© Confederation of Indian Industry Energy Conservation Opportunities in Boilers & Steam system © Confederation of Indian Industry Centre of “Excellence” for Energy, Environment, Green Buildings, Renewable energy, Water & Climate change activities in India CII – Sohrabji Godrej Green Business Centre, Hyderabad A unique Public – Private Partnership ( CII, Govt of Andhra Pradesh, USAID and Pirojsha Godrej Foundation ) © Confederation of Indian Industry Agenda v Approach for energy conservation Example from sports v Opportunities for energy efficiency improvement – Case studies © Confederation of Indian Industry Two Examples from Sports… v Sergei Bubka - Ukranian pole vaulter q I person to cross 6-m mark q Continuously improved q Broke his own records > 14 times! Efficiency Improvement - Continuous Olympic Gold Medal Winners in High Jump 2.6 2.4 2.2 2 1.8 1.6 1900 1920 1940 1960 1980 Scissors Western Roll Straddle Fosbury Flip Source: Pascale v Fosbury q Basically a Gymnast - Not successful q Applied principles of Gymnastics to High Jump q Result - A Quantum Jump !!! Adopt the Latest Technology Inputs from Other Industries - Innovation Inference from Sports… © Confederation of Indian Industry

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

© Confederation of Indian Industry

Energy Conservation

Opportunities in

Boilers & Steam system

© Confederation of Indian Industry

Centre of “Excellence” for Energy, Environment, Green Buildings, Renewable energy, Water & Climate change activities in India

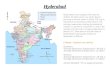

CII – Sohrabji Godrej Green Business Centre, Hyderabad

A unique Public – Private Partnership( CII, Govt of Andhra Pradesh, USAID and Pirojsha Godrej Foundation )

© Confederation of Indian Industry

Agenda

v Approach for energy conservation

Ø Example from sports

v Opportunities for energy efficiency

improvement – Case studies

© Confederation of Indian Industry

Two Examples from Sports…

v Sergei Bubka - Ukranian pole vaulter

q I person to cross 6-m mark

q Continuously improved

q Broke his own records > 14 times!

Efficiency Improvement - Continuous

Olympic Gold Medal Winners in High Jump

2.6

2.4

2.2

2

1.8

1.6

1900 1920 1940 1960 1980

Scissors

Western Roll

Straddle

FosburyFlip

Source: Pascale

v Fosbury

q Basically a Gymnast - Not successful

q Applied principles of Gymnastics to High

Jump

q Result - A Quantum Jump !!!

Adopt the Latest Technology Inputs from Other Industries - Innovation

Inference from Sports…

© Confederation of Indian Industry

© Confederation of Indian Industry

Few Case Studies…

Arrest air infiltration through APH

ESP

ESP

Q –122.56 M3/sH –406 mmM –725 kW

2.3 % O2

APH

4.6 % O2

6.7 % O2

6.8 % O2

Unit I

© Confederation of Indian Industry© Confederation of Indian Industry

Observation - Air infiltration in Air Preheater

151338151339TempoC

3006CO (ppm)

14.316.413.815.6% CO2

2.8

Inlet

APH -B

4.74.62.3% O2

OutletOutletInlet

APH -AUnit –1

v Online flue gas analyzer available

Ø Before & after air pre heater

v Combustion analysis carried out

Ø Using portable combustion analyser

© Confederation of Indian Industry© Confederation of Indian Industry

Air infiltration in Air Preheater

155325156323TempoC

0000CO (ppm)

