HNF-FRDC-62005 Revision 2 Projects L-849 and L-850, Replacement of the 200E and 200W Potable Water Tanks Functional Requirements and Design Criteria Prepared for the U.S. Department of Energy Assistant Secretary for Environmental Management Contractor for the U.S. Department of Energy under Contract DE-AC06-09RL14728 P.O. Box 650 Richland, Washington 99352 Approved for Public Release; Further Dissemination Unlimited

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

HNF-FRDC-62005Revision 2

Projects L-849 and L-850, Replacement of the200E and 200W Potable Water Tanks Functional Requirements and Design Criteria

Prepared for the U.S. Department of EnergyAssistant Secretary for Environmental Management

Contractor for the U.S. Department of Energyunder Contract DE-AC06-09RL14728

P.O. Box 650 Richland, Washington 99352

Approved for Public Release; Further Dissemination Unlimited

HNF-FRDC-62005Revision 2

EDC#: ECR-20-000611

Projects L-849 and L-850, Replacement of the 200E and 200W PotableWater Tanks Functional Requirements and Design Criteria

Project No: L-849, L-850 Document Type: FRDC

C. S. ELLSMission Support Alliance

B. D. PRATTMission Support Alliance

M. A. PEARSONMission Support Alliance

Date PublishedMay 2020

Prepared for the U.S. Department of EnergyAssistant Secretary for Environmental Management

Contractor for the U.S. Department of Energyunder Contract DE-AC06-09RL14728

P.O. Box 650 Richland, Washington 99352

Release Approval Date Release Stamp

By Julia Raymer at 11:21 am, May 07, 2020

Approved for Public Release; Further Dissemination Unlimited

May 07, 2020DATE:

•

APPROVEDL _,

HNF-FRDC-62005Revision 2

TRADEMARK DISCLAIMERReference herein to any specific commercial product, process, or service bytradename, trademark, manufacturer, or otherwise, does not necessarilyconstitute or imply its endorsement, recommendation, or favoring by theUnited States Government or any agency thereof or its contractors orsubcontractors.

This report has been reproduced from the best available copy.

Printed in the United States of America

Total pages: 39

A-7320-005 (04/04)

RECORD OF REVISION

(2) Title

Change Control Record

Projects L-849 and L-850, Replacement of the 200E and 200W Potable Water Tanks

HNF-FRDC-62005

(1) Document NumberPage 1 of 1

(3) Revision (4) Description of Change - Replace, Add, and Delete Pages

(5) DA/TA DateAuthorized for Release

2 Minor text and code year reference updates. 5/7/20203~.;~--~

Page 1 of 35

HNF-FRDC-62005, Revision 2 Projects L-849 & L-850

Projects L-849 and L-850, Replacement of the 200E and 200W Potable Water Tanks

Functional Requirements and Design Criteria

Chris Ells, PE, Civil Project Engineer Mark Pearson, PE, Mechanical Project Engineer Brad Pratt, PE, PMP, Project Manager

Mission Support Alliance, LLC

Date Published May 2020

P.O. Box 650 Richland, Washington 99352

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 2 of 35

TABLE OF CONTENTS

1.0 Introduction ............................................................................................................... 7

1.1. Background ............................................................................................................ 7

1.1.1. Existing Potable Water Storage Tanks..................................................................... 7

1.1.2. Existing Sanitary Water Distribution Pumping ........................................................ 7

1.2. Scope, Mission and Justification ............................................................................. 8

1.2.1. Project L-849 ......................................................................................................... 8

1.2.2. Project L-850 ......................................................................................................... 9

1.3. Site Location .......................................................................................................... 9

2.0 Functional Requirements ......................................................................................... 11

2.1. Process, Production Requirements..........................................................................11

2.2. Operational Effectiveness Requirements.................................................................12

2.3. Preferred Technology ............................................................................................12

2.3.1. Energy Efficiency .................................................................................................12

2.3.2. Corrosion Control .................................................................................................12

2.3.3. Tank Life Extension ..............................................................................................12

2.3.4. Tank Level Sensors ...............................................................................................12

2.3.5. Flow Measurement ................................................................................................12

2.4. Materials of Construction.......................................................................................13

2.4.1. Tank Material........................................................................................................13

2.4.2. Above Grade Piping ..............................................................................................14

2.4.3. Below Grade Piping ..............................................................................................14

2.5. Identification of Studies, Analyses, and Other Reports ............................................14

2.6. Unique Testing and Inspection Requirements .........................................................14

2.7. Design Life ...........................................................................................................15

2.8. Special Safeguards and Security Requirements .......................................................15

2.9. Environmental, Safety, and Health .........................................................................15

2.9.1. Environmental.......................................................................................................15

2.9.2. Industrial Hygiene .................................................................................................16

2.9.3. Radiological Control .............................................................................................16

2.9.4. Waste Management ...............................................................................................16

2.9.5. Cyber Security ......................................................................................................16

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 3 of 35

3.0 Project Inputs ........................................................................................................... 17 3.1. Description of Existing System(s) ..........................................................................17

3.2. Physical and System Interfaces ..............................................................................17

3.2.1. Interrelationship with Other Processes ...................................................................17

3.2.2. Interrelationship with Other Facilities ....................................................................18

3.2.3. Interrelationship with Other Systems......................................................................18

3.2.4. Interrelationship with Other Projects ......................................................................19

3.2.5. Interferences with Other Structures and Infrastructure ............................................19

3.2.5.1. Railroads ...........................................................................................................19

3.2.5.2. Piping................................................................................................................19

3.3. Design Assumptions ..............................................................................................20

3.4. Design Constraints ................................................................................................21

4.0 Design Criteria ......................................................................................................... 23 4.1. General Criteria .....................................................................................................23

4.1.1. Design Specific Quality Assurance Requirements...................................................23

4.1.2. Additional Evaluations ..........................................................................................23

4.1.3. Requirements for Flexibility and Future Expansion ................................................23

4.1.4. Verification and Validation Strategy ......................................................................24

4.1.5. Approach to Natural Phenomenon..........................................................................24

4.1.6. System Status Indicators ........................................................................................24

4.1.7. Fire Protection, Fire Detection, and Fire Suppression Requirements........................24

4.1.8. Tank Mixing System .............................................................................................24

4.1.9. Redundant Piping and Bypass Lines.......................................................................25

4.1.10. Valve and Component Selection ............................................................................25

4.1.11. Specific Tank Requirements ..................................................................................25

4.2. Process Design Guidelines and Constraints.............................................................25

4.3. Facility Criteria .....................................................................................................25

4.3.1. Architectural and Civil/Structural ..........................................................................26

4.3.2. Heating, Ventilation, and Air Conditioning ............................................................26

4.3.2.1. Water heating requirements................................................................................26

4.3.3. Utility Requirements .............................................................................................27

4.3.4. Maintenance..........................................................................................................27

4.4. Modifications to Existing Facility ..........................................................................29

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 4 of 35

4.5. Equipment Instrumentation, Controls and Automation ............................................29

4.6. Operational Requirements......................................................................................30

4.7. Decontamination and Decommissioning.................................................................30

5.0 Codes and Standards................................................................................................ 30

5.1. Code of Record .....................................................................................................30

5.2. Regulations, Orders, and Procedures ......................................................................33

5.3. Washington Administrative Code Requirements .....................................................34

5.4. Sustainability Requirements...................................................................................34

5.5. Washington State Department of Health Permit(s) ..................................................34

6.0 References ................................................................................................................ 34

FIGURES

Figure 1: Conceptual Location of New Tank 283WG in 200E for Project L-849 ......................10 Figure 2: Conceptual Location of New Tank 283WG in 200W for Project L-850.....................11

