Not Good( ) - Check running cond Motor #3 Good( ) / Not Good( ) - Measure motor demands Motor #4 Good( ) / Not Good( ) 5. Emergency Motor - Check coupling condition & chain link Motor #1 Good( ) / Not Good( ) - Check limit switch working condition Motor #2 Good( ) / Not Good( ) 6. Air Filter Motor #1 Good( ) / Not Good( ) - Check clealiness Motor #2 Good( ) / Not Good( ) Motor #3 Good( ) / Not Good( ) Motor #4 Good( ) / Not Good( ) 7. Housekeeping All location Done( ) / Not Done( )

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

20 - MAIN HOIST GEARBOX / REDUCER

Description Location Observation

1. Gearbox oil

- Inspect oil level and oil condition Gearbox #1 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( )

2. Structure & Frame

- Inspect mounting bolts tightness and crack Gearbox #1 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( )

3. Bearing

- Inspect abnormal sound Gearbox #1 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( )

4. Temperature (40 ~ 60 degree) Gearbox #1 : _________degree Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 : _________degree Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

30 - MAIN HOIST DRIVE & BLOWER MOTOR

Description Location Observation

1. Sound inspection Motor #1 Good( ) / Not Good( )

Note : Fill up where applicable Motor #2 Good( ) / Not Good( )

2. Check heater Motor #1 Good( ) / Not Good( )

Note : For DC motor only Motor #2 Good( ) / Not Good( )

3. Visual check

- Check coupling motor & gear box (Bush Coupling) Motor #1 Good( ) / Not Good( )

- Check terminations Motor #2 Good( ) / Not Good( )

- Check mounting bolts and frame Motor #3 Good( ) / Not Good( )

Note : Fill up where applicable Motor #4 Good( ) / Not Good( )

4. Check blower motor cond. Motor #1 Good( ) / Not Good( )

- Check rotation Motor #2 Good( ) / Not Good( )

- Check running cond Motor #3 Good( ) / Not Good( )

- Measure motor demands Motor #4 Good( ) / Not Good( )

5. Emergency Motor

- Check coupling condition & chain link Motor #1 Good( ) / Not Good( )

- Check limit switch working condition Motor #2 Good( ) / Not Good( )

6. Air Filter Motor #1 Good( ) / Not Good( )

- Check clealiness Motor #2 Good( ) / Not Good( )

Motor #3 Good( ) / Not Good( )

Motor #4 Good( ) / Not Good( )

7. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

40 - MAIN HOIST WIRE ROPE INSPECTION

Description Location Observation

1. Visual check

- Check broken strands, deformation and kinks Drum Good( ) / Not Good( )

- Diameter (NOELL/ZPMC-A : 26.2mm~28.0mm) Backreach Good( ) / Not Good( )

Trolley platform Good( ) / Not Good( )

- Diameter (MITSUI : 26.2mm~23.3mm) Headblock Good( ) / Not Good( )

- Diameter (ZPMC-C : 32.00mm~29.76mm)

- Broken strands (<18 wires)

Note : Fill up where applicable

2. Clips/Clamp and turnbuckles Length #1 Good( ) / Not Good( )

- Check loosed nut and condition Length #2 Good( ) / Not Good( )

Length #3 Good( ) / Not Good( )

Length #4 Good( ) / Not Good( )

3. Check for lubrication Length #1 Good( ) / Not Good( )

- Check rusty Length #2 Good( ) / Not Good( )

Length #3 Good( ) / Not Good( )

Length #4 Good( ) / Not Good( )

4. Support roller and plate

- Check condition All rollers and plates Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

50 - MAIN HOIST WIRE ROPE DRUM INSPECTION

Description Location Observation

1. Check wire rope anchor All drums Good( ) / Not Good( )

2. Check bearing any abnormal noise All drums Good( ) / Not Good( )

3. Check groove surface condition All drums Good( ) / Not Good( )

4. Check structure and mounting All drums Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

General Remark :

- Diameter (IMPSA : 26.7mm~28.5mm)

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

60 - MAIN HOIST SHEAVE AND BEARING INSPECTION

Description Location Observation

1. Check groove condition any damaged or rope trace mark Backreach Good( ) / Not Good( )

Note : Fill up where applicable Trolley platform Good( ) / Not Good( )

Headblock Good( ) / Not Good( )

Boom tip Good( ) / Not Good( )

2. Check locking / keeper plate condition Backreach Good( ) / Not Good( )

Note : Fill up where applicable Trolley platform Good( ) / Not Good( )

Headblock Good( ) / Not Good( )

Boom tip Good( ) / Not Good( )

3. Check bearing condition Backreach Good( ) / Not Good( )

Note : Fill up where applicable Trolley platform Good( ) / Not Good( )

Headblock Good( ) / Not Good( )

Boom tip Good( ) / Not Good( )

4. Housekeeping All location Done( ) / Not Done( )

70 - MAIN HOIST MOTOR AND GEARBOX COUPLING INSPECTION

Description Location Observation

1. Check abnormal sound All couplings Good( ) / Not Good( )

2. Check coupling cover

Note : Fill up where applicable All couplings Good( ) / Not Good( )

3. Check rubber insert condition

Note : Fill up where applicable All couplings Good( ) / Not Good( )

4. Structure

- Check bolt tightness and condition All couplings Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

80 - MAIN HOIST CAM SWITCH INSPECTION

Description Location Observation

1. Cable termination

- Check cable damage and breakage at cable lugs Main hoist drum Good( ) / Not Good( )

2. Cam switch functionality

- Function test All switches Good( ) / Not Good( )

3. Cam switch coupling tightness

- Check bolt tightness All couplings Good( ) / Not Good( )

Note : Fill up where applicable

4. Check 3-way gear condition Main hoist drum Good( ) / Not Good( )

Note : Fill up where applicable

5. Driven belt / driven chain / Coupling Driven

- Check condition and retigten Main hoist drum Good( ) / Not Good( )

Note : Fill up where applicable

6. Driven pulley

- Check pulley mounting, side guide, wear and crack Main hoist drum Good( ) / Not Good( )

Note : Fill up where applicable

7. Housekeeping All location Done( ) / Not Done( )

90 - MAIN HOIST LIMIT SWITCH INSPECTION

Description Location Observation

1. Cable / conduit

- Check cable condition, insulation and cable lug Trolley platform / trolley house Good( ) / Not Good( )

2. Limit switch

- Check positioning, rusty, functionality and mounting Trolley platform / trolley house Good( ) / Not Good( )

3. Counter weight

- Check condition Trolley platform / trolley house Good( ) / Not Good( )

Note : Fill up where applicable

4. Striker

- Check condition Spreader cable / headblock Good( ) / Not Good( )

Note : Fill up where applicable

5. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

100 - MAIN HOIST ENCODER INSPECTION

Description Location Observation

1. Coupling

- Check mounting, rusty, alignment and sprider wear Main hoist motor and drum Good( ) / Not Good( )

Note : Fill up where applicable

2. Driven belt / driven chain/ Driven coupling

- Check belting condition and any crack Main hoist drum Good( ) / Not Good( )

Note : Fill up where applicable

3. Driven pulley

- Check pulley mounting, side guide, wear and crack Main hoist drum Good( ) / Not Good( )

Note : Fill up where applicable

4. Electrical

- Check cable connection Main hoist drum Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

110 - MAIN HOIST OVER SPEED DETECTOR INSPECTION

Description Location Observation

1. Cable termination

- Check cable damage and breakage at cable lugs Main hoist drum Good( ) / Not Good( )

2. Coupling tightness

- Check bolt tightness All couplings Good( ) / Not Good( )

3. Check 3-way gear condition Main hoist drum Good( ) / Not Good( )

Note : Fill up where applicable

4. Housekeeping All location Done( ) / Not Done( )

120 - SPREADER CABLE REEL INSPECTION

Description Location Observation

1. Spreader drum

- Check drum condition Trolley platform / trolley house Good( ) / Not Good( )

- Check cable condition Good( ) / Not Good( )

2. Driven belt / driven chain (cam switch)

- Check belting condition and any crack Trolley platform / trolley house Good( ) / Not Good( )

Note : Fill up where applicable

3. Driven pulley (cam switch)

- Check pulley mounting, side guide, wear and crack Trolley platform / trolley house Good( ) / Not Good( )

Note : Fill up where applicable

4. Electrical

- Check cable connection and slip ring carbon brushes Trolley platform / trolley house Good( ) / Not Good( )

- Check short length cable and junction box Headblock Good( ) / Not Good( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

