Operational – P1 Section A – Managing short-term finance Chapter 1: Working capital and the operating cycle Working capital cycle The Working Capital Cycle (otherwise known as the Cash Operating Cycle) is the length of time between payment for raw materials and cash receipt from the sale of finished goods. It indicates the number of days for which finance is required. It is given by Raw materials days WIP days Finished goods days Receivables days Less (Payables days) RM / RM purchases (or Usage) for the year x 365 WIP / Cost of production (or Sales) x 365 FG / Cost of sales x 365 Receivables / Credit sales (or Revenue) x 365 Payables / Credit purchases (or Cost of sales) x 365 – The numerators refer to the year-end amounts (or a particular time), while the denominators refer to a 12 month period – The Receivables Days can be otherwise known as the Average Debt Collection Period – In the absence of WIP, Raw Materials or Finished Goods, use Inventory Days = Inventory / Cost of sales x 365 – Sometimes starting balances will be given, alongside information to get the closing balances, always work out and use the latter – When starting balances and closing balances are given use the average figures – Receipts refer to the income of cash Risks of not monitoring working capital Every company intends on reducing its Working Capital Cycle so that money isn’t tied up. If it is not monitored, the following can occur: Overtrading – where even if a business is operating at a profit, there is a shortage of cash to pay due debts Overcapitalization – where there is excessive working capital Influencing the cycle The Working Capital Cycle can be sped up by (but also has consequences of): 1. Hold less raw materials to reduce RM days but may result in stock outs 2. Speed up production to reduce WIP days but it will cost more (overtime) 3. Produce when required to reduce FG days but loss of customer goodwill if they have to wait 4. Reduce credit period to reduce receivables days but loss of customer goodwill 5. Take longer to pay to increase payables days but may incur financial penalties The aforementioned are also short term methods of increasing cash. Adjusting working capital

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Operational – P1

Section A – Managing short-term finance

Chapter 1: Working capital and the operating cycle

Working capital cycle

The Working Capital Cycle (otherwise known as the Cash Operating Cycle) is the length of time between payment for raw materials and cash receipt from the sale of finished goods. It indicates the number of days for which finance is required. It is given by

Raw materials days WIP days Finished goods daysReceivables days

Less (Payables days)

RM / RM purchases (or Usage) for the year x 365WIP / Cost of production (or Sales) x 365FG / Cost of sales x 365Receivables / Credit sales (or Revenue) x 365

Payables / Credit purchases (or Cost of sales) x 365

– The numerators refer to the year-end amounts (or a particular time), while the denominators refer to a 12 month period

– The Receivables Days can be otherwise known as the Average Debt Collection Period– In the absence of WIP, Raw Materials or Finished Goods, use Inventory Days = Inventory / Cost

of sales x 365– Sometimes starting balances will be given, alongside information to get the closing balances,

always work out and use the latter– When starting balances and closing balances are given use the average figures– Receipts refer to the income of cash

Risks of not monitoring working capital

Every company intends on reducing its Working Capital Cycle so that money isn’t tied up. If it is not monitored, the following can occur:

Overtrading – where even if a business is operating at a profit, there is a shortage of cash to pay due debtsOvercapitalization – where there is excessive working capital

Influencing the cycle

The Working Capital Cycle can be sped up by (but also has consequences of):

1. Hold less raw materials to reduce RM days but may result in stock outs2. Speed up production to reduce WIP days but it will cost more (overtime)3. Produce when required to reduce FG days but loss of customer goodwill if they have to wait4. Reduce credit period to reduce receivables days but loss of customer goodwill5. Take longer to pay to increase payables days but may incur financial penalties

The aforementioned are also short term methods of increasing cash.

Adjusting working capital

The impact of changing the inventory, receivables and payables days is threefold:

Customer relationships – reduction in receivables days may deter customers to suppliers who offer more liberal payment terms Supplier relationships – reduction in payables days may result in foregone discounts, increase in prices from suppliers and lost goodwillStock out – reducing inventory days requires strong relationships with suppliers, but they will be unwilling to offer this service

Liquidity ratios

The Working Capital Cycle and the below Liquidity ratios are only useful when comparing against industry averages, prior period figures or expectations. If a liquidity ratio falls, the risk of

bankruptcy increases, these are given by:

Working capital = Current assets – Current liabilitiesCurrent ratio = Current assets / Current liabilitiesQuick ratio = (Current assets not including inventory) / Current liabilities

Some quick operational changes can create the following effects:

1. Halving the credit terms will half the trade receivables, which is offset by an increase in cash by the same amount

2. Paying off an overdraft will reduce cash and liabilities3. Purchases of inventories on credit will increase assets and liabilities by the same amount.

Business policy

A business divides its assets into:

1. Permanent current assets – the core levels of cash and inventory that is maintained2. Fluctuating current assets – that vary depending on activity

Businesses that accept a greater level of risk will hold fewer permanent assets i.e. holding less inventory reduces holding costs but increases risk of not being able to respond to demand. The aforementioned are funded by the following policies:

Conservative – All permanent and some fluctuating assets are financed by long-term fundingAggressive – All the fluctuating and some permanent assets are financed by short-term fundingModerate – Fluctuating assets are financed by short-term funding and permanent assets by long-term funding

Chapter 2: Cash flow forecasts

A cash budget is a detailed forecast of expected cash receipts, payments and cash balances over a planning period. A broad guideline to the preparation of a cash budget is:

Step 1: Identify the starting cash positionStep 2: Determine the period in which receivables and payables impacts the cashStep 3: Set out the cash budget month-by-month.

