© 2014, General Electric Company. Proprietary information. All rights reserved. Abu Dhabi, UAE | 12-14, October 2014 Power-GEN Middle East Jeffrey Goldmeer, Ph.D. GE Syngas turbines

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

© 2014, General Electric Company. Proprietary information. All rights reserved.

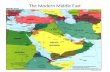

Abu Dhabi, UAE | 12-14, October 2014

Power-GEN Middle East

Jeffrey Goldmeer, Ph.D.

GE Syngas turbines

© 2014, General Electric Company. Proprietary information. All rights reserved.

© 2014, General Electric Company.

GE Proprietary Information - The information contained in this document is

General Electric Company (GE) proprietary information. It is the property of GE

and shall not be used, disclosed to others or reproduced without the express

written consent of GE, including, but without limitation, in the creation,

manufacture, development, or derivation of any repairs, modifications, spare

parts, or configuration changes or to obtain government or regulatory approval

to do so, if consent is given for reproduction in whole or in part, this notice and

the notice set forth on each page of this document shall appear in any such

reproduction in whole or in part. The information contained in this document may

also be controlled by the US export control laws. Unauthorized export or re-

export is prohibited.

GE Power & Water

All relative statements are with respect to GE technology unless otherwise noted.

2

© 2014, General Electric Company. Proprietary information. All rights reserved.

Syngas study assumptions

• Two options: − Blending syngas and natural gas

− 100% Westinghouse plasma syngas

• Calculations performed on a delta basis − Baseline performance on new and clean gas turbine

configured to operate on natural gas with a Dry Low

NOx (DLN) combustion system

• Fuel composition:

− 45.5% CO, 22.4% H2, 16.4% CO2, 10.3% N2, 1.63% CH4,

1.28% Ar, plus 1.64% higher hydrocarbons and small

amounts of NH3, H2S and COS.

• Ambient conditions: − 1.0 atm, 15 C and 60% relative humidity, and 0 meters

altitude

3

Notes: (1) New and clean delta performance should be similar to delta for gas turbine unit that has been

in operation on natural gas for some period prior to the switch to blended fuel. (2) Switch to blended fuel may require fuel nozzles to be optimized to new fuel based on revised

fuel composition and heating value.

© 2014, General Electric Company. Proprietary information. All rights reserved.

Option 1: blended syngas and natural gas

• Blend limited by CO and/or H2 content to stay within DLN combustion system limits

• Plant configuration impact:

- Fuel blending generally requires a blending skid, gas measuring instruments, and new gas turbine controls.

4

© 2014, General Electric Company. Proprietary information. All rights reserved.

7E.03 • Output (MW): +1.0% • Heat rate (kJ/kWhr): - 0.38% • Exhaust Energy (GJ/hr): +0.48%

5

Results for blended natural gas and syngas Changes relative to natural gas performance

6B.03 • Output (MW): +1.23% • Heat rate (kJ/kWhr): - 0.4% • Exhaust Energy (GJ/hr): +0.65%

Assuming that blend stays within limits and DLN combustion system is retained.

9F.03 • Output (MW): +0.74% • Heat rate (kJ/kWhr): -0.19 % • Exhaust Energy (GJ/hr): +0.46%

© 2014, General Electric Company. Proprietary information. All rights reserved.

Option 2: 100% syngas

• Use of 100% syngas generally requires switching from DLN to a diffusion combustion system. Therefore, the fuel is not limited by CO and/or H2 content.

• Converting to 100% syngas fuel generally requires new controls, syngas and diluent modules, as well as changes to other BOP systems.

6

© 2014, General Electric Company. Proprietary information. All rights reserved.

7

Results for 100% syngas Changes relative to natural gas performance

6B.03* • Output (MW): +0.53% • Heat rate (kJ/kWhr): - 1.17% • Exhaust Energy (GJ/hr): +1.79% * Reference to 6B.03 performance on natural gas

Generally requires change from DLN to diffusion flame combustor to

support 100% syngas operation

© 2014, General Electric Company. Proprietary information. All rights reserved.

• GE is a world leader in generating power from low

calorific value fuels, including syngas, with more

than 2.1 million operating hours

• GE gas turbines are capable of operating on a

variety of types of syngas, including the

Westinghouse plasma syngas

8

Summary

© 2014, General Electric Company. Proprietary information. All rights reserved.