Description Location Observation

5. Limit switch

- Check limit switch condition Trolley platform / trolley house Good( ) / Not Good( )

6. Absorber

- Check condition Headblock Good( ) / Not Good( )

7. Housekeeping All location Done( ) / Not Done( )

130 - SPREADER HEADBLOCK INSPECTION

Description Location Observation

1. Twistlock

- Check gap, lock pin and condition All twistlocks Good( ) / Not Good( )

2. Electrical

- Check limit switch and functionality Headblock lock/unlock lever Good( ) / Not Good( )

3. Structure

- Check condition, ladder, hand rail and grating Good( ) / Not Good( )

4. Housekeeping All location Done( ) / Not Done( )

140 - TRIM, LIST AND SKEW (TLS) SYSTEM INSPECTION

Description Location Observation

1. Power pack

- Check oil level, condition and cleanliness

- Check working pressure (160±10 psi) Backreach / TLS platform / trolley house Good( ) / Not Good( )

- Check hose, valve and piping Pressure : _________ psi Good( ) / Not Good( )

2. Hydraulic cylinder

- Check oil leak, guide roller and condition Backreach / TLS platform / trolley house Good( ) / Not Good( )

3. Positioner sensor

- Check wire string, mounting and crack All cylinders Good( ) / Not Good( )

4. Motor and pump

- Check abnormal sound, overheating, and cover All motors and pumps Good( ) / Not Good( )

- Check electrical connection

5. TLS control panel

- Check wire termination, conduit and DC supply All control boxes Good( ) / Not Good( )

- Check door and lock condition

6. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

150 - TROLLEY BRAKE INSPECTION

Description Location Observation

1. Reserve stroke height (10 mm) Brake #1 (Height : _________ mm) Good( ) / Not Good( )

- Inspect stroke indicator setting and manual release Brake #2 (Height : _________ mm) Good( ) / Not Good( )

Note : Fill up where applicable Brake #3 (Height : _________ mm) Good( ) / Not Good( )

Brake #4 (Height : _________ mm) Good( ) / Not Good( )

Brake #1 (Torque : ________________ Nm) Good( ) / Not Good( )

- Inspect setting and mechanical component Brake #2 (Torque : ________________ Nm) Good( ) / Not Good( )

Note : IMPSA-A : ≥ 977Nm, NOELL /MITSUI/ZPMC-A : ≥ 1890Nm Brake #3 (Torque : ________________ Nm) Good( ) / Not Good( )

Brake #4 (Torque : ________________ Nm) Good( ) / Not Good( )

3. Air gap

- Check any rubbing All brakes Good( ) / Not Good( )

4. Brake pad and disc Brake #1 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

- Inspect pad and disc (Pad : ≥ 5 mm, Disc : ≥ 27 mm) Brake #1 LHS : ______mm Good( ) / Not Good( )

ZPMC-C: Disk wear >20% from 30mm, Pad >3mm Brake #2 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

ZPMC(Pad : ≥ 3 mm, Disc : ≤ 1.0mm wear on each side) Brake #2 LHS : ______mm Good( ) / Not Good( )

- Check and clean disc surface Brake #3 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

Note : Fill up where applicable Brake #3 LHS : ______mm Good( ) / Not Good( )

Brake #4 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

Brake #4 LHS : ______mm Good( ) / Not Good( )

5. Check AWC condition Brake #1 Good( ) / Not Good( )

- Check one way bearing and adjusting nut condition Brake #2 Good( ) / Not Good( )

Note : Fill up where applicable Brake #3 Good( ) / Not Good( )

Brake #4 Good( ) / Not Good( )

6. Check wedge and shackle kit Brake #1 Good( ) / Not Good( )

Note : Fill up where applicable Brake #2 Good( ) / Not Good( )

Brake #3 Good( ) / Not Good( )

Brake #4 Good( ) / Not Good( )

7. Servolifter / Thruster All servolifters Good( ) / Not Good( )

- Inspect oil, electrical and mechanical part

8. Structure

- Check pivot pin, linkage and mounting Good( ) / Not Good( )

9. Limit Switch a. Brake manual release Good( ) / Not Good( )

- Check setting and functionality b. Brake release Good( ) / Not Good( )

Note : Fill up where applicable c. Brake pad wear Good( ) / Not Good( )

10. Housekeeping All location Done( ) / Not Done( )

General Remark :

2. Braking torque

IMPSA-B : ≥ 977Nm, ZPMC-B : ≥ 5175 Nm, ZPMC-C : 5500Nm

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

160 - TROLLEY GEARBOX INSPECTION

Description Location Observation

1. Gearbox oil Gearbox #1 Good( ) / Not Good( )

- Inspect oil level and oil condition Gearbox #2 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #3 Good( ) / Not Good( )

Gearbox #4 Good( ) / Not Good( )

2. Structure Gearbox #1 Good( ) / Not Good( )

- Inspect mounting bolts tightness and crack Gearbox #2 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #3 Good( ) / Not Good( )

Gearbox #4 Good( ) / Not Good( )

3. Bearing Gearbox #1 Good( ) / Not Good( )

- Inspect abnormal sound Gearbox #2 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #3 Good( ) / Not Good( )

Gearbox #4 Good( ) / Not Good( )

4. Temperature (40 ~ 60 degree) Gearbox #1 : _________degree Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 : _________degree Good( ) / Not Good( )

Gearbox #3 : _________degree Good( ) / Not Good( )

Gearbox #4 : _________degree Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

170 - TROLLEY MOTOR INSPECTION

Description Location Observation

1. Sound inspection Motor #1 Good( ) / Not Good( )

Note : Fill up where applicable Motor #2 Good( ) / Not Good( )

Motor #3 Good( ) / Not Good( )

Motor #4 Good( ) / Not Good( )

2. Check heater condition

Note : For DC motor only Motor #1 Good( ) / Not Good( )

Note : Fill up where applicable Motor #2 Good( ) / Not Good( )

3. Visual check

- Check armature winding for burn marks, scratches Motor #1 Good( ) / Not Good( )

and damages (For DC motor only) Motor #2 Good( ) / Not Good( )

- Check structure and wire termination Motor #3 Good( ) / Not Good( )

Note : Fill up where applicable Motor #4 Good( ) / Not Good( )

4. Check motor in running condition for sparks Motor #1 Good( ) / Not Good( )

Note : For DC motor only Motor #2 Good( ) / Not Good( )

5. Emergency motor

- Check coupling condition Motor #1 Good( ) / Not Good( )

- Check limit switch working condition Motor #2 Good( ) / Not Good( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

Description Location Observation

6. Carbon brush and holder Motor #1 - Top (3 pcs) Good( ) / Not Good( )

- Check length and condition Motor #1 - Bottom (3 pcs) Good( ) / Not Good( )

Note : For DC motor only Motor #1 - Right (3 pcs) Good( ) / Not Good( )

Motor #1 - Left (3 pcs) Good( ) / Not Good( )

Motor #2 - Top (3 pcs) Good( ) / Not Good( )

Motor #2 - Bottom (3 pcs) Good( ) / Not Good( )

Motor #2 - Right (3 pcs) Good( ) / Not Good( )

Motor #2 - Left (3 pcs) Good( ) / Not Good( )

7. Housekeeping All location Done( ) / Not Done( )

180 - TROLLEY WIRE ROPE INSPECTION

Description Location Observation

1. Visual check

- Check broken strands, deformation and kinks Drum Good( ) / Not Good( )

- Diameter (2 6.2mm~mm) Backreach Good( ) / Not Good( )

- Broken strands (<18 wires) Trolley platform Good( ) / Not Good( )

Note : Fill up where applicable Boom tip Good( ) / Not Good( )

2. Clips and turnbuckles Length #1 Good( ) / Not Good( )

- Check loosed nut and condition Length #2 Good( ) / Not Good( )

3. Check for lubrication Length #1 Good( ) / Not Good( )

- Check rusty Length #2 Good( ) / Not Good( )

4. Support roller and plate

- Check condition All rollers and plates Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

190 - TROLLEY WIRE ROPE DRUM INSPECTION

Description Location Observation

1. Check wire rope anchor All drums Good( ) / Not Good( )

2. Check bearing any abnormal noise All drums Good( ) / Not Good( )

3. Check groove surface condition All drums Good( ) / Not Good( )

4. Check structure and mounting All drums Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

200 - TROLLEY SHEAVE AND BEARING INSPECTION

Description Location Observation

1. Check groove condition any damaged or rope trace mark Backreach Good( ) / Not Good( )

Note : Fill up where applicable Trolley platform Good( ) / Not Good( )

