Department of Mechanical and Aeronautical Engineering SCREWS, FASTENERS AND NON PERMANENT JOINTS 2 MOW 227 2014

Welcome message from author

This document is posted to help you gain knowledge. Please leave a comment to let me know what you think about it! Share it to your friends and learn new things together.

Transcript

Department of Mechanical and Aeronautical Engineering

SCREWS, FASTENERS AND NON

PERMANENT JOINTS

2

MOW 227 2014

Department of Mechanical and Aeronautical Engineering

•Yielding take place in the first thread with cold work

strengthening

•Never re-use nuts in structural connections because their

thread gets damaged

•

Department of Mechanical and Aeronautical Engineering

• Washers underneath bolt head

• Purpose of a bolt is to clamp two or more parts

together

• Turn the nut not the bolt if possible. Why?

Department of Mechanical and Aeronautical Engineering

COMPRESSION OF BOLTED MEMBERS

• There may be more than two members in the grip of

the bolt

• The total member stiffness of the joint

– If one of the members is a gasket the stiffness is

so soft relative to the other members that for all

practical purpose, the others can be neglected

and only the gasket used

nm kkkkk

11111

321

++++= L

Department of Mechanical and Aeronautical Engineering

COMPRESSION OF BOLTED

MEMBERS

( )2 2

2 2

0tan

2 2

tan tan2 2

i

D dA r r x

D d D dx x

π π α

π α α

= − = + −

+ − = + +

Department of Mechanical and Aeronautical Engineering

(2 tan )( )ln

tan (2 tan )( )

tan

(2 tan )( )ln(2 tan )( )

P t D d D d

Ed t D d D d

P Edk

t D d D d

t D d D d

αδ

π α α

π α

αδ

α

+ − +=

+ + −

= =+ − +

+ + −

The contraction of an element in the cone of thickness dx,

subjected to a compressive force P is:

Substituting A into the previous equation and integrating the

resulting equation from 0 to t gives.

Pdxd

EAδ =

Department of Mechanical and Aeronautical Engineering

COMPRESSION OF BOLTED MEMBERS

• Assuming:

– dw = 1.5 d, and α = 30°, and l=2t

+⋅

+⋅

⋅⋅⋅=

dl

dl

dEkm

5.25774.0

5.05774.05ln2

5774.0 π

Department of Mechanical and Aeronautical Engineering

� Bolt strength is specified by:

1. minimum proof strength Sp

2. or minimum proof load Fp, 3. and minimum tensile strength, Sut

� The proof load is the maximum load (force)

that a bolt can withstand without acquiring a

permanent set.

� The proof strength is the quotient of the

proof load and the tensile-stress area.

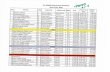

Table 8-9 to 8-11

Bolt Strength

Department of Mechanical and Aeronautical Engineering

• Read section 8-6

*Use same grade nuts as the bolt

Department of Mechanical and Aeronautical EngineeringFi

P

BOLTED JOINTS IN TENSION

• Clearance between the bolt and hole

• Preload - Fi

• External tensile load – P

• External shear load – Ps

• Collar friction: fc

• Thread friction: ft

Department of Mechanical and Aeronautical Engineering

BOLTED JOINTS

• Purpose of preload is to place the bolted member

components in compression for better resistance to

the external tensile load and to create a friction force

between the parts to resist shear load

• Joint has failed when

– resulting loading between members equals 0

– The load in the bolt exceeds yield

Department of Mechanical and Aeronautical Engineering

BOLTED JOINTS

Spring constant or stiffness constant

– δ : Deflection

– F : Force

– A : Area

– E : Modulus of elasticity (Steel: E=200GPa)

Stiffness constant, k

L

EAFk

⋅==

δ

EA

LF

⋅

⋅=δ

Department of Mechanical and Aeronautical Engineering

BOLTED JOINTS

• P – total external load on bolted assembly

• Fi – Preload due to tightening

• Pb – Portion of P taken by bolt

• Pm – Portion of P taken by members

• Fb – Resultant bolt load = Pb + Fi

• Fm – Resultant load on members = Pm - Fi

• C – Fraction of P taken by bolt

mb PPP +=

Department of Mechanical and Aeronautical Engineering

BOLTED JOINTS

• Increase in deformation of the bolt

• Compression of members

b

b

k

P=∆δ

m

m

k

P=∆δ

Department of Mechanical and Aeronautical Engineering

BOLTED JOINTS

• On the assumption that the members have not separated, the

increase in deformation of the bolt must equal the decrease in

deformation of the members

– But

– rearranging

m

m

b

b

k

P

k

P==δ

mb PPP +=

PCPkk

kP

mb

bb ⋅=⋅

+=

Department of Mechanical and Aeronautical Engineering

BOLTED JOINTS

• The resultant load on the bolt is

• The resultant load on the member is

THESE EQUATIONS ARE ONLY VALID AS LONG AS SOME OF

THE INITIAL COMPRESSION REMAINS IN THE MEMBERS

iibb FPCFPF +⋅=+=

iimm FPCFPF −⋅−=−= )1(

mb

b

kk

kC

+=

Department of Mechanical and Aeronautical Engineering

RELATING BOLT TORQUE TO BOLT TENSION

• Torque to produce preload:

• Simplifying

collarthreads TTT +=

2sec

sec

2

cci

m

mmi dfF

lfd

dfldFT

⋅⋅+

⋅−⋅

⋅⋅+⋅=

απ

απ

dFKT i ⋅⋅=

*K = Torque factor

Department of Mechanical and Aeronautical Engineering

• Tension, not torque, indicates proper joint tightness.