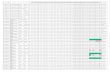

Cash inflowsFrom Sales

– 30 days– 60 days– 90 days

Other cash receipts

Cash outflowsPurchases

– 30 days– 60 days– 90 days

OverheadsWages

Net cash flowCash b/fCash c/f

Jan

XXXX

(X)(X)(X)(X)(X)

XXX

Feb

XXXX

(X)(X)(X)(X)(X)

XXX

Mar

XXXX

(X)(X)(X)(X)(X)

XXX

– Gains are not included within the Cash Budget as only cash elements are– Unless otherwise stated, credit terms start from the beginning of the month after which it is

purchased. So, a 30 day credit term means that if X is purchased in May, it is required to pay for the item at the end of June, so is included in June’s budget

– If a probability of cash flow is given, then use the expected value to include in the Cash Budget. It is important noting that the expected balance is pointless in being used for planning as their will only be two outcomes (X or Y), which make up the EV, but the outcome will never actually be EV

Chapter 3: Cash management

Short-term finance

Some of the actions that an organisation can take to generate short-term

1. Increasing the Overdraft facility 2. Taking out a Short-Term Loan 3. Spreading CAPEX over installments rather than paying for it all immediately, or leasing CAPEX

rather than purchasing it outright4. Decreasing credit terms (all the way to asking for payment in advance)5. Delaying supplier payments

Overdraft vs. Bank loan

The advantages of borrowing through an overdraft are:– Interest is not paid on the full facility– Compared with other types of loans it is quick and easy to set-up

The disadvantages of borrowing through an overdraft are:– Overdrafts carry greater financial risk as they are repayable on demand– Term loans can be negotiated over a timescale relating to the company’s forecast– A lower interest rate than an overdraft can be attained

Export finance

An entity selling abroad will experience a longer Working Capital Cycle as a result of payments not being received in time. The options for medium-term finance include:

Bill of exchange – A supplier draws up a bill of exchange and the customer signs it to acknowledge the debt. The supplier can hold the bill until the due date or discount the bill with a bank or transfer the bill to its own supplier to settle its debts with themForfaiting – The customer makes a small payment and a promissory note to cover the balance during a sale. An avalising bank guarantees the payment of the note. The supplier sells the notes to a forfaiting bank at a discount to obtain financeLetter of credit – A document issued by a bank on behalf of a customer authorizing them to draw money to a specified amount

The benefits of all of the above include:

1. Immediate access to cash2. Exporter carries no liability to bank3. Exporter transfers all risks4. Allows transactions to be entered into which may not otherwise be possible

Debt factoring

Where the sale of debts is made to a third party in return for prompt cash. It can be with recourse (debts passed back to entity) or without recourse (factor bearing all risks). The drawbacks of such a system include:

Customer relationship – a debt factor places a barrier between supplier and customerReputation – debt factoring is perceived as a sign of financial difficultyInternal debt-collection team – indicator they are not doing there job properly

When ultimately deciding on whether to use a debt-factoring service compare benefits and costs

Benefits – Admin savings, Bad debt recovery, Receivables given in advanceCosts – Annual fee, Extra interest = (Interest payable to debt factoring company – interest rate from bank) x advanced receivables

Managing cash surpluses and investment options

When considering the method of investing cash surpluses, consider the Risk, Liquidity and Return in decreasing levels of importance

Treasury bills – Short-term, risk-free government debt that repays greater than its purchase price on redemption (rather than interest)Local authority stocks – Similar to Treasury bills but not valued quite as highCertificate of deposit – Fixed-term risk-free bank deposits, which can be liquidated at any time but at the cost of a lower yieldBonds – Long-term, risky debt instrument that offers a fixed-rate of interest over a fixed period of time with a redemption value

– Lower interest rates normally follow lower risk– Price risk refers to interest changes impacting the tradable value of an investment (if interest

rates depreciate to 1%, while the bond offers 2.5%, the bond will be worth more)– Short-term cash surpluses are invested in liquid options (Bank Deposits) and not risky options

(Bonds) Yield on investments

The Yield on an investment is the rate of return and is given by

Interest yield = Gross interest / Market value x 100%

The Yield-to-Maturity is the overall return a security holder achieves over the period of holding the security. It is the combination of interest received on a security and repayment at maturity, and is calculated using the internal rate of return (IRR). The Coupon Rate of a security is the actual amount of interest that is paid on the security based upon its face value.

Chapter 4 – Receivables and payables

Reasons to offer credit

Offering credit terms has benefits and costs

Benefits: Additional sales volume generated, Profitability of the extra salesCosts: Extra length of the average debt collection period, Required rate of return

Compare additional profit against cost when determining the impact of credit terms. The cost is the increase in working capital, given by:

Additional receivables: sales revenue per annum x credit term periodAdditional inventories(Additional payables): Net increase in working capital x interest rate

Cost of offering settlement discounts

Discounts are offered to incentivize early payments.

Cost of Early Settlement Discount = (100 / 100 – discount)360 / Days early – 1Where, Days early = Credit term length – Discount length

The Cost of Early Settlement Discount is the Required Rate of Return for the buyer. If the Cost is greater than the Required Rate of Return then reject the discount.

The credit cycle

The Credit Control function occupies a number of stages which together makes up the credit cycle.

Order Cycle – Customer places order, Establishes credit status, Checks credit limit, Issues delivery note, Delivers goods, Raise invoicesCollection Cycle – Customer receives invoice, Sends statement, Sends remainder letter, Calls customer, Receives cash

Finance requirements

The annual financing requirements of an organisation are:

Total inventories + Total receivables – (Total payables x Cost of capital)

Age analysis

An aged analysis on the outstanding balance normally dictates 3 consecutive 30-day periods, with the outstanding receivables placed in each category depending on when the invoice was raised. It highlights the overdue amounts that the credit controller needs to chase up. It also highlights particular customers who may have a large outstanding balance, and to whom no further goods should be delivered until the account is settled.