Boom tip Good( ) / Not Good( )

2. Check locking / keeper plate condition Backreach Good( ) / Not Good( )

Note : Fill up where applicable Trolley platform Good( ) / Not Good( )

Boom tip Good( ) / Not Good( )

3. Check bearing condition Backreach Good( ) / Not Good( )

Note : Fill up where applicable Trolley platform Good( ) / Not Good( )

Boom tip Good( ) / Not Good( )

4. Housekeeping All location Done( ) / Not Done( )

210 - TROLLEY MOTOR AND GEARBOX COUPLING INSPECTION

Description Location Observation

1. Check abnormal sound All couplings Good( ) / Not Good( )

2. Check coupling cover

Note : Fill up where applicable All couplings Good( ) / Not Good( )

3. Check rubber insert condition

Note : Fill up where applicable All couplings Good( ) / Not Good( )

4. Structure

- Check bolt tightness and condition All couplings Good( ) / Not Good( )

220 - TROLLEY WHEEL INSPECTION

Description Location Observation

1. Wheel Wheel #1 Good( ) / Not Good( )

- Check wheel bearing condition and abnormal sound Wheel #2 Good( ) / Not Good( )

Wheel #3 Good( ) / Not Good( )

Wheel #4 Good( ) / Not Good( )

2. Structure Wheel #1 Good( ) / Not Good( )

- Check wheel flange cracks or damages and condition Wheel #2 Good( ) / Not Good( )

Wheel #3 Good( ) / Not Good( )

Wheel #4 Good( ) / Not Good( )

3. Guide roller Wheel #1 Good( ) / Not Good( )

- Check bearing and guide roller condition Wheel #2 Good( ) / Not Good( )

Wheel #3 Good( ) / Not Good( )

Wheel #4 Good( ) / Not Good( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

Description Location Observation

4. Floating shaft Floating shaft LHSS Good( ) / Not Good( )

- Check coupling condition and bolt tighness Floating shaft LHLS Good( ) / Not Good( )

Note : Fill up where applicable Floating shaft RHLS Good( ) / Not Good( )

Floating shaft RHSS Good( ) / Not Good( )

5. Plumber block Plumber block LHSS Good( ) / Not Good( )

- Chek abnormal sound Plumber block LHLS Good( ) / Not Good( )

Note : Fill up where applicable Plumber block RHLS Good( ) / Not Good( )

Plumber block RHSS Good( ) / Not Good( )

6. Housekeeping All location Done( ) / Not Done( )

230 - TROLLEY RAIL INSPECTION

Description Location Observation

1. Trolley rail structure

- Check greasy or oily All Good( ) / Not Good( )

- Check rail clip, bolt and nut All Good( ) / Not Good( )

- Check welded part cracked or chipped All Good( ) / Not Good( )

- Check side plate bolt tightness Boom joint Good( ) / Not Good( )

- Check trolley rail gap Boom joint Good( ) / Not Good( )

2. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

240 - TROLLEY LIMIT SWITCH INSPECTION

Description Location Observation

1. Cable and conduit

- Check insulation, termination and condition Good( ) / Not Good( )

2. Limit switch

- Check condtion, mounting and functionality All limit switches Good( ) / Not Good( )

3. Flag sensor

- Check condtion, mounting and functionality All flag sensors Good( ) / Not Good( )

4. Slowdown magnet Boom tip Good( ) / Not Good( )

- Check condtion, mounting and functionality Backreach Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

250 - TROLLEY ENCODER INSPECTION

Description Location Observation

1. Coupling

- Check mounting, rusty, alignment and sprider wear Trolley motor Good( ) / Not Good( )

Note : Fill up where applicable

2. Electrical

- Check cable connection Trolley motor Good( ) / Not Good( )

3. Structure

- Check mounting, wheel and bearing condition Trolley LS LHS Good( ) / Not Good( )

Note : Fill up where applicable

4. Encoder sensor

- Check sensor surface and condition Trolley motor Good( ) / Not Good( )

3. Housekeeping All location Done( ) / Not Done( )

260 - TROLLEY CATENARY INSPECTION

Description Location Observation

1. Wheel bearings

- Check abnormal noise All location Good( ) / Not Good( )

2. Trolley wheel

- Check any crack or damage on wheel flange All wheels Good( ) / Not Good( )

- Check wheel bracket bolts tighten All wheel brackets Good( ) / Not Good( )

- Check wheel cover bolt tightness All bolts Good( ) / Not Good( )

Note : Fill up where applicable

3. Sheave and bearing

- Check groove condition 1. Boom tip LHS and RHS Good( ) / Not Good( )

- Check sheave bearing abnormal sound and condition 2. Catenary LS LHS and RHS Good( ) / Not Good( )

- Check locking /keeper plate bolts and nuts condition 3. Catenary SS LHS and RHS Good( ) / Not Good( )

Note : Fill up where applicable 4. Backreach LHS and RHS Good( ) / Not Good( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

Description Location Observation

4. Catenary wire rope

- Visual check for wear, deformation and kinks 1. Drive rope LHS and RHS Good( ) / Not Good( )

Note : Fill up where applicable 2. Tie rope LHS and RHS Good( ) / Not Good( )

5. Clip and turnbuckle

- Check clips and turnbuckles condition All location Good( ) / Not Good( )

Note : Fill up where applicable

6. Structure

- Check catenary structure condition 1. Catenary LHS Good( ) / Not Good( )

Note : Fill up where applicable 2. Catenary RHS Good( ) / Not Good( )

7. Guide roller

- Check guide roller tighness and condition All location Good( ) / Not Good( )

8. Support roller

- Check support roller, bearing and shaft condition All location Good( ) / Not Good( )

9. Housekeeping All location Done( ) / Not Done( )

270 - TROLLEY WIRE ROPE TENSIONER INSPECTION

Description Location Observation

1. Cylinder

- Check abnormal sound and cylinder condition

- Check hose and any leakage All cylinders Good( ) / Not Good( )

Note : Fill up where applicable

2. Cross joint

- Check vibration and any abnormal sound All location Good( ) / Not Good( )

- Check bearing and shaft condition All location Good( ) / Not Good( )

3. Sheave

- Check bolt tighness, sheave and bearing condition All location Good( ) / Not Good( )

4. Limit switch

- Check limit switch condition and functionality All limit switches Good( ) / Not Good( )

5. Hydraulic power pack

- Check tank, hose and fitting condition All limit switches Good( ) / Not Good( )

- Check any leakage and oil level

6. Power unit for motor pump

- Check abnormal sound, termination and condition All power units Good( ) / Not Good( )

7. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

280 - FESTOON SYSTEM INSPECTION

Description Location Observation

1. Festoon rail

- Check deformation, dents and leveling condition Along rails Good( ) / Not Good( )

2. Festoon cable

- Check cable and cable clamp mouting condition All cables Good( ) / Not Good( )

3. Sling shackle and elastic cord

- Check any cut, broken and wear condition All shackles and elastic cords Good( ) / Not Good( )

- Check sling shackle missing and condition

4. Festoon bumper

- Check mounting and bumber condition All bumpers Good( ) / Not Good( )

5. Side roller, runner wheel and anti-lift roller

- Check roller condition and abnormal sound All rollers Good( ) / Not Good( )

- Check mounting condition

6. Belting system

- Check belting, pulley and bearing condition Motor #1 and #2 Good( ) / Not Good( )

Note : Fill up where applicable

7. Motor (Brand : VAHLE or WAMPFLER)

- Check abnormal sound and mounting condition Motor #1 and #2 Good( ) / Not Good( )

- Check bolt tightness and motor cover condition

Note : Fill up where applicable

8. Trolley festoon box

- Check cable termination and slot connection condition Trolley platform Good( ) / Not Good( )

- Check door seal condition

9. Festoon carrier

- Check carrier condition All carrier Good( ) / Not Good( )

10. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

290 - GANTRY BRAKE INSPECTION

Description Location Observation

1. Gantry brake

- Check wire termination

- Check friction disc, stationary disc and coil assembly All brakes Good( ) / Not Good( )

- Check mounting cover and silicon seal condition

Note : Fill up where applicable

2. Reserve stroke height (10 mm) Lanside

- Inspect stroke indicator setting and manual release Height : #1 : ______ mm #5 : ______ mm) Good( ) / Not Good( )

Note : Fill up where applicable Height : #2 : ______ mm #6 : ______ mm) Good( ) / Not Good( )