13.413.613.314.1% CO2

4.9

Inlet

APH -B

5.44.94.6% O2

OutletOutletInlet

APH -AUnit –2

© Confederation of Indian Industry© Confederation of Indian Industry

Air infiltration in Air Preheater

Air preheater1 Kg flue gas2.3 % O2

X Kg of air20.9 % O2

1+ X Kg of Flue gas4.6 % O2

v Quantity of air infiltrationØ Unit -1

Ø APH - A - 14.1 %Ø APH – B - 11.72 %

Ø Unit –2Ø APH –A - 1.8 %Ø APH – B - 3.2 %

© Confederation of Indian Industry© Confederation of Indian Industry

v Unit – 1 quantity of air ingress is significant

v Unit -1 due for maintenance

v Arrest air preheater leakage during the maintenance

v Online monitoring available before & after APH

Ø Periodically cross check using portable analyser

v Equivalent coal saving - 0.5 tons/hr

Air infiltration in Air Preheater

© Confederation of Indian Industry

v Holes in ID fan duct bends & corners

Ø Erosion due to flue gas especially in

locations where direction of flow changes

v Increased air infiltration & hence increased

ID fan power consumption

Methods for reducing air infiltration in flue gas side

© Confederation of Indian Industry

Ceramite coating in the bends

© Confederation of Indian Industry

Castable refractory for reducing Erosion

© Confederation of Indian Industry

v Covered with “Thermal Fabric Expansion”

Ø Special material-can withstand temperature upto 700-

800oC

Ø Sandwiched with “Glass Wool”

Ø Can be installed “ON line”

Methods for reducing air infiltration in flue gas side

© Confederation of Indian Industry© Confederation of Indian Industry

v What is the effect of vacuum on turbine performance?

v Turbine capacity - 37 MW

v Present load - 15 MW

loaded less than 50% of the capacity

v During normal operating condition very low vacuum has been

achieved

Ø Achieved vacuum - 0.04 kg/cm2 (a)

Ø Design vacuum - 0.1 kg/cm2 (a)

2.Operate the condenser at design vacuum level

© Confederation of Indian Industry© Confederation of Indian Industry

v Effect of lower vacuum compared to design

v Life of the turbine

Ø Reduction in dryness fraction of exhaust steam

q Turbines normally designed for 0.86 dryness fraction

Ø Increased pitting on LP turbine blades

v Increase in energy consumption

Ø Velocity of steam flow increases

Ø Exhaust loss increases

Operate the condenser at design vacuum level

© Confederation of Indian Industry© Confederation of Indian Industry

Turbine Exhaust loss curve

© Confederation of Indian Industry© Confederation of Indian Industry

Operate the condenser at design vacuum level

6.52010.04

3.81630.05

3.0137.50.06

2.4104.80.08

2.593.80.09

2.8850.1

Exhaust loss kCal/kg

Velocity (m/sec)Pressure (kg/cm2)

© Confederation of Indian Industry© Confederation of Indian Industry

v The exhaust loss is the lowest at 0.08 kg/cm2 (a) vacuum

v How to maintain the design vacuum

Ø Reduce the quantity of water supply

Ø Optimise the operation of cooling tower fan

Ø Control on Ejector

v Equivalent reduction in steam consumption - 300 kg/hr

Operate the condenser at design vacuum level

Annual Saving - Rs 27.00 Lakhs

© Confederation of Indian Industry

v Waste heat recovery boiler in operation

v Operating steam parameters

Ø Pressure - 38 kg/cm2

Ø Saturated steam

Ø Capacity - 12 – 13 tons/hr

v Steam utilised for turbo driven circulating water

pump & exhaust steam for process

3. High efficiency Micro turbine

© Confederation of Indian Industry

v Power generation potential partially

utilised

v Specification of circulation water pump

Ø Flow - 280 m3/hr

Ø Head - 48.9 m

v Power requirement - 60 kW

High efficiency Micro turbine

© Confederation of Indian Industry

v Conventional turbine with exhaust in

superheated condition

Ø Turbine single stage

v Power generation potential – 75 kW

v Latest double stage turbine gives excellent

potential

Ø Power generation opportunity - 500 kW

Power generation potential

© Confederation of Indian Industry

Steam and Power Costing

~Two stage turbine

Pr – 38 kg/cm2 (g)Temp – satFlow – 12 tons/hr

Pr – 5 kg/cm2 (g)Temp –158oCDryness fraction –0.93

500 kW

Excellent potential for power generation

© Confederation of Indian Industry

v Supplier guaranteed upto - 560 kW

v Existing circulation water pumps needs to

be electrical motor driven

v Net power generation - 500 kW

Power generation potential

Annual Saving - Rs 105.60 LakhsInvestment - Rs 70.00 LakhsPayback period - 8 months

