Power Control System for Power Control System for a Concrete Durability a Concrete Durability Test Cabinet – Phase 2 Test Cabinet – Phase 2 Jacob Jameson Madhav Kothapalli Thomas Persinger Andrew Versluys

Power Control System for a Concrete Durability Test Cabinet – Phase 2 Jacob Jameson Madhav Kothapalli Thomas Persinger Andrew Versluys.

Dec 23, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Power Control System for a Power Control System for a Concrete Durability Test Concrete Durability Test Cabinet – Phase 2 Cabinet – Phase 2

Jacob Jameson

Madhav Kothapalli

Thomas Persinger

Andrew Versluys

Problem StatementProblem Statement

The National Concrete Pavement Technology Center needs a system to perform temperature tests on concrete samples.◦ The temperature test consists of 300 cycles between

0º and 40º F (±3ºF error).◦ The client wants the system to be monitored and

controlled with LabVIEW.◦ There is existing hardware and software in place, but

it does not achieve consistent results.

Need StatementNeed Statement

We need to fix the existing system to run the tests consistently.◦ Clean up the temperature sensors◦ Re-write the software

Concept Sketch – Test Concept Sketch – Test CabinetCabinet

Concept Sketch – Concept Sketch – Temperature Chart RecorderTemperature Chart Recorder

Concept Sketch – User Concept Sketch – User InterfaceInterface

System DescriptionSystem Description LabVIEW Program

◦ In local computer

◦ Accessible by remote desktop

◦ Sends commands to temperature controller.

Temperature Sensors ◦ Old system analog thermostat

◦ High temperature shut-off

◦ Circle graph recorder.

◦ New system thermocouple measuring the internal temperature of the concrete specimens within the cabinet.

System Processes

◦ Measured temperature approaches 0º, System activates a relay that shuts off the compressor and turns on the heater.

◦ Measured temperature approaches 40º, System activates a relay that shuts off the heater and turns on the compressor.

◦ Cycle continues until the user ends it.

System Block DiagramSystem Block Diagram

Operating EnvironmentOperating Environment

The system will operate in an indoor laboratory.

This lab works with concrete so there is a chance of dust getting into the system.

Water is poured into the system before running the freeze/thaw test, so the system must be sealed.

User InterfaceUser Interface Records the data from the tests

Allows the user to analyze data in

graphical form

Allows the user to change the freeze-thaw controls manually

Accessible by remote desktop

Functional RequirementsFunctional Requirements The freezing-thawing apparatus shall have automatic

controls which are able to continuously reproduce cycles from 0±3°F to 40±3°F.

The heat-cool cycle shall take between 2-5 hours.

The time between freezing and thawing phases shall not exceed 10 minutes.

The new system shall operate completely separate from the old system.

All of the temperature data shall be recorded to an Excel spreadsheet.

Non Functional Non Functional RequirementsRequirements All of the electrical components shall be housed in a

waterproof enclosure.

The system shall not cause any fire hazards or electrical shocks.

The user interface shall show a temperature vs. time graph of the current test.

Market/Literature Survey Market/Literature Survey System Manufacturers

◦Humboldt Manufacturing◦ScienTemp◦Schleibinger

Buying a new system replacement is not an option because of the high cost.

DeliverablesDeliverables Computerized system

◦ Automatically controls the freeze-thaw cycle of the test cabinet

◦ Automatic system error adjustments◦ Accurate temperature sensing

User interface ◦ Allows users to input and analyze data◦ Allows users to change the freeze-thaw

controls manually

System manual for reference

Work Breakdown Work Breakdown ScheduleSchedule Learn LabVIEW

Group Website

System Testing

Test Temperature Probes

Analyze Results of Temperature Probe Tests

Test Freeze-Thaw Cabinet System Response

Analyze Results of System Response Tests

Project Design

Develop Simulated Freeze-Thaw Cabinet in LabVIEW

Develop New Control System in LabVIEW

Simulated Testing and LabVIEW Program Revision

LabVIEW Interface

Bound Report/Final Website

Implementation and Testing

Implement New LabVIEW Program

Test New LabVIEW Program

LabVIEW Program Revision and Error Correction

Documentation of Results

Develop User Manual

Final Report and Presentation

Project Poster

Resource RequirementsResource Requirements Hours: Jacob Jameson 181Madhav Kothapalli 175Thomas Persinger 184Andrew Versluys 174 Project Labor Cost: Jacob Jameson $3620Madhav Kothapalli $3500Thomas Persinger $3680Andrew Versluys $3480

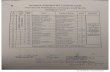

Project ScheduleProject Schedule

Questions?Questions?

Related Documents