Height : #3 : ______ mm #7 : ______ mm) Good( ) / Not Good( )

Height : #4 : ______ mm #8 : ______ mm) Good( ) / Not Good( )

Seaside

Height : #1 : ______ mm #5 : ______ mm) Good( ) / Not Good( )

Height : #2 : ______ mm #6 : ______ mm) Good( ) / Not Good( )

Height : #3 : ______ mm #7 : ______ mm) Good( ) / Not Good( )

Height : #4 : ______ mm #8 : ______ mm) Good( ) / Not Good( )

Lanside

- Inspect setting and mechanical component Torque : #1 : ______ Nm #5 : ______ Nm) Good( ) / Not Good( )

Note : Fill up where applicable Torque : #2 : ______ Nm #6 : ______ Nm) Good( ) / Not Good( )

IMPSA-B : > 207Nm, ZPMC-B : >320Nm, ZPMC-C : 350Nm Torque : #3 : ______ Nm #7 : ______ Nm) Good( ) / Not Good( )

Torque : #4 : ______ Nm #8 : ______ Nm) Good( ) / Not Good( )

Seaside

Torque : #1 : ______ Nm #5 : ______ Nm) Good( ) / Not Good( )

Torque : #2 : ______ Nm #6 : ______ Nm) Good( ) / Not Good( )

Torque : #3 : ______ Nm #7 : ______ Nm) Good( ) / Not Good( )

Torque : #4 : ______ Nm #8 : ______ Nm) Good( ) / Not Good( )

4. Air gap

- Check any rubbing All brakes Good( ) / Not Good( )

Note : Fill up where applicable

5. Brake pad and disc (Landside)

- Inspect pad and disc (Pad : ≥ 5 mm, Disc : ≥ 27 mm) Brake #1 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

- Check and clean disc surface Disc : _____mm Good( ) / Not Good( )

Note : Fill up where applicable

Brake #2 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #3 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #4 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #5 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #6 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #7 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #8 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

3. Braking torque

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

Description Location Observation

6. Brake pad and disc (Seaside) Brake #1 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

- Inspect pad and disc (Pad : ≥ 5 mm, Disc : ≥ 27 mm) Disc : _____mm Good( ) / Not Good( )

- Check and clean disc surface

Note : Fill up where applicable Brake #2 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #3 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #4 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #5 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #6 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #7 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

Brake #8 RHS : _____mm, LHS _____mm Good( ) / Not Good( )

Disc : _____mm Good( ) / Not Good( )

7. Check AWC condition

- Check one way bearing and adjusting nut condition All brakes Good( ) / Not Good( )

Note : Fill up where applicable

8. Servolifter / Thruster

- Inspect oil, electrical and mechanical part All servolifters Good( ) / Not Good( )

Note : Fill up where applicable

9. Structure and limit switch

- Check pivot pin, linkage, mounting and cover All brakes Good( ) / Not Good( )

- Check limit switch setting and functionality All brakes Good( ) / Not Good( )

10. Housekeeping All location Done( ) / Not Done( )

300 - GANTRY GEARBOX INSPECTION

Description Location Observation

1. Gearbox oil

- Inspect oil level and oil condition All gearboxes Good( ) / Not Good( )

2. Structure

- Inspect mounting bolts tightness and crack All gearboxes Good( ) / Not Good( )

Note : Fill up where applicable

3. Bearing

- Inspect abnormal sound All gearboxes Good( ) / Not Good( )

Note : Fill up where applicable

4. Temperature (40 ~ 60 degree) All gearboxes Good( ) / Not Good( )

Note : Fill up where applicable

5. Coupling

- Check rubber insert for coupling condition

- Check circlips condition All couplings Good( ) / Not Good( )

Note : Fill up where applicable

6. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

310 - GANTRY MOTOR INSPECTION

Description Location Observation

1. Sound inspection

- Check any abnormal sound All motors Good( ) / Not Good( )

2. Electrical

- Check wire termination at motor termination box All motors Good( ) / Not Good( )

3. Structure

- Check cover, mounting and body codition All motors Good( ) / Not Good( )

4. Housekeeping All location Done( ) / Not Done( )

320 - GANTRY RAIL CLAMP AND ANCHOR PIN INSPECTION

Description Location Observation

1. Rail clamp hydraulic unit

- Check oil condition and level

- Check piping, any leakage and hose condition All units Good( ) / Not Good( )

- Check wire termination

2. Rail clamp motor

- Check any abnormal sound and vibration All motors Good( ) / Not Good( )

- Check wire termination

3. Limit switch

- Check condition and functionality All location Good( ) / Not Good( )

- Check leakage and mounting condition

4. Structure

- Check any leakage and cylinder condition

- Check brake shoe / lining condition All location Good( ) / Not Good( )

- Check mounting condition

Note : Fill up where applicable

5. Housekeeping All location Done( ) / Not Done( )

330 - GANTRY ANTI-COLLISION CRANE TO SHIP INSPECTION

Description Location Observation

1. Anti-collision limit switch

- Check functionality Right and left side of boom girder Good( ) / Not Good( )

- Check wire termination and micro switch condition

2. Wire rope

- Check wire rope rusty and stringness Right and left side of boom girder Good( ) / Not Good( )

Note : Fill up where applicable

3. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

340 - GANTRY ALARM SYSTEM INSPECTION

Description Location Observation

1. Siren

- Check siren functionality and condition All sirens Good( ) / Not Good( )

- Check wire termination condition

2. Warning light

- Check bulb and motor condition

- Check lamp cover and mounting condition All warning lights Good( ) / Not Good( )

- Check wire termination condition

3. Housekeeping All location Done( ) / Not Done( )

350 - GANTRY WHEEL INSPECTION

Description Location Observation

1. Wheel

- Check wheel bearing condition and abnormal sound All wheels Good( ) / Not Good( )

2. Structure

- Check wheel flange cracks or damages and condition All wheels Good( ) / Not Good( )

- Check mounting condition

3. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

360 - BOOM BRAKE INSPECTION

360.1 - SERVICE BRAKE

Description Location Observation

1. Reserve stroke height (10 mm) Brake #1 (Height : _________ mm) Good( ) / Not Good( )

- Inspect stroke indicator setting and manual release

- Inspect setting and mechanical component Brake #1 (Torque : ________________ Nm) Good( ) / Not Good( )

Note : IMPSA-A : ≥ 1890Nm, NOELL/MITSUI/ZPMC-A: ≥ 14850 Nm,

IMPSA-B : >7200Nm, ZPMC-B : >5940Nm, ZPMC-C: >6000Nm

3. Air gap

- Check any rubbing Service brake Good( ) / Not Good( )

4. Brake pad and disc Brake pad RHS : ________mm Good( ) / Not Good( )

- Check and clean disc surface Brake pad LHS : ________mm Good( ) / Not Good( )

- Inspect pad and disc (Pad : ≥ 5 mm, Disc : ≥ 27 mm) Brake disc : ________mm Good( ) / Not Good( )

5. Check AWC condition

- Check one way bearing and adjusting nut condition Service brake Good( ) / Not Good( )

6. Check wedge and shackle kit Service brake Good( ) / Not Good( )

7. Servolifter / Thruster

- Inspect oil, electrical and mechanical part Service brake Good( ) / Not Good( )

8. Structure

- Check pivot pin, linkage and mounting Good( ) / Not Good( )

9. Limit Switch a. Brake manual release Good( ) / Not Good( )

- Check setting and functionality b. Brake release Good( ) / Not Good( )

c. Brake pad wear Good( ) / Not Good( )

360.2 - EMERGENCY BRAKE

Description Location Observation

1. Hydraulic power pack

- Check oil condition and working pressure (150-180 bar) Hydraulic oil tank Good( ) / Not Good( )

2. Hydraulic cylinder and block

- Check leakage Good( ) / Not Good( )

3. Proximity Sensor & Motor

- Check setting and functionality All location Good( ) / Not Good( )

- Check electrical and mechanical parts Good( ) / Not Good( )

4. Brake pad and disc Brake #1 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

- Inspect pad and disc (Pad : ≥ 8 mm, Disc : ≥ 28 mm) Brake #1 LHS : ______mm Good( ) / Not Good( )

- Check and clean disc surface Brake #2 RHS : ______mm Good( ) / Not Good( )

Note : Fill up where applicable Brake #2 LHS : ______mm Good( ) / Not Good( )

Brake #3 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

Brake #3 LHS : ______mm Good( ) / Not Good( )

Brake #4 RHS : ______mm Good( ) / Not Good( )

