PRODUCT LIFE CYCLE MANAGEMENT CASE STUDY OF NISSAN GROUP 2 Irham Satria Yudha Khaira Al-hafi Saleh Ardiansyah Septy Aprilliandary PRODUCT LIFECYCLE MANAGEMENT LECTURE INDUSTRIAL ENGINEERING DEPARTMENT UNIVERSITAS INDONESIA 2013

Product life cycle management case study of nissan

Sep 11, 2014

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

PRODUCT LIFE CYCLE MANAGEMENT

CASE STUDY OF NISSANGROUP 2

Irham Satria Yudha

Khaira Al-hafi

Saleh Ardiansyah

Septy Aprilliandary

PRODUCT LIFECYCLE MANAGEMENT LECTUREINDUSTRIAL ENGINEERING DEPARTMENTUNIVERSITAS INDONESIA2013

AGENDA

> PLC Definition

> Roles & Importance of PLCM

Introduction

> Background

> Product Strategy

> Product Family/Platform

Company profile Analysis Conclusion

INTRODUCTION

Product Lifecycle

• Product life cycle is a business analysis that attempts to identify a set of common stages in the life of commercial products. In other words the 'Product Life cycle' PLC is used to map the lifespan of the product such as the stages through which a product goes during its lifespan.

• Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal of manufactured products.

• PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprise

Documented Benefits of ProductLifecycle Management

• Reduced time to market

• Increase full price sales

• Improved product quality and reliability

• Reduced prototyping costs

• More accurate and timely request for quote generation

• Ability to quickly identify potential sales opportunities and revenue contributions

• Savings through the re-use of original data

• A framework for product optimization

• Reduced waste

• Savings through the complete integration of engineering workflows

• Ability to provide contract manufacturers with access to a centralized product record

• Seasonal fluctuation management* Improved forecasting to reduce material costs

• Maximize supply chain collaboration

Areas of PLM

• Systems engineering (SE)

• Product and portfolio (PPM)

• Product design (CAx)

• Manufacturing process management (MPM)

• Product Data Management (PDM)

COMPANY PROFILE

Nissan Motor Company LtdEstablished in Yokohama, Kanagawa in 1933, Nissan Motor Co., Ltd. currently manufactures vehicles in20 countries and areas around the world, including Japan. Global unit sales in fiscal 2011 totaled 4.845million vehicles. In addition to vehicles, Nissan also develops, manufactures and markets and marineequipment.

Company Profile

Nissan’s Brief History…

Nissan History

….Mission of Nissan

Vision of Nissan…

About Nissan…

7th Position in World’s Biggest AutoCompanies 2013, After Volkswagen,Toyota, Daimler, Ford Motor, BMW Group,and General Motor – Forbes

Nissan has a portfolio of two brands, NISSAN and INFINITI,both sold worldwide. NISSAN vehicles are marketed in allmajor market worldwide. INFINITI was launched as aluxury brand in North America in 1989.

Before 1981, people known Nissan branded their car asDatsun brand, but In 1981, After selling 20 million carsin 190 countries around the world, the Datsun brand isphased out, and the Nissan name is used as thecompany expands globally

Product Strategy : Nissan’s Orchard Concept

Nissan’s Core Values - Four Strategic Technology Fields -

• Nissan's orchard has four areas: the environment, safety, dynamic performanceand life on board.

• Nissan create original value in each of these four areas in order to provide their customers with “trusted driving pleasure”

Environmental Technologies

• Nissan has set a target for 2050 of reducing new car CO2 emissions by 90%, compared to year 2000 levels.

• Nissan is taking a multi-pronged approach to achieving this mid-term goal.

Environmental Technologies – Triple Layered Approach

Safety Technologies

Nissan aims to halve the number of fatal and serious injuries from accidents involving Nissan vehicles in Japan by 2015 compared with 1995.

Based on analysis of real-world accidents, Nissan has been working progressively to design and engineer safer vehicles with Safety Shield

Safety Technologies – Triple Layered Approach

Dynamic Performance : "Anyone, Anytime, Anywhere"

Nissan seeks to make cars that will be appreciated for their Nissan qualities by all users in all situations

Dynamic PerformanceEach vehicle in Nissan's extensive lineup offers its own

distinctive features. Dynamic Performance technology supports this with four root values.

Life on Board : "Amazing Value and Artisanship"

The car provides unprecedented value at every stage -getting into the vehicle, preparing to drive, actually

driving and, finally, getting out.

Life On BoardDelivering Three Kinds of Value

Technological innovation focused on three aspects of the interior

Product Family

Globally, Nissan Motor Company have 4 division. Every division have different product.

1. Nissan (Main Division)

This division produce commercial car, from city car, SUV, sports car untill electric vehicle.

2. Infiniti

Infiniti is brand from Nissan that produce luxury car and segmented for upper class.

3. Datsun

In 2013 Nissan Relaunch Datsun brand for emerging market, which is India & Indonesia.

4. Nissan Marine

Nissan Marine produce outboard motor for speed boat.

Product Family For Nissan (Main Division)

1. MPV (Multi Purpose Vehicle)

Nissan Grand Livina, Serena, Elgrand etc

3. City Car

Nissan March/Micra

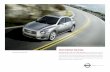

4. Sedan

Nissan Teana, altima , sentra, etc.2. SUV (Sport Utility Vehicle)

Nissan X-Trail, Murano, Juke, Rogue, etc.

