POM - J. Galván POM - J. Galván 1 PRODUCTION AND PRODUCTION AND OPERATIONS MANAGEMENT OPERATIONS MANAGEMENT Ch. 8: Capacity Planning Ch. 8: Capacity Planning

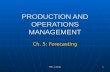

POM - J. Galván 1 PRODUCTION AND OPERATIONS MANAGEMENT Ch. 8: Capacity Planning.

Mar 31, 2015

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

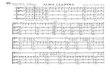

POM - J. GalvánPOM - J. Galván 11

PRODUCTION AND PRODUCTION AND OPERATIONS OPERATIONS

MANAGEMENTMANAGEMENT

Ch. 8: Capacity PlanningCh. 8: Capacity Planning

POM - J. GalvánPOM - J. Galván 22

Definition and Measures of CapacityDefinition and Measures of Capacity

Capacity:

Designed Capacity:

Effective capacity or utilization:

Rated Capacity:

The maximum output of a system in agiven period

The maximum capacity that can beachieved under ideal conditions

The percent of design capacity actuallyexpected

Maximum usable capacity of aparticular facility

RC = (Capacity)(Utilization)(Efficiency)

POM - J. GalvánPOM - J. Galván 33

Measure of planned or actual Measure of planned or actual capacity usage of a facility, work capacity usage of a facility, work center, or machinecenter, or machine

Measure of planned or actual Measure of planned or actual capacity usage of a facility, work capacity usage of a facility, work center, or machinecenter, or machine

UtilizationExpected capacity

Capacity

Planned hours to be usedTotal hours available

UtilizationUtilization

POM - J. GalvánPOM - J. Galván 44

Measure of how well a facility or Measure of how well a facility or machine is performing when usedmachine is performing when used

Measure of how well a facility or Measure of how well a facility or machine is performing when usedmachine is performing when used

EfficiencyActual output

Effective capacity

Actual output in unitsStandard output in units

Average actual timeStandard time

EfficiencyEfficiency

POM - J. GalvánPOM - J. Galván 55

ForecastDemand

ComputeNeeded

Capacity

ComputeRated

Capacity

EvaluateCapacity

Plans

ImplementBest Plan

QualitativeFactors

(e.g., Skills)

Select BestCapacity

Plan

DevelopAlternative

Plans

QuantitativeFactors

(e.g., Cost)

Capacity Planning ProcessCapacity Planning Process

POM - J. GalvánPOM - J. Galván 66

WHY PLANNING CAPACITY?WHY PLANNING CAPACITY?

POM - J. GalvánPOM - J. Galván 77

TYPICAL QUESTIONSTYPICAL QUESTIONS

How many machines should be purchased? How many workers should be hired? Consequences of a 20% increase in demand? How many counters should be opened to

maintain customer wait below 10 minutes? How many assembly stations are needed to

maintain backorders below 20? How often will all 6 operating rooms be full? How will congestion at Logan change if a 5th

runway is built?

POM - J. GalvánPOM - J. Galván 88

Add FacilitiesAdd long lead time equipment

Schedule Jobs Schedule Personnel Allocate Machinery

SubcontractAdd EquipmentAdd Shifts

Add PersonnelBuild or Use Inventory

Long Range Planning

Intermediate Range Planning

Short Range Planning

Modify Capacity Use Capacity

*

*

*Limited options exist

CAPACITY ALTERNATIVESCAPACITY ALTERNATIVES

POM - J. GalvánPOM - J. Galván 99

Theory of Constraints

1. Identify the system bottleneck(s)

2. Exploit the bottleneck(s)3. Subordinate all other

decisions to step 24. Elevate the bottleneck(s)5. Do not let inertia set in

4-9

POM - J. GalvánPOM - J. Galván 1010

Capacity BottlenecksCapacity Bottlenecks

Inputs To customers

(a) Operation 2 a bottleneck

50/hr

1 2 3

200/hr 200/hr

4-10

POM - J. GalvánPOM - J. Galván 1111

(b) All operations bottlenecks

2 31Inputs To customers

200/hr 200/hr 200/hr

Capacity BottlenecksCapacity Bottlenecks

4-11

POM - J. GalvánPOM - J. Galván 1212

Capacity CushionCapacity Cushion

Reserve capacity used to deal with Reserve capacity used to deal with

sudden increases in demand sudden increases in demand (100% - Average Utilization %)(100% - Average Utilization %)

Primary DisadvantagePrimary Disadvantage unused capacity costs moneyunused capacity costs money

POM - J. GalvánPOM - J. Galván 1313

Output rate (patients per week)

Economies & Diseconomies of Scale

250-bed hospital

Av

era

ge

un

it c

os

t (d

olla

rs p

er

pat

ien

t) 500-bed hospital

Economies of scale

750-bed hospital

Diseconomies of scale

POM - J. GalvánPOM - J. Galván 1414

Capacity StrategyCapacity Strategy

Expansionist Expansionist StrategyStrategy

Looking to Looking to capture strong capture strong economies of economies of scale scale