Brake #4 LHS : ______mm Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

2. Braking torque

ZPMC (Pad : >3.0 mm, Disc : >1.0mm wear on each side)

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

370 - BOOM GEARBOX / REDUCER

Description Location Observation

1. Gearbox oil

- Inspect oil level and oil condition Gearbox #1 Good( ) / Not Good( )

2. Structure

- Inspect mounting bolts tightness and crack Gearbox #1 Good( ) / Not Good( )

3. Bearing

- Inspect abnormal sound Gearbox #1 Good( ) / Not Good( )

4. Temperature (40 ~ 60 degree) Gearbox #1 : _________degree Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

380 - BOOM MOTOR

Description Location Observation

1. Sound inspection Boom motor Good( ) / Not Good( )

2. Visual check

- Check structure and wire termination Boom motor Good( ) / Not Good( )

3. Emergency Motor

- Check coupling condition Boom emergency motor Good( ) / Not Good( )

- Check limit switch working condition

4. Housekeeping All location Done( ) / Not Done( )

390 - BOOM WIRE ROPE INSPECTION

Description Location Observation

1. Visual check

- Check broken strands, deformation and kinks Wire rope drum Good( ) / Not Good( )

- Broken strands (<18 wires) Boom tip Good( ) / Not Good( )

- Diameter : IMPSA-A : >28.8mm, IMPSA-B : >34.2mm, A-Frame Good( ) / Not Good( )

ZPMC-A/C : 36mm~33.4mm, ZPMC-B : 32.4mm

NOELL/MITSUI : 30mm~2 7.9mm

2. Clips and turnbuckles

- Check loosed nut and condition Length #1 Good( ) / Not Good( )

Note : Fill up where applicable Length #2 Good( ) / Not Good( )

3. Check for lubrication

- Check rusty Wire rope Good( ) / Not Good( )

4. Support plate

- Check condition All plates Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

400 - BOOM WIRE ROPE DRUM INSPECTION

Description Location Observation

1. Check wire rope anchor All drums Good( ) / Not Good( )

2. Check bearing any abnormal noise All drums Good( ) / Not Good( )

3. Check groove surface condition All drums Good( ) / Not Good( )

4. Check structure and mounting All drums Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

410 - BOOM SHEAVE AND BEARING INSPECTION

Description Location Observation

1. Check groove condition any damaged or rope trace mark Boom tip Good( ) / Not Good( )

A-Frame Good( ) / Not Good( )

2. Check locking / keeper plate condition Boom tip Good( ) / Not Good( )

A-Frame Good( ) / Not Good( )

3. Check bearing condition Boom tip Good( ) / Not Good( )

A-Frame Good( ) / Not Good( )

4. Structure and mounting Boom tip Good( ) / Not Good( )

- Check condition and bolt tightness A-Frame Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

420 - BOOM MOTOR AND GEARBOX COUPLING INSPECTION

Description Location Observation

1. Check abnormal sound All couplings Good( ) / Not Good( )

2. Check coupling cover

Note : Fill up where applicable All couplings Good( ) / Not Good( )

3. Check rubber insert condition

Note : Fill up where applicable All couplings Good( ) / Not Good( )

4. Structure and mounting

- Check bolt tightness and condition All couplings Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

430 - BOOM LIMIT SWITCH INSPECTION

Description Location Observation

1. Cable / conduit

- Check cable condition, insulation and cable lug A-Frame Good( ) / Not Good( )

2. Limit switch

- Check positioning, rusty, functionality and mounting A-Frame Good( ) / Not Good( )

3. Striker

- Check condition A-Frame Good( ) / Not Good( )

4. Housekeeping All location Done( ) / Not Done( )

440 - BOOM CAM SWITCH INSPECTION

Description Location Observation

1. Cable termination

- Check cable damage and breakage at cable lugs Boom drum Good( ) / Not Good( )

2. Cam switch functionality

- Function test All switches Good( ) / Not Good( )

3. Cam switch coupling tightness

- Check bolt tightness All couplings Good( ) / Not Good( )

4. Check 3-way gear condition Boom drum Good( ) / Not Good( )

Note : Fill up where applicable

5. Driven belt / driven chain

- Check belting condition and any crack Boom drum Good( ) / Not Good( )

Note : Fill up where applicable

6. Driven pulley

- Check pulley mounting, side guide, wear and crack Boom drum Good( ) / Not Good( )

Note : Fill up where applicable

7. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

450 - BOOM LATCH INSPECTION

Description Location Observation

1. Servolifter

- Check oil condition and any leakage

- Check linkage split-pin and conduit condition A-Frame Good( ) / Not Good( )

- Check rubber bumper

Note : Fill up where applicable

2. Limit Switch

- Check condition and functionality All limit switches Good( ) / Not Good( )

Note : Fill up where applicable

3. Structure and mounting

- Check condition and bolt tightness Boom latch Good( ) / Not Good( )

Note : Fill up where applicable

4. Power pack

- Check oil condition and any leakage A-Frame Good( ) / Not Good( )

Note : Fill up where applicable

5. Plunger

- Check plunger and spring condition A-Frame Good( ) / Not Good( )

Note : Fill up where applicable

6. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

460 - EMERGENCY STOP SYSTEM INSPECTION

Description Location Observation

1. Machinery house Electrical room (inside) Good( ) / Not Good( )

- Check functionality and condition PLC panel Good( ) / Not Good( )

Note : Fill up where applicable DC bus shift cub Good( ) / Not Good( )

Machinery house Good( ) / Not Good( )

2. Trolley Trolley / hoist emergency station Good( ) / Not Good( )

- Check functionality and condition Trolley house inside Good( ) / Not Good( )

Note : Fill up where applicable Trolley house panel Good( ) / Not Good( )

3. Boom Boom emergency station Good( ) / Not Good( )

- Check functionality and condition Boom top outside Good( ) / Not Good( )

Note : Fill up where applicable Boom top inside Good( ) / Not Good( )

Boom girder end Good( ) / Not Good( )

4. Cabin Checker cabin panel Good( ) / Not Good( )

- Check functionality and condition Cabin operator console Good( ) / Not Good( )

Note : Fill up where applicable Boom opeartor cabin Good( ) / Not Good( )

5. Portal Portal landside left Good( ) / Not Good( )

- Check functionality and condition Portal landside right Good( ) / Not Good( )

Note : Fill up where applicable Portal seaside left Good( ) / Not Good( )

Portal seaside right Good( ) / Not Good( )

6. Others Gantry operation station Good( ) / Not Good( )

- Check functionality and condition High voltage cable reel station Good( ) / Not Good( )

Note : Fill up where applicable TLS station Good( ) / Not Good( )

7. Housekeeping All location Done( ) / Not Done( )

470 - FLOODLIGHT INSPECTION

Description Location Observation

1. Boom floodlight Boom tip Good( ) / Not Good( )

- Check functionality and condition Boom joint Good( ) / Not Good( )

- Check wire termination Boom center cross beam Good( ) / Not Good( )

Boom center Good( ) / Not Good( )

2. Trolley floodlight Trolley platform Good( ) / Not Good( )

- Check functionality and condition Operator cabin Good( ) / Not Good( )

- Check wire termination

Note : Fill up where applicable

3. Machinery house Seaside Good( ) / Not Good( )

- Check functionality and condition Right hand side Good( ) / Not Good( )

- Check wire termination Left hand side Good( ) / Not Good( )

Note : Fill up where applicable Landside RHS Good( ) / Not Good( )

Landside LHS Good( ) / Not Good( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

Description Location Observation

4. Backreach

- Check functionality and condition Backreach Good( ) / Not Good( )

- Check wire termination Multi-functional platform Good( ) / Not Good( )

Note : Fill up where applicable

5. Portal beam

- Check functionality and condition Right hand side Good( ) / Not Good( )

- Check wire termination Left hand side Good( ) / Not Good( )

Note : Fill up where applicable

6. Housekeeping All location Done( ) / Not Done( )

480 - OPERATOR CABIN INSPECTION

Description Location Observation

1. Master controller / joystick

- Check functionality and condition Right side consol Good( ) / Not Good( )

- Check wire termination Left side consol Good( ) / Not Good( )

2. Electrical system Wall fan Good( ) / Not Good( )

- Check functionality and condition Cabin lamp Good( ) / Not Good( )

- Check wire termination Power socket Good( ) / Not Good( )

- Check power supply functionality Access gate limit switch Good( ) / Not Good( )

Electrical panel Good( ) / Not Good( )

3. Selector switch and push button

- Check functionality and condition Right side consol Good( ) / Not Good( )