Methods of payment

Different transactions have more suitable methods of payment

Cash – Convenient but Needs to be kept secure, Difficult to control, Bad for record keepingCheques – Convenient, Widely used but Security problems with theft, Slow method of payment

Chapter 5 – Managing inventory

Reasons and costs for holding inventory

Inventory is held in order to Prevent stock-outs, Hedge against price increases and Secure quantity purchase discounts

The costs associated with holding inventory include:

Order costs = (annual demand / quantity) x cost per order; Admin, DeliveryHolding costs = (quantity / 2) x holding cost per unit; Opportunity cost, Warehousing, Insurance and obsolescencePurchase costs = annual demand x price after discount; Amount paid for order

Economic Order Quantity (EOQ)

The model finds the Order Quantity that minimizes annual inventory costs, it is calculated by:

√ 2CoDCh

D = Annual demand in units, Co = Order cost per order, Ch = Holding cost per unit of inventory

The EOQ is dependent on the assumptions that 1. Demand is constant and certain (no stock-out costs)2. Delivery is instantaneous3. Purchase costs are constant (no discounts for bulk purchases)

If the supplier does offer a discount, calculate the EOQ as normal, and then recalculate the EOQ with the discount if it falls within a discount bad. Moreover, calculate the EOQ at the lower boundary of each discount bound. Select the order quantity that minimizes costs

– If the question is stated with two different elements, reword the information into a common element before working out, i.e. Co being given in trolleys whereas Ch given in wheels – reword Co into wheels and use this in the EOQ

Section B – Cost accounting systems

Chapter 6 – Fundamentals of absorption and marginal costing

Absorption costing

The premise of Absorption Costing is to included Fixed Production Costs into the Cost per unit card. Its element of the Cost per unit card is given as:

OAR = Fixed Production Overheads / Expected activity level, this can be in terms of units, labour hours or kg

The income statement under absorption costing principles is structured around the split between production and non-production costs

Year 1£ £

Year 2£ £

Sales

Cost of sales: Opening inventoryProduction: Variable costs Absorbed production fixed costs

Closing inventory(Over)/under absorptionGROSS PROFITVariable selling and distributionFixed selling & distributionNET PROFIT

-

26, 4008, 80035, 200(1, 600)(300)

42, 000

(33, 300)8, 700(4, 200)(2, 000)2, 500

1, 600

22, 8007, 60032, 000-900

40, 000

(32, 900)7, 100(4, 000)(2, 000)1, 100

– Closing inventory is given as Opening Inventory + Purchases – Sales, valued at full cost (All Variable Costs + OAR)

– The over/under absorption relates to the difference between Absorbed Production Overheads and Actual Production Overheads Over/under absorption = (Budgeted OAR x Actual Units) – Actual Overheads

Marginal costing

Marginal costing is based on a principle that Variable Production Costs are charged to cost units and Fixed Costs attributed to relevant periods. This means that Inventory is valued at Variable Production Costs only

The income statement under marginal costing principles is structured around the split between Fixed and Variable Costs

SalesVariable costs: Opening inventory Production costs (Labour, Materials): Less: Closing inventory

Less: Variable costs of sales (Selling, Distribution and Administration costs)CONTRIBUTIONLess: Total Fixed costs (Production & selling, administration)PROFIT

£

XX(X)

£X

(X)(X)X(X)X

Absorption costing vs marginal costing

The arguments for the use of traditional absorption costing rather than marginal costing for profit reporting and inventory valuation include:

1. Faire share – it is fair to charge all output with a share of fixed production costs2. IAS 2 requirements – follows the requirements of international accounting standard on

inventory valuation3. Matching concept – consistent with the accruals concept4. Recoverable profit – charging fixed overheads to a product allows the organisation to determine

the price and sales to break evene ar

The argument against it is that it allows profit to be manipulated.

Reconciling absorption and marginal costing proforma

There are steps taken to reconcile these forms of costing, if moving from Absorption to Marginal

costing, follow these steps:

1. Set up a cost card:Direct materials and labor per unit (direct materials and labor / production units)Variable overheads per unitFixed overheads per unitTotal cost per unit

2. Separate Variable OverheadsA line for Overhead’s will contain Variable and Fixed elements within it. Use the high-low method across two years to separate these costs, using Actual Overheads (Overheads + (over)/under absorption) and Production Units. This will give Variable Overheads per Unit, multiply this by Production units to get the Variable Overheads.

3. Separate Fixed Production CostsDivide Overheads (without adjustment for (over)/under absorption) by Production Units to get the Total Overhead Cost per Unit. Remove the Variable Overheads per Unit from this to get the Fixed Overheads per Unit.

4. Adjust inventoryDivide Inventory by Total Overhead Cost per Unit and then multiply by Variable Overheads per Unit to get the new Marginal Costing Opening and Closing Inventories

5. Selling, distribution and adminUse the above method to separate any Non-Production Overheads that have a mixture of Fixed and Variable Costs, however multiply by Sales Units in the calculation this time

– The High-Low Method is calculated by Variable Cost per Unit = (y2 – y1) / (x2 – x1), where y refers to Cost and x refers to Production

– The above method can be used to separate Fixed and Variable costs in Overheads for budgets as well

Reconciling absorption and marginal costing profits

The size of each profit is dependent on the amount of inventory left at the end of the year:

Sales = production, AC profit = MC profitSales > production, AC profit < MC profitSales < production, AC profit > MC profit

Absorption Costing increases the value of Inventory (as it adds OAR in comparison to Marginal Costing). As Cost of Sales is removed from Revenue, which is given as (Opening Inventory + Expenses – Closing Inventory), it means that Inventory increases over the course of the year (through Production being greater then Sales), less is taken off Reenue as Closing Inventory increases, making profit larger.