TABLES Table 1: Collection of Average Winter Water Temperatures....................................................26 Table 2: National Consensus Standards – Code of Record .......................................................30 Table 3: Regulations, Orders, and Procedures .........................................................................33 Table 4: Washington Administrative Codes ............................................................................34

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 5 of 35

Acronyms and Abbreviations

200E 200 East Area 200W 200 West Area A/E Architectural / Engineering Firm ACI American Concrete Institute AISC American Institute of Steel Construction ANSI American National Standards Institute APE Area of Potential Effect ASCE American Society of Civil Engineers ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials ATS Automatic (Electrical) Transfer Switch AWS American Welding Society AWWA American Water Works Association CAT Construction Acceptance Test COTS Commercial-off-the-shelf CPWTF Central Plateau Water Treatment Facility CT (disinfectant) Contact Time DBP Disinfection Byproducts DFLAW Direct Feed Low Activity Waste DI Ductile Iron (pipe) DOE U.S. Department of Energy DOE-RL U.S. Department of Energy, Richland Operations Office EW Export Water FAT Factory Acceptance Test FEMA Federal Emergency Management Agency FRDC Functional Requirements and Design Criteria FSS Fire Suppression System GPM Gallons per Minute HP Horsepower HMI Human Machine Interface HSESP Hanford Site Electrical Safety Program IBC International Building Code ICC International Code Council ICS Instrumentation and Control System IEEE Institute of Electrical and Electronics Engineers IH Industrial Hygiene ISMS Integrated Safety Management System kVA Kilovolt Amps

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 6 of 35

MCC Motor Control Center MG Million Gallons MSA Mission Support Alliance, LLC NEMA National Electrical Manufacturers Association NEPA National Environmental Policy Act NFPA National Fire Protection Association NSF National Sanitation Foundation OAT Operational Acceptance Test OSHA Occupational Safety and Health Administration PLC Programmable Logic Controller PSI Pounds per Square Inch PVC Polyvinyl Chloride PW Potable Water RCA Radiologically Controlled Area RMS Root Mean Square (a method for obtaining a weighted average value) RPBA Reduced Pressure Backflow Assembly RSS Radiological Site Services RW Raw Water SBS Standby Storage SDD System Design Description SEPA State and Environmental Policy Act SW Sanitary Water TEDF Treated Effluent Disposal Facility THM Trihalomethane UL Underwriters Laboratories WAC Washington Administrative Code WDOH Washington State Department of Health WLAN Water (Utilities’) Local Area Network WTF Water Treatment Facility WTP Waste Treatment Plant

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 7 of 35

1.0 INTRODUCTION

1.1. Background

Due to Hanford mission needs, the systems are being updated to supply safe and reliable Sanitary Water (SW) for ongoing Hanford site cleanup activities. The existing storage tanks, 283EA and 283WA, serve the SW system. The SW system produces Potable Water (PW).

1.1.1. Existing Potable Water Storage Tanks

Project B-604, Water System Upgrades was initiated in the mid-1990’s to provide upgrades to Hanford’s Export Water (EW), Raw Water (RW) and SW systems. The purpose of the upgrades was to meet the U.S. Department of Energy’s (DOE) requirement for two reliable, independent sources of water available for fire suppression for the Central Plateau in 200 East (200E) and 200 West (200W) areas. The project included the construction of two PW storage tanks serving the RW and SW systems, each with a nominal storage capacity of 1.16 million gallons (MG) and a design life of 20 years. The tanks, 283EA and 283WA, were constructed of welded carbon steel and are located in the 200E and 200W areas of the Hanford Site, respectively.

The tank interiors have documented inspections for the years of 2007, 2013 and 2017. The 2007 inspection assigned a rust rating to the various interior tank surfaces based on American Society for Testing and Materials (ASTM) D610, Standard Practice for Evaluating Degree of Rusting on Painted Steel Surfaces. Most surfaces had a rating of 8 or better, which corresponds to a maximum surface rust area of 0.1%. Exceptions included the anti-vortex plate, graded 5, or up to 3% of the total surface area and the roof vent with a grade of 7 (up to 0.3%). The 2013 inspection stated that the tanks exhibited staining, bubble formation, and cracks in the interior coating. Corrosion above the high-water mark was more pronounced with the roof showing widespread corrosion and paint loss. The 2017 inspection report noted heavy rusting at the high-water mark and above, including heavy deterioration of the roof support I-beam and heavy corrosion in the hatch area. Areas of rust and paint bubbling were observed below the high-water mark.

1.1.2. Existing Sanitary Water Distribution Pumping

The two SW pump house facilities, 283E and 283W, are rapid gravity, dual media filtration water treatment facilities constructed in 1944. Only 283W remains operational; however, each facility contains two functioning clear wells, which are approximately 200,000 gallons each, and both facilities contain active SW distribution pumps. The existing SW distribution pumps located in pump house buildings 283E in 200E, and 283W in 200W will be replaced with new pumps as part of the upgrades under Project L-849 in existing pump house 282EC and Project L-850 in existing pump house 282WC.

The four existing SW distribution pumps in 283W and in 283E have a combined pumping capacity of 3,400 Gallons per Minute (GPM) at 110 pounds per square inch

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 8 of 35

(PSI). Three of the four SW pumps in 283E have been replaced since 2015. One of four pumps in 283W has been replaced since 2015.

1.2. Scope, Mission and Justification

Two replacement PW storage tanks will be designed and constructed. The L-849 tank will be located near 282E RW Reservoir and the L-850 tank will be located near 282W RW Reservoir. The total volume of the tanks will be increased per the quantities provided within HNF-CALC-64157, Basis of Tank Size with each tank serving as a redundant supply to the SW system.

This Functional Requirements and Design Criteria (FRDC) document addresses both Projects L-849 and L-850, because it is assumed the tanks will differ only in the following ways:

• A boost chlorination injection system shall be designed and installed as part of the ProjectL-849 work scope.

• Project L-850 will be serve a dual function as (1) water storage and (2) the contact timechamber for proposed new Central Plateau Water Treatment Facility (CPWTF) the tankwill be required to have internal baffling.

1.2.1. Project L-849

Project L-849 will design and construct a new PW storage tank (283EG) with a minimum total volume of 1.5 MG usable capacity based on HNF-CALC-64157, Basis of Tank Size, to replace the existing PW storage tank, 283EA in 200E. The storage volume is based on worst-case fire suppression water demand of 3,000 GPM and a peak hotel/domestic PW demand of 2,220 GPM.

Project L-849 will remove existing RW booster pumps and associated electrical, and add new SW pumps and associated electrical for pressurizing the SW grid, as well as a tank recirculation pump. The new pumps shall be installed in the existing 282EC pump house and will be designed to meet projected fire suppression demand of 3,000 gpm and peak domestic demand of 2,220 gpm at 110 psi. Standby power is required and the existing 282ED generator shall be evaluated for sufficient capacity to support electrical load demands for Project L-849.

The new PW storage tank 283EG will require freeze protection, booster chlorination system, tank mixing, and piping reconfigurations to allow for the new SW distribution pumps and existing fire pump inside 282EC to draw from the new tank 283EG. No internal baffling is required for the L-849 tank since it includes a tank mixing system.

The project shall be in accordance with Washington Administrative Code (WAC) 246-290, American Water Works Association (AWWA) requirements, and applicable sections of the latest Washington State Department of Health (WDOH), Water System Design Manual.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 9 of 35

The existing PW storage tank 283EA shall be decommissioned, demolished and removed leaving only the concrete foundation following final commissioning and acceptance of the WDOH Construction Completion Report for Project L-849.

1.2.2. Project L-850

Project L-850 will design and construct a new PW storage tank (283WG) with a minimum total volume of 1.5 MG usable capacity based on HNF-CALC-64157, Basis of Tank Size, 283WG, to replace the existing PW storage tank, 283WA in 200W. This new tank will function as both storage and the contact time chamber for CPWTF. The storage volume is based on worst-case fire suppression water demand of 3,000 GPM and a peak hotel/domestic PW demand of 2,220 GPM.