Back-up

© 2014, General Electric Company. Proprietary information. All rights reserved.

GE 6B.03 performance – NG/syngas blend Estimated performance – new & clean conditions. For study purposes only.

11

Simulation assumptions: • Gas turbine equipped with DLN1+ combustion system • Estimates based on Westinghouse Plasma syngas

composition.

Ambient conditions: pressure: 1.0135 bar; altitude: 0 meters; Temperature: 15 C; Relative humidity: 60%

• GE simulated performance of a 6B.03 operating on a fuel blend composed of natural gas and syngas generated from a Westinghouse Plasma gasification system.

• To maintain current DLN1+ combustion system, the amount of syngas was limited by CO concentration in the blended fuel.

• Operating with fuel blend provides roughly a 1% increase in output, and a small increase in efficiency (reduction in heat rate.)

• Fuel blending requires a blending skid, gas measuring instruments, and new gas turbine controls.

• May require fuel nozzles enhanced to new fuel based on revised fuel MWI.

• Max blend will requires H2 content to be greater than 5% (by volume). This may

require changes to existing fuel accessory system.

GT Model 6B 6B

Fuel NG BLEND

Load Condition BASE BASE

Output MW 43 +1.23%

Heat Rate (LHV) kJ/kWh 10,740 -0.40%

Heat Cons. (LHV) GJ/hr 462 +0.82%

Exhaust Energy GJ/hr 301 +0.65%

SG % of Total HC (LHV) 0.0% 12.0%

© 2014, General Electric Company. Proprietary information. All rights reserved.

GE 7E.03 performance – NG/syngas blend Estimated performance – new & clean conditions. For study purposes only.

12

Simulation assumptions: • Gas turbine equipped with DLN1+ combustion system • Estimates based on Westinghouse Plasma syngas

composition.

Ambient conditions: pressure: 1.0135 bar; altitude: 0 meters; Temperature: 15 C; Relative humidity: 60%

• GE simulated performance of a 7E.03 operating on a fuel blend composed of natural gas and syngas generated from a Westinghouse Plasma gasification system.

• To maintain current DLN1+ combustion system, the amount of syngas was limited by CO concentration in the blended fuel.

• Operating with fuel blend provides roughly a 1% increase in output, and a small increase in efficiency (reduction in heat rate.)

• Fuel blending requires a blending skid, gas measuring instruments, and new gas turbine controls.

• May require fuel nozzles enhanced to new fuel based on revised fuel MWI.

• Max blend will requires H2 content to be greater than 5% (by volume). This may

require changes to existing fuel accessory system.

GT Model 7E.03 7E.03

Fuel NG BLEND

Load Condition BASE BASE

Output MW 90 +1.00%

Heat Rate (LHV) kJ/kWh 10,614 -0.38%

Heat Cons. (LHV) GJ/hr 955 +0.63%

Exhaust Energy GJ/hr 613 +0.48%

SG % of Total HC (LHV) 0.0% 12.0%

© 2014, General Electric Company. Proprietary information. All rights reserved.

GT Model 9E.03 9E.03

Fuel NG BLEND

Load Condition BASE BASE

Output MW 130 +1.13%

Heat Rate (LHV) kJ/kWh 10,403 -0.37%

Heat Cons. (LHV) GJ/hr 1,352 +0.76%

Exhaust Energy GJ/hr 866 +0.60%

SG % of Total HC (LHV) 0.0% 12.0%

GE 9E.03 performance – NG/syngas blend Estimated performance – new & clean conditions. For study purposes only.

13

Simulation assumptions: • Gas turbine equipped with DLN1+ combustion system • Estimates based on Westinghouse Plasma syngas

composition. Ambient conditions: pressure: 1.0135 bar; altitude: 0 meters; Temperature: 15 C; Relative humidity: 60%

• GE simulated performance of a 9E.03 operating on a fuel blend composed of natural gas and syngas generated from a Westinghouse Plasma gasification system.

• To maintain current DLN1+ combustion system, the amount of syngas was limited by CO concentration in the blended fuel.

• Operating with fuel blend provides roughly a 1% increase in output, and a small increase in efficiency (reduction in heat rate.)

• Fuel blending requires a blending skid, gas measuring instruments, and new gas turbine controls.

• May require fuel nozzles enhanced to new fuel based on revised fuel MWI.