To reconcile AC and MC simply add the OAR x inventory which is also (all variable costs + OAR – variable production costs) x inventory

AC Profitadd: fixed overhead in opening inventory (OAR x opening inventory)less: fixed overhead in closing inventory (OAR x closing inventory)MC profit

Year 12, 500-4002, 100

Year 21, 100400-2, 100

Reconciling profits over time

Profits under absorption costing principles can be reconciled by

Profit in X1Increase/Decrease in Sales Volume (Profit per Unit x Sales)Difference in overhead recoveryIncrease/Decreases in Distribution Costs

XX/(X)balancing figureX/(X)X

Profit in X1

Breakeven point

The break-even point is given as:

Breakeven point = Total Fixed Overheads / Contribution per Unit

Where Contribution = Total Sales less Variable Costs; and,Contribution per Unit = Selling Price per Unit – Variable Cost per Unit

Chapter 7 – Standard costing and variance analysis

Standard cost

A standard cost is a benchmark measurement of resource cost and usage. It can be determined through pricing discussions with suppliers, purchase contracts already signed and forecasted movements of price.

Internal benchmarking likely to be more useful than external benchmarking as it is easier to source and business practices can be transferred more easily. Moreover, external benchmarking may be useless if the company is unable to understand how the external organisation achieved the performance

Setting standards

The setting of standards raises the problem of how demanding the standard should be, there are four types of standard:

1. Ideal standard – Attainable under near-perfect conditions, causes unfavorable motivational impact as Variances are always adverse

2. Current standard – Attainable under current operation standard, do not attempt to improve current levels of efficiency

3. Basic standard – Unaltered standard over a lengthy period of time, may become out of date4. Attainable standard – Attainable under efficient conditions with allowances made for waste, will

provide a positive psychological incentive by giving employees a realistic but challenging target

Similarity of budgets and standards

A Budget and a Standard are both predetermined quantities targets, both of which look to the future and are used for control purposes. They are also different as Standards are limited to situations where Output can be measured, while Budgets can only be in monetary terms.

Limitations of standard costing

The three limitations and criticisms of standard costing include:

1. Dynamic business environment – Standards can become out of date in a modern business environment as technology and customer demand changes rapidly, it would be time-consuming and expensive to revise so often

2. Labour focus – Standard costing was created for labour-intensive operations, but as processes have become more automated, the cost of labour has become a small proportion of total costs, thus making its variances of little value

3. Cost control focus – Standard costing tends to focus on controlling costs, whereas the modern business environment should focus on quality and continuous improvement

Variances

Material Variances –PriceShould have cost (Actual purchases kg x Budgeted price)Did cost (Actual purchases kg x Actual price)Variance = Difference

UsageShould have used (Actual units x Budgeted kg/unit)Did use (Actual units x Actual kg/unit)Variance = Difference x Standard cost/kg

Variable Overhead Variances –

Expenditure Should have cost (Actual used purchases x Budgeted price)Did cost (Actual used purchases x Actual price)Variance = Difference

EfficiencyShould have used (Actual units x Budgeted kg/unit)Did use (Actual units x Actual kg/unit)Variance = Difference x Standard cost/kg

Labour Variances –RateShould have cost (Actual hours worked x Budgeted price)Did cost (Actual hours worked x Actual price)Variance = Difference

EfficiencyShould have used (Actual units x Budgeted hours/unit)Did use (Actual units x Actual hours/unit)Variance = Difference x Standard cost/hour

Idle Time Hours workedHours paidVariance = Difference x Standard cost/hour

Fixed Overhead Variances –Expenditure Budgeted expenditure Actual expenditureVariance = Difference

Volume Variance (only exists for Absorption Costing)Budgeted unitsActual unitsVariance = Difference x OAR per Unit

Sales Variances – PriceX Units should have sold for (Budgeted price x X)X Units sold for (Actual price x X)Variance = Difference

Volume Profit/ContributionBudgeted sales unitsActual sales unitsVariance = Difference x Standard Contribution/unit (Profit per unit for absorption costing)

Mix/Quantity contribution/profit – used instead of Volume Profit/Contribution when there is more than one output

OnionsTomatoes

Actual Std Mix7507501, 500

Actual/Budget Mix6009001, 500

Difference150 (F)150 (A)

X £stdx£4x£2

Variance600 (F)300 (A)300 (F)

Variance = Difference x Standard Contribution/unit (Profit per unit for absorption costing)Actual Standard Mix is Actuals in budget proportion. Use Actual Output Mix for Mix and Unflexed Budget Output Mix for Quantity.

– Mix tells us how contribution changes when proportion of products sold are different to those in the budget, while Quantity tells us difference in contribution as a result of difference in sales volumes

– It highlights the fact that maximizing sales volume may not be as advantageous as creating the most profitable mix of products

Planning variances – Labour Rate/Materials PriceActual units x Original hours/unit x Original standard £X per hourActual units x Original hours/unit x Revised standard £Y per hour

Labor Efficiency/Material UsageX units should original take L hoursX units should revised take M hoursVariance = Difference x Original Standard £X/hours

Variance = Difference

Operational variances – PriceActual kg/hours x Revised standard £Y per hourActual kg/hours x Actual standard £X per hourVariance = Difference

Labor Efficiency/Material UsageRevised A units should take L hours Actual A units did take M hoursVariance = Difference x Revised Standard £X/hours

Materials mix variances –Represents the financial impact of using a different proportion of raw materials to the standard

OnionsTomatoes

Actual Std Mix7507501, 500

Actual Mix6009001, 500

Difference150 (F)150 (A)

X £stdx£4x£2

Variance600 (F)300 (A)300 (F)

The Actual Standard Mix is obtained by dividing the Total Actual Mix by the original Standard Mix proportions

Yield variances –Represents the financial impact of the input yielding a different level of output to the standardActual inputs should yieldActual inputs did yieldVariance = Difference x Standard £X/hours

– Original standard is the same as budgeted standard

Advantages of planning and operational variances

A standard costing system that identifies planning and operational variances have three advantages of

1. Controllable vs uncontrollable – The analysis highlights the variances that are controllable and uncontrollable, allowing management to focus on those variances that can be impacted

2. Motivation – Managers will not be held responsible for poor planning and faulty standard setting3. Improved standard setting – Observant models will ensure the planning and standard setting

process should improve

Flexible budgeting

A Flexed Budget is calculated for all Costs and Revenue, using the original Price per Unit but for the Actual Units. The advantages of flexible budgeting include:

1. Pinpoints problem areas – Flexible budgets are more likely to pinpoint actual problem areas on which control may be exercised.