– Often, preload can be set more accurately by

controlling the number of turns rather than input

torque.

– Turn-of-nut method

• After the snug-tightening procedure is

completed, each bolt in the connection is pre-

tensioned additionally by the applicable amount

of relative rotation

Department of Mechanical and Aeronautical Engineering

STATICALLY LOADED TENSION JOINT

• Tensile stress failure

– Stress in bolt

– Introducing a load factor n:

• Where Sp is the proof stress

ib FPCF +⋅=

t

i

t

bA

F

A

PC+

⋅=σ

p

t

i

t

b SA

F

A

PnC=+

⋅⋅=σ

Department of Mechanical and Aeronautical Engineering

STATICALLY LOADED TENSION JOINT

• Joint separation

– The value of the load that will cause separation = P0

– At Joint Separation

• The Bolt Is Carrying All The Load

– Safety factor against separation, n0:

0PFb =

0)1( 0 =−⋅−= im FPCF

P

Pn 0

0 =

Portion of external

load carried by member

)1( CP

Fn i

o−−−−

====

Ratio of opening load

compared to external load

Department of Mechanical and Aeronautical Engineering

PRELOAD

• It is recommended that for static and fatigue

loading the following be used for preload

– Fi = 0.75 Fp (reused connections)

– Fi = 0.90 Fp (permanent connections)

– Where Fp is the proof load

ptp SAF ⋅=

Department of Mechanical and Aeronautical Engineering

FATIGUE LOADING

• Already corrected for notch sensitivity and surface finish

• Peterson – typical bolt failures

– 15% under head

– 20% at end of shank

– 65% in the thread

• usually safe to assume that the fasteners have rolled threads –unless specific information is available

• Use machined finish for the body of the bolt if nothing is stated

Department of Mechanical and Aeronautical Engineering

Endurance Limit

• Fully corrected (including Kf) axial endurance

strength for rolled threads

Department of Mechanical and Aeronautical Engineering

FATIGUE LOADING• External load fluctuates between 0 and some

maximum force P

– Fmax = Fb

– Fmin = Fi

– Alternating component:

• Fa = (Fmax - Fmin)/2 = (Fb - Fi)/2

– Mean component:

• Fm = (Fmax+ Fmin)/2= (Fb + Fi)/2

– Alternating stress:

– Mean stress:

tt

ii

t

iba

A

PC

A

FFPC

A

FF

⋅

⋅=

⋅

−+⋅=

⋅

−=

22

)()

2(σ

t

i

tt

ii

t

ibm

A

F

A

PC

A

FFPC

A

FF+

⋅

⋅=

⋅

++⋅=

⋅

+=

22

)()

2(σ

iam σσσ +=

Load + pre-tension

Pre-tension

Department of Mechanical and Aeronautical Engineering

Mean Stress

• Goodman

• Soderberg

• Gerber

• ASME elliptic

1=+u

m

e

a

SS

σσ

1)( 2 =+u

ma

e

a

SS

σσ

1=+y

m

e

a

SS

σσ

1)()( 22 =+y

m

e

a

SS

σσ

Department of Mechanical and Aeronautical Engineering

FATIGUE LOADING

• Goodman

– But

(Applying the load factor to the alternating component only)

1=+u

m

e

a

SS

σσ

iam σσσ +=

1=+

+u

ia

e

a

SS

σσσ

1=+⋅

+⋅

u

iaf

e

af

S

n

S

n σσσ

)(

)(2

eu

ituef

SSPC

FASSn

+⋅

−⋅⋅=

Department of Mechanical and Aeronautical Engineering

160 kN

40 mm Table A-29 nut thickness 14.8 mm

20

20

M16 x 60 Grade 8.8

4 mm

40 + 14.8 + 4 =58.8 mm

..

Department of Mechanical and Aeronautical Engineering

60 mm

2 x 16 + 6 = 38 mm

60 – 38 = 22 mm

18 mm 157 mm2

0.0162 201 m m2

6102215718201

207157201

×+×

××

923.68 MN/m

100 GPa

⋅+⋅

⋅+⋅

⋅

165.2405774.0

165.0405774.05ln2

161005774.0 π

1609.08 MN/m

mMN

e

/19.1594

77871.016100 40/1661616.0

=

⋅⋅= ⋅

Department of Mechanical and Aeronautical Engineering

365.008.160968.923

68.923=

+

11, Sp=600MPa

(157)600 = 70.65kN

96.470650157600

1602365.0=

−⋅

⋅⋅

5

02.2)5160000(365.0

70650157600=

−⋅

5

0.9

Department of Mechanical and Aeronautical Engineering

Gasketed Joints

[[[[ ]]]]

63

)1(

)1(

≤≤≤≤≤≤≤≤

−−−−−−−−====

−−−−−−−−====

−−−−====

Nd

D

A

NCnPFp

FnPCF

NA

Fp

b

g

i

im

g

m

ππππ

Pressure p on gasket

Forces on members

Load Factor

Gasket pressure

To maintain adequate uniformity of pressure the bolts must

be spaced, not more than six diameters apart (rough rule)

Department of Mechanical and Aeronautical Engineering

Summary: BOLT SIZING

• Factors used during bolt sizing

– Bolt size

– Number of bolts

– Bolt material

– Type of loading

– Bolt preload

– Safety factor

– Load/pressure at failure

– Member material

• Note:

– Any of the above can be used as an entry point for

the sizing of a bolted connections

Related Documents