Project L-850 will remove existing RW booster pumps and associated electrical, and adds new SW pumps and associated electrical for pressurizing the SW grid as well as a tank recirculation pump. The new pumps shall be installed in the existing 282WC pump house and will be designed to meet projected fire suppression demand of 3,000 gpm and peak domestic demand of 2,220 gpm at 110 psi. Standby power is required and the existing 282WD generator shall be evaluated for sufficient capacity to support electrical load demands for Project L-850.

The new tank will require freeze protection and piping reconfigurations to allow for the new SW distribution pumps and existing fire pump in 282WC to draw from the new tank 283WG, as well as bypass the 283WG tank in the event of a loss of tank accident.

The project shall meet WAC 246-290, AWWA requirements, and applicable sections of the latest Washington State Department of Health, Water System Design Manual.

As part of the water treatment process that will involves the L-850 tank and the CPWTF (Project L-897), this tank is required to be part of the WDOH Tracer Study for overall WDOH approval and use of each facility. The Tracer Study will be performed by Project L-897.

The existing tank 283WA shall be decommissioned, demolished, and removed leaving only the concrete foundation following final commissioning and acceptance of the WDOH Construction Completion Report for Project L-850.

1.3. Site Location

Project L-849 will be located near the existing tank, 283EA, in 200E (see Figure 1). Project L-850 will be located in close proximity to the existing tank, 283WA, in the 200W (seeFigure 2). Exact locations will be determined upon completion of the selection of the type ofstorage tank system, soils analysis, and review of existing site utilities and infrastructure inand around the qualifying sites. The new SW distribution pumps will be installed in existingpump houses 282EC and 282WC which presently house inactive RW booster pumps and anactive fire pump.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 10 of 35

Figure 1: Conceptual Location of New Tank 283EG in 200E for Project L-849

BALT M0FiE AsiF N

2S3EA

Existing Tank 283EG

(New Tank)

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 11 of 35

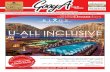

Figure 2: Conceptual Location of New Tank 283WG in 200W for Project L-850

2.0 FUNCTIONAL REQUIREMENTS

2.1. Process, Production Requirements

The sizing requirements for the two replacement storage tanks is documented in HNF-CALC-64157, Basis of Tank Size.

The function of the tanks provided under Projects L-849 and L-850 is to store PW for fire suppression and PW hotel loads. The tank under project L-850 will also serve as the contact

iit

••=

283WG -

(New Tank) •

283WA

(Existing Tank)

U

2 83WE

20TH STREET

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 12 of 35

time chamber for the new CPWTF. Both projects will also provide new SW distribution pumps and recirculation pumps.

2.2. Operational Effectiveness Requirements

The SW storage system must be operationally effective 24-hours a day, 365-days a year.

2.3. Preferred Technology

2.3.1. Energy Efficiency

Technology such as variable frequency drives and pumps that reduce energy consumption shall be considered.

2.3.2. Corrosion Control

Corrosion control in the form of a passive Cathodic Protection (CP) systems shall be designed, analyzed, and installed to protect the PW storage tanks.

Corrosion control for the rest of the project components shall also be analyzed and included in the design and installation.

2.3.3. Tank Life Extension

Technologies that remove disinfection byproducts and mitigate future corrosion above the waterline to extend tank life shall be included in the design.

2.3.4. Tank Level Sensors

PLC monitored level sensors shall be used to continuously monitor tank volume and alarm conditions.

2.3.5. Flow Measurement

The SW pump discharge flow and recirculation line flow shall be measured by flow meters with Flow Indicating Transmitters (FITs) and shall be monitored by the Programmable Logic Controller (PLC). The HMIs shall display each real-time flow measurement in Gallons Per Minute (GPM) and display the local demand flow rate supplied to the SW grid by summing the four main pump flows and subtracting the two recirculation line flows.

An Instrumentation and Control System (ICS) shall provide a total flow for both SW systems (282EC and 282WC) that shall also be available for display on the local HMIs.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 13 of 35

2.4. Materials of Construction

The Architectural/Engineering firm (A/E) shall evaluate the following materials for construction:

• Carbon Steel• Pre-Stressed concrete• Stainless steel• Polyvinyl Chloride (PVC)

2.4.1. Tank Material

The A/E shall provide a technical evaluation, under the L-850 project scope, of each material taking into consideration for the material to be used on both tanks:

• Capital costs and schedule durations for design, construction, and commissioning

• 50 year design life

• Operations and Maintenance

o Accessibilityo Maintainabilityo Reliabilityo Serviceabilityo Water Quality

Note: Although draining the tanks will be required for maintenance purposes, this removes the tanks from service and is therefore undesirable. Material consideration should include design features (stairs, hatches, manholes, etc.) for optimizing maintenance.

• Cost Effectivenesso Life-cycle Costo Breakeven Cost

• Constructability

• Materials furnished by the tank manufacturer, which are in contact with stored water,shall be certified to meet NSF/ANSI 61.

• Piping and appurtenances shall be in accordance with the codes and standards listedin Section 6.0.

As of revision 1 to this FRDC, the material Epoxy-Fused-to-Steel Bolted Tank with Aluminum Geodesic Dome Roof has been selected based on the technical evaluation performed under Project L-850 (HNF-RPT-64604, L-849 and L-850 Tank Material Evaluation) and shall be used for both the L-849 and L-850 tanks.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 14 of 35

2.4.2. Above Grade Piping

Above-grade piping within buildings shall be constructed of a coated carbon steel (CS) and shall comply with Section 6.0, Codes and Standards.

Above-grade piping outside of building 282WC shall be constructed of ductile-iron (DI) and shall be coated on both the interior and exterior with a fusion-bonded epoxy coating. Additionally, all materials and coatings shall comply with Section 6.0, Codes and Standards.

All exposed piping outside of Buildings 282WC and 282EC shall be insulated and heat traced. The L-850 tank emergency bypass line shall be insulated; however, heat trace is not required since this bypass line is not used during normal operations.

Piping associated with the fire sprinkler systems will be designed and tested in accordance with the more conservative standard of those listed herein. Where conflicts exist with piping associated with the fire system, the governing, conservative design standard shall be applied. Any additional variations to the code requirements will be required to be approved by the Owner and/or the Owner’s Representative(s).

2.4.3. Below Grade Piping

Below-grade piping shall be Polyvinyl Chloride (PVC) and/or fusion-bonded epoxy lined Ductile Iron (DI) and comply with Section 6.0.

2.5. Identification of Studies, Analyses, and Other Reports

The following list of studies, analysis, calculations, and reports are relevant to the development and planning of the new 200E and 200W water storage tanks:

• HNF-5828, Hanford Site Water System Master Plan

• HNF-CALC-64157, Basis of Tank Size

• HNF-61874, Evaluation and Determination of Maximum Central Plateau Fire Flow

• HNF-RPT-64604, L-849 and L-850 Tank Material Evaluation

2.6. Unique Testing and Inspection Requirements

There are no plans for unique testing and inspections at this time for the replacement water tanks, distribution pumps and recirculation pumps. The new water tanks will use standard commercial-off-the-shelf (COTS) equipment for pumps, heating and air venting, controls, and temperature monitoring.

Factory Acceptance Test (FAT), Construction Acceptance Test (CAT), and Operational Acceptance Test (OAT) testing/inspections shall be in accordance with, but not limited to, MSC-PRO-ENG-286, Testing of Equipment and Services, and Section 6.0 of this document.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 15 of 35

FAT, CAT and OAT procedures shall be developed in accordance with MSC-PRO-ENG-286, Testing of Equipment and Systems and MSC-STD-ENG-60816, Engineering Test Documentation. Inspection and functional testing will be performed in accordance with approved CAT to be developed as part of the project. Final system acceptance testing will be performed in accordance with an approved OAT, to be developed as part of the project.