- Check wire termination Left side consol Good( ) / Not Good( )

4. Indicator light

- Check functionality and condition All location Good( ) / Not Good( )

- Check wire termination

5. Consol Right side consol Good( ) / Not Good( )

- Check wire termination and condition Left side consol Good( ) / Not Good( )

6. Foot siren

- Check functionality and condition Siren Good( ) / Not Good( )

- Check wire termination

7. Structure Cabin door Good( ) / Not Good( )

- Check structure condition Access gate Good( ) / Not Good( )

- Check wind screen/ glass condition All bushings Good( ) / Not Good( )

Handrail Good( ) / Not Good( )

Access ladder Good( ) / Not Good( )

Support beam Good( ) / Not Good( )

Platform Good( ) / Not Good( )

8. Public access (PA) system

- Check functionality and condition Amplifier and speaker Good( ) / Not Good( )

- Check wire termination

9. Operator seat

- Check functionality and condition Operator seat Good( ) / Not Good( )

10. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

490 - AIR-CONDITIONER INSPECTION

Description Location Observation

1. Compressor

- Check structure and condition Control room Good( ) / Not Good( )

- Check wire termination and functionality Operator cabin Good( ) / Not Good( )

- Check gas quantity and any leakage Checker cabin Good( ) / Not Good( )

Note : Fill up where applicable

2. Indoor unit

- Check structure and condition Control room Good( ) / Not Good( )

- Check wire termination and functionality Operator cabin Good( ) / Not Good( )

Note : Fill up where applicable Checker cabin Good( ) / Not Good( )

3. Tubing and fitting

- Check tube condition and any leakage All location Good( ) / Not Good( )

4. Mechanical part

- Check blower motor mounting condition All location Good( ) / Not Good( )

- Check belting condition

- Check cleanliness

5. Housekeeping All location Done( ) / Not Done( )

500 - SOFTWARE AND PROGRAM MONITORING

Please see attachment (if any)

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

510 - MAIN HOIST SYSTEM GREASING

Description Location Observation

1. Main hoist system

- Pump-in new grease into greasing point Headblock sheave Done( ) / Not Done( )

Note : Fill up where applicable Headblock twistlock Done( ) / Not Done( )

Backreach-main hoist sheave Done( ) / Not Done( )

Trolley platform-main hoist sheave Done( ) / Not Done( )

Main hoist drum sheave Done( ) / Not Done( )

2. Housekeeping All location Done( ) / Not Done( )

520 - TROLLEY SYSTEM GREASING

Description Location Observation

1. Trolley system

- Pump-in new grease into greasing point Trolley sheave Done( ) / Not Done( )

Note : Fill up where applicable Trolley floating shaft Done( ) / Not Done( )

Trolley plumber block Done( ) / Not Done( )

Catenary wheel Done( ) / Not Done( )

Catenary sheave Done( ) / Not Done( )

Catenary McGill guide roller Done( ) / Not Done( )

Backreach-catenary sheave Done( ) / Not Done( )

Backreach rope tensioner bearing Done( ) / Not Done( )

2. Housekeeping All location Done( ) / Not Done( )

530 - BOOM SYSTEM GREASING

Description Location Observation

1. Boom system

- Pump-in new grease into greasing point Boom drum Done( ) / Not Done( )

Note : Fill up where applicable

2. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

540 - PASSENGER LIFT INSPECTION

Description Location Observation

1. Guide rail

- Check buffer spring and rail condition All location Good( ) / Not Good( )

- Check mounting condition

2. Gear

- Check rack and pinion gear condition All location Good( ) / Not Good( )

3. Reduction gear box

- Check gearbox condition All location Good( ) / Not Good( )

- Check mounting condition

4. Motor

- Check casing and mounting condition Top of cabin Good( ) / Not Good( )

5. Brake

- Check functionality and brake condition All brakes Good( ) / Not Good( )

6. Cabin level

- Check setting on each floor level All floors Good( ) / Not Good( )

7. Push button

- Check functionality and condition All push buttons Good( ) / Not Good( )

8. Cable

- Check cable insulation and condition Power cable Good( ) / Not Good( )

- Check protection rubber and mounting condition

9. Carrier structure

- Check door and roof door condition Carrier Good( ) / Not Good( )

- Check ladder condition

10. Intercomm

- Check condition and functionality Inside carrier Good( ) / Not Good( )

11. Housekeeping All location Done( ) / Not Done( )

550 - FIRE ALARM SYSTEM INSPECTION

Description Location Observation

1. Electrical part

- Check AC power LED light up Machinery house

- Determine standby battery condition ( 25.5 ≤ x ≤ 26.6 Vdc ) - Zone 1 Good( ) / Not Good( )

- Check any alarm LED light up from panel - Zone 2 Good( ) / Not Good( )

- Fire, Fault, Off, Extinguisher release, Walk test, External - Zone 3 Good( ) / Not Good( )

acoustic alarm off, CPU fault, Power supply fault. - Zone 4 Good( ) / Not Good( )

- Any fault message on the display (Stated the fault message) - Main Good( ) / Not Good( )

Note : Fill up where applicable - Charger Good( ) / Not Good( )

- Evacuate Good( ) / Not Good( )

2. Mechanical Part

- Visual Check for cylinder pressure gauge reading

(±170 bar for 225 bar system) Good( ) / Not Good( )

- Examine cylinder valve and hoses for sign of damage,

wear or leakage Good( ) / Not Good( )

- Inspect all piping & nozzles for any sign damage & leakage Good( ) / Not Good( )

Note : Fill up where applicable

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

560 - MAINTENANCE HOIST CRANE INSPECTION

Description Location Observation

1. Limit switch and functional test

- Hoist up stop Machinery house Good( ) / Not Good( )

- Hoist up slow down Machinery house Good( ) / Not Good( )

- Hoist down stop Machinery house Good( ) / Not Good( )

- Trolley forward stop Machinery house Good( ) / Not Good( )

- Trolley forward slow down Machinery house Good( ) / Not Good( )

- Trolley backward stop Machinery house Good( ) / Not Good( )

- Trolley backward slow down Machinery house Good( ) / Not Good( )

- Gantry right stop Machinery house Good( ) / Not Good( )

- Gantry right slow down Machinery house Good( ) / Not Good( )

- Gantry left stop Machinery house Good( ) / Not Good( )

- Gantry left slow down Machinery house Good( ) / Not Good( )

2. Control console

- Check functionality and condition Machinery house Good( ) / Not Good( )

- Check structure

3. Structure

- Check structure condition Rubber buffer Good( ) / Not Good( )

- Check hook and latch condition Hook block Good( ) / Not Good( )

4. Wire rope and turn buckle

- Check loosed nut and wire rope condition Machinery house Good( ) / Not Good( )

- Check any rusty

5. Electrical part

- Check wire termination and contactor condition Electrical box Good( ) / Not Good( )

6. Housekeeping All location Done( ) / Not Done( )

570 - AIR COMPRESSOR INSPECTION

Description Location Observation

1. Compressor

- Check oil level sufficient, air filter, V-belt, pressure gauge, Machinery house Good( ) / Not Good( )

safety valve, piping and mounting condition

- Check any abnormal sound or vibration

2. Pressure Switch

- Check pressure setting Machinery house Good( ) / Not Good( )

Note : Cut in: 9.9 kg/cm2 & Cut out: 8.0 kg/cm2

- Adjusting screw locknut and check wire termination

3. Motor

- Check mounting and any abnormal sound Machinery house Good( ) / Not Good( )

4. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

580 - QC CHECKER CABIN INSPECTION

Description Location Observation

1. Socket & power supply

- Check mounting and condition All location Good( ) / Not Good( )

2. Check lighting condition and functionality Cabin ceiling Good( ) / Not Good( )

3. Intercomm

- Check condition and functionality Good( ) / Not Good( )

4. Structure

- Check mounting and condition All location Good( ) / Not Good( )

- Check door and glass

5. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

590 - BOOM FORESTAY INSPECTION

Description Location Observation

1. Bushing

- Check abnormal sound and vibration All location Good( ) / Not Good( )

2. Structure and mounting

- Check condition and mounting All location Good( ) / Not Good( )

3. Rest support

- Check forestay rest support condition All supports Good( ) / Not Good( )

4. Boom buffer

- Check condition and mounting A-Frame Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

600 - BOOM SHEAVE INSPECTION

Description Location Observation

1. Check bearing condition All sheaves Good( ) / Not Good( )

2. Check grove condition All sheaves Good( ) / Not Good( )

3. Structure

- Check mounting and condition All sheaves Good( ) / Not Good( )

4. Housekeeping All sheaves Done( ) / Not Done( )

610 - BOOM CABIN INSPECTION

Description Location Observation

1. Indicator bulb

- Check condition and functionality All indicators bulbs Good( ) / Not Good( )

2. Check lighting condition and functionality Cabin ceiling Good( ) / Not Good( )

3. Structure

- Check mounting and condition All location Good( ) / Not Good( )

- Check door and glass

4. Intercomm

- Check condition and functionality Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

620 - GANTRY SYSTEM GREASING

Description Location Observation

1. Gantry system

- Pump-in new grease into greasing point All boggies Done( ) / Not Done( )

2. Housekeeping All location Done( ) / Not Done( )

630 - BOOM SYSTEM GREASING

Description Location Observation

1. Boom system

- Pump-in new grease into greasing point All boom sheaves Done( ) / Not Done( )

2. Housekeeping All location Done( ) / Not Done( )

640 - MAIN HOIST WIRE ROPE LUBRICATION

Description Location Observation

1. Main hoist wire rope

- Check condition and lubricate wire rope All main hoist wire ropes Done( ) / Not Done( )

2. Housekeeping All location Done( ) / Not Done( )

650 - TROLLEY WIRE ROPE LUBRICATION

Description Location Observation

1. Trolley wire rope

- Check condition and lubricate wire rope All trolley wire ropes Done( ) / Not Done( )

Note : Fill up where applicable

2. Housekeeping All location Done( ) / Not Done( )

660 - BOOM WIRE ROPE LUBRICATION

Description Location Observation

1. Boom wire rope

- Check condition and lubricate wire rope All boom wire ropes Done( ) / Not Done( )

2. Housekeeping All location Done( ) / Not Done( )

670 - CATERNARY WIRE ROPE LUBRICATION

Description Location Observation

1. Catenary wire rope

- Check condition and lubricate wire rope All caternary wire ropes Done( ) / Not Done( )

Note : Fill up where applicable

2. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

680 - MAIN CABLE REEL INSPECTION

Description Location Observation

1. Motor

- Check mounting and condition Main cable reel motor Good( ) / Not Good( )

2. Main cable

- Check cable condition Main power cable Good( ) / Not Good( )

3. Structure

- Check mounting and condition All mounting Good( ) / Not Good( )

4. Slip ring

- Check slip rings condition Good( ) / Not Good( )

5. Gearbox

- Check gearbox oil condition Good( ) / Not Good( )

- Check mounting and condition Good( ) / Not Good( )

- Check any abnormal sound Good( ) / Not Good( )

6. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

690 - BOOM BACKSTAY GREASING

Description Location Observation

1. Boom backstay

- Pump-in new grease into greasing point All greasing points Done( ) / Not Done( )

Note : Fill up where applicable

2. Housekeeping All location Done( ) / Not Done( )

700 - KBT COUPLING GREASING

Description Location Observation

1. KBT coupling

- Pump-in new grease into greasing point Done( ) / Not Done( )

Note : Fill up where applicable

Please see attachment (No. : )

2. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

710 - MAIN HOIST AC & DC MOTOR INSULATION READING

Note : Fill up where applicable

Please see attachment (No. : )

720 - TROLLEY AC & DC MOTOR INSULATION READING

Note : Fill up where applicable

Please see attachment (No. : )

730 - BOOM AC & DC MOTOR INSULATION READING

Note : Fill up where applicable

Please see attachment (No. : )

740 - GANTRY AC & DC MOTOR INSULATION READING

Note : Fill up where applicable

Please see attachment (No. : )

General Remark :

#REF!

#REF!

#REF!

4 of 38

HOIST : Page 3 of 8

Remark

Remark

#REF!

#REF!

#REF!

5 of 38

HOIST : Page 4 of 8

Remark

Remark

#REF!

#REF!

#REF!

6 of 38

HOIST : Page 5 of 8

Remark

Remark

#REF!

#REF!

#REF!

7 of 38

HOIST : Page 6 of 8

Remark

Remark

#REF!

#REF!

#REF!

8 of 38

HOIST : Page 7 of 8

Remark

Remark

Remark

#REF!

#REF!

#REF!

9 of 38

HOIST : Page 8 of 8

Remark

Remark

Remark

#REF!

#REF!

#REF!

10 of 38

TROLLEY : Page 1 of 8

Remark

#REF!

#REF!

#REF!

11 of 38

TROLLEY : Page 2 of 8

Remark

Remark

#REF!

#REF!

#REF!

12 of 38

TROLLEY : Page 3 of 8

Remark

Remark

Remark

#REF!

#REF!

#REF!

13 of 38

TROLLEY : Page 4 of 8

Remark

Remark

Remark

#REF!

#REF!

#REF!

14 of 38

TROLLEY : Page 5 of 8

Remark

Remark

#REF!

#REF!

#REF!

15 of 38

TROLLEY : Page 6 of 8

Remark

Remark

Remark

#REF!

#REF!

#REF!

16 of 38

TROLLEY : Page 7 of 8

Remark

Remark

#REF!

#REF!

#REF!

17 of 38

TROLLEY : Page 8 of 8

Remark

#REF!

#REF!

#REF!

18 of 38

GANTRY : Page 1 of 4

Remark

#REF!

#REF!

#REF!

19 of 38

GANTRY : Page 2 of 4

Remark

Remark

#REF!

#REF!

#REF!

20 of 38

GANTRY : Page 3 of 4

Remark

Remark

Remark

#REF!

#REF!

#REF!

21 of 38

GANTRY : Page 4 of 4

Remark

Remark

#REF!

#REF!

#REF!

22 of 38

BOOM : Page 1 of 5

Remark

Remark

#REF!

#REF!

#REF!

23 of 38

BOOM : Page 2 of 5

Remark

Remark

Remark

#REF!

#REF!

#REF!

24 of 38

BOOM : Page 3 of 5

Remark

Remark

Remark

#REF!

#REF!

#REF!

25 of 38

BOOM : Page 4 of 5

Remark

Remark

#REF!

#REF!

#REF!

26 of 38

BOOM : Page 5 of 5

Remark

#REF!

#REF!

#REF!

27 of 38

AUXILARY : Page 1 of 3

Remark

Remark

#REF!

#REF!

#REF!

28 of 38

AUXILARY : Page 2 of 3

Remark

Remark

#REF!

#REF!

#REF!

29 of 38

AUXILARY : Page 3 of 3

Remark

#REF!

#REF!

#REF!

30 of 38

GREASE : Page 1 of 1

Remark

Remark

Remark

#REF!

#REF!

#REF!

31 of 38

AUXILARY : Page 1 of 3

Remark

Remark

#REF!

#REF!

#REF!

32 of 38

AUXILARY : Page 2 of 3

Remark

Remark

#REF!

#REF!

#REF!

33 of 38

AUXILARY : Page 3 of 3

Remark

#REF!

#REF!

#REF!

34 of 38

BOOM: Page 1 of 1

Remark

Remark

Remark

#REF!

#REF!

#REF!

35 of 38

GREASE : Page 1 of 1

Remark

Remark

Remark

Remark

Remark

Remark

#REF!

#REF!

#REF!

36 of 38

GANTRY : Page 1 of 1

Remark

#REF!

#REF!

#REF!

37 of 38

GREASE : Page 1 of 1

Remark

Remark

#REF!

#REF!

#REF!

38 of 38

AC/DC MEGGER : Page 1 of 1

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

QUAY CRANEPREVENTIVE MAINTENANCE CHECKLIST

MONTH / YEAR :

CRANE NUMBER :

JOB NUMBER :

W.O. NUMBER :

DATE /TIME START :

DATE/TIME END :

CRANE :

MAIN HOIST : LAND SIDE (FOR DUAL HOIST CRANE)

SEA SIDE (FOR DUAL HOIST CRANE)

TROLLEY :

GANTRY :

BOOM :

Please tick ( X ) where applicable :

Page 1 to page 30 ( )

Page 1, page 31 to page 36 ( )

Page 1, page 37 to page 38 ( )

Page 1 to page 38 ( )

SYSTEM : PREPARED BY : SIGNATURE :

MAIN HOIST SYSTEM Date :

TROLLEY SYSTEM Date :

GANTRY SYSTEM Date :

BOOM SYSTEM Date :

AUXIALLARY SYSTEM Date :

GREASING Date :

VERIFIED BY : SIGNATURE :

Date :

HOUR METER READING :

PM CHECKLIST TYPE :

MONTHLY PM :

QUARTERLY PM :

SEMI-ANNUALLY PM :

ANNUALLY PM :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

10 - MAIN HOIST BRAKE

10.1 - SERVICE BRAKE

Description Location Observation

1. Reserve stroke height (10 mm) Brake #1 (Height : _________ mm) Good( ) / Not Good( )

- Inspect stroke indicator setting and manual release Brake #2 (Height : _________ mm) Good( ) / Not Good( )

Note : Fill up where applicable Brake #3 (Height : _________ mm) Good( ) / Not Good( )

Brake #4 (Height : _________ mm) Good( ) / Not Good( )

Brake #1 (Torque : ________________ Nm) Good( ) / Not Good( )

- Inspect setting and mechanical component Brake #2 (Torque : ________________ Nm) Good( ) / Not Good( )

Note : IMPSA-A :≥ 15.75kNm, NOELL/MITSUI : ≥ 14.85kNm, Brake #3 (Torque : ________________ Nm) Good( ) / Not Good( )

Brake #4 (Torque : ________________ Nm) Good( ) / Not Good( )

3. Air gap

- Check any rubbing All brakes Good( ) / Not Good( )

4. Brake pad and disc Brake #1 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

- Inspect pad and disc Brake #1 LHS : ______mm Good( ) / Not Good( )

- Check and clean disc surface Brake #2 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

Note : Fill up where applicable Brake #2 LHS : ______mm Good( ) / Not Good( )

All cranes (Pad : ≥ 5 mm, Disc : ≥ 27 mm) Brake #3 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

ZPMC-B (Pad : ≥ 3 mm, Disc :≤1.0mm wear) Brake #3 LHS : ______mm Good( ) / Not Good( )

ZPMC-C (Pad : > 3 mm, Disc wear more than 20%) Brake #4 RHS : ______mm , Disc : ______mm Good( ) / Not Good( )

Brake #4 LHS : ______mm Good( ) / Not Good( )

5. Check AWC condition Brake #1 Good( ) / Not Good( )

- Check one way bearing and adjusting nut condition Brake #2 Good( ) / Not Good( )

- Check gap AMC to catched plate Brake #3 Good( ) / Not Good( )

- Check adjustment AWC pin drive Brake #4 Good( ) / Not Good( )

6. Check wedge and shackle kit Brake #1 Good( ) / Not Good( )

Note : Fill up where applicable Brake #2 Good( ) / Not Good( )

Brake #3 Good( ) / Not Good( )

Brake #4 Good( ) / Not Good( )

7. Servolifter / Thruster All servolifters Good( ) / Not Good( )

- Inspect oil, electrical and mechanical part

8. Structure

- Check pivot pin, linkage and mounting Good( ) / Not Good( )

9. Limit Switch a. Brake manual release Good( ) / Not Good( )

- Check setting and functionality b. Brake release Good( ) / Not Good( )

Note : Fill up where applicable c. Brake pad wear Good( ) / Not Good( )

10. Housekeeping All location Done( ) / Not Done( )

General Remark :

2. Braking torque

IMPSA-B : 27kNm, ZPMC-A : 12.6kNm

ZPMC-A : ≥ 14.85kNm, ZPMC-C : 19kNm

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

10.2 - EMERGENCY BRAKE ( MAIN & AUX)

Description Location Observation

1. Hydraulic Tank Mechinery House

- Check oil condition Good( ) / Not Good( )

- Check oil level Good( ) / Not Good( )

- Check working pressure (150 -180 bar) Good( ) / Not Good( )

- Check tank condition Good( ) / Not Good( )

2. Hydraulic cylinder and block

- Check hoses leakage Good( ) / Not Good( )

- Check solenoid coil & dim plugs Good( ) / Not Good( )

- Check valve leakage & functions Good( ) / Not Good( )

3. Proximity sensor

- Check setting and functionality Good( ) / Not Good( )

Note : Fill up where applicable

4. Motor & Electrical Components

- Check electrical termination Good( ) / Not Good( )

- Measure Motor demands Phase 1: _______(A) Good( ) / Not Good( )

Phase 2: _______(A)

Phase 3: _______(A)

5. Brake pad and disc

- Inspect pad and disc (Pad : ≤ 8 mm, Disc : ≥ 28 mm) Disc Plate#1 RHS : ______mm Good( ) / Not Good( )

- Check and clean disc surface Disc Plate#1 LHS : ______mm Good( ) / Not Good( )

Note : Fill up where applicable Disc Drum#1 RHS : ______mm Good( ) / Not Good( )

Disc Drum #1 LHS : ______mm Good( ) / Not Good( )

Disc Plate#2 RHS : ______mm Good( ) / Not Good( )

Disc Plate #2 LHS : ______mm Good( ) / Not Good( )

Disc Drum#2 RHS : ______mm Good( ) / Not Good( )

Disc Drum #2 LHS : ______mm Good( ) / Not Good( )

6. Housekeeping All location Done( ) / Not Done( )

General Remark :

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

20 - MAIN HOIST GEARBOX / REDUCER

Description Location Observation

1. Gearbox oil

- Inspect oil level and oil condition Gearbox #1 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( )

2. Structure

- Inspect mounting bolts tightness and crack Gearbox #1 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( )

3. Bearing

- Inspect abnormal sound Gearbox #1 Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 Good( ) / Not Good( )

4. Temperature (40 ~ 60 degree) Gearbox #1 : _________degree Good( ) / Not Good( )

Note : Fill up where applicable Gearbox #2 : _________degree Good( ) / Not Good( )

5. Housekeeping All location Done( ) / Not Done( )

30 - MAIN HOIST DRIVE & BLOWER MOTOR

Description Location Observation

1. Sound inspection Motor #1 Good( ) / Not Good( )

Note : Fill up where applicable Motor #2 Good( ) / Not Good( )

Motor #3 Good( ) / Not Good( )

Motor #4 Good( ) / Not Good( )

2. Check heater Motor #1 Good( ) / Not Good( )

Note : For DC motor only Motor #2 Good( ) / Not Good( )

3. Visual check

- Check coupling motor & gear box (Bush Coupling) Motor #1 Good( ) / Not Good( )

- Check terminations Motor #2 Good( ) / Not Good( )

- Check mounting bolts and frame Motor #3 Good( ) / Not Good( )

Note : Fill up where applicable Motor #4 Good( ) / Not Good( )

4. Check blower motor cond. Motor #1 Good( ) / Not Good( )

- Check rotation Motor #2 Good( ) / Not Good( )

- Check running cond Motor #3 Good( ) / Not Good( )

- Measure motor demands Motor #4 Good( ) / Not Good( )

- Check coupling condition

5. Emergency Motor

- Check coupling condition & chain link Motor #1 Good( ) / Not Good( )

- Check limit switch working condition Motor #2 Good( ) / Not Good( )

6. Air Filter Motor #1 Good( ) / Not Good( )

- Check clealiness Motor #2 Good( ) / Not Good( )

Motor #3 Good( ) / Not Good( )

Motor #4 Good( ) / Not Good( )

7. Housekeeping All location Done( ) / Not Done( )

Document No.

Revision No.

Effective Date

SUPPORTING DOCUMENT Page

TITLE : QUAY CRANE PREVENTIVE MAINTENANCE CHECKLIST

40 - MAIN HOIST WIRE ROPE INSPECTION

Description Location Observation

1. Visual check

- Check broken strands, deformation and kinks Drum Good( ) / Not Good( )

- Diameter (NOELL/ZPMC-A : 26.2mm~28.0mm) Backreach Good( ) / Not Good( )

Trolley platform Good( ) / Not Good( )

- Diameter (MITSUI : 26.2mm~23.3mm) Headblock Good( ) / Not Good( )

- Diameter (ZPMC-C : 32.00mm~29.76mm) Main Girder Area (5 mtr before Joint) Good( ) / Not Good( )

- Broken strands (<18 wires) Boom Girder Area (5 mtr after Joint) Good( ) / Not Good( )

Note : Fill up where applicable

2. Clips and Clamp Length #1 Good( ) / Not Good( )

- Check loosed nut and condition Length #2 Good( ) / Not Good( )

- Check installation Length #3 Good( ) / Not Good( )

Length #4 Good( ) / Not Good( )

3. Check for lubrication Length #1 Good( ) / Not Good( )

- Check rusty Length #2 Good( ) / Not Good( )

Length #3 Good( ) / Not Good( )

Length #4 Good( ) / Not Good( )