Positive learningPositive learning

Time

Cap

acit

y

Planned Capacity

Expected Demand

POM - J. GalvánPOM - J. Galván 1515

Capacity StrategyCapacity Strategy

Build-to-Forecast Build-to-Forecast StrategyStrategy

Trying to match Trying to match capacity and capacity and demand demand

Time

Cap

acit

y

Planned Capacity

Expected Demand

POM - J. GalvánPOM - J. Galván 1616

Capacity StrategyCapacity Strategy

The Maximize The Maximize Utilization Utilization StrategyStrategy

Maintains little or Maintains little or no capacity no capacity cushion cushion

Time

Cap

acit

y

Planned Capacity

Expected Demand

POM - J. GalvánPOM - J. Galván 1717

Systematic Approach to Capacity Decisions

1.1. Estimate Capacity RequirementsEstimate Capacity Requirements

2.2. Identify GapsIdentify Gaps

3.3. Develop AlternativesDevelop Alternatives

4.4. Evaluate AlternativesEvaluate Alternatives

POM - J. GalvánPOM - J. Galván 1818

Capacity DecisionsCapacity DecisionsEstimate Capacity RequirementsEstimate Capacity Requirements

Item Client X Client Y

Annual demand forecast (copies) (D) 2000.00 6000.00Standard processing time (hour/copy)(p) 0.50 0.70Average lot size (copies per report)(Q) 20.00 30.00Standard setup time (hours)(s) 0.25 0.40

Example 4.1

[Dp + (D/Q)s]product 1 + ... + [Dp + (D/Q)s]product n

N[1 – (C/100)]M =

4-18

POM - J. GalvánPOM - J. Galván 1919

Item Client X Client Y

Annual demand forecast (copies) 2000.00 6000.00Standard processing time (hour/copy) 0.50 0.70Average lot size (copies per report) 20.00 30.00Standard setup time (hours) 0.25 0.40

[2000(0.5) + (2000/20)(0.25)]client X + [6000(0.7) + (6000/30)(0.4)]client Y

(250 days/year)(1 shift/day)(8 hours/shift)(1.0 – 15/100)M =

Capacity DecisionsCapacity Decisions

4-19

Estimate Capacity RequirementsEstimate Capacity RequirementsExample 4.1

Used capacity: 85%

POM - J. GalvánPOM - J. Galván 2020

Item Client X Client Y

Annual demand forecast (copies) 2000.00 6000.00Standard processing time (hour/copy) 0.50 0.70Average lot size (copies per report) 20.00 30.00Standard setup time (hours) 0.25 0.40

M = = 3.12 4 machines5305

1700

Capacity DecisionsCapacity Decisions

4-20

Estimate Capacity RequirementsEstimate Capacity RequirementsExample 4.1

POM - J. GalvánPOM - J. Galván 2121

Waiting-Line Models Models Often used in Capacity PlanningOften used in Capacity Planning

• Balances customer service & the cost of Balances customer service & the cost of extra capacityextra capacity

Use probability distributions to Use probability distributions to estimate:estimate:

Avg.Customer DelayAvg.Customer Delay Avg. Length of Waiting LinesAvg. Length of Waiting Lines Work Center UtilizationWork Center Utilization

POM - J. GalvánPOM - J. Galván 2222

Simulation

A tool that helps identify:A tool that helps identify:• Process BottlenecksProcess Bottlenecks• Capacity CushionsCapacity Cushions

More effective for More effective for

complex waiting-line complex waiting-line

problemsproblems

POM - J. GalvánPOM - J. Galván 2323

Capacity Capacity DecisionsSimulationSimulation

Figure 6.5(a)

POM - J. GalvánPOM - J. Galván 2424

Figure 4.8

Capacity DecisionsCapacity Decisions

SimulationSimulation

4-24

POM - J. GalvánPOM - J. Galván 2525

Vary staffingVary staffing Change equipment Change equipment

& processes& processes Change methodsChange methods Redesign the product Redesign the product

for faster processingfor faster processing

Capacity Management

¨ Vary pricesVary prices

¨ Vary promotionVary promotion

¨ Change lead timesChange lead times(e.g., backorders)(e.g., backorders)

¨ Offer complementary Offer complementary productsproducts

Demand Management

Managing Existing CapacityManaging Existing Capacity

POM - J. GalvánPOM - J. Galván 2626

Complementary ProductsComplementary Products

Time (Months)

Sales (Units)

Light clothes

Heavy clothes

Total

0

1,000

2,000

3,000

4,000

5,000

J M M J S N J M M J S N J

POM - J. GalvánPOM - J. Galván 2727

Matching Capacity to DemandMatching Capacity to Demand

Demand ManagementDemand Management• vary pricesvary prices• change lead timeschange lead times• encourage/discourage businessencourage/discourage business

Capacity ManagementCapacity Management• adjust staffingadjust staffing• adjust equipment and processesadjust equipment and processes• change methods to facilitate productionchange methods to facilitate production• redesign the product to facilitate redesign the product to facilitate

productionproduction

Related Documents