© Confederation of Indian Industry

4.Steam Ejector / Vacuum Pump

Condenseror

vessel

CW

Existing

Pro

pose

d

Steamejector

Steam

Water ringvacuum pump © Confederation of Indian Industry© Confederation of Indian Industry

v Presently steam ejector is in operation

v Design specification

Ø Working steam pr - 10 ata

Ø Steam temperature - 350oC

Ø Steam consumption - 1000 kg/hr

Ø Suction pressure - 0.035 ata

Ø Capacity of dry air - 20.4 kg/hr

Ø Dry air + water vapour - 65.4 kg/hr

Install vacuum pump in lieu of steam ejector

© Confederation of Indian Industry© Confederation of Indian Industry

vMain steam utilised as auxiliary steam

v From the turbine characteristic curve – Power

generation potential for 1 ton/hr of steam -250 units

v Install vacuum pump in lieu of steam ejector

v Vacuum pump specification

ØPressure - 660 mmHg

ØCapacity - 0.3 m3/sec

v Estimated power consumption - 47 kW

Install vacuum pump in lieu of steam ejector

© Confederation of Indian Industry© Confederation of Indian Industry

v Temperature gain in ejector condensor - 10oC

v Increase in steam consumption in deaerator - 1 ton/hr

steam at 5.5 kg/cm2

v Reduction in power generation - 100 units/ton

v Net benefit - 100 kW

Install vacuum pump in lieu of steam ejector

Annual Saving - Rs 48.00 LakhsInvestment - Rs 15 Lakhs

Payback period - 4 Months

© Confederation of Indian Industry

5. Install Thermo compressor and recover flash steam from feed tank

v Condensate from digester – Collected in feed tank

v Heat balance of feed tank and estimation of flash steam quantity indicate

q Flash steam quantity is about 2.55 tons/hr

Flash Steam t o atomos phere

(Y) kg

Water in feed tank @ 0.3 kg/cm2

170 TPH

Condensate (1 – Y) kg

98 °C

Flash vessel

© Confederation of Indian Industry

Install Thermo compressor and recover flash steam from feed tank

Motive Steam @ 33 kg/cm2(abs)Temp – 390 oCFlow – 1.5 tons/hr (approx)

LP Steam @ 0.1 kg/cm2(abs)Temp – 100oCFlow – 2.0 tons/hr

Discharge Steam @ 2.5 kg/cm2(abs)Flow – 3.5 tons/hr

© Confederation of Indian Industry

Install Thermo compressor and recover flash steam from feed tank

v Good potent ial to recover the flash steam

v Best option - Installing thermo compressor and inject ing

back to low pressure header

Annual saving - Rs 28.16 LakhsInvestment - Rs 30.00 LakhsPayback - 13 Months

© Confederation of Indian Industry

To sum up…

vTremendous potential for Energy Saving in

Boilers & Steam systems

vBecome a world class energy efficient unit

ØImplement the latest technologies

ØLearning the best practices from other sector /

industries

© Confederation of Indian Industry

Contact…

S KarthikeyanSenior Counsellor

CII-Sohrabji Godrej Green Business Centre

Confederation of Indian IndustrySouthern Regional Headquarters

98/1 Velacherry Main Road, GuindyChennai – 600 032

Email : [email protected] : +91 98400 02983

Website : www.greenbusinesscentre.com / www.cii.in

Thank You…

Related Documents