• Max blend will requires H2 content to be greater than 5% (by volume). This may

require changes to existing fuel accessory system.

© 2014, General Electric Company. Proprietary information. All rights reserved.

GE 7F.04 performance – NG/syngas blend Estimated performance – new & clean conditions. For study purposes only.

14

Simulation assumptions: • Gas turbine equipped with DLN2.6 combustion system • Estimates based on Westinghouse Plasma syngas

composition.

Ambient conditions: pressure: 1.0135 bar; altitude: 0 meters; Temperature: 15 C; Relative humidity: 60%

• GE simulated performance of a 7F.04

operating on a fuel blend composed of

natural gas and syngas generated from a

Westinghouse Plasma gasification

system.

• To maintain current DLN2.6+ combustion

system, the amount of syngas was limited

by H2 concentration in the blended fuel.

• Operating with fuel blend provides roughly

a 0.75%% increase in output, and a small

increase in efficiency (reduction in heat

rate.)

• Fuel blending requires a blending skid, gas

measuring instruments, and new gas

turbine controls.

• May require fuel nozzles enhanced to new

fuel based on revised fuel MWI.

GT Model 7F.04 7F.04

Fuel NG BLEND

Load Condition BASE BASE

Output MW 187 +0.74%

Heat Rate (LHV) kJ/kWh 9,337 -0.18%

Heat Cons. (LHV) GJ/hr 1,746 +0.56%

Exhaust Energy GJ/hr 1,060 +0.46%

SG % of Total HC (LHV) 0.0% 5.4%

© 2014, General Electric Company. Proprietary information. All rights reserved.

GE 9F.03 performance – NG/syngas blend Estimated performance – new & clean conditions. For study purposes only.

15

Simulation assumptions: • Gas turbine equipped with DLN2.6+ combustion system • Estimates based on Westinghouse Plasma syngas

composition.

Ambient conditions: pressure: 1.0135 bar; altitude: 0 meters; Temperature: 15 C; Relative humidity: 60%

• GE simulated performance of a 9F.03

operating on a fuel blend composed of

natural gas and syngas generated from a

Westinghouse Plasma gasification

system.

• To maintain current DLN2.6+ combustion

system, the amount of syngas was limited

by H2 concentration in the blended fuel.

• Operating with fuel blend provides roughly

a 0.75%% increase in output, and a small

increase in efficiency (reduction in heat

rate.)

• Fuel blending requires a blending skid, gas

measuring instruments, and new gas

turbine controls.

• May require fuel nozzles enhanced to new

fuel based on revised fuel MWI.

GT Model 9F.03 9F.03

Fuel NG BLEND

Load Condition BASE BASE

Output MW 265 +0.74%

Heat Rate (LHV) kJ/kWh 9,517 -0.19%

Heat Cons. (LHV) GJ/hr 2,522 +0.55%

Exhaust Energy GJ/hr 1,546 +0.46%

SG % of Total HC (LHV) 0.0% 5.4%

© 2014, General Electric Company. Proprietary information. All rights reserved.

GE 6B.03 performance –100% syngas Estimated performance – new & clean conditions. For study purposes only.

16

Simulation assumptions: • Baseline Gas turbine equipped with DLN1+ combustion system • Gas turbine combustor switched to Single Nozzle combustor for

100% syngas operation • Estimates based on Westinghouse Plasma syngas composition.

Ambient conditions: pressure: 1.0135 bar; altitude: 0 meters; Temperature: 15 C; Relative humidity: 60%

• GE simulated performance of a 6B

operating on 100% syngas generated

from a Westinghouse Plasma gasification

system.

• Operating on 100% syngas provides

roughly a 0.5% increase in output. The

increase in efficiency comes in part from

the increased flow of fuel and diluent.

• This will require switching from a DLN to a

MNQC combustion system.

• This will also require the addition of

syngas and diluent modules, new fuel

piping, new controls, potentially an air

extraction module, as well as

modifications to other balance of plant

systems.

GT Model 6B.03 6B.03

Fuel NG 100% SYNGAS

Load Condition BASE BASE

Output MW 43 +0.53%

Heat Rate (LHV) kJ/kWh 10,740 -1.17%

Heat Cons. (LHV) GJ/hr 462 -0.69%

Exhaust Energy GJ/hr 301 +1.79%

SG % of Total HC (LHV) 0.0% 100.0%

Related Documents