2. Removes volume effect – Relying on a fixed budget will create large variances as forecast volume is unlikely to be matched

3. Helps monitor efficiency of operations – Flexible budgets gives a better indication of performance since it shows what costs or revenues should have been at the actual activity level

Flexed budget additional costs = Additional units x variable costs

Reconciling profit

A budget can be reconciled to actuals using variances

Budgeted sales(Opening Inventory – Closing Inventory)Budgeted variable overheadsBudgeted fixed overheadsFlexed budget additional costs

(F) (A) $

Budgeted profit

Sales volume profit varianceSales price varianceLabour rate varianceLabour efficiency varianceMaterials price varianceMaterials usage varianceMaterials mix varianceMaterials yield varianceVariable overhead expenditureVariable overhead efficiencyFixed overhead expenditure varianceFixed overhead volume varianceActual profit

X X

X

XX

– Budgeted and standard are synonymous– If reconciling Total Cost use the same method but remove Budgeted Sales, Sales Volume and

Sales Price Variance– If there are more than two outputs Sales Volume Profit Variance splits into Sales Mix Profit and

Sales Quantity Profit Variance– Materials mix and yield are only included if there are more than two types of materials– Planning and operational variance are only included if there has been a price change, it

replaces the Price Variance in this case– Fixed overhead volume variance does not exist for Marginal costing so this is removed– If reconciling Materials Cost only, use Materials Price Variance for each input, and Materials Mix

and Yield. If there is a price change in any of the Materials, replace the Materials Price Variance with Materials Planning Price and Material Operational price Variance

Investigating variances

The three factors that should be considered before deciding to investigate a variance are:

Materially – obtaining explanations for variances is time-consuming and so small variations are not worthwhile Cost – the cost of the variance needs to be weighed against the cost to the organisation of allowing variance to continue in future periods.Controllability – whether the variance can be influenced anyway

McDonalisation

This has been facilitated through the idea of Standard Costing as every meal is identical in terms of the way it looks, the materials used in its process and the amount of materials used in each item. This has been achieved by reducing human influence by substituting machines for humans, and has ensured that each meal has a measurable standard cost unit. These standard costs has enabled the organisation to

Chapter 8 – The modern business environment

Traditional production methods focused on high volume, low cost output. In today’s environment the emphasis has shifted towards quality and being flexible to customers’ requirements. This is embodied in the philosophy of world class manufacturing which has the following features:

Quality improvement –

Get it right, first time so that cost of preventing mistakes is less than the cost of correcting them if they occur; this means having prevention and appraisal costs that are less than external and internal failure costs.

There is also a focus on continuous improvement, which is measured using a number of different metrics.

Problems with implementing this is that it can be demotivating to constantly strive for better, not everyone can be involved and it relies heavily on the quality of suppliers.

Optimsed production technology – a technique whre the primary goal is to amximise throughput hile simualtnously maintain or decreasing inventory and operating costs

Just-in-time –

A system whose objective is to produce or procure products or compoennts as they are required by a customer or for use, rather than fro iventory

JIT is a system which produces or buys units when they are required rather than for inventory. It has zero inventories, buys raw materials when needed and uses raw materials as soon as they are delivered. It aims for low cost, high quality, on-time production by minimizing inventory levels between processes and minimizing idle equipment, facilities and workers.

Benefits1. Reduction in inventory holding costs2. Reduced manufacturing lead times

Limitations– Not always appropriate (hospital)– Large up-front costs of a full study on

production methods– Access to sizeable funds is required

to run a JIT purchasing system

Backflush accounting

Backflush accounting is a method of accoutnting that is used with JIT production systems. It saves consideratbale amount of time as it avoids having to make a number ofa ccountting entries that are required by a traditional system. In Backflush account, costs are caclualted and charged when the product is sold or when it si transferred to the finished goods store.

There are three accounts of

Conversion account = Conversion x unitSales account = Price x unitCost of Sales account = (Standard cost) x unit + excess conversion costs

What goes into sales account is cost

Computer-integrated manufacturing (CIM) brings together advanced manufacturing technologyand modern quality ontrol into a single comptuerised coherent system

Flexible manufacturing systems (FMS) is an integrated, computer-controlled production system which is capable of producing any of a range of parts, and of switching quickly and economically between them

Electronic data interchange (EDI) facilitates communication between an organisation an dits customer and suppliers by the electronic transfer of infromation

Chapter 10 – Modern costing techniques

Throughput accounting (TA) is an accounting system based on constraints, which identifies material costs as the only variable cost in the short run (even labour is treated as fixed). Profit is determined by the throughput generated – how quickly raw materials can be turned into sales to generate cash.

The throughput of a factory is reflected in the TA ratioa) Throughput return per unit = Sales price – Materials costb) Throughput return per hour = Throughput return per unit x Output per hour (in units)c) Throughput cost per hour = Total factory costs per period / Total bottleneck hours per periodd) TA = Throughput return per hour / Throughput cost per hour

Products are ranked by the TA ratio – the ratio should be greater than 1 if a product is to be viable.

Identifying the bottle neck

The bottleneck process is the one that has the highest machine utilization rate. Start by calculating

the maximum units of demand for each machine and then divide this by the capacity of the machine to get the fraction.

Machine utilization rate = Hours required to meet maximum demand / Hours available

Back flush accounting is a simplified standard costing system, which works backwards to attribute costs to inventory and sales. The two trigger points that determine when entries are made are purchase of materials and sale of goods. When a sale is made, the following is recorded at standard cost

DR Cost of SalesCR MaterialsCR Conversion costs

The credits are split according to the weight of pricing, while purchases and conversion costs are added to the T accounts from the information.

Back flush accounting is most suitable in a JIT environment so that the bulk of manufacturing costs are in costs of sale.

Advantagesa) Fewer entries so saves time

and cost of operating a complex accounting system

Disadvantagesb) It doesn’t operate well when

inventory levels are significantc) Absence of financial information may

make management control more difficult

Chapter 11 – Modern costing techniques

Traditional absorption costing uses a single basis for absorbing all overheads into cost units for a particular production cost center. Activity based costing (ABC) is an extension to this, usually for when more than one product is produced and specifically considering the cause of each type of overhead – the process is:

Step 1: Group fixed overheads into activities or cost pools according to how they are driveni.e. Machining, Packaging, Distributing, Quality control

Step 2: Identify the cost drivers for each activityi.e. Machining → No. of machine hours, Quality control → No. of production runs, Packing → No. of customer orders

Step 3: Calculate a cost per unit for cost driversCost per unit = Full activity cost / Required time for activity, i.e. £3000 / 5000 machine hours

Step 4: Absorb activity costs into production based on usage of cost drivers: Cost per unit x activityThe total the absorbed costs will be the fixed overheads and this divided by the number of units being produced will give the cost per unitFixed overheads cost per unit = Cost per unit x activity

Activity based costing should be used when production overheads are high relative to prime costs or where consumption of resources is not driven by volume.

The use of ABC allows for better cost control and information by allowing for efficient management of cost drivers as well as information to assist pricing decisions.

However, it is time consuming and expensive and which has a reduced benefit if only one product is being produced.

Chapter 12 – Environmental costing

There are many benefits of having a clear understanding of the environment-related costs of business activities and these include:1. Ethical issues – businesses should be aware of how their production affects the environment2. Brand image – green ways of doing business can be a selling point3. Once identified, environmental costs can be controlled and reduced4. Associating environmental costs with individual products leads to more accurate pricing

Environmental costs are categorized as either:

Internalized environmental costs: The company pays the full cost as the impact is contained within the company i.e. emissions permit, waste disposal costs, training, environmental taxesExternalized environmental costs: Wider society has to pay at least an element of these costs i.e. carbon emissions, pollution, energy control

Internal failure costs: The costs of putting things right while they are still under the control of the organisation and hve yet to impact the external environmentExternal failure costs: The costs incurred when an organisations activities has an adverse impact on the external environment

The standard Total Quality Management (TQM) principles of get it right the first time and continuous improvement can be applied to environmental management. The objective would be to minimize externalized costs

Chapter 13 – Budgeting

A budget is a financial and/or quantitative plan of operations for a forthcoming period. They allow for planning, integration between departments, employee motivation and evaluation against actuals.

There are a number of different types of budgets

Incremental budgetingBased on previous years results plus extra for growth.

Zero-based budgetingStarting from zero every process, activity and expenditure must be justified before it is included in the budget.

Rolling budgetsThese are prepared every month and running for 12 months each time.

Advantages: Easy to prepareDisadvantages: Rigid

Advantages: Removes inefficient operations, Disadvantages: Emphasizes short-term over long term and requires time and effort

Advances: Regular assessment means planning and control will be based on a more recent planDisadvantages: Demotivating to managers if they cannot see benefits and effort and expense required

An operating budget often requires sales quantities and materials purchases for inventories to be adjusted. The closing inventory is always the opening inventory for the next period for both finished goods and materials.

Production

SalesAdd: Closing inventoryLess: Opening inventoryMaterials usage

Materials usage Add: Closing inventoryLess: Opening inventoryTotal

January

X(X)X

X(X)X

Chapter 14 – Preparing forecasts

The four main components of a time series are:1. Trend: the underlying increase or decrease in demand2. Seasonal variations: short-term repeated fluctuations from the trend3. Cyclical variations: long-term repeated fluctuations from trend4. Random variations: seen in past data but can’t be included in future estimates

When forecasting use the trend and then adjust for seasonal variation

The trend within data can be found by using the Hi-Lo method, which is:y = a + bx, where b = y2 – y1 / x2 – x1 where 1 and 2 indicates the highest and lowest levels of activity respectively

Seasonal variations are either fixed amounts (additive) TS = T + SV or constant proportions of trend (multiplicative) T = T x SV.

Advantages of time series forecasts are that it reflects the underlying pattern and is a simple and cheap method of forecasting. However, it is disadvantageous as it assumes all changes are time related, equal weight are given to all figures and extrapolation is inherently risky.

Chapter 15 – Investment decision-making

The payback period of an investment at the point where the cumulative cash flow reaches a positive

T0123

Cash inflow(500)150220310

Cumulative cash inflow(500)(350)(130)180

As capital expenditure involves the outlay of large sums of money and benefits may take a while to accrue, it is critical that investment decisions are subject to appraisal and control. These steps involve:1. Origination of proposals i.e. environmental scanning, internal innovation2. Project screening – high level criteria must be met before financial analysis3. Analysis and acceptance – a financial analysis is undertaken with a yes/no decision4. Monitoring and review

The accounting rate of return is given by:ARR = Average annual profit from investment / Initial investment or Average investment x 100

where, Average annual profit = (Profit inflow after depreciation) / number of yearsAverage investment = (Initial outlay + Scrap value) / 2

The advantages of using ARR to determine investment is that profit is easy to understand while it suffers from the fact that no account is taken of time value of money.

Post-completion audits can’t reverse decisions but ensures lessons are learned, managers are rewarded, cost overruns do not occur and failing projects are identified and abandoned. However, they often are expensive and time-consuming as well as creating a risk-averse attitude.

Chapter 16 – DCF techniques of investment appraisal

DCF techniques take into account the time value of money. This is critical when cash flows are going to be spread across several years. The process of adjusting a project’s cash flows to reflect the return that the investor could get elsewhere is known as discounting the cash flows.

Only the cash flows affected by the decision to invest should be considered when appraising investments, these are called relevant cash flows. Relevant cash flows also include opportunity cost and avoidable costs (costs avoided if activity did not exist). Non-relevant cash flows include Depreciation, Allocated Overheads, Sunk costs (market research, surveyor fees)

A scrap value on materials reduces the cost so reduces cash outflow.