Product Family For Nissan (Main Division)

5. Trucks & Commercial Car

Nissan Frontier, Titan and NV Cargo

7. Sports Car

Nissan GT-R and 370 Z

6. Electric Vehicle & HybridNissan LEAF and Pathfinder Hybrid

Product Platform

After Founded in 1999, the Renault-Nissan Alliance has become the longest-lasting cross-cultural combination

among major carmakers. Nissan survive from the crisis in 1999 with help from Renault. Now the Alliance make a

platform – sharing project for their car, Nissan Micra/March and Renault Pulse are the example.

•Basic Product Platform Element1. Component

With platform – sharing project , for sure there will be component that will be common in both car Nissan & Renault.

2. ProcessesProduction process for platform – sharing project obviusly has the same process, for the example is frame production.

3. ArchitectureDesign for the car, such as frame & suspension will be the same.

• Platform Classification

Nissan used Modular (Functional) Platform for their product. Modular platforms allow creation of

functionally different product variants. A good example of such a platform is Nissan Tiida & March,

Nissan Frontier & Titan.

Product Platform

• Deployment Strategies

Nissan mainly used Horizontal Leveraging Strategy

for their product deployment. The platform is shared

across different brands but within the same class of

market segment. Example Nissan Altima & Renault

Laguna. For some product Nissan used the Vertival

Leveraging Strategy, example Nissan Qashqai and

Nissan Grand Livina.

• Product Platform Application for Nissan

Product Platform

Product Platform

•On 1999 Nissan almost collapse, but after alliance with Renault, Nissan not just Survived but also climb upsignificantly.•Their R&D division develop ‘Common Module Family’ (CMF). CMF used by the new Alliance approach forcommon parts, a system expected to generate significant cost savings. A module is a set of parts and derivativesthat can be applied to different car models and power trains. With a limited number of variations, the modulewill cover a large part of the Renault and Nissan product range.

ANALYSIS

ANALYSIS

In the end of 1998, Nissan was in bad position financially

Inability to establish a purchasing policy or a system

of relations with suppliers

Having accumulated

debts totaling 23 billion euros

Declining market share from 6.4% in 1990 to

4.9% in 1998

Focusing on high quality and engineering innovation without

focusing on the resulting cost

ANALYSIS

Ultimate solution:A partner to not only help financially but also

allow Nissan to help with the production system and purchasing policy

The making of a global alliance with Renault

Phase I: in 1999 where Renault took a 36.8%

stake in Nissan for about €4.4 billion with the option for Nissan to take a stake in Renault at a

later date.

Phase II: On May 2002, the second phase of

the alliance was initiated as Nissan took a 15% stake in Renault

PLCM Strategy

Defined a set of messages that included specific timeframes for corporate improvement.

Nissan formed a number of Cross Functional Teams (CFTs). Each team was comprised of a

number of individuals throughout the organization,

each with a different background.

Nissan Revival Plan (NRP)

Designed to focus on design and delivery of more attractive

vehicle models to the global automotive market.

Nissan Value-Up Innovation of Product, Process and Program (V-3P)

Nissan simply and clearly defines

V-3P as follows:

The activity of dramatically improving QCT metrics by creating and capturing Nissan’s Know-How about “KURUMA-ZUKURI” (i.e., vehicle design and manufacture best

Consistently executing the development process from Styling Freeze to SOP in 10.5 months utilizing one physical prototype prior to formal production

PLCM STRATEGY IN NISSAN

Standardized design

Performance analysis

Production & plant engineering

Visualizing product and process information

RESULTS

Nissan’s product lifecycle

is in mature phase

RESULTS

Starting point of Nissan

The incoming wave: environment technology

NISSAN & KONDRATIEFF WAVES

Nissan is ready to enter the 6th

Kondratieff wave

NISSAN Leaf EV

The Nissan Leaf is an all-electric, mid-sized hatchback that seats five adults

The Leaf is fitted with a zero emission power train; unlike gas electric hybrids, the Leaf does not contain an internal combustion engine or tailpipe (Nissan 2009).

Nissan Introduced the Leaf in August 2009. Nissan positioned the Leaf as a holistic car –“100% Electric, 100 Mile Range, 100% Torque”

CONCLUSION

By merging an alliance with Renault in 1999, Nissan not only encountered its almost bankruptcy well, but also improved significantly in area of production system, design, and R & D.

Programs such as NRP, CFT, V-3P are successful in giving great impact to Nissan by reducing cost and increasing sales volume which also affect to higher profit. Currently, Nissan is in mature phase seen from its stable market share globally.

Nissan is also ready to face the 6th Kondratieff Waves which lies in environmental technology, nano/biotechnology, and healthcare by developing Electric Vehicle (EV) called Nissan Leaf. Nissan Leaf is amazingly popular seen from its sales graphic.

For further development, Nissan needs to expand its successful program such as V-3P to its supply chain network. Specifically, Nissan can start to apply the same method to supplier community which involve directly to Nissan.

REFERENCES

• Budiarto, Teguh.1993.Dasar Pemasaran.Jakarta: Gunadarma

• CIM Data, Inc., Nissan Motor Corporation “Product Lifecycle Management Case Study”, April 2008

• Park, Jason & Hattem, Isaac, Renault/Nissan: The Making of a Global Alliance

• http://cessee.com/2011/06/30/karakteristik-dan-tahap-tahap-dalam-siklus-hidup-produk.html

• www.nissan-global.com

THANK YOU

Related Documents