As part of the water treatment process that will involves the L-850 tank and the CPWTF (Project L-897), this tank is required to be part of the WDOH Tracer Study for overall WDOH approval and use of each facility. The WDOH Tracer Study will be performed by Project L-897.

2.7. Design Life

All design disciplines will review applicable codes to ensure facility design and material selections will meet the International Building Code (IBC), Risk Category IV “Essential Facility” safety, functionality, longevity, and operational obligations to meet a 50 year operational life to support the current Hanford Site Cleanup Mission schedule. Ease of replacement will be considered for equipment and systems when a 50-year life is not practical.

2.8. Special Safeguards and Security Requirements

The 282EC/WC Buildings are to be locked and access to these buildings shall be controlled by Water and Sewer Utilities (W&SU) Operations to ensure W&SU remains in accordance with WAC 246-290-415, Operations and Maintenance.

2.9. Environmental, Safety, and Health

2.9.1. Environmental

NEPA coverage for the proposed actions is provided by the Tank Closure and Waste Management Environmental Impact Statement (TC&WM-EIS). This coverage has been approved by the DOE-NCO and is documented by the NEPA Review Screening Form (DOE-0415) titled Central Plateau Water Treatment Facility – Consolidation of Projects L-849, L-850, L-894, L-895, and L-897. Attention will be given to fostering preservationand minimizing adverse environmental impacts during site development, and balancingthe site mission with resource stewardship obligations. Additional environmental aspectswill be considered during project design including, but not limited to, reductions in airemissions, pollution prevention, energy and water use, minimization of toxic andhazardous materials use and storage, and regulated and sanitary waste generation andmanagement. The final location(s) of the project shall comply with the approved SiteEvaluation, cultural and ecological resource clearances, and NEPA documentation.

All work shall be performed safely, in a manner that ensures adequate protection of human health and the environment; in compliance with applicable federal, state, and local environmental laws, regulations, permits, and agreements/orders; will fulfill the

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 16 of 35

environmental provisions of the Mission Support Contract; and will implement applicable tenets of the Mission Support Alliance, LLC (MSA) Environmental Management System (EMS) and the MSA Integrated Safety Management System (ISMS). Industrial Safety

Safety is a top priority for MSA. Safety shall be a consideration in all aspects of the design, construction and operation of the Project scopes. The Project shall follow all core functions and guiding principles of the Integrated Safety Management System (ISMS) and industry best practices.

Additionally, both Projects (L-849 and L-850) shall be designed in accordance with 10 CFR 851.21, Hazard Identification and Assessment and 10 CFR 851.22, Hazard Prevention and Abatement the design shall start to identify hazards and consider elimination, substitution or engineering controls of the hazard where feasible or appropriate.

2.9.2. Industrial Hygiene

There are no unique Industrial Hygiene (IH) issues associated with the design of the new storage tanks and distribution pumps. IH involvement in the construction process may consist of monitoring for cold stress, heat stress, air monitoring, and air sampling.

2.9.3. Radiological Control

There are currently no radiological protection requirements for the area where work is to be performed. Intermittent Radiological Control Technician (RCT) support will be provided prior to starting work and to perform radiological surveys of all materials being removed during work and from the Hanford Site or transported to Pit 9. Required RCT support for excavation work will be listed on approved Excavation Permit.

2.9.4. Waste Management

Waste will be managed in accordance with the Hanford Site and MSA specific procedures. If during the course of construction, the project generates onsite related construction waste, this waste material shall be disposed of onsite per applicable requirements for inert waste or disposed of offsite after radiological release. Recycling and/or re-use of materials generated during this project must be considered. All Subcontractor related products and materials, hazardous or non-hazardous, must be removed from the job site upon completion of the work in accordance with proper waste disposal methods.

2.9.5. Cyber Security

Designation of work activities for this FRDC are Low/Medium and shall be in accordance with the Federal Information Processing Standard FIPS PUB 199.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 17 of 35

3.0 PROJECT INPUTS

3.1. Description of Existing System(s)

The existing 1.16 MG storage tank 283WA receives PW from the existing 283W Water Treatment Facility (WTF). The PW storage in the tank serves as the source water for the 200W fire pump located in 282WC, as well as 200W PW storage. The tank also serves as the source of fire protection water for the RW distribution system in 200W. Project L-894, Raw Water Cross Connection Isolation 200E/W will sever all connections between the SW and RW systems.

The existing 1.16 MG storage tank 283EA also receives water from the existing 283W WTF. The PW storage in the tank serves as the source water for the 200E fire pump located in 282EC. The tank also serves as the source of fire protection water for the RW distribution system in 200E.

SW distribution pumps located in 283E and 283W fill the storage tanks. There are four pumps in each facility, two constant speed and two variable speed. All have 100 horsepower (HP) and have a combined pumping capacity of 3,400 GPM at 254 ft. of head. Pump houses 282EC and 282WC each contain a 110 GPM recirculation pump for recirculation in addition to the fire pumps which provide suction at the tank bottoms. The fire pump in 282EC is capable of pumping 4,500 GPM at 254 ft. (110 PSI) of head. The fire pump in 282WC is capable of pumping 4,000 GPM at 254 ft. of head.

A detailed description of the existing 283EA and 283WA storage tanks is available in HNF-59688, Sanitary Water System Design Description (SDD) Section 4.1.1.3. Additionally, a detailed description of the distribution and fire pumps can be found in Section 4.1.1.4.

3.2. Physical and System Interfaces

3.2.1. Interrelationship with Other Processes

The new L-849 and L-850 storage tanks are critical components to the Central Plateau PW distribution system and fire suppression water storage. The L-850 tank shall also fulfill the required disinfectant contact time (CT) for the new CPWTF per WAC-246-290, Group A Public Water Supplies. This new CPWTF is designed as a hollow fiber membrane microfiltration plant. Baffling inside the L-850 tank will be used to achieve adequate chlorine disinfection CT.

Connections to the 282E and 282W RW reservoirs will be required to dispose of the water required for filling, checking the new storage tanks for leaks and flushing of the storage tanks and associated piping installed under the three projects (L-849, L-850, and L-897).

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 18 of 35

3.2.2. Interrelationship with Other Facilities

The new PW storage tanks constructed within Projects L-849 and L-850 will initially receive PW from the existing 283W WTF. Once the new CPWTF is operational, the CPWTF will be the sole source of PW for the storage tanks. The new tank drain and overflow lines will be routed to the respective 282E/282W RW Reservoirs. The new distribution pumps will be installed in 282EC and 282WC in place of inactive RW booster pumps.

3.2.3. Interrelationship with Other Systems

The new storage tanks will interface with the following systems:

• The filtrate to the L-850 200W tank will be supplied directly from the newCPWTF under Project L-897.

• The PW to the L-849 200E tank will be supplied by the new SW distributionpumps in 282WC.

o To further describe the supply from 282WC to 200E; the current systemconfiguration, SW is supplied from the 200W distribution pumps to the200E area grid connections near the existing 283EA tank through the sitecross-tie piping system. The site cross-tie piping consists of 8-inch and12-inch lines which do not consist of a single continuous run. The 8-inchsection begins south of 282W and routes to Radiological Site Services(RSS) supply lines. From the RSS, the grid cross-tie branches off to a 12-inch section of line past the fire station (Station 92) and continues east tothe 282E and 282EA grid supply connections.

• Project L-849 and L-850 will maintain RW service to the 282EC and 282WCbuilding fire suppression systems.

