BULK MATERIALS HANDLING 2014 Presenta(on by COO Paul ToussaintJackson DFD and FDTS Concepts Designer and Developer 1 FLOATING DECK SOLUTIONS: A NEW WAY FOR THE PILBARA AND BEYOND

Paul Toussaint Jackson, Dampier Port Authority, Floating Deck Solutions – The Pilbara and Beyond

Jun 25, 2015

Paul Toussaint Jackson delivered the presentation at 2014 Bulk Materials Handling Conference.

The 11th annual Bulk Materials Handling Conference is an expert led forum focusing on the engineering behind the latest expansions and upgrades of bulk materials facilities. This conference will evaluate the latest engineering feats that are creating record levels of throughput whilst minimising downtime.

For more information about the event, please visit: http://www.informa.com.au/bulkmaterials14

The 11th annual Bulk Materials Handling Conference is an expert led forum focusing on the engineering behind the latest expansions and upgrades of bulk materials facilities. This conference will evaluate the latest engineering feats that are creating record levels of throughput whilst minimising downtime.

For more information about the event, please visit: http://www.informa.com.au/bulkmaterials14

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

BULK MATERIALS HANDLING 2014 Presenta(on by COO Paul Toussaint-‐Jackson

DFD and FDTS Concepts Designer and Developer 1

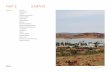

FLOATING DECK SOLUTIONS: A NEW WAY FOR THE PILBARA AND BEYOND

• The DFD (Dampier Floating Deck) and FDTS (Floating Deck Trans-shipment System) are two projects that I have designed and developed on behalf of the Port of Dampier to improve critical supply chain constraints affecting both the Port and the Pilbara region in general.

• These projects are intended have the maximum trade facilitation impact at a fraction of

the cost of conventional infrastructure and with much shorter development times.

• The DFD I conceived as a forward floating supply base function to directly assist the logistics of supplying offshore oil and gas platforms out of Dampier.

• The FDTS I designed as a land-backed facility with a moving floating deck that will allow genuine international liner cargo shipping services to call at Dampier for the first time.

• Both the FDTS and DFD are designed as logistics systems rather than simple infrastructure solutions and are highly adaptable including inwards supply for mine and port construction and as platforms for conveyors and export facilities.

• These projects are game changers for logistics into the Northwest and are expected to do much to fundamentally address some of the core logistics productivity issues we have in that very important region for the Australian economy.

Floating Deck Systems: New Projects for Dampier

• Easily and rapidly scalar to suit developing trade; • Uses shallow bathymetry (for the FDTS) as an asset rather than an obstacle: no

dredging is required. These facilities have minimal environmental impact;

• Rapidly constructed in a far shorter timeframe than conventional infrastructure;

• Far lower capital cost than conventional infrastructure of equivalent capability;

• Highly robust, safe and flexible and be highly suitable for use in cyclone prone areas; • Readily handled by existing port services and operations;

• Completely privately funded but provide good revenue returns to the State, legacy assets for the State and retain key controls for the State over the land or seabed through lease/license instruments;

• Open access for general custom and have Customs and AQIS approved facilities.

• All types of project cargo handled including multi-thousand tonne pre-assembled modules;

Floating Deck System Design Elements

Current logistics constraints • The Port of Dampier is one of the world’s largest bulk export ports and has excellent

private facilities for the export of LNG, condensate, iron ore and salt. These facilities are profit-driven and fit for purpose.

• The principal import facility however, the Dampier Cargo Wharf (DCW), requires expanded capacity to cope with the growth in trade. Congestion causes delays and demurrage costs for project vessels, additional costs to projects and reinforces the use of inefficient long-distance road-haul services to our region for large oversize and out of gauge project cargo.

• In 2011 I undertook a study to find a solution to not only the constraints of the DCW

facility but also the wider logistics productivity issue for the Pilbara.

• From this study I identified two critical supply chains that conflict at Dampier:

- Critical Supply Chain 1 – The high cycle marine services supply to offshore oil and gas installations; and, - Critical Supply Chain 2 – The inwards industrial supply chain including mine supply. • Both of these supply chains rely heavily on access to the DCW.

• Finally I recognised the advantages of enabling direct call international liner services.

GENERAL CARGO VESSELS CAN BE ALONGSIDE FOR A WEEK TO SUIT CRANE TO TRUCK OPERATIONS

OFFSHORE SUPPLY VESSELS NEED RAPID CYCLE ACCESS TO THE DCW.

THE DCW : DUE TO WIDTH AND SWL LIMITS CARGO CANNOT BE STACKED ON THE WHARF BUT MUST BE WORKED TO TRUCK

• Critical Supply Chain 1 (high cycle offshore support) is constrained because its vessels need frequent and ready access to the DCW. The development of trade requires further berths: a general cargo vessel can occupy the existing western berths for up to a week.

• Critical Supply Chain 2 (Inwards industrial supply) is constrained because the development of trade requires further berths: project or general cargo exchange requires extra time due to the need to work crane to truck.

• Both supply chains do not have stacking and handling areas available within the port gates and must rely on private sites located elsewhere. Available land for private use in the general port environs for cargo facilitation is in limited supply and in high demand. The DCW cargo operations are therefore impacted by varying truck cartage cycle times, the number of available trucks and the additional time required to stevedore oversize and out of gauge cargo.

• By removing the constraints to both critical supply chains I realised that regular internationally networked cargo liner shipping services to the Pilbara could be facilitated. This would allow re-work of current supply networks through Eastern and Southern main ports and reduce an over reliance on long-distance road-haul. To get genuine liner services to call at the port would however require a complete re-think on infrastructure.

Legend Current rail haul

Current road haul

East Coast liner route

Optional road haul

New West Coast liner options

5

4

4

12 3

4

5

2

3

Currently China to Pilbara supply chain takes 31 days

(red route)

5

6

4

FDTS supports China to Pilbara supply chain of just

9 days 2

FDTS provides a general cargo terminal function at Dampier supporting the development of new liner services.

DFD 3500 m2 25 tonnes/m2 2 x 100m berths Drilling mud Fuel Fresh water All hydraulic Lateral movement <100mm Demobilisation < 1 hour

OFFSHORE PLATFORMS MUST HAVE ACCESS TO A SUPPLY BASE FUNCTION THAT IS CLOSE BY TO OPTIMISE THE SUPPLY CHAIN AND REDUCE CHARTER COSTS. DAMPIIER IS IN PROXIMITY TO THE OFFSHORE DEVELOPMENTS AND ITS DFD PROJECT IS IDEALLY SITUATED TO FACILITATE PLATFORM SERVICES.

• Directly addresses berth constraints for both OSV and general freight and project tonnage into the Pilbara; • Creates forward ‘supply base’ function to facilitate the service supply chain for the oil and gas industry and to enable its re-design reducing pressure on land close to the Port; • Reduces cost to the oil and gas industry by improving cycle times for OSVs and reducing overall charter requirements.

DFD: solution for critical supply chain 1

FDTS 3500 m2 floating decks 15000 tonne cargo dwt Land-backed terminal AQIS wash-down Customs licensed

FDTS: the ‘shock absorber’ Trans-shipment in sheltered port anchorage RORO or LOLO exchange Deep water allows port access by large cargo liners At Dampier floating deck will take 1.5 hours to shore

13

DFD and FDTS for Dampier 2014

14

15

FDTS Floating Deck Cargo Area Capacity

Sample cargo area capacity (theoretical tight stow only) based on 110m x 38m floating deck (4180 m2 of useable area).

CAT 797 Mining Haul Trucks Largest mechanical haul trucks in the world

(400 tonne payload)

CAT D9 Tractors 48.8 tonnes

TEU Sea Containers double stacked or 280 single stacked

Hammersley Iron Ore Rail Wagons

OR

OR

28 114

144 560+

17

18

Floating decks de-mobilised to sheltered cyclone moorings

FDTS – The Logistics Game Changer • Enables for the first time a pure cargo liner service to operate to the Pilbara by acting as

a logistics ‘shock absorber’ thereby removing all current constraints to liner services.

• Is ideally suited to a global RORO break-bulk service enabling realignment of major industrial supply chains. This can include mine establishment, support and major construction works such as the construction of wharves and loaders;

• Has national supply chain ramifications including reducing supply chain times from China by up to 70%;

• Facilitates LOLO operations and relieves spot-chartered general cargo vessel congestion;

• Facilitates cold supply chain into the Pilbara;

• Reduces oversize vehicle movements on the North West Coastal Highway;

• Improves the economics and prospects for coastal shipping services.

Floating Deck Systems – further applications • It is clear from the projects at Dampier that this type of infrastructure could have ready

application elsewhere. I believe it is infrastructure for the future.

• Coastal topography, meteorological and environmental conditions need to be carefully assessed for each new development;

• The real solution for each site is not as infrastructure alone but as a logistics system if the full value of the installation is to be realised.

• The many attributes of these systems including lower capital cost make them attractive to the private sector.

• The systems are designed to be complementary to traditional infrastructure and can be applied to developed ports or greenfield sites.

• Low environmental impact makes the systems ideal for environmentally sensitive sites.

Floating Decks – stability, flexibility, strength • The floating decks are very stable allowing structure of very large weight and weight to

be located on an otherwise very shallow draught platform. This can include loaders and conveyors in various forms, stockpiles, workshops and berth space;

• The floating decks can be easily modularised to create greater working area;

• Floating decks allow shallow bathymetry to be used as an opportunity rather than as a problem – they can be used to bridge to deeper water either as a static or moving installation;

• The simplicity of floating deck installations makes them easy to work within the normal colour and movement of a port;

• Floating decks can be easily fit to simple shore-side construction to provide the option of legacy (shore land) assets that may be important in achieving permission from the State.

• The Floating decks can be readily transferred to other sites or sold.

FDTS first stage development – Dampier, WA

Related Documents