The sum of cash in and outflows for a particular period multiplied by the discount factor generates a present value – the sum of present values is the net present value (NPV) and a positive NPV means that the project is always accepted

The discount factor is given by ¿ where r=discount/interest rate and n=time period of cash flow

The discounted payback (DPP) is the time it will take before a project’s cumulative NPV turns from being negative to being positive. It is when the project has paid back its initial costs.

The internal rate of return is calculated by:

IRR=a+NPV a

NPV a−NPV b

(b−a)

Where a = the first discount rate giving NPVa and b = the second discount rate giving NPVb when using the same cash flowsa and b have to give a positive and negative cash flow

The rule is then to accept all projects that has an IRR that is greater than the cost of capital

Advantages of the IRR is that it takes into account the time value of money, can provide a breakeven point and considers all cash flows, however it may conflict with the NPV decision and assumed cash s reinvested at IRR.

There are occasions where the results from an NPV and IRR calculation provide conflicting information (i.e. NPV is greater in one but IRR is greater in the other), in this case accept the NPV result as the IRR doesn’t take into account the relative size of the projects. Choosing projects based on NPV will ensure wealth maximization.

Chapter 17 – Taking account of taxation and inflation

The NPV proforma is laid out as

SalesCost (variable and fixed)Operating cash flow

TaxationCapital ExpenditureScrap valueTax benefits of capital allowanceWorking capitalNet cash flows

Discount factors @ post-tax cost of capitalPresent value

0

(X)

(X)X

X

(X)

1X(X)X

(X)

X

(X)X

X

X

2X(X)X

(X)

X

(X)X

X

X

3X(X)X

(X)

X

(X)X

X

X

4X(X)X

(X)

XX

XX

X

X

5

(X)

X

.X

X

(X)

In year 0, is where the investment is made which indicates why there are no costs or sales but just a large capex spend. In year 4, the investment is sold at its scrap value

Some pointers when given a cash flow proforma include:1. Only include overheads that are relevant to the project and none that are reallocated

(sometimes this might be mean taking a percentage of initial overheads)2. Sunk costs such as research and surveying costs are not included3. Only revenue cash flow pertaining to an as a result of the investment should be included on the

proforma

Corporate tax on profits can be either1. Tax payments all in the year of the cash flow2. Tax payments in the year after the cash flow3. Half in the year of the cash flow and half the following year

For the last option the tax is based on the operating cash flow, but because this tax is split over two years use a the following workings

Year 1Year 2Year 3

Operating CF(30)340740

Tax @ 30%9(102)(22)

Payable

1

4.5

2

4.5(51)

3

(51)(111)

4

(11)

Total tax

4.5 (46.5) (162) (111)

A business can claim tax allowances, called capital allowances, on certain purchases or investments, which should also be included and shown as a separate cash flow. This cash flow is an inflow as the purpose of the capital allowances is to reduce the tax liability of the company.

The capital expenditure that qualifies for allowances will be indicated into the question by stating that it is tax depreciable at a particular rate. The cash timing of the allowance will be the same as the corporation tax timing – if corporation tax is paid in two installments so will the allowance.

So if a 750 capital expenditure qualified for tax depreciation at a rate of 20%, which is resold in year 4 for 200, this will be calculated as:

Year120% WDA220% WDA320% WDA4Proceeds Balancing allowance

Asset balance750(150)600(120)480(96)384(200)184

Tax saved

45

36

29

55165

1

23

23

2

22

18

40

3

18

15

33

4

14

2842

5

2727

Major projects will require an injection of funds to finance the level of working capital required. Questions will only show the total amount of working capital required at that point. So if the working capital requirements over four years is 250, 300, 375 and 350

Year

1234

Annual working capital requirement250300375350

Increment

(250)(5)(75)25

In the year that it is sold, the sum of the working capital increments are released and shown on the proforma

An investor will require a higher return on their investment in the presence of inflation. If there is a single rate of inflation, it is easier to use real cash flows and an inflated (real) discount rate, which

is given by:

(1+r ) (1+i )=(1+m)where r=realcost of capital ,i=inflation rate, m=inflated (money) cost of capital or

discount rate

From here, the NPV is calculated by discounting using the real cost of capital

If there is more than one rate of inflation affecting cash flows, inflation will impact profit and therefore needs to be including in the NPV. In this case, the cash flows must be inflated and inflation must also be incorporated into the discount rate. Working capital is a function of sales and purchases; it then follows that if sales and purchases are to be inflated, then any figures resulting from them (receivables, payables, inventories) should also be inflated.

Chapter 18 – Further aspects of investment decision-making

Sensitivity analysis measures how sensitive the success or failure of a project is to changes in one of the factors influencing the project. This is calculated using:

Sensitivity = NPV of project / NPV of variable x 100%

Where the NPV of the variable is the risk variable and the sensitivity gives the percentage change in the risk variable to reach an NPV of zero. The variable will often be revenues or total costs.

Questions will require the disclaimer of “costs will have to increase by X% for the project to fail, assuming all other variables are in line with expectations”.

Asset replacement analysis measure the optimal replacement cycle. When cash flows do not inflate, this is determined by calculating the equivalent annual cost which gives an equivalent money payable each year of the asset’s life

EAC = NPV of one cycle of replacement / Cumulative discount factor for this cycle length

Where CDF is simply the addition of all discount factors for this cycle (i.e. 2 years = 2 DF’s). The target is to have the cycle of replacement which has the lowest EAC

When cash flows inflate, the EAC cannot be used, as an annuity cannot exist. To calculate the optimal replacement cycle now, the lowest common multiple is needed. So if the option of replacement is either 2 years or 3 years, draw up a proforma for 6 (2 x 3) years for both:

Machine purchaseRunning costsResaleNet cash flowDFPVNPV

0(X)(X)

(X)%XX

1

(X)

(X)%X

2(X)(X)X(X)%X

3

(X)

(X)%X

4(X)(X)X(X)%X

5

(X)

(X)%X

6

(X)X(X)%X

Calculate the NPV for both and choose the one that has the highest NPV (if negative, the lowest absolute NPV)

Capital rationing arises when there is insufficient capital to invest in all available projects, which have a positive NPV. The objective is maximize total NPV from available investment capital, the first step to achieving this is ranking all projects by their profitability index

Profitability index = NPV / Capital Invested

If projects can be subdivided then it will all the projects from the top to bottom until all capital invested (the last chosen project will normally have to be subdivided so that all capital is used).

If projects cannot be subdivided then the steps to take are:1. Starting from the top, add each successive project until no more projects can be added2. If a project had to be skipped as a result of it insufficient funds and a project further down the

list is added, then check other combination by completing the process again but this time starting from the second highest ranked project and going down

Choose the combination that yields the highest total NPV

The rate of return on investments is called the yield – the yield on debentures, loan sstock and bonds is measured either with:

Interest yield = Gross interest / Market value x 100%

or using yield to maturity, which recognises that investments can be purchased at one price and redeemed at a different price, often a premium. It is calculated using the internal rate of return (IRR).

The coupon rate is not the discount factor – it is cash flow revenue which is the percentage of the redeemable value that is returned each period, this amount will have to be discounted

If you are discounting over a number of years where the return is constant i.e. 10 is received every year, the net present value of these cash flows can be easily calculated by

10 x CDF

where CDF is the cumulative discount factors and is simply the sum of all discount factors across the periods

Chapter 19 – Risk and uncertainty in decision-making

Risk exists where a decision-maker has knowledge that several different future outcomes are possible. Past experience enables a decision-maker to estimate the probability of the likely occurrence of each potential future outcome

Uncertainty exists when the future is unknown and the decision-maker has no past experience on which to base predictions.

When there is a risk, a range of possible future outcomes can be quantified and probabilities assigned to them and an expected value (weighted average) of these calculated

EV=∑ pxwhere x is the value( profit∨cost )∧p is probability of occurringp0.20.60.2EV

X0.2 x 4, 2000.6 x 4, 2000.2 x 4, 2004, 200

Y0.2 x 4, 1000.6 x 4, 6000.2 x 4, 6004, 500

Z0.2 x 3, 5000.6 x 4, 0000.2 x 5, 0004, 100

Although Y has the highest EVX is risk free, and guarantees 4, 200Z is chosen by risk seeker as it could generate the highest 5, 000Z is avoided by risk averse as it could generate the lowest 3, 500

The limitations of EV are that it ignores risk – risk can be defined as a variability of return, or the range of possible outcomes. Risk can be measured through standard deviation of the expected value, which compares all actual outcomes with the expected value and calculates how far on

average the actual outcomes deviate from the mean

σ=√∑p ¿¿

The coefficient of variation measures the standard deviation as a percentage of the mean (σ /EV ) and the higher the percentage, the higher the dispersion

For the above example, the standard deviation of Y can be calculated as

x4, 1004, 600

x - EV(400)100

(x – EV)2

160, 00010, 000

p0.20.8 (0.6 + 0.2)

p(x – EV)2

32, 0008, 00040, 000

Standard deviation = √40 ,000Coefficient of variation = 200 / 500 = 4.4%

these metrics are only useful when they are compared against each other, but on their own hold no value.

A maximin decision is taken by risk-averse decision-makers and they choose the option that maximizes the minimum return (in the above example this would be X i.e. 4, 200). A maximax decision is taken by the risk-seeking decision-makers and they choose the option that maximizes the maximum return (in the above example this would be Z i.e. 5, 000)

A minimax regret is calculated from opportunity cost, where decisions are taken to minimize the maximum opportunity cost from making the wrong decision. The process is to find the maximum return for each probability and then find the opportunity cost of not receiving this

p0.20.60.2

Max regretMinimum regretChoose Y

X-400800

800

Y100-400

400400

Z700600-

700

The value of perfect information is calculated as the difference between the EV (with perfect information) and EV (without perfect information). With perfect information we know all the outcomes so for each probability we simply choose the option that provides the greatest return (or lowest cost)

p0.20.60.2

OptionXYZ

Value4, 2004, 6005, 000

EV (px)8402, 7601, 0004, 600

The EV this time is 4, 600 and as the EV last time was 4, 500 – we can say tha the value of perfect information is 100

If instead of one, two variables are uncertain or risk, it will require a joint probability table that records the range of possible outcomes. These tables do not permit a decision to be taken but do allow the risks to be assessed.

A two way table for profit essentially determines the profit at a combination of outcomes, while the joint probability table determines the probability of the joint outcome

XYZ

A290260230

B280250220

C270240219

X 0.2Y 0.35Z 0.45

A0.40.080.140.18

B0.50.10.1750.225

C0.10.020.0350.045

If the corresponding cells on both tables are then multiplied it is possible to get the expected value of profit table

XYZ

A23.236.441.4

B2843.7549.5

C5.48.49,45

To then determine the probability of the company making a profit of at least 230, all you then need to do is sum the joint probabilities that provides a profit of above 230

XYZ

A290260230

B280250

C270240 X 0.2

Y 0.35Z 0.45

A0.40.080.140.18

B0.50.10.175

C0.10.020.035

Probability = 73%

A decision tree is a probability tree, which shows the sequence of interrelated decisions and their expected outcomes. They will incorporate both the probabilities of, and value of expected outcomes, and are used in decision-making. They are most useful when there are several decisions and ranges of outcome

The steps involved with creating one are:

Plan the tree diagram and tick off all the information in the question as you use it in the planDraw the tree from left to right, using a ruler, giving yourself as much space as possibleShow a key in the answer detailing the symbols for decisions and outcomes

Related Documents