• Projects L-849 and L-850 will integrate instrumentation and controls for suchthings as pumps, electrical equipment, sensors, etc., these instrumentation andcontrols shall communicate/interface from their local PLC to the new CPWTF’sICS. The current PLCs monitor signals from the fire pump and the generator.The design shall convert these existing signals to report the new PLC/HMI controlsystem. These PLCs will connect to the WLAN network via network architectureavailable in 282EC and 282WC. Both newly installed PLC cabinets in 282EC and282WC will have network switches in them that will be attached to the WLANnetwork, allowing operators remote monitoring capabilities.

• Normal Electrical and Standby Power sources are currently available in the282EC and 282WC pump houses.

• The new SW distribution pumps shall be located in existing pump houses 282WCand 282EC.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 19 of 35

• The new systems will interface directly with the Hanford 200E/W SW firesuppression systems.

3.2.4. Interrelationship with Other Projects

Project L-897, Central Plateau Water Treatment Facility requires the completion of Project L-850 before it can be tested and operated. The storage tank provided by L-850 will serve as the clear well for the CPWTF and its distribution pumps will provide the motive force to pump the filtrate into the SW distribution system. Project L-897 will perform the Tracer Study for both Projects L-897 and L-850, which is required to be submitted for approval by the WDOH.

Project L-849 is indirectly related to this Project. Project L-849’s design is not required to be completed prior to turnover of the CPWTF.

Project L-894, Raw Water Cross Connection Isolation 200E/W eliminates all rigid connections between RW, EW and SW, largely replacing them with air gaps per WAC 246-290-490, Cross-connection Control, and includes installing a new 30-inch cross-site tie between 200E and 200W in the RW system to replace lost redundancy. Project L-894 will eliminate SW backup for RW fire suppression by removing the SW to RW cross-tie connections (located within or adjacent to 282EC and 282WC as Reduced Pressure Backflow Assemblies (RPBAs) and installing new isolation valves within the SW system so that no connection between SW and RW exists. The existing SW fire pumps in 282EC and 282WC will continue to provide additional pumping capacity for SW fire suppression requirements/demands.

3.2.5. Interferences with Other Structures and Infrastructure

3.2.5.1. Railroads

Due to the congestion of existing underground utilities and the need to route the new SW piping around existing Tanks 283EA and 283WA without causing any problems with the tank’s stability, the permanent removal of railroad lines is allowed for routing of any required tanks or piping configurations/designed locations. Rail and associated materials will need to be removed and managed in accordance with the requirements of WAC 173-303-071(3)(g)(ii), Excluded Categories of Waste.

3.2.5.2. Piping

Project L-849 - Due to congestion of existing underground utilities around tank 283EA and nearby structures, abandoned equipment and associated piping/electrical may be able to be demolished/removed with MSA approval.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 20 of 35

3.3. Design Assumptions

Design Assumptions for both Projects L-849 and L-850:

• Both Project L-849 and L-850 shall install a new PLC and HMI for each pump house(e.g. 282EC and 282WC) to replace the existing PLC panels that were installed underthe Project L-778, Plateau Water Improvements. The existing sensors and actuatorsconnected to these existing PLCs shall be removed.

• The proposed location for each new storage tank is illustrated in Figures 1 and 2 (seeSection 1.3 of this SOW).

• The PW storage tanks shall have a minimum storage capacity which will adequatelysupport ongoing and future Hanford Cleanup Mission needs. The storage capacitycan be found in HNF-CALC-64157.

• Level sensors with user-configurable alarms, or equivalent, will be used toadministratively control and monitor tank volumes.

• The existing components listed below shall be disconnected and removed within the282EC and 282WC buildings:

o RW pumps and all associated equipmento Associated Automatic Transfer Switches (ATSs), except the existing fire pump

ATS will remain in placeo Water heater and associated equipment.o Steam/condensate lines and associated equipmento Electrical disconnect(s)o Alarm Annunciator Panel(s)o Existing PLC Cabinetso Existing UPS and associated equipment.

• The existing building Motor Control Center’s (MCC) shall remain, with MCCcomponents reused when possible, replaced when necessary, to support the newelectrical loads.

• The existing fire pump and associated ATS shall remain.

• The new SW distribution pumps shall be capable of maintaining current SW systempumping capacity (e.g. pressure and flow) while utilizing variable speed to reduceenergy consumption during low water demand periods.

Specific Design Assumptions for Project L-849:

• For Project L-849 the routing of piping under Baltimore Ave. is acceptable as long asit remains within the Area of Potential Effect (APE).

• The recirculation loop heater and sodium hypochlorite skid systems shall be operatedfrom the ICS PLC.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 21 of 35

Specific Design Assumptions for Project L-850:

• The proposed Project L-850 storage tank shall have the capability to store both SWand fire suppression system (FSS) water, serve as the CPWTF clear well, providenew SW distribution pumps, and a recirculation pump.

• The recirculation loop heater shall be operated from the PLC.

3.4. Design Constraints

Design Constraints for both Projects L-849 and L-850:

• The current 283W WTF will remain in operation until approval from the WDOH andconcurrence from U.S. Department of Energy, Richland Operations Office (DOE-RL) isgiven and turnover of the new CPWTF to MSA W&SU has been granted.

• The existing SW pipeline(s) shall be protected from heavy surcharge traffic loads whichmight disrupt or damage the pipeline(s). It is the intent of the projects to leave theexisting SW line in service during installation of the new pipeline(s) from the new waterstorage tanks to the pump buildings (282EC and 282WC).

• Tank level sensors shall be used to administratively segregate FSS from SW.

• During construction activities the fire pumps located in 282EC and 282WC shall remainin service and available to provide a constant water supply, with minimal outages.

• Tank drain and tank overflow connections shall be required for each storage tank to theirrespective RW reservoirs (e.g. 282E RW and 282W RW).

• SW lines in the same trench shall have a minimum 5-feet of horizontal spacing, pipeouter diameter to pipe outer diameter, between them, in order for maintenance access.Separation between potable and non-potable lines shall be in accordance with WDOHrequirements (see DOH/Ecology 06-10-029, Pipeline Separation Design and InstallationReference Guide, Version 9).

• Underground piping below roads shall be a minimum 5-feet below grade.

• The timeframe in which the residual water left within the heel of the tank (e.g. residualwater left after using the tank drain) is to be drained shall take no longer than 10 hours.

• SW system interface control documents (ICD) with Other Hanford Contractors (OHC)must be considered during design and testing of the new pumps. The design shall ensurethe pumps are capable of maintaining the minimum pressure and flow rate requirementsat maximum demand.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 22 of 35

Specific Design Constraints for Project L-849:

• Project L-849 storage tank will store SW and FSS water, provide new SW distributionpumps, a recirculation pump, and a sodium hypochlorite booster pump.

o The addition of the sodium hypochlorite is required to provide local boostchlorination, as needed, to increase outgoing chlorine residual. The sodiumhypochlorite shall be added into the tank fill piping configuration to meet the residualchlorine ranges of 0.2-4.0 mg/L as required by WAC 246-290. Operationally, MSAprefers a residual chlorine range of 1.0-1.5 mg/L leaving the tank.

• If space becomes an issue for pipelines, it is acceptable to route SW pipelines underBaltimore Ave.

• Tank level control valves and a total residual chlorine analyzer shall be located within thepump house 282EC prior to the tank fill inlet.

• A total residual chlorine analyzer shall also be located within the pump house and prior toentry into the distribution system.

• A Disinfection Byproduct and pH measurement instrument shall be located prior to entryinto the distribution system using Hach in-line instrumentation (or Engineering approvedequal).

• The replacement storage tank shall have a single tank fill pipeline capability to the SWgrid and tank fill isolation valves. The tank fill shall be sized to provide an 8-hour refillof the tank after 4 hours of peak fire protection and SW system demands, referenceHNF-CALC-64157, Basis of Tank Size. The control system shall include provisions toprevent short-cycling of the flow from the 282EC pump house in the event the supplyfrom 200W is lost.

• During commissioning of the L-849 tank, 283EG, tie-ins with isolation valves will berequired with the existing tank, 283EA.Note: Tie-in piping shall be a minimum of 12-inch diameter.

Specific Design Constraints for Project L-850:

• The replacement tank for 283WA must be in the vicinity of the CPWTF (283WR).

• Project L-850 shall have redundant tank fill pipeline capability.

• During commissioning of the L-850 storage tank, 283WG, and the new CPWTF, tie-inswith isolation valves will be required with the existing tank, 283WA, and the existingWTF (283W).

• A total residual chlorine analyzer shall be located within the pump house 282WC prior tothe tank fill inlet.

• A total residual chlorine analyzer shall also be located within the pump house and prior toentry into the distribution system. The residual chlorine ranges of 0.2-4.0 mg/L as

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 23 of 35

required by WAC 246-290. Operationally, MSA prefers a residual chlorine range of 1.0-1.5 mg/L leaving the tank.

• A Disinfection Byproduct and pH measurement instrument shall be located prior to entryinto the distribution system using HACH in-line instrumentation (or Engineeringapproved equal).

Note: Tie-in piping shall be a minimum of 12-inch diameter.

4.0 DESIGN CRITERIA

4.1. General Criteria

4.1.1. Design Specific Quality Assurance Requirements

The new tanks shall be designed, built, and operated as a “Critical and Essential Facility” in accordance with the IBC, American Society of Civil Engineers (ASCE), and Federal Emergency Management Agency (FEMA) as defined in Section 4.3. There is no safety significant or safety class equipment.

The tanks, distribution pumps, and components in substantial contact with SW shall be NSF 61 certified, and shall be rated as General Service, Quality Level 3 (QL-3), and Performance Category 1 (PC-1) in accordance with MSC-PRO-QA-259, Graded Approach and MSC-PLN-QA-599, Quality Assurance Program Description.

The A/E shall maintain and implement a Quality Program to the extent applicable to the scope of work. Documentation of the A/E’s Quality Program shall remain current and on record with MSA’s Project Quality Engineering Organization. Any changes to their approved Quality Program shall be submitted to the Contract Specialist in writing for review and approval by applicable MSA Representatives.

4.1.2. Additional Evaluations

The A/E shall perform a technical evaluation of the tank material in accordance with the criteria provided in Section 2.4, 3.3, and 3.4.

A geotechnical soil evaluation was performed at the proposed tank locations near the existing tanks 283EA and 283WA, see Geotechnical Engineering Evaluation HNF-RPT-64172.

4.1.3. Requirements for Flexibility and Future Expansion

The tank size has already factored for the projected increase in SW and FSS demands for the Central Plateau for Direct Feed Low Activity Waste (DFLAW) and the Waste Treatment Plant (WTP). The tanks will support the initial maximum capacity of 3.5 MG per day produced by the CPWTF, as well as the expansion capacity of up to 5 MG per day. The L-850 tank size also aligns with the WAC requirements for CT in accordance with WAC-246-290. There are no CT requirements for the L-849 tank.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 24 of 35

4.1.4. Verification and Validation Strategy

Design verification shall be performed in accordance with MSC-PRO-EN-8336, Design Verification.

Prior to installation, components shall undergo FAT per industry standards. Post-installation pump/motor alignment and testing shall be completed. CATs shall be performed on the system and OATs shall be completed and documented in accordance with MSA procedures.

4.1.5. Approach to Natural Phenomenon

Natural Phenomena Hazards will be analyzed in accordance with MSC-STD-ENG-097, MSC Engineering Design Codes, Standards and Site Specific Design Parameters.

4.1.6. System Status Indicators

Distribution system pressure, pump speeds and flow rate will be monitored by the PLC. All system status parameters will be integrated into Wonderware™ on Water Utilities’ Local Area Network (WLAN).

4.1.7. Fire Protection, Fire Detection, and Fire Suppression Requirements

Fire protection, detection and suppression will be designed and installed to comply with DOE requirements and codes and standards as listed in Section 6.0. Guidance of FM Global Loss Prevention Data Sheet 3-2 should be considered as a best practice as referenced by DOE-STD-1066-2012, Fire Protection.

All elements of the L-849 and L-850 projects are subject to approval and permitting by the Hanford Fire Marshal’s Office.

4.1.8. Tank Mixing System

Project L-849 design shall use a PAX Water Technologies (or Engineering approved equal) active mixer, ventilator (roof-mounted), and associated controls and water property data loggers. The tank mixing system shall be designed to remove disinfection byproducts (DBPs) and trihalomethane (THM) formations. Water quality monitoring shall include DBP and pH measurement and shall be performed using HACH in-line instrumentation (or Engineering approved equal).

Note: Additional data on DBPs and THM formation are available from W&SU Operations upon request.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 25 of 35

4.1.9. Redundant Piping and Bypass Lines

L-850 shall have redundant pipelines between the following:

• From CPWTF to the new storage tank (283WG)• From new storage tank (283WG) to 282WC• From 282WC to the SW grid.

L-850 piping shall have the ability to bypass the new tank for maintenance andinoperable tank conditions. Bypass shall be fed directly from the CPWTF filtrate piping.

4.1.10. Valve and Component Selection

The following valves are acceptable for use for Projects L-849 and L-850 (or Engineering approved equal):

• Post Indicating Gate Valves – Kennedy Valve• OS&Y Gate Valves – Kennedy Valve• Check Valves – Valmatic• Fill Valves – Cla-Val• Pressure Sustaining Valves – Cla-Val• Air Release Valves – Cla-Val• Back Flow Prevention Valves – WATTS.

Note: If the above listed valves cannot be used, additional valve manufactures can be submitted to MSA for review as an Engineering approved equal.

4.1.11. Specific Tank Requirements

Project L-850, shall have baffling inside the tank, which will be used to achieve adequate chlorine CT, and it will be designed to withstand up to 5,220 GPM flowing through the tank based on the combined peak SW system demand and peak fire protection demands per HNF-CALC-64157.

4.2. Process Design Guidelines and Constraints

WDOH Water System Design Manual (see Section 6.0 for acceptable years per project) is the primary design guideline for Projects L-849 and L-850.

There are no other unique process guidelines or constraints associated with the L-849 or L-850 projects.

4.3. Facility Criteria

Projects L-849 and L-850 will require the completed tanks to successfully meet the “Critical and Essential Facility” requirements as described in the following National Consensus Standards:

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 26 of 35

• IBC, Chapter 16, Section 1604.5 Risk Category, Table 1604.5 Risk Category ofBuildings and Other Structures, Risk Category IV, Buildings and Other StructuresDesignated as Essential Facilities

• ASCE, see Section 1.0, page 4, Table 1.5-1 Risk Category of Buildings and OtherStructures for Flood, Wind, Snow, Earthquake, and Ice Loads, Risk Category, CategoryIV, Buildings and Other Structures Designated as Essential Facilities

• FEMA’s National Disaster Recovery Framework, (FEMA 2011), Pre, Post Disaster andSteady State Roles addressing critical facilities and Risk Category III and IV structures(p 40).

4.3.1. Architectural and Civil/Structural

The water storage tanks shall be designed using a concrete foundation in accordance with all applicable codes and standards listed within Section 5.0.

4.3.2. Heating, Ventilation, and Air Conditioning

There are no normally occupied structures associated with Projects L-849 and L-850.Pump houses 282EC and 282WC have existing heating and air conditioning systems.

4.3.2.1. Water heating requirements

The water storage tanks shall have freeze protection. The water temperature shall be maintained at a minimum of 42°F (5.6℃) by any efficient combination of insulation, circulation and heating and will be vented in accordance with Section 6.0.

Below are some average winter SW water temperatures which have historically entered the existing storage tanks. These temperatures are based on a collection of data for water temperatures leaving the 283W WTF (see Table 1 below).

Table 1: Collection of Average Winter Water Temperatures

SW Temp. Data (°C)

Nov 15’

Dec 15’

Jan 16’

Feb 16’

Nov 16’

Dec 16’

Jan 17’

Feb 17’

Nov 17’

Dec 17’

Jan 18’

Feb 18’

Minimum 9 9 7 9 14 7 7 9 13 12 5 8 Average 14.4 10.5 8.8 10.7 16.9 9.7 6.3 7.7 17.6 15.5 13.4 13.9

Additionally, the expected SW hotel usage rates for the 200E and 200W areas are projected out to 2028 and documented within HNF-5828, Table 3-2, Sanitary Water Nominal Use. This summarized table of the Nominal SW System Water Demand in conjunction with Table 1 listed above shall be used to adequately size the tank heaters, recirculation pumps and insulation required for the new storage tanks.

M c /-~

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 27 of 35

4.3.3. Utility Requirements

Electrical service in 282EC and 282WC pump houses are already in place. There is a 1,875 kilovolt amp (kVA) standby diesel generator serving the 282WC RW pump house, and a 1,560 kVA standby diesel generator serving the 282EC RW pump house. The generators serve selected loads in both the 282E/W and 282EC/WC facilities.

Note: Adequacy of electrical service will need to be confirmed during design and revised as necessary.

An Automatic Transfer Switch (ATS) shall be incorporated in the design of each electrical system to provide capability for all 282EC and 282WC electrical loads including the SW distribution pumps to be powered from the standby generators should normal power fail.

4.3.4. Maintenance

Reliability, availability, maintainability, and serviceability of the tanks, pumps, VFD’s, valves, monitoring systems, etc. shall be considered in all aspects of design and installation.

Aspects to consider include, but are not limited to:

• Systems and subsystems shall be as functionally, mechanically, electrically, andelectronically independent as practical

• Reduce to a minimum the incidence of preventive and corrective maintenance

• Minimize maintenance complexity

• Minimize the time requirements for maintenance

• Minimize the equipment and tools required for maintenance

• Minimize maintenance requiring special skills

• General accessibility to perform inspections and maintenance

• Design shall preclude the introduction of hazardous conditions duringpreventative maintenance procedures (e.g. activities requiring lockout/tagout)

• Critical systems shall be capable of undergoing maintenance without theinterruption of critical services

• Notification of loss of operational redundancy shall be provided immediately.

The A/E will identify and prepare an owner/operator maintenance schedule/manual for the selected exterior and interior materials and equipment specified in the final design construction documents. A Pre-Startup Pre-Operational Test Plan will be produced by the A/E that will ensure critical components are installed and operate correctly.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 28 of 35

The design shall limit the creation of new maintenance requirements. Recommended changes to the SW system maintenance shall be identified and documented in the final design. Maintenance manuals for all new equipment shall be provided.

As part of meeting the requirements of MSC-PRO-MN-56346, Predictive Maintenance Program, and MSC-PRO-WC-19304, Periodic Maintenance Process, pumps and motors will be required to have design features that allow the installation of long-term bearing vibration and bearing housing temperature monitoring equipment.

This equipment’s intended use is to monitor, measure, and trend bearing vibration and bearing housing temperature for inboard and outboard bearings of designated pumps and motors. The data gathered shall be compared to operational limits established by the equipment vendors and/or by a Reliability Engineer with a vibration analyst certification. This bearing vibration and bearing housing temperature equipment is to be installed prior to completion of the project turnover to Operations.

Condition monitoring equipment shall be coordinated with a commercially available data acquisition system that will interpret the data and activate alarms when operational limits are exceeded, communicate with analysis software approved by MSA’s Cyber Security Program, and allow the data to be accessed and downloaded from local and remote locations. This type of system is commonly known as an online condition monitoring system. This condition monitoring system shall be compatible with the system integration project that spans W&SU. This data shall be, but is not limited to, vibration readings in velocity Root Mean Square (RMS), temperature readings in Fahrenheit, live (or most recent) vibration levels in velocity RMS and acceleration RMS, Time Wave Form data, and Frequency Spectra (Fast Fourier Transform) data. This will allow specified personnel to be notified of a vibration or bearing temperature alarm, allow the vibration analyst to trend data over time, and perform in-depth analysis. The necessary software for vibration analysis needs to be used in conjunction with a shaft speed sensor (tachometer) for proper analysis.

Triaxial and biaxial vibration sensors, with integrated temperature sensors, are to be used for monitoring designated motor and pump bearings. These sensors must be 100mV/g (millivolt per gravitational constant) piezoelectric accelerometers with a maximum frequency response range of at least 10kHz (10,000 Hertz). Triaxial sensors shall be used for outboard bearings (non-drive end) and biaxial sensors shall be used for inboard bearings (drive end).

The MSA Cyber Security ensures that all cyber assets within the Hanford Accreditation Boundary are protected from threats throughout the complete project life. W&SU shall collaborate with MSA Cyber Security to demonstrate any data or cyber assets used in support of predictive maintenance are compliant with Hanford’s National Institute of Standards and Technology (NIST) compliant Risk Management Framework.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 29 of 35

Any software used shall comply with MSC-PRO-IS-61311, Hanford Information System Inventory, MSC-PRO-IS-309, Controlled Software Management, and MSC-PRO-IS-47277, Systems Engineering Change Board (SECB).

4.4. Modifications to Existing Facility

The existing 282EC and 282WC facilities will be modified per this FRDC.

The existing 283EA and 283WA storage tanks will remain in service until the new tanks have been successfully turned over and are operational. Upon turnover of the new tanks, the existing 283EA and 283WA tanks shall be decommissioned, demolished and removed with the exception of the foundations following final commissioning and WDOH approval of Projects L-850 and L-897.

All piping penetrations in the concrete slab shall be filled with grout and all protrusions removed flush with the slab.

4.5. Equipment Instrumentation, Controls and Automation

For Projects L-849 and L-850 the tank water level shall be monitored by level transmitters that continuously monitor the SW tank levels and send a signal to the PLC.

The SW pumps shall be controlled by the local PLC to maintain a target manifold pressure on the SW grid. At minimum SW demand, one pump shall operate at minimum speed and excess water is recirculated through a pressure relief valve. As demand increases, the recirculation is stopped and the pump will operate at a speed sufficient to maintain target pressure. As the demand further increases and the pump approaches maximum speed an additional pump shall be started and the speeds of both pumps matched and controlled to maintain target pressure. As demand increases additional pumps shall be started and speed matched to maintain target pressure. As demand decreases, pumps shall be slowed and shut down in the reverse order. A lead pump rotation scheme shall be used to distribute the elapsed operating time of all pumps evenly. There shall also be a provision for the Operator to disable or manually operate any pump from the HMI. Pump capacity shall be such that the SW system peak hourly demand (PHD), as identified in HNF-5828 Section 3.1, can be met with one pump out of service.

The water heater in the recirculation line shall have a thermostat to activate the water heater when the water temperature is below its setpoint. The PLC shall monitor the water temperature at the heater and shall have the ability, through Operator command on the HMI, to also activate the water heater.

The local PLC shall transmit the tank level, pump motor status, pump flow rates, water temperature and other data of interest back to the CPWTF (283WR). An Operator at the new CPWTF shall have the same functionality on that HMI as at the individual pump houses with user-configurable alarms. The current PLCs monitor signals from the fire pump and the generator. The design shall convert these existing signals to report the new PLC/HMI control system.

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 30 of 35

A new PLC shall be located in each pump house and shall replace the PLC panels that were installed under project L-778 (282E Plateau Water PLC and 282W Plateau Water PLC). Unused PLC equipment will be removed during tank demolition phase.

Projects L-849 and L-850 shall include Hansford/Uptime Solutions (or W&SU Reliability Engineering approved equal) to provide vibration and temperature monitoring, trending and data analysis for the pumps and motors. The design shall include the necessary features and components that provide the ability to connect the vibration and temperature monitoring signals from the pumps and motors to the PLC for remote monitoring and alarm capabilities.

4.6. Operational Requirements

The water storage system shall include sufficient redundancy to be operationally effective 24-hours a day, 365-days a year. Pump capacity shall be such that system demand may be metwith one pump out of service.

Projects L-849 and L-850 shall have flow meters installed on each pump discharge line and the recirculation lines.

Projects L-849 and L-850 shall additionally have the ability to monitor pump head pressure(s) on both the pump suction header and discharge header.

4.7. Decontamination and Decommissioning

Decontamination is not expected to be required. Upon turnover of the new tanks, the existing 283EA and 283WA tanks will be decommissioned and demolished except for the foundations following final commissioning and WDOH approval of new tanks 283EG and 283WG

5.0 CODES AND STANDARDS

The code of record for L-850 was established upon approval and release of this FRDC (HNF-FRDC-62005) revision 0.

The code of record for L-849 shall be established upon approval and release of this FRDC (HNF-FRDC-62005) revision 1.

5.1. Code of Record

Table 2: National Consensus Standards – Code of Record

American Concrete Institute (ACI) ACI-318 -2014 Building Code Requirements for Structural Concrete American Institute of Steel Construction (AISC) AISC 325 (14th Ed.) AISC Steel Construction Manual AISC 341-2010 Seismic Provisions for Structural Steel Buildings

-

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 31 of 35

American National Standards Institute (ANSI) ANSI Y32.9, 1972 American National Standard Graphic Symbols for Electrical Wiring

and Layout Diagrams Used in Architecture and Building Construction American Society of Civil Engineers (ASCE) ASCE 7-2010 Minimum Design Load for Buildings and Other Structures American Society of Mechanical Engineers (ASME) ASME B1.20.1 Straight Pipe Threads for Mechanical Joints (NPSM) ASME B16.5 Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24

Metric/Inch Standard ASME B31.3-2016 Process Piping ASME B31.9-2014 Building Service Piping ASME Code Section V-2017

Nondestructive Examination and Qualification Standard for Welding, Brazing, and Fusing Procedures; Welders; Brazers; and Welding, Brazing, and Fusing Operators

ASME Y14.38-2007 (R2103)

Abbreviations and Acronyms for Use on Drawings and Related Documents

American Society for Testing and Materials (ASTM) ASTM A36-2014 Structural Steel ASTM A123-2017 Standard Specification for Zinc (Hot Dip Galvanized) Coatings on

Iron and Steel Products ASTM A312-2017 Standard Specification for Seamless and Welded Austenitic

Stainless Steel Pipes ASTM C39/C39M-1999

Standard Test Method for Compression Strength of Cylindrical Concrete Specimens

ASTM F708-1992(2014)

Standard Practice for Design and Installation of Rigid Pipe Hangers

American Welding Society (AWS) AWS D1.1/D1.1M-2010

Structural Steel Welding Code

AWS D1.6-2017 Structural Welding Code – Stainless Steel AWS D9.1-2012 Sheet Metal Welding Code AWS QC1 Standard for AWS Certification of Welding Inspectors American Water Works Association (AWWA) AWWA C206-2017 Field Welding of Steel Water Pipe AWWA C509-2015 Resilient-Seated Gate Valves for Water Supply Service AWWA C605-2013 Underground Installation of PVC Pressure Pipe Fittings for Water AWWA C651-2014 Disinfecting Water Mains AWWA C652-2011 Disinfection of Water-Storage Facilities AWWA C909-2016 Molecularly Oriented Polyvinyl Chloride (PVCO) Pressure Pipe, 4 In.

and Larger

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 32 of 35

AWWA D100-2011 Welded Carbon Steel Tanks for Water Storage AWWA D102-2014 Coating Steel Water-Storage Tanks AWWA D103-2009 Factory-Coated Bolted Carbon Steel Tanks for Water Storage AWWA D104-2011 Automatically Controlled, Impressed-Current Cathodic Protection for

the Interior Submerged Surfaces of Steel Water Storage Tanks AWWA D106-2016 Sacrificial Anode Cathodic Protection Systems for the Interior

Submerged Surfaces of Steel Water Storage Tanks AWWA D108-2010 Aluminum Dome Roofs for Water Storage Facilities AWWA E103-2015 Horizontal and Vertical Line-Shaft Pumps AWWA M42-2013 Manual - Steel Water Storage Tanks American National Standards Institute NACE RP0193-2001 External Cathodic Protection of On-Grade Carbon Steel Storage Tank

Bottoms Federal Information Processing Standard FIPS PUB 199 Standards for Security Categorization of Federal Information and

Information Systems International Code Council (ICC) IBC-2015 International Building Code IMC-2015 International Mechanical Code IFGC-2018 International Fuel Gas Code Institute of Electrical and Electronics Engineers (IEEE) IEEE C57.12.00-2015

Standard for General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers

IEEE C57.12.01-2015

Standard General Requirements for Dry-Type Distribution and Power Transformers Including Those with Solid Cast and/or Resin-Encapsulated Windings

IEEE STD 141™ 1993

Recommended Practice for Electric Power Distribution for Industrial Plants (Red Book™)

IEEE STD 142™ 2007

Recommended Practice for Grounding of Industrial and Commercial Power Systems (Green Book™)

IEEE STD 242™ 2001

Recommended Practice for Protection and Coordination of Industrial and Commercial Power Systems (Buff Book™)

IEEE STD 399™ 1997

Recommended Practice for Industrial and Commercial Power Systems Analysis (Brown Book™)

IEEE STD 446™ 1995

Recommended Practice for Emergency and Standby Power Systems for Industrial and Commercial Applications (Orange Book™)

IEEE STD 493™ 2007

Recommended Practice for the Design of Reliable Industrial and Commercial Power Systems (Gold Book™)

NESC®-2017 National Electrical Safety Code®

Functional Requirements and Design Criteria HNF-FRDC-62005, Rev. 2

Project L-849 & L-850, Replacement of the 200E and 200W Potable Water Tanks

Page 33 of 35

National Electrical Manufacturers Association (NEMA) NEMA 250-2014 Enclosures for Electrical Equipment (1,000V Maximum) NEMA ICS 1-2000 Industrial Controls and Systems NEMA MG-1-2016 Motors and Generators National Fire Protection Association (NFPA) NFPA 1-2018 Fire Code NFPA 20-2019 Standard for the Installation of Stationary Fire Pumps for Fire

Protection NFPA 22-2018 Standard for Water Tanks for Private Fire Protection NFPA 24-2016 Standard for the Installation of Private Fire Service Mains and Their

Appurtenances NFPA 70-2017 National Electrical Code® NFPA 70E-2018 Standard for Electrical Safety in the Workplace NFPA 72-2016 National Fire Alarm and Signaling Code NFPA 101-2018 Life Safety Code® NFPA 780-2017 Standard for the Installation of Lightning Protection Systems NFPA 801-2020 Standard for Fire Protection for Facilities Handling Radioactive

Materials National Sanitation Foundation (NSF International) NSF/ANSI-60 – 2017 Drinking Water Treatment Chemicals – Health Effects NSF/ANSI-61 - 2016 Drinking Water System Components – Health Effects Underwriters Laboratories (UL) UL 508-1999 UL Standard for Industrial Control Equipment – 17th Edition UL 508A-2017 UL Standard for